If you are reading this, you are likely standing at a pivotal moment for your business. You have the raw mineral resource—whether it is limestone, calcite, gypsum, or barite—and you see the market potential. But to unlock that profit, you need to turn raw rock into fine powder. This requires a Raymond Mill.

Purchasing a grinding mill is not like buying a consumable product; it is a major capital investment that will dictate your operational costs for the next ten years. A wrong choice here, based solely on a low initial price tag, can bleed your company dry through high energy bills, constant downtime, and inconsistent product quality.

Table of Contents

Part 1: Decoding the Raymond Mill Price

One of the most confusing aspects for buyers is the price variance. You might send out three inquiries and get three wildly different quotes: $25,000, $45,000, and $70,000. All for a machine that claims to do the same job. Why is this?

The price of a Raymond Mill is never arbitrary. It is a calculated sum of Raw Materials, Technology, and Scope of Supply. Understanding these three will help you see the “invisible” costs.

1. The Quality of Steel (The Hidden Cost)

A Raymond mill is a machine designed to destroy itself. It works by grinding heavy rollers against a ring under immense pressure.

- The Low-Price Trap: Cheap manufacturers reduce costs by using standard carbon steel for the main shaft and frame. They use recycled scrap steel for the castings. To the naked eye, it looks the same when painted. But under load, this steel flexes. This flexing causes vibration, which destroys bearings.

- The ZONEDING Standard: We use high-grade carbon steel for the structure and specialized High-Manganese Steel (Mn13) or High-Chrome alloys for the wear parts (rollers and rings). High-Manganese steel has a unique property: it work-hardens. The more it is impacted, the harder the surface becomes. This costs more to buy and machine, but it doubles the service life of your mill.

2. The Electrical Components

The mill is powered by a high-voltage motor and controlled by an electrical cabinet.

- Budget Option: Many low-cost mills use refurbished motors or “no-name” local brands. Their control cabinets use generic contactors that are prone to fusing shut, which can burn out your motor during a power surge.

- Quality Standard: A reliable price includes a motor from a Tier-1 brand (like Siemens or reputable Chinese equivalents like Wannan). The control panel should feature components from Schneider, ABB, or Chint. You are paying for the assurance that when you push the “Start” button, the machine actually starts—every single day.

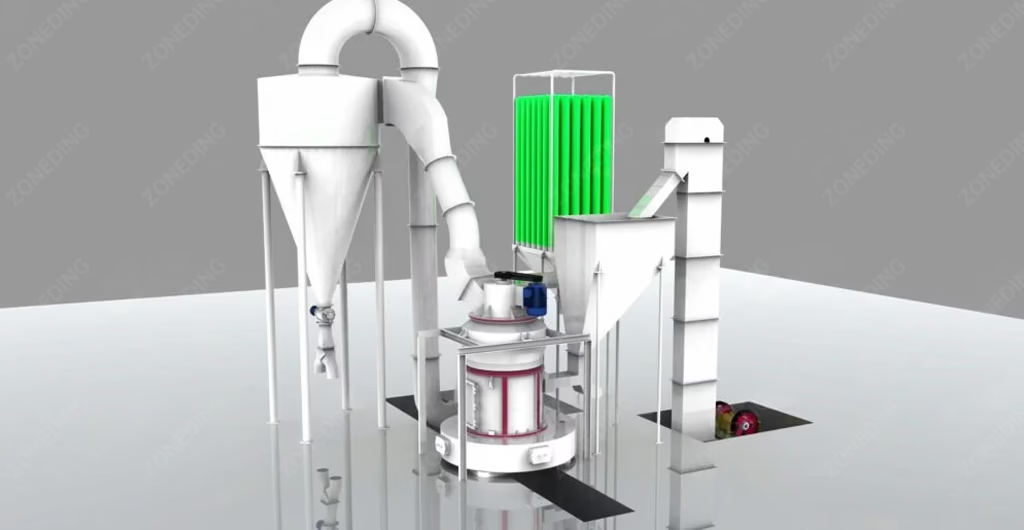

3. Scope of Supply: “Bare” vs. “Turnkey”

This is the most common trick in the industry.

- Quote A ($20k): Includes only the main unit. No motor. No blower. No pipes. No cyclone. No crusher.

- Quote B ($45k): Include the Main Unit, Classifier, Blower, Cyclone Collector, Pipes, Jaw Crusher (for prep), Bucket Elevator, Hopper, Vibrating Feeder, and Electrical Panel.

Never compare the bottom-line number. Compare the Bill of Materials (BOM). ZONEDING always provides a complete packing list so you know exactly what you are getting.

Part 2: Critical Specifications You Must Define

Salespeople typically ask, “What tonnage do you want?” While important, this is not enough. To get the right machine, you need to be an educated buyer regarding specifications.

1. Mesh Size (Fineness)

This is the single most important variable. “Mesh” refers to the number of holes per linear inch of a screen.

- 80-325 Mesh: This is the standard range for a Raymond Mill. It is highly efficient here.

- 400-800 Mesh: This requires a specialized High-Pressure Suspension Mill.

- Relationship to Yield: There is a physics law you must respect: The finer the powder, the lower the capacity. A mill that produces 10 tons/hour at 100 mesh might only produce 2.5 tons/hour at 400 mesh.

- Don’t Overspecify: If your end client only needs 200 mesh, do not buy a machine set up for 400 mesh. You are wasting energy.

2. Moisture Content

Raymond mills use air to transport powder. If your raw material is wet, the powder sticks.

- Limit: Standard mills handle up to 6% moisture.

- The Risk: If your limestone is dug from a riverbed with 15% moisture, a standard mill will clog in 10 minutes. You would need a Rotary Dryer before the mill. Be honest with your supplier about your material’s condition.

3. Material Hardness (Mohs Scale)

The hardness determines which mill model you need.

- Soft (Mohs 1-3): Gypsum, Talc, Coal. Very easy to grind. High capacity.

- Medium (Mohs 4-6): Limestone, Calcite, Dolomite, Barite. The ideal range for Raymond Mills.

- Hard (Mohs 7+): Quartz, Graphite, Granite. Warning: While a Raymond mill can grind these, the wear cost is astronomical. You will change rollers every 2 weeks. For these materials, a Ball Mill is often a smarter financial choice despite its lower efficiency.

Part 3: Supplier Selection – Factory vs. Trader

In the digital world, every website looks professional. You might be talking to a large factory with 500 workers, or a single person in an apartment brokering deals. For heavy machinery, this distinction is life or death for your project.

The “Trader” Risk

Trading companies are great for buying t-shirts, but terrible for machinery.

- Technical Disconnect: The trader is a salesperson, not an engineer. If you have a technical problem, they have to email the factory, wait for a reply, and translate it back to you. This “telephone game” causes massive delays.

- Spare Parts: When the trader goes out of business (which happens often), you have no source for parts. Your machine becomes useless scrap metal.

- Markup: You are paying the factory price plus the trader’s 20% margin.

The ZONEDING Factory Advantage

We are the manufacturer. When you buy from ZONEDING:

- Direct Access: You can speak directly to the engineer who designed your airflow system.

- Parts Security: We keep the molds for our rollers and rings. Even 10 years from now, we can cast a replacement part that fits your machine perfectly.

- Customization: Because we own the welding robots and the lathes, we can modify the machine. Need a taller cyclone to fit your building? We can build it. Need the motor on the left side instead of the right? We can do it.

Part 4: ROI Calculation & Operating Costs

Smart investors look at Total Cost of Ownership (TCO), not just Purchase Price. Let’s calculate the ROI using a simplified model.

1. Energy Consumption (The Biggest Cost)

Over 5 years, the electricity bill will exceed the cost of the machine.

- ZONEDING mills use optimized air channels that reduce air resistance. This means our blowers do the same work with less power.

- Example: If a ZONEDING mill saves 15 kW per hour compared to an inefficient older design, and you run 10 hours a day at $0.15/kWh, that is a saving of $8,200 per year. In three years, the energy savings alone pay for the price difference of a quality machine.

2. Wear Part Consumption

- Generic Rollers: Change every 500 hours. Cost per set: $1,000.

- ZONEDING High-Mn Rollers: Change every 1200 hours. Cost per set: $1,500.

- The Math: Over 6000 operating hours…

- Generic: 12 changes x $1,000 = $12,000 + 12 days of downtime.

- ZONEDING: 5 changes x $1,500 = $7,500 + 5 days of downtime.

- Result: You save $4,500 in parts and gain 7 extra days of production.

Part 5: Common Pitfalls and How to Avoid Them

We have helped many customers who came to us after having a bad experience with other suppliers. Here are the most common pitfalls.

1. Buying Undersized Capability

A customer wants 10 tons per hour. The dishonest supplier sells them a mill that can theoretically do 10 tons, but only under perfect lab conditions (softest rock, perfectly dry). In reality, it does 6 tons.

Solution: Always oversize your requirement by 20%. If you need 8 tons, ask for a machine rated for 10-12 tons. This gives you a safety buffer for wet days or harder rocks.

2. Ignoring Dust Regulations

Many countries now strictly enforce air pollution laws. Standard Raymond mills leak dust if not sealed properly.

Solution: Do not rely on old-fashioned “Open Cyclone” systems if your factory is near a residential area. Invest in a Pulse Bag Dust Collector. It creates negative pressure, sucking all dust into filter bags. It keeps your factory clean and the environmental inspectors happy.

3. Neglecting the Ancillary Equipment

A mill is useless without a good Crusher and Elevator.

- The Bottleneck: If you buy a massive mill but a tiny Bucket Elevator, the mill will starve.

- The ZONEDING Way: We calculate the flow rate of every single component. We ensure the crusher produces exactly enough gravel to keep the mill full, and the elevator lifts exactly fast enough to keep the hopper filled. Balance is everything.

Part 6: Why ZONEDING is Your Best Choice

We understand you have many options. Here is why mining companies in 120 countries choose ZONEDING.

Manufacturing Power

Our factory covers 8,000 square meters. We are not a small workshop. We possess:

- Large Vertical Lathes: Essential for machining the grinding ring to be perfectly round. If the ring is slightly oval (a common defect in cheap mills), the rollers will bounce, causing destructive vibration.

- Heavy Boring Machines: To ensure the main shaft alignment is precise to the micron.

- Annual Output: We produce over 500 grinding mills a year. This volume gives us purchasing power for raw materials, allowing us to pass savings on to you.

Engineering Expertise

We have a team of 15 specialized engineers. We don’t just send you a PDF catalog.

- Site Design: You send us your land plot (CAD or sketch). We draw the layout, showing where the truck dumps, where the mill sits, and where the product is bagged.

- Start-up Support: For new plants, we can send a senior engineer to your site. They stay until your local team knows how to operate the machine, how to change the oil, and how to adjust the mesh size.

Global Logistics

Shipping a 20-ton machine requires skill. We know how to disassemble the mill to maximize container space (saving you ocean freight cost) while ensuring delicate parts like the electrical motor are protected from salt water corrosion.

Conclusion

Buying a Raymond Mill is a journey of balancing Performance, Service, and Cost.

If you buy the cheapest machine, you are not saving money; you are buying a future liability. You are buying unreliability. You are buying lost production days.

If you choose ZONEDING, you are investing in a verified system. You are getting a machine built with premium steel, powered by Tier-1 electronics, and backed by a factory that has been doing this for two decades. We focus on your cost per ton of production, not just the price of the iron.

Contact ZONEDING today to get a free flow chart design and a precise quotation.

Last Updated: January 2026