全站搜索

Search the entire website

Search the entire website

Choosing the right rock crusher is a major decision for your quarry or mining operation. The wrong choice can lead to wasted money, inefficient production, and lower profits. Jaw crushers and impact crushers are two of the most common types of crushers. But what are the differences, and which one is right for you? In this guide, we will break down the key differences between jaw crushers and impact crushers. Then we will show you how to select the perfect crusher for your specific needs and maximize your profitability.

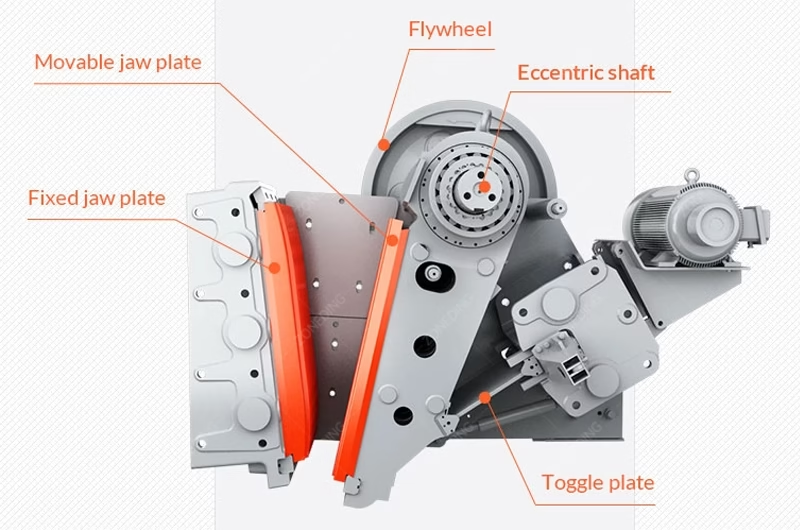

Jaw crushers are heavy-duty machines used for primary crushing of hard, abrasive materials. They work by compressing rock between a fixed jaw and a moving jaw. The moving jaw is driven by an eccentric shaft, creating a powerful crushing action. The crushed material then falls through a discharge opening at the bottom. Jaw crushers are known for their ability to handle large feed sizes and extremely hard rock. These features make them ideal for the first stage of crushing in many mining and quarrying operations. The robust design and simple operation of jaw crushers make them a reliable workhorse in any crushing circuit.

Impact crushers use impact rather than compression to break down materials. There are two main types of impact crushers: horizontal shaft impactors (HSI) and vertical shaft impactors (VSI). HSI crushers use a rotating rotor with hammers or blow bars to strike the rock. This shatters the rock upon impact. VSI crushers use a high-speed rotor to throw rock against a stationary anvil, causing it to fracture. Impact crushers are generally used for secondary or tertiary crushing. They are better suited for softer materials and produce a more cubical product shape than jaw crushers. Their versatility and ability to produce a consistent product make them valuable in various applications.

Understanding the key differences between jaw crushers and impact crushers is essential for making the right choice for your operation. The differences extend beyond the basic working principle and influence everything from the types of materials you can process to the final product shape and your maintenance costs.

Jaw crushers have a simpler, more robust structure compared to impact crushers. This difference in structure directly affects the durability, maintenance requirements, and suitability for different operating environments. A jaw crusher consists mainly of a heavy-duty frame, a fixed jaw, a moving jaw, and an eccentric shaft. This simple design makes them incredibly reliable and able to withstand harsh conditions. The robust frame provides stability, and the few moving parts minimize the risk of breakdowns.

Impact crushers, on the other hand, have a more complex structure with a rotor, hammers or blow bars, impact plates, and adjustable settings. This added complexity makes them more versatile but also more prone to wear and tear. The rotor assembly, in particular, is a high-stress area that requires careful maintenance and timely replacement of wear parts. The adjustable settings on an impact crusher allow for fine-tuning of the output product size and shape, but they also add to the complexity of the machine.

Jaw crushers rely on compressive force, while impact crushers use impact force. This fundamental difference dictates which materials each crusher can effectively process and the type of product they produce.

Jaw crushers slowly crush rock between two jaws, making them ideal for hard, abrasive materials. The compressive force is concentrated on a relatively small area, allowing them to break even the toughest rocks.

Impact crushers shatter rock with a rapid impact, which is more effective for softer, less abrasive materials. The impact force is distributed over a larger area, causing the rock to fracture along its natural planes of weakness. This results in a more cubical product shape. Think of it like this: a jaw crusher is like squeezing a rock until it breaks, while an impact crusher is like hitting a rock with a hammer.

Jaw crushers are typically used as primary crushers, while impact crushers are used as secondary or tertiary crushers. This difference in role is determined by the size of the feed material and the desired output product size.

As primary crushers, jaw crushers reduce large rocks to a manageable size for further processing. They can accept very large feed sizes, making them ideal for the initial stage of crushing.

Impact crushers then take the material from the primary crusher and further refine it to the desired size and shape. They are not designed to handle large feed sizes and are more effective at reducing already-crushed material.

For example, in a typical quarry operation, a jaw crusher might be used to reduce rocks from several feet in diameter to several inches. An impact crusher would then be used to further reduce the material to the desired aggregate size.

Jaw crushers excel at crushing hard, abrasive rocks, while impact crushers are better for softer, less abrasive materials. This is a critical consideration when choosing a crusher. The hardness and abrasiveness of the material will significantly impact the wear rate of the crusher parts and the overall efficiency of the crushing process.

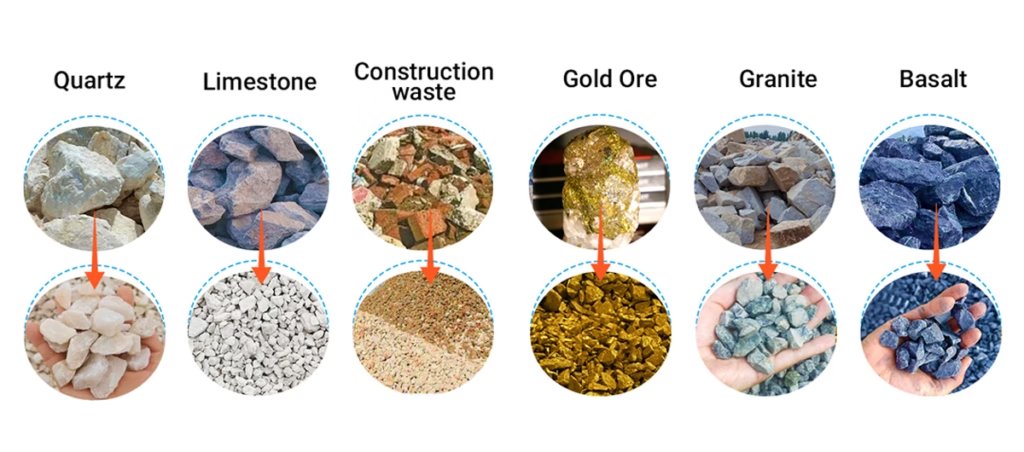

Jaw crushers can handle granite, basalt, river gravel, and other tough materials. Their robust design and compressive crushing action make them well-suited for these abrasive materials.

Impact crushers are better suited for limestone, concrete, and recycled asphalt pavement (RAP). These materials are generally softer and less abrasive, making them ideal for impact crushing. Using an impact crusher on extremely hard rock can lead to excessive wear and tear and reduced efficiency.

Jaw crushers typically have lower capacities than impact crushers. This is because their crushing action is slower and more deliberate. The compressive crushing action of a jaw crusher takes more time than the rapid impact crushing action of an impact crusher. Impact crushers can process a higher volume of material due to their rapid impact crushing action.

However, capacity also depends on the size of the crusher and the material being processed. A large jaw crusher can have a higher capacity than a small impact crusher. It’s important to consider the specific capacity requirements of your operation when choosing a crusher.

Impact crushers generally produce a finer, more cubical product than jaw crushers. This is because the impact crushing action tends to fracture the rock along natural planes of weakness. The hammers or blow bars in an impact crusher strike the rock with high force, causing it to shatter along its natural cleavage lines. This results in a more uniform, cubical product shape.

Jaw crushers produce a more elongated, less uniform product. The compressive crushing action of a jaw crusher tends to create more irregular shapes. If product shape is important for your application, such as in the production of concrete aggregate, an impact crusher is generally a better choice. The cubical shape of the aggregate improves the strength and workability of the concrete.

Jaw crushers are generally easier and less expensive to maintain than impact crushers. Their simpler design means there are fewer parts to wear out or break. The main wear parts in a jaw crusher are the jaw plates, which are relatively inexpensive and easy to replace.

Impact crushers have more moving parts, such as hammers or blow bars, that require regular replacement. The hammers or blow bars are subjected to high impact forces and abrasive wear, and they need to be replaced more frequently than the jaw plates in a jaw crusher. The more complex design of an impact crusher also means that it requires more specialized maintenance skills.

Jaw crushers typically have a lower upfront cost than impact crushers of comparable capacity. This is due to their simpler design and fewer moving parts. However, the total cost of ownership depends on factors such as maintenance costs, wear part life, and energy consumption.

While jaw crushers may be cheaper initially, the cost difference is not very large. Impact crushers may have higher upfront costs, but their higher capacity and ability to produce a more desirable product shape can offset these costs in the long run. It’s important to consider all the costs associated with owning and operating a crusher when making a purchase decision. Consider the price of parts.

ZONEDING Machinery stands out by offering high-quality crusher wear parts which are designed for extended life and optimal performance, reducing downtime and enhancing overall productivity.

Choosing between a jaw crusher and an impact crusher depends on several factors. It’s critical to consider your specific application, the materials you’ll be crushing, and the desired output. Here’s a step-by-step guide:

ZONEDING has been a trusted manufacturer of crushing equipment for over 30 years. We understand the unique challenges of the crushing industry. We design our crushers to be reliable, durable, and efficient. Our jaw crushers are known for their robust construction and ability to handle the toughest materials.

Our impact crushers deliver high-capacity crushing and superior product shape. Whether you need a single crusher or a complete crushing plant, ZONEDING has the expertise and experience to meet your needs. We use high wear resistance material.We offer:

Choosing between a jaw crusher and an impact crusher is a critical decision that impacts your productivity and profitability. Consider the material you’re crushing, the desired product size and shape, and your budget.

ZONEDING is committed to providing you with the best crushing equipment. Contact us today to discuss your specific needs and find the perfect crusher for your operation.

Everything you need to know about pebble sand manufacturing. From selecting the right pebbles to configuring your equipment line and calculating your ROI.

View detailsFollow a step-by-step guide to vermiculite processing. Understand this unique mineral's definition, properties, and wide range of applications.

View detailsDid you know your house is full of nonferrous metals? This 8 examples, from the nickel in your coins to the titanium in your glasses, you probably use everyday.

View detailsExplore the full lifecycle of an aggregate processing plant. Learn about crushing, screening, washing, and every stage involved in producing aggregates.

View details