全站搜索

Search the entire website

Search the entire website

The demand for high-quality sand and gravel is higher than ever, driven by global construction and infrastructure projects. If you’re looking to enter this market or improve your current operation, understanding the complete sand and gravel making process is the first step to building a profitable business. A well-designed sand making plant doesn’t just produce aggregate; it creates a valuable, engineered product that is essential for modern construction. This comprehensive guide will walk you through all the key steps, from analyzing your raw material to selecting the best machinery and optimizing your layout, helping you turn common rock into exceptional profit.

Sand and gravel are granular materials that form the literal backbone of construction. Gravel consists of larger rock fragments, while sand is made of much finer particles, typically less than 5mm in diameter. For centuries, we have relied on natural sand dredged from rivers, lakes, and pits. However, these sources are rapidly depleting, and environmental regulations are becoming much stricter. This global challenge has fueled the rise of manufactured sand. Manufactured sand is not a byproduct; it is intentionally produced by crushing larger rocks in a controlled process. This modern sand and gravel making process gives you complete control over particle shape, size distribution, and cleanliness, often resulting in a product superior to its natural counterpart.

Sand and gravel are the most-consumed raw materials in the world after water. You will find them in almost every building, road, and bridge project. The quality of your aggregate directly impacts the strength, durability, and safety of the final structure. This immense and continuous demand makes the sand and gravel making process a stable and fundamentally important industry.

Here are their most common applications, where quality is paramount:

Yes, the sand and gravel making process can be exceptionally profitable. The key to maximizing your profit is through operational efficiency. Your profit margin is a balance of three main factors: the cost of your raw material, your operational costs per ton, and the market price for your final product. As natural sand becomes scarce and more expensive, the market price for high-quality manufactured sand is steadily rising.

By investing in a modern, efficient sand making plant, you can minimize your operational costs. These costs include electricity, wear parts for your crushers, labor, and fuel. For instance, using energy-efficient crushers from a reputable manufacturer like ZONEDING and designing a smart plant layout can save you a significant amount on your monthly power bills. This allows you to produce a superior, certified product at a competitive price, leading to excellent and reliable returns on your investment.

Your raw material is the single most important factor in designing your sand making plant. Different types of rock have vastly different characteristics, mainly hardness and abrasiveness. This directly dictates which type of crusher will perform best and be most cost-effective. Choosing a crusher that isn’t suited for your specific rock can lead to extremely high wear costs, frequent downtime, and a poor-quality final product.

At ZONEDING, our process always begins with a detailed analysis of your raw material. This allows us to design the most efficient and durable sand and gravel making process for your unique situation.

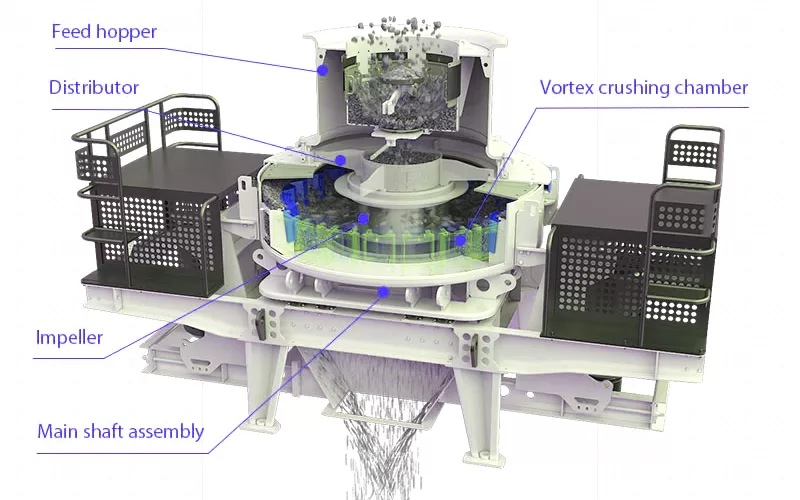

The VSI (Vertical Shaft Impactor) crusher is unquestionably the heart of any modern sand making plant. While jaw and cone crushers are the workhorses that do the heavy lifting of reducing large rocks, the VSI crusher is the finishing tool that gives your final product its high value. It is a specialized, high-speed machine designed specifically for the final stage of crushing, known as tertiary or quaternary crushing.

The VSI operates on a unique and highly efficient “rock-on-rock” principle. Material is fed into the center of a rotor that spins at very high speed.

Centrifugal force throws the material outwards at speeds of 45-65 meters per second. The particles then collide with other rocks in the crushing chamber. This high-velocity impact causes the rock to shatter along its natural fracture lines. This process is far superior to simply squeezing the rock (compression crushing), as it produces sand particles with an excellent, cubical shape.

You achieve a perfect cubic shape consistently by using a VSI crusher. The shape, or “particle morphology,” of your sand is incredibly important, especially for making high-strength concrete. Sand particles that are long, flat, or flaky are undesirable. When used in concrete, they create voids, have a higher surface area, and require more water and expensive cement to achieve the desired strength, which significantly increases costs and can compromise durability.

The high-speed, free-body impact in a VSI Sand Making Machine creates particles that are evenly shaped, or “cubic.” This is the ideal shape for concrete. Cubic particles interlock like building blocks, creating a stronger final product with fewer voids. They have a lower surface area, which means you need less water and cement paste to coat them. This results in stronger, more durable, and more cost-effective concrete. This is the primary reason why high-quality manufactured sand is often specified and preferred over natural sand in major projects.

A sand washer is not always necessary, but it is often a crucial step for producing premium-grade sand. The final step in many high-spec sand and gravel making processes is washing. The main purpose of a sand washing machine is to remove excess fine dust (fines), silt, and clay from the final product. If your source rock is very clean and breaks without creating excessive dust, you might not need one.

However, for most applications, especially for concrete sand, asphalt sand, and mortar sand, the specifications are very strict. These standards limit the amount of fine material (typically particles smaller than 75 microns or 200 mesh) that is allowed. Too much dust can weaken the bond between the aggregate and the cement paste. A sand washer effectively cleans the sand, ensuring it meets these important standards. It also improves the overall quality and appearance of your product, allowing you to command a higher price.

You control sand gradation using a precise combination of the VSI crusher settings and multi-deck vibrating screens. Gradation refers to the distribution of different particle sizes within your final sand product. Think of it like a recipe. Concrete specifications require a specific mix of coarse, medium, and fine particles to minimize voids and maximize strength.

Here is how you control this in the sand and gravel making process:

To reduce your long-term costs, you must focus on Total Cost of Ownership (TCO), not just the initial machine price. The biggest ongoing expenses in a sand making plant are energy and wear parts. Making smart choices in these areas at the beginning will dramatically lower your production cost per ton over the life of the plant.

Here’s how you can achieve this:

A bottleneck is any point in your process that restricts the overall output of the entire system. Even the most powerful and expensive crusher is useless if it’s not being fed properly or if the material after it cannot be cleared away fast enough. Identifying and eliminating these choke points is essential to maximizing your plant’s capacity and profitability.

Common bottlenecks include:

A professional plant layout is the blueprint for profitability and safety. It’s about much more than just finding a place to put the equipment. An optimized layout, designed by experienced engineers, ensures a smooth, continuous flow of material from the raw feed to the final stockpile, which directly impacts your operational costs, output, and safety record.

Here’s how a professional ZONEDING design helps:

Our VSI crusher is designed for lower operating costs and higher product quality. At ZONEDING, we focus on engineering that makes you more money over the long term. Our VSI sand making machine is a more profitable choice because it is built for efficiency, durability, and ease of maintenance, which are all key in the abrasive sand and gravel making process.

We provide complete, turnkey solutions for your entire sand and gravel making process. Setting up an aggregate production line is a complex project that is more than just buying machines. It requires expert process design and layout to ensure every component works together in perfect harmony for maximum efficiency. At ZONEDING, we have a dedicated team of experienced engineers who can help you from the initial idea to full production.

Our turnkey process includes:

The sand and gravel making process is a business with a solid and growing future. By understanding the fundamentals—from a deep analysis of your raw material to the critical role of the VSI crusher—you can build an operation that is both highly efficient and highly profitable. The key to long-term success is to focus on producing a high-quality, consistent product that meets the ever-stricter demands of the modern construction industry.

Are you ready to turn your rock resources into a valuable, in-demand commodity? A well-designed sand making plant is your path forward. Partnering with an experienced manufacturer who understands the entire process from quarry to stockpile is the surest way to achieve your production goals and maximize your return on investment.

Need to know ferrous metals? This guide introduces iron and its common alloys (steel, cast iron), outlining their basic composition and industrial relevance.

View detailsLearn differences between Ball mill and hammer mill in working principles, reduction ratios, and output size (mesh). Learn which grinder suits your material.

View detailsLearning how to crush coal efficiently is vital for energy production. From primary breaking to fine pulverizing, we explain process and match right crushers.

View detailsA step-by-step guide covers everything from crushing and grinding to advanced magnetic separation and dewatering, ensuring efficient magnetite processing.

View details