At ZONEDING, our business is on processing the raw materials of the earth. We’ve seen rocks of all types enter our machines, but few are as fundamental to our world as iron ore. This humble reddish rock is the starting point for nearly all the steel that builds our cities, cars, and tools. Understanding what iron ore is reveals the first, crucial step in modern industry. This guide will explain everything you need to know about its types, how to process it, and its most important uses. We will show you how to transform this raw material from a simple rock into the backbone of our civilization.

Table of Contents

What Exactly is Iron Ore?

Iron ore is a rock that contains enough iron metal for it to be profitable to mine and process. You can’t just dig pure iron out of the ground. The iron comes with oxygen and other elements. An “ore” is simply a natural rock that holds valuable minerals. The main job in processing is to break apart these bonds to extract the pure iron. The higher the iron content in the rock, the more valuable the ore will be. Rocks with less than 50% iron are low-grade and require more processing to be useful.

Why is Iron Ore So Important?

The importance of iron ore comes down to one word: steel. Over 98% of all iron ore mined applies to make steel. Steel is the most essential construction and manufacturing material in the world. Think about your daily life. The building you’re in, the car you drive, the ships that carry goods, the paper clips on your desk, and even the washing machine in your home are all made with steel. Without a steady supply of iron ore, we could not produce the steel needed to build and maintain our modern world. It is not just a rock; it’s the foundation of global industry and infrastructure.

Most of the world’s major iron ore deposits formed over 1.8 billion years ago. At that time, the Earth’s oceans contained a lot of dissolved iron. When the first photosynthetic organisms, like cyanobacteria, began releasing oxygen into the atmosphere, a massive chemical reaction happened. This oxygen reacted with the iron in the water, causing it to “rust” and settle on the ocean floor. Over millions of years, these layers of iron sediment were compressed by pressure and heat, forming the massive rock deposits we mine today. These formations are often called banded iron formations.

What are the Main Types of Iron Ore?

Iron ore is not just one type of rock. It comes in several different mineral forms, each with unique properties. The type of ore determines its value and how to process it. Understanding these iron ore types is key to efficient extraction.

Hematite

- Chemical Formula: Fe₂O₃ (Ferric Oxide)

- Iron Content: Typically 60-70%

- Key Characteristics: This is the most important and abundant type of iron ore. It gets its name from the Greek word for blood, “haima,” because it has a distinct reddish-brown to black color. When ground into a powder, it leaves a red streak.

- Applications: It is the primary raw material for the world’s steel industry due to its high iron content and relatively simple processing requirements.

- Deposits: Major deposits are in Australia, Brazil, China, and India.

Magnetite

- Chemical Formula: Fe₃O₄ (Ferrous Ferric Oxide)

- Iron Content: Can exceed 70%

- Key Characteristics: Magnetite is the iron ore with the highest iron content. As its name suggests, its defining feature is that it is naturally magnetic. This property is incredibly useful during processing.

- Applications: The magnetic properties allow for easy and cost-effective separation from waste rock using large magnets, a process we are very familiar with at ZONEDING. This often results in a very high-quality concentrate for steel production.

- Deposits: Found in the United States (Mesabi Range), Sweden, and Russia.

Taconite

- Chemical Formula: A mix of Hematite/Magnetite with silica.

- Iron Content: Low, typically 25-30%

- Key Characteristics: Taconite is not a specific mineral but a low-grade iron-bearing rock. It is very hard and requires significant processing to become useful. The valuable iron minerals must be liberated from the surrounding silica.

- Applications: It must be finely crushed and ground, and then the iron is separated out. The resulting powder is then formed into small pellets, which can be used in a blast furnace. The need to process hard taconite drives demand for powerful crushing and grinding equipment.

- Deposits: The Mesabi Iron Range in North America is a major source of taconite.

Goethite & Limonite

- Chemical Formula: FeO(OH) (Hydrated Iron Oxide)

- Iron Content: 30-60%

- Key Characteristics: These are often yellowish or brownish and are known as hydrated iron oxides because they have water molecules in their structure. Limonite is not a true mineral but a mix of similar hydrated iron minerals.

- Applications: They are used in steelmaking, but the water content must be driven off first, which requires extra energy. They were also historically used as a pigment (ochre).

- Deposits: Found worldwide, often formed from the weathering of other iron minerals.

Siderite

- Chemical Formula: FeCO₃ (Iron Carbonate)

- Iron Content: Around 48%

- Key Characteristics: Siderite contains a lower percentage of iron compared to other ores. Its value is often in its “self-fluxing” properties, meaning it requires fewer additives in the steelmaking process.

- Applications: It is less commonly mined for steel compared to Hematite or Magnetite but can be a valuable source where it occurs in large deposits.

- Deposits: Important deposits are in the United Kingdom and Austria.

How to Process the Iron Ore?

Transforming raw iron ore from a bulky rock into a product ready for the steel mill is a multi-stage journey. This process, known as beneficiation, aims to increase the iron content and remove impurities.

- Mining: The ore is first extracted from the ground, usually from massive open-pit mines. This involves blasting and digging to get the raw rock.

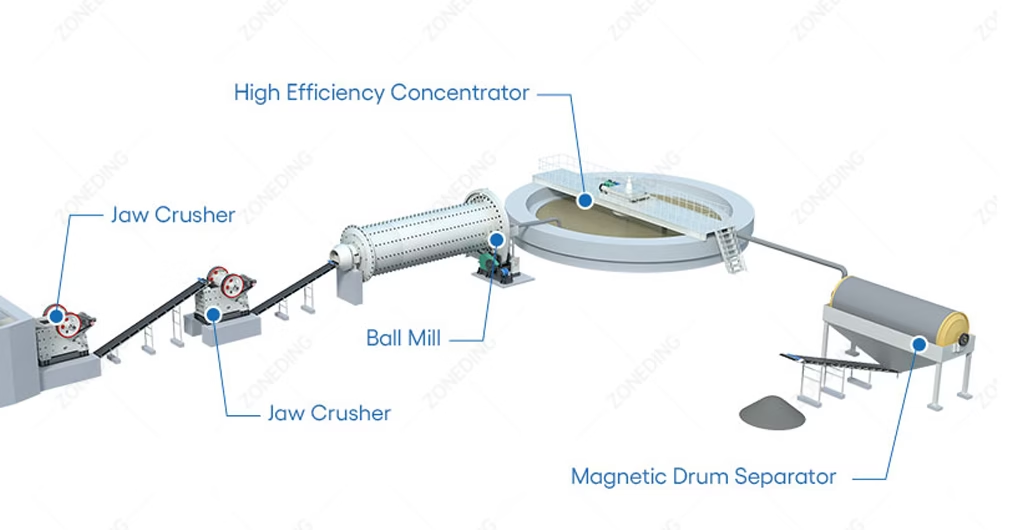

- Crushing and Grinding: The large rocks go to a processing plant. The first step is crushing them into smaller, more manageable pieces using equipment like jaw crushers and cone crushers. Then, they are fed into large grinding mills that turn the rock into a fine powder. This step is crucial to free the iron mineral particles from the waste rock.

- Separation: This is where the magic happens. A variety of techniques apply to separate the valuable iron minerals. For Magnetite, large magnetic rollers are used. For other ores like Hematite, a process called froth flotation or gravity separation using spiral concentrators might be used.

- Pelletizing: The fine, concentrated iron powder is mixed with a binder and rolled into small, hard balls called pellets. These pellets are then heated to harden them. This form is ideal for shipping and for use in the blast furnace to make steel.

What are the Main Impurities in Iron Ore?

When we extract iron, we are really trying to remove everything that isn’t iron. The main impurities, often is “gangue,” can harm the quality of the final steel if they are still in the ore.

- Silica (SiO₂): This is essentially sand or quartz. It is the most common impurity and remove it to avoid making the steel brittle.

- Alumina (Al₂O₃): This is a clay-like material. Too much alumina can make the molten slag in the blast furnace too thick and difficult to manage.

- Phosphorus and Sulfur: These are particularly harmful impurities. Even in tiny amounts, phosphorus can make steel brittle at cold temperatures, and sulfur can make it crack during high-temperature manufacturing processes.

What is the Main Equipment for Iron Ore Beneficiation?

A successful iron ore operation relies on a chain of robust and efficient machinery. At ZONEDING, we provide many of the core components for these processing lines. The essential equipment includes:

- Crushers:Jaw crushers for primary crushing of large rocks, and cone crushers for secondary and tertiary size reduction.

- Grinding Mills: Large ball mills or rod mills apply to grind the crushed ore into a fine powder.

- Vibrating Screens: These apply to sort the material by size at different stages of crushing and grinding.

- Magnetic Separators: Absolutely essential for processing Magnetite ore. They use powerful magnets to pull the iron away from non-magnetic waste.

- Flotation Machines: Used for non-magnetic ores, these machines use air bubbles and chemicals to make the iron particles float to the surface for collection.

- Thickeners and Filters: These apply at the end of the process to remove water from the iron concentrate.

What is the Cost of an Iron Ore Processing Plant?

An iron ore processing plant doesn’t have a fixed price tag. The investment can range from a few hundred thousand dollars for a basic setup to many millions for a high-capacity, automated facility. Ultimately, the total cost is determined by the entire system designed for your specific operational needs, not just the price of individual machines.

The final price tag depends directly on several key factors:

- Processing Capacity: How many tons per hour (TPH) do you need to process? A plant designed for 50 TPH will be significantly less expensive than one built for 500 TPH.

- Ore Characteristics: The hardness, grade, and mineral composition of your ore determine the type and size of equipment required. For example, processing hard Taconite requires more powerful and expensive crushers and mills compared to softer Hematite.

- Process Complexity: A basic crushing and screening line is the most affordable. If your process requires advanced stages like grinding, magnetic separation, flotation, or pelletizing, each additional step will add to the overall cost.

- Automation and Technology: You can choose between basic manual controls or a fully automated plant managed by a Siemens PLC system. At ZONEDING, we engineer solutions to match your budget and operational goals, offering everything from single machines to complete turnkey plants.

How Do You Choose a Reliable Supplier?

Choosing an equipment supplier is one of the most critical decisions you will make for your mining operation. This is more than a purchase; it’s a long-term partnership.

To ensure you find a reliable partner, focus on these key factors:

- Deep Industry Experience: Look for a manufacturer, not just a seller. Your investment is safer with a company that has a long history of engineering and problem-solving. This kind of deep experience, which we at ZONEDING have cultivated for over 30 years, means we’ve likely already designed solutions for ore bodies just like yours.

- One-Stop Solution Capability: Think about the complexity of coordinating multiple suppliers for your crushers, mills, and separation units. It can be a logistical nightmare. At ZONEDING, creating these complete, turnkey solutions is our specialty.

- Engineering and Customization: Every ore deposit is unique.You need a supplier with a strong in-house engineering team that can customize equipment to your exact needs. ZONEDING can provide this customization service.

- Factory-Direct Value and Quality: While cost is important, the “cheapest” option often leads to higher long-term expenses due to breakdowns and poor performance. This factory-direct model, which we use at ZONEDING, eliminates middlemen and allows you to invest in higher-quality machines built with wear-resistant steel and components from globally recognized brands like Siemens and Schneider.

- Global Reach and Full-Service Support: The partnership doesn’t end when you receive the equipment. A top-tier supplier provides comprehensive after-sales support, including installation guidance, operator training, and a reliable supply chain for spare parts. ZONEDING has experience exporting to over 120 countries, as we do, it demonstrates they understand international logistics and can support your operation no matter where you are located.

Conclusion

Iron ore is far more than just a reddish rock; it is the bedrock of modern society. From its formation billions of years ago to its complex processing journey, every step is vital. Hematite and Magnetite are the primary sources for the global steel production that builds our world. The process of turning this raw ore into a usable product requires powerful, reliable equipment for crushing, grinding, and separation. Understanding the different iron ore types and their properties is the first step toward efficient and profitable extraction.

FAQ

- What is the main use of iron ore?

The absolute primary use of iron ore is to make steel. Over 98% of all mined iron ore ends up in steel products, which are used in construction, transportation, machinery, and countless consumer goods.

- How does iron ore turn into steel?

The iron ore to steel process starts in a blast furnace. Iron ore pellets, coke (a form of coal), and limestone are heated to extreme temperatures. This process melts the iron and removes oxygen and other impurities, creating molten iron. This iron is then further processed to control the carbon content and add other elements to create different grades of steel.

- What is iron ore used for besides steel?

While rare, there are a few other iron ore uses. Powdered iron can for certain types of magnets and auto parts. Some low-grade iron ore, particularly limonite, can make cement. Historically, it can create pigments like yellow ochre and red sienna.

- What is the environmental impact of mining iron ore?

Like all large-scale mining, iron ore mining has environmental impacts. These can include land disruption, water usage, and greenhouse gas emissions from machinery and processing. Modern mines focus on responsible practices like water recycling, land reclamation after mining is complete, and using more efficient equipment to reduce their footprint.

- What is the future of iron ore mining?

The future of iron ore mining focused on efficiency and sustainability. This includes developing technologies to process lower-grade ores more effectively, increasing automation and using remote-controlled equipment to improve safety, and finding ways to reduce energy consumption and emissions in the “green steel” movement.