A concrete crusher is a powerful machine that breaks down large pieces of concrete from demolition sites into smaller, reusable aggregates. At my company, ZONEDING, we specialize in this technology, which allows you to turn construction waste into a valuable resource. Essentially, a concrete crusher helps you recycle old concrete instead of sending it to a landfill. This not only saves you significant money on disposal and material costs but also contributes to a more sustainable construction industry.

Table of Contents

What is a Concrete Crusher?

A concrete crusher is a piece of heavy equipment that uses immense force to fracture concrete into smaller, more manageable sizes. Think of it as the starting point for recycling. Demolished structures, old sidewalks, and retired roadbeds are full of concrete that would otherwise take up space in a landfill. A concrete crusher takes this debris and reduces it to a usable size, often referred to as recycled concrete aggregate (RCA). This powerful process makes it possible to give old materials a new life in future construction projects. It is a key machine for any circular economy model in the building industry.

Why Do We Need a Concrete Crusher?

You might wonder why you should invest in crushing concrete instead of just hauling it away. The answer comes down to significant financial and environmental benefits. A concrete crusher transforms what is typically considered a costly waste product into a profitable asset for your business. At ZONEDING, we’ve seen our clients completely change their cost structure by adopting on-site recycling.

Here are the primary benefits for your business:

- Drastically Reduced Costs: You eliminate landfill tipping fees and the high cost of transporting heavy debris. You also save money by producing your own aggregate instead of buying and hauling in new materials.

- Creation of a New Revenue Stream: The recycled concrete aggregate you produce is a valuable commodity. You can sell it to other contractors, landscapers, or municipalities, creating an additional source of income.

- Environmental Sustainability: Recycling concrete conserves natural resources by reducing the need to quarry new gravel and sand. It also frees up valuable landfill space and lowers the carbon footprint associated with transporting materials.

- Increased Project Efficiency: With a mobile concrete crusher, you can process material directly on-site. This minimizes truck traffic, reduces project delays, and streamlines your entire operation from demolition to rebuilding.

What are the Applications of Concrete Crushers?

The output of a concrete crusher—recycled aggregate—is surprisingly versatile. The ability to create different sizes of material means it can be used in a wide range of applications, often replacing virgin materials without compromising quality. This makes your operation more self-sufficient.

Common uses for crushed concrete aggregate include:

- Base Material: It serves as an excellent, compactable base layer for new roads, highways, and building foundations.

- Asphalt and Concrete Production: The aggregate can be mixed into new asphalt and concrete, reducing the need for new stone.

- Backfill and Drainage: It’s widely used for backfilling trenches, retaining walls, and in French drain systems.

- Landscaping and Erosion Control: Smaller-sized aggregate can be used for gravel paths, driveways, or to prevent soil erosion on slopes.

What is the Main Material for a Concrete Crusher Plant?

A concrete crusher plant is designed to handle the tough, abrasive materials found on demolition and construction sites. The primary input is, of course, used concrete. However, this is rarely clean and often comes mixed with other construction waste.

The main materials fed into a crusher include:

- Demolished Concrete: Slabs, columns, and beams from old buildings and structures.

- Concrete Pavement: Chunks of old roads, runways, and sidewalks.

- Reinforced Concrete: Concrete that contains steel rebar, which requires a system for separation after crushing.

- Precast Concrete Waste: Rejected or broken pieces from concrete product manufacturing plants.

A key challenge is handling contaminants. A well-designed crushing plant, like the ones we engineer at ZONEDING, will include mechanisms like overband magnets to automatically remove reinforcing steel after the concrete is broken apart.

What are the Different Types of Concrete Crushers?

There isn’t one type of crusher that fits all jobs. The right choice depends on the material’s size, hardness, and the desired final product size. At ZONEDING, we manufacture several types to create complete, efficient crushing lines.

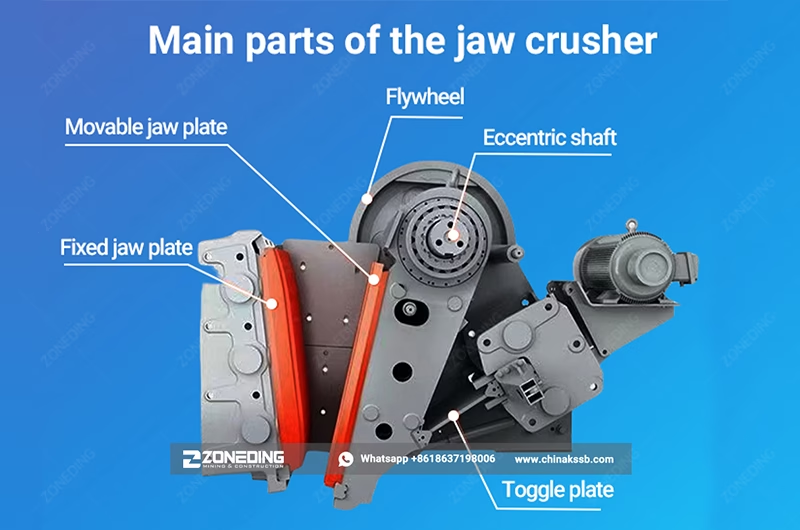

Jaw Crushers

- Structure: A jaw crusher has two heavy steel plates, or jaws. One is fixed, and the other is mounted on a pivot and moves back and forth. This creates a V-shaped crushing chamber.

- Work Principle: Material is fed into the top of the “V”. As the moving jaw compresses against the fixed jaw, it crushes the concrete. The material gets smaller as it travels down the chamber and is discharged at the bottom once it’s small enough to pass through the opening. They are perfect for primary crushing—the first stage of breaking down very large pieces.

Impact Crushers

- Structure: An impact crusher consists of a chamber with high-speed rotors that have “hammers” or “blow bars” attached.

- Work Principle: Instead of squeezing the material, an impact crusher shatters it. Material is fed into the chamber and struck by the rapidly spinning hammers. This impact throws the material against breaker plates inside the chamber, causing it to fracture further. They are excellent for producing a more cubical, uniformly shaped aggregate and are often used in the secondary crushing stage.

Cone Crushers

- Structure: A cone crusher has a cone-shaped mantle that rotates inside a concave bowl.

- Work Principle: Material is fed into the top. As the mantle gyrates, it squeezes and crushes the material against the bowl liner. Cone crushers are typically used in secondary or tertiary stages for hard and abrasive materials, producing very fine and uniform aggregates.

What is the Whole Process of Crushing Concrete?

A complete concrete recycling operation is more than just a single machine. It’s a systematic process designed to efficiently turn rubble into a clean, graded product. ZONEDING specializes in designing these complete production lines for you.

- Feeding and Pre-Screening: Raw demolition debris is loaded into a vibrating feeder, which controls the flow of material into the primary crusher. A pre-screen might remove dirt and fine particles first.

- Primary Crushing: The large chunks of concrete are fed into a primary crusher (usually a jaw crusher) to break them down into a more manageable size.

- Metal Separation: After the first crush, the material moves along a conveyor belt that passes under a powerful electromagnet. This magnet pulls out all the steel rebar and other metal contaminants.

- Secondary Crushing: The material is then transported to a secondary crusher (like an impact or cone crusher) to be reduced to the final desired aggregate sizes.

- Screening and Sizing: A multi-deck vibrating screen separates the crushed material into different sizes (e.g., 3/4″, 1/2″, etc.). Oversized pieces are often sent back to the secondary crusher for another pass.

- Stockpiling: The final, graded aggregates are moved via conveyors into separate stockpiles, ready for sale or reuse.

What is the Price of a Concrete Crusher?

The price of a concrete crusher can range from $50,000 for a small, basic stationary jaw crusher to over $600,000 for a large-capacity, fully-featured mobile track-mounted plant. There is no single price tag because the cost depends entirely on your specific needs.

Factors that influence the final price include:

- Type of Crusher: Jaw crushers are generally less expensive upfront than impact or cone crushers.

- Capacity: How many tons per hour (TPH) can the machine process? Higher capacity means a higher price.

- Stationary vs. Mobile: Mobile crushers on tracks or wheels offer incredible flexibility but come with a higher initial investment compared to stationary models.

- Features and Automation: Options like advanced PLC control systems (we use Siemens), dust suppression systems, and integrated screens will add to the cost.

- Manufacturer: As a factory-direct manufacturer since 1990, ZONEDING eliminates dealer markups, offering you better value and more competitive pricing on high-quality equipment.

How to Choose the Right Concrete Crusher?

Choosing the right concrete crusher is a major decision. You need a machine that is reliable, efficient, and perfectly matched to your project’s demands. As a partner to our clients, we always recommend you consider these factors:

- Analyze Your Raw Material: How large are the initial chunks of concrete? Is there a lot of rebar? The nature of your input material will determine if you need a primary jaw crusher or can start with an impactor.

- Define Your Final Product: What size aggregate do you need to produce? If you need a uniform, cubical product for making new concrete, an impact or cone crusher is essential in the process.

- Determine Your Capacity Needs: How many tons of concrete do you need to process per day or per hour? Choose a machine that can comfortably handle your target volume without being overworked.

- Assess Your Job Site: Will you be working in one fixed location or moving between multiple sites? For multiple sites, the higher upfront cost of a mobile crusher will quickly pay for itself in saved transport and setup time.

- Evaluate the Manufacturer: Look for a supplier with extensive experience, a strong engineering team, and a history of successful projects. A good supplier provides full-process support, from design and manufacturing to installation, training, and reliable after-sales service.

FAQ

- What valuable materials can you make from crushed concrete?

- From crushed concrete, you can produce several valuable materials. The primary product is recycled concrete aggregate (RCA) in various sizes, which is used as a base for roads and foundations. You can also create screened sand and collect scrap steel from the rebar, both of which can be sold.

- Can recycled concrete aggregate be used to make new blocks?

- Yes, absolutely. Recycled aggregate can be a component in the production of new concrete blocks. At ZONEDING, many of our clients pair a concrete crusher with a concrete block machine to create a closed-loop system, turning demolition waste directly into new, sellable building products.

- How do you handle rebar and other contaminants in the concrete?

- Rebar is handled after the initial crushing stage. Once the concrete is broken, the steel is freed. The crushed material is passed under a powerful overband magnet, which lifts the rebar and other metals off the conveyor, separating it into a different pile for recycling.

- What does the concrete crushing process look like on-site?

- On-site, a mobile crushing plant is typically used. A loader feeds demolition debris into the crusher. The machine breaks the material, separates the metal, and then screens it, dropping finished aggregate into piles via conveyor belts. It is a self-contained, efficient operation that minimizes material handling.

- What are the key benefits for my construction business?

- The key benefits are lower operating costs (no landfill or transport fees), increased revenue (selling aggregate and scrap metal), improved project timelines (on-site material availability), and a better environmental profile for your company.

Conclusion

At ZONEDING, we have been manufacturing heavy-duty crushing and block-making machinery since 1990. Our 30+ years of experience mean we do more than just sell equipment; we provide complete, customized solutions. We offer a comprehensive range of crushers and full production lines built with high-wear-resistant steel and components from world-renowned brands like Siemens, Schneider, and Omron. Because we are a factory-direct manufacturer with a team of 15 professional engineers, we can design a plant that fits your exact needs and budget, eliminating middleman costs. We have successfully exported to over 120 countries and provide full-process support, from installation and training to long-term parts supply.

Contact our team today for a free consultation. Let’s work together to turn your construction waste into a valuable asset.