全站搜索

Search the entire website

Search the entire website

Choosing the right primary crusher is the most important decision you will make for your quarry or mine. At ZONEDING, we have been manufacturing mining machinery since 1990, and we know this first step sets the stage for your entire operation’s efficiency and profitability. This guide will walk you through how to choose a primary crusher. We will explain the different types, their key differences, and the critical crusher selection factors you must consider. The right primary crusher selection ensures lower operating costs and higher productivity from day one.

The primary crusher is the first machine in your processing circuit. It is the workhorse responsible for taking the large, blasted rock directly from the mine (called Run-of-Mine or ROM feed) and breaking it into a smaller, more manageable size. Think of it as the first big bite. This initial reduction is called primary crushing. The output from the primary crusher is then sent downstream to secondary and tertiary crushers for further size reduction. Its job is to handle the largest, toughest rocks your site produces.

You need a primary crusher to start the process of comminution, which is the technical term for reducing particle size. Without a primary crusher, your operation simply cannot function.

Primary crushers are used in any industry that needs to break down large, hard materials.

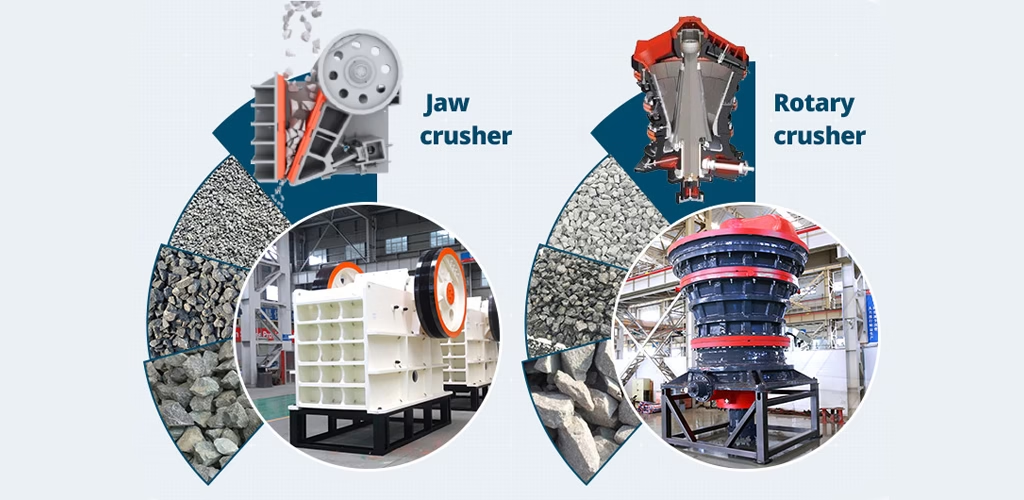

For large-scale quarry and mine operations, there are two main types of primary crushers you will encounter. Each works on a different principle.

The choice of jaw crusher vs gyratory is a critical one and depends entirely on the scale and nature of your project. They are not interchangeable.

Here is a simple breakdown:

| Feature | Jaw Crusher | Gyratory Crusher |

|---|---|---|

| Capacity | Lower to Medium (Up to ~1,500 tph) | Very High (Up to ~12,000 tph) |

| Feed Size | Limited by the gape (opening) size | Can accept very large boulders |

| Crushing Action | Intermittent (crushes on each “squeeze”) | Continuous (crushes during its full rotation) |

| Suitable For | Small to medium quarries, hard rock applications | Large mines, high-tonnage quarries |

| Capital Cost (CAPEX) | Lower | Very High |

| Installation | Simpler, less concrete work | Complex, requires massive foundations |

| Operational Cost (OPEX) | Higher wear on jaw plates, but parts are cheaper | Lower wear cost per ton due to larger surface |

ZONEDING has extensive experience manufacturing robust jaw crushers. We can help you determine if its capacity and operational profile are the right fit for your project.

The price of a primary crusher varies dramatically based on its type, size, and capacity. It is a major capital investment.

This price is just for the machine itself. You must also budget for foundations, chutes, conveyors, electrical systems, and installation, which can significantly add to the total project cost.

This is where you combine all the information. To select a primary crusher, you must analyze these key factors:

You should buy a primary crusher from a reputable manufacturer with proven experience. ZONEDING is a factory-direct manufacturer. This means you are buying directly from the people who designed and built the machine. This has several advantages:

Selecting the right primary crusher is a crucial engineering decision, not just a purchase. It impacts your capital outlay, your daily operational costs, and the overall productivity of your mine or quarry. The choice between a jaw crusher and a gyratory crusher is a fundamental one, driven by the scale of your operation. By carefully analyzing your material, capacity needs, and budget, you can make an informed decision that will serve your project well for years.

The most important advice we can give is to partner with an experienced manufacturer. An expert supplier can help you with your crusher capacity calculation, analyze your rock properties, and recommend the ideal machine for your specific conditions. This upfront collaboration is the best way to ensure long-term success.

Contact us today to discuss your project. Let’s work together to build the foundation of your success.

An expert comparison of 4 stone crushers: Jaw, Cone, Impact (HSI), and Hammer, including advantages,disadvantages ,cost, output shape, and suitable rock types.

View detailsUnderstand froth flotation (foam flotation) in mineral processing. Explore its core principles, key steps, and how it separates valuable minerals from ore.

View detailsDiscover 5 strategies to turn tailings and waste rock into profitable assets, from recovering critical minerals to creating green construction materials.

View detailsDiscover why mine dewatering is crucial. Explore equipment like dewatering screens, learn about costs, maintenance, and see how ZONEDING can boost efficiency.

View details