Choosing the right stone crusher is the most critical decision for the profitability and efficiency of any quarry, mining, or recycling operation. The crusher is the heart of your plant. The wrong choice leads to high operating costs, poor product quality, frequent downtime, and lost revenue. With several primary types available, each with unique strengths and weaknesses, navigating the options can seem overwhelming.

This definitive guide provides a clear, in-depth comparison of the four main types of stone crushers: the Jaw Crusher, Cone Crusher, Impact Crusher (HSI), and Hammer Crusher. This guide will go beyond a simple overview, exploring the detailed working principles, critical advantages and disadvantages, maintenance considerations, and ideal applications for each.

At ZONEDING, our decades of experience in designing, manufacturing, and deploying these machines worldwide give us the expertise to help you make a confident, informed, and profitable decision.

Table of Contents

1. The Jaw Crusher: The Primary Workhorse

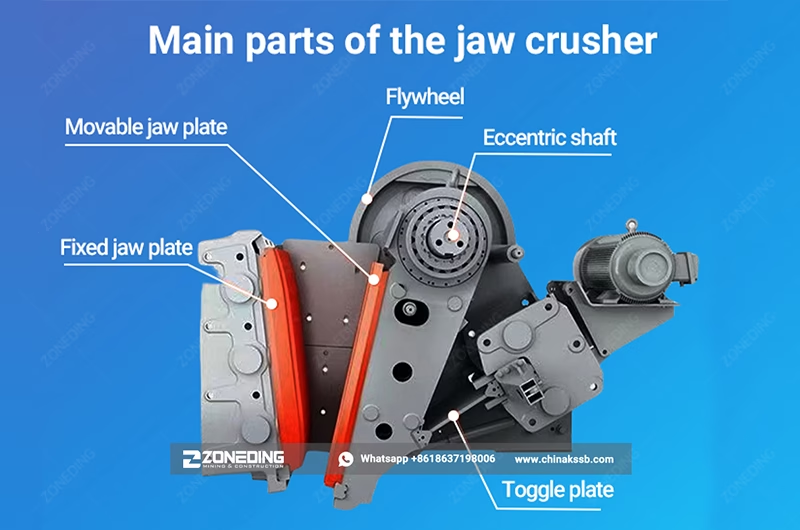

The Jaw Crusher is the undisputed champion of primary crushing. We design it as the first machine in the crushing circuit, engineered to take large, formidable boulders and break them down into a more manageable size for secondary processing. Its simple, robust design has made it a staple in the industry for over a century due to its unparalleled reliability and effectiveness with hard, abrasive materials.

Its working principle relies purely on compression. Material enters a V-shaped crushing chamber between a stationary jaw plate and a movable (swing) jaw plate. An eccentric shaft drives the swing jaw, creating a reciprocating motion that compresses the rock. The angle between the two jaws, known as the “nip angle,” is critical; the angle must be sharp enough to grip the rock and pull it down into the chamber for effective crushing. As the jaws squeeze the rock, it fractures, and the smaller pieces exit through the adjustable discharge opening at the bottom.

ZONEDING engineers its Jaw Crushers with heavy-duty frames and high-manganese steel jaw plates that operators can flip and reverse, doubling their lifespan and ensuring they withstand the immense forces of primary crushing.

Advantages

- Handles Massive Feed Sizes: Its wide opening accepts very large boulders directly from the quarry face, making it an indispensable primary crusher.

- Extreme Durability & Reliability: The simple mechanical design with few moving parts makes it exceptionally reliable and gives it a very long service life with straightforward maintenance.

- Low Operating Cost: The wear parts (jaw plates) are massive and made of highly resistant materials. This leads to lower consumption costs per ton compared to other crushers, especially with abrasive rock.

- Versatile Material Handling: It can effectively crush a vast range of materials, from soft limestone and construction debris to the hardest granite, basalt, and iron ore.

Disadvantages

- Produces Flaky Output: Because it uses pure compression, the crushing action tends to create more elongated or flaky particles. This shape is less than ideal for high-specification concrete and asphalt, which require a more cubical aggregate.

- Limited Reduction Ratio: This machine is not designed for fine crushing. Its typical reduction ratio is around 6:1, meaning it focuses on bulk reduction, not producing a finished product in a single pass.

- Continuous, Not Choke-Fed: It operates best when the chamber is not completely full (choke-fed), as this condition can cause excessive stress and wear.

Best Uses & Maintenance Tips

- Best Use: Use it as the first stage in any hard rock crushing plant, from stationary aggregate operations to mobile recycling setups.

- Maintenance Tip: Regularly check the wear on the jaw plates and rotate or flip them to ensure even wear. Monitor the tension of the V-belts and check the lubrication of the main bearings daily to prevent costly failures. A properly maintained jaw crusher can be the most reliable machine in your entire plant.

2. The Cone Crusher: The High-Capacity Refiner

After the jaw crusher has completed the initial break, the Cone Crusher enters the scene. This machine is the specialist for secondary and tertiary crushing, particularly for medium-to-extremely hard and abrasive materials. We designed it to take pre-crushed rock and efficiently refine it into smaller, more valuable, and uniformly shaped aggregates.

A cone crusher refines the principle of compression. It squeezes rock between an eccentrically rotating spindle (mantle) and a stationary bowl (concave). What makes it unique is that the machine crushes the material multiple times in different zones as it travels down through the progressively narrowing chamber. This “inter-particle crushing”—where rocks also crush against each other—is key to producing a superior cubical shape and minimizing the creation of excess fine dust.

Modern cone crushers, like ZONEDING’s Symons and single-cylinder hydraulic models, feature hydraulic systems for quick output size adjustment. They also include Tramp Release Cylinders that allow uncrushable material (like stray metal) to pass, which protects the machine from damage.

Advantages

- Excels with Hard, Abrasive Rock: This is the most economical machine for processing materials like granite, basalt, river pebbles, and iron ore with minimal wear.

- Produces Superior Cubical Shape: The combination of compression and inter-particle attrition results in well-shaped, cubical aggregates that meet strict specifications for concrete and asphalt.

- High Throughput Capacity: We build cone crushers for high production rates, making them the cornerstone of large-scale quarrying operations.

- Highly Adjustable: You can easily adjust the output size (Closed Side Setting or CSS) via the hydraulic system, even while the machine is running. This allows for precise control over the final product.

Disadvantages

- Higher Initial Investment: Cone crushers are complex, precision-engineered machines. Their advanced hydraulic and lubrication systems mean a higher upfront capital cost.

- Requires Controlled Feed: It operates most efficiently under choke-fed conditions; you must keep the crushing chamber full. It cannot accept oversized feed and requires a consistent material flow for optimal performance.

- More Complex Maintenance: While reliable, its hydraulic and lubrication systems require a higher level of technical skill for maintenance and troubleshooting compared to simpler crushers.

Best Uses & Maintenance Tips

- Best Use: Utilize it for secondary, tertiary, and even quaternary crushing stages in high-capacity hard rock quarries and mining operations.

- Maintenance Tip: The oil is the lifeblood of a cone crusher. Monitor the temperature, pressure, and cleanliness of the lubrication oil daily. Regularly inspect the wear patterns on the mantle and concave to ensure you get the most life out of your liners.

3. The Impact (HSI) Crusher: The Shaping and Recycling Champion

The Impact Crusher, also known as a Horizontal Shaft Impactor (HSI), revolutionizes the crushing process by using velocity instead of compression. It shatters material through high-speed impact. This makes it an exceptional machine for producing highly cubical aggregates and achieving a massive reduction ratio in a single machine.

Inside an HSI crusher, a heavy rotor fitted with blow bars spins at high speed. As material enters the crusher, the blow bars strike it with incredible force, instantly shattering it. The machine then launches the fragmented pieces at high velocity against stationary impact plates (or curtains), causing further breakage. This violent, multi-impact process produces a final product with an unmatched cubical shape, free of the internal stresses that compression crushing creates.

ZONEDING designs its impact crushers with hydraulic curtain adjustment and a user-friendly design that allows operators to change blow bars quickly, minimizing downtime.

Advantages

- Unmatched Cubical Product Shape: It produces the best-shaped, most consistently cubical aggregate of any crusher type. This quality is highly sought after for premium construction projects.

- Extremely High Reduction Ratio: It can achieve reduction ratios of up to 20:1. This allows it to potentially replace a two-stage cone crusher circuit in certain applications, saving capital cost.

- Perfect for Recycling: Its ability to liberate materials of different friability makes it excellent for recycling concrete and asphalt. It easily separates rebar from concrete, which a magnet then removes.

- Lower Capital Cost than a Cone Crusher: For a similar production capacity, an HSI often has a lower initial purchase price than a cone crusher.

Disadvantages

- High Wear in Abrasive Applications: This is its critical weakness. The high-impact nature means that blow bars and impact plates wear out very quickly when processing hard, abrasive rock like granite or high-silica river gravel. This leads to high operating costs and frequent downtime for maintenance.

- Best Suited for Softer Rock: Its economic sweet spot is with softer, less abrasive materials like limestone, dolomite, gypsum, and asphalt.

- Generates More Fines: The high-impact action can produce a higher percentage of fine dust, which may be a waste product if you do not manage or sell it.

Best Uses & Maintenance Tips

- Best Use: Apply it in secondary and tertiary crushing in limestone quarries, cement plants, and concrete/asphalt recycling operations.

- Maintenance Tip: The blow bars are the key wear part. Monitor their condition closely. Operators can rotate most blow bars once to use a second wear edge before replacement. Keeping a spare set on hand is essential to reduce downtime.

4. The Hammer Crusher: The Simple, All-in-One Solution

The Hammer Crusher is the epitome of simplicity and versatility. For certain materials, it can serve as both a primary and secondary crusher in a single unit. It offers a very high reduction ratio and a low capital cost, making it an excellent choice for small to medium-scale operations or for processing less abrasive materials.

A hammer crusher utilizes a high-speed rotor to which swinging hammers are attached. As raw material enters the chamber, the rotating hammers strike it with great force, shattering it. The material breaks down further as it collides with a breaker plate before discharging through a grate at the bottom. The size of the openings in the grate determines the final product size. This simple, direct crushing method makes it easy to operate and maintain.

ZONEDING offers a range of hammer crushers that provide a cost-effective, one-step crushing solution for materials like limestone, coal, gypsum, and salt.

Advantages

- Very Low Initial Cost: It is one of the most affordable types of crushers, providing a budget-friendly entry point for new crushing businesses.

- Simple Structure, Easy Maintenance: Its mechanical design is not complex. Repairs and maintenance, like replacing hammers and grates, are straightforward.

- Very High Reduction Ratio: It can take a feed size of up to 600-800mm and reduce it to less than 25mm in a single pass.

- Handles Moist & Sticky Material: The design is less susceptible to plugging when processing materials with moderate moisture or clay content, which can be problematic for other crushers.

Disadvantages

- Extremely High Wear on Hard Rock: Similar to an HSI, but even more pronounced. The hammers wear down extremely fast when used on anything abrasive, making it completely uneconomical for hard rock.

- Can Produce Excessive Fines: The intense shattering action can create a very large amount of dust and super-fines, which may require additional processing or result in lost yield.

- Less Control Over Product Shape: It produces a final product shape that is generally irregular or sub-angular and not as well-controlled as the output from a cone or VSI crusher.

Best Uses & Maintenance Tips

- Best Use: Single-stage crushing of soft to medium-hard, non-abrasive materials in cement, coal, power, and chemical industries.

- Maintenance Tip: The hammers and grate bars are the primary wear items. You can often reverse the hammers to use all four corners, extending their life. Regularly check the condition of the grate to ensure consistent product sizing.

FAQ: Choosing Your Stone Crusher

- Question 1: What’s the difference between an Impact Crusher (HSI) and a VSI?

- Both use impact, but their orientation differs. An HSI has a horizontal rotor and uses blow bars to strike the material. A VSI (Vertical Shaft Impactor) has a vertical rotor. It uses centrifugal force to sling rock outwards at high speed, causing it to shatter against stationary anvils or other rocks (a “rock-on-rock” crushing chamber). A VSI is primarily a tertiary or sand-making machine, while an HSI typically serves as a secondary crusher.

- Question 2: How does a rock’s moisture content affect crusher performance?

- High moisture, especially with clay or fine material, can be problematic. It can cause “packing” or “plugging” in Jaw and Cone crushers, reducing their efficiency. Impact and Hammer crushers can handle slightly higher moisture, but excessive stickiness can still cause buildup on the internal components.

- Question 3: What is a “crushing ratio” and why does it matter?

- The crushing ratio (or reduction ratio) is the ratio of the feed size to the product size. For example, if you feed 100mm rock into a crusher and the output is 20mm, the ratio is 5:1. A machine with a high reduction ratio, like a Hammer or Impact Crusher, can accomplish more size reduction in a single stage, potentially reducing the number of machines you need in a plant.

- Question 4: What is more important: low initial cost or low operating cost?

- For long-term, high-production operations facing hard rock, low operating cost is almost always more important. You will repay the higher initial investment in a durable Cone Crusher many times over through savings on wear parts and downtime. For smaller-scale operations or for processing soft rock, a lower initial cost from an Impact or Hammer Crusher might be the more profitable choice.

Conclusion and Final Thoughts

There is no single “best” stone crusher. The optimal choice is a strategic decision based on a clear understanding of your specific needs. To make the right choice, you must answer three questions:

- What is my raw material? Its hardness, abrasiveness, and size will dictate the most suitable crushing technology.

- What is my desired final product? High-quality, cubical concrete aggregate has different requirements than road base or industrial minerals.

- What are my production and budget goals? Your target capacity and financial plan will determine the right balance between capital investment and long-term operating costs.

The Jaw Crusher is the essential starting point for primary crushing. The Cone Crusher is the economical champion for high-volume, hard rock processing. The Impact Crusher is the master of shaping and recycling non-abrasive materials. And the Hammer Crusher offers a simple, low-cost solution for specific single-stage applications.

Why Choose ZONEDING?

At ZONEDING, we recognize that your success relies on having optimized equipment. We provide complete, engineered solutions, not just machines.

- Comprehensive Product Portfolio: We manufacture all four main types of crushers, plus VSI sand makers and complete mobile crushing stations. This allows us to provide an unbiased, fully customized recommendation for the right machine or complete crushing plant for your unique project.

- Engineered for the Toughest Conditions: We build our crushers with high-quality alloys and robust designs to ensure long service life and maximum uptime, no matter how challenging your application.

- Expert Engineering Support: Our team of 15 experienced engineers will partner with you to analyze your material, design an efficient flowsheet, and configure a crushing circuit that maximizes your productivity and profit margins.

- Proven Global Experience: With ZONEDING equipment successfully operating in over 120 countries, we have the global expertise to support your project from concept to commissioning and beyond.

Contact ZONEDING today for a professional consultation and a custom-engineered solution for your crushing needs.