全站搜索

Search the entire website

Search the entire website

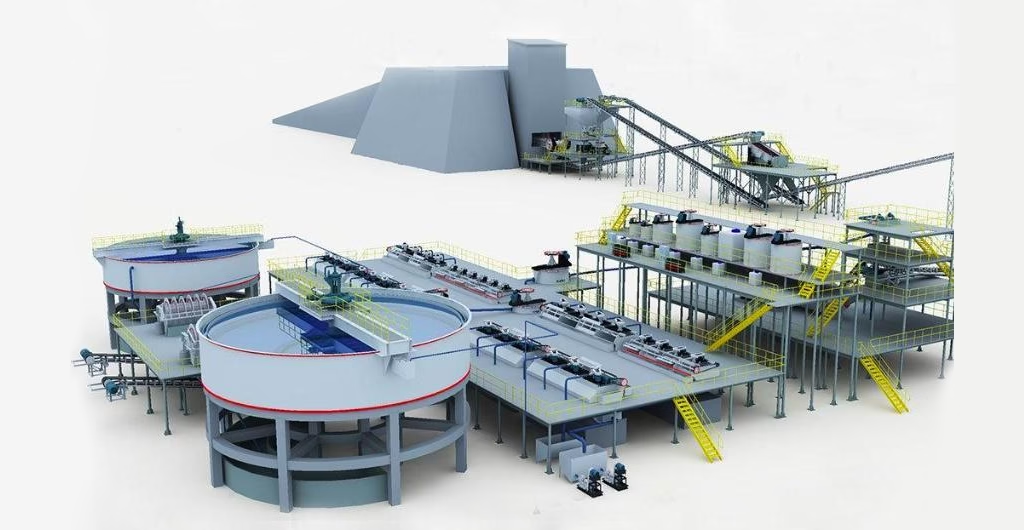

Mineral ore dressing processes extract valuable minerals from raw ore. This is a critical step in mining. Ore dressing removes gangue, or waste rock. It produces a concentrated mineral product. This concentrated product is more valuable. It is also suitable for further refining. These processes rely on distinct physical and chemical principles. They separate minerals based on their unique properties. Efficient mineral separation maximizes recovery and reduces waste.

This guide explores five common mineral ore dressing processes. It details their working principles. It also highlights their applications. Understanding these methods is key to optimizing mining operations. It ensures sustainable resource utilization. ZONEDING specializes in providing the mineral processing equipment needed for these methods.

Mineral ore dressing is also known as mineral beneficiation. It is a multi-step process. It separates valuable minerals from gangue. This yields a mineral concentrate. Raw ore, as it comes from the mine, contains a low percentage of desired minerals. It is not economically viable to refine directly. Ore dressing increases the mineral content. This makes subsequent metallurgical processes more efficient. It also reduces transportation costs. This process is complex. It involves various physical and sometimes chemical techniques.

The goal of mineral ore dressing is twofold:

ZONEDING provides a full range of mineral processing equipment. This includes machines for every step in ore dressing. This includes equipment for various mineral ore dressing processes. Understanding the fundamental concepts drives efficiency.

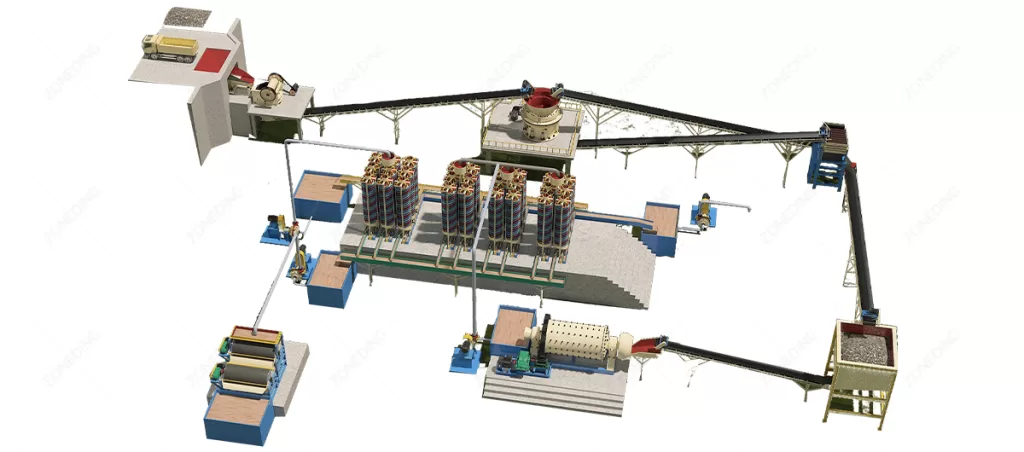

Crushing and grinding are the initial, mechanical stages of mineral ore dressing processes. These steps are crucial for liberation. Liberation means breaking the ore down. This frees the valuable mineral particles from the surrounding waste rock. This process reduces the particle size. It prepares the ore for subsequent separation methods. It is essential for efficient mineral recovery.

Crushing reduces large ore chunks into smaller pieces. This is the first stage of size reduction. Miners often use several types of crushing equipment in sequence.

Grinding follows crushing. It reduces the ore to a very fine powder. This achieves mineral liberation at a finer scale.

Careful control of crushing and grinding is vital. Over-grinding wastes energy. It also creates very fine particles. These are difficult to separate. Under-grinding means poor liberation. This results in lost minerals for subsequent mineral ore dressing processes.

Flotation is one of the most widely used mineral ore dressing processes. It separates minerals based on differences in their surface properties. This method is particularly effective for fine-grained ores. It works for sulfide minerals, non-sulfide minerals, and coal. Flotation is a complex physico-chemical process. It involves flotation reagents.

Flotation cells are the key mineral processing equipment for this method. ZONEDING flotation machines are engineered for high recovery rates. Flotation processes can be tailored. They can separate multiple minerals from one ore body. This is done through sequential flotation stages.

Magnetic separation is a physical mineral ore dressing process. It separates minerals based on their magnetic susceptibility. This method is highly effective for iron ores. It also works for other magnetic or weakly magnetic minerals. This includes chromite, manganese, and ilmenite. It offers an environmentally friendly alternative to chemical methods.

Magnetic separators come in various designs. These include:

The strength of the magnetic field is adjustable. This allows for selective separation of minerals. Magnetic separation is a cost-effective and efficient method. It is central to many mineral ore dressing processes.

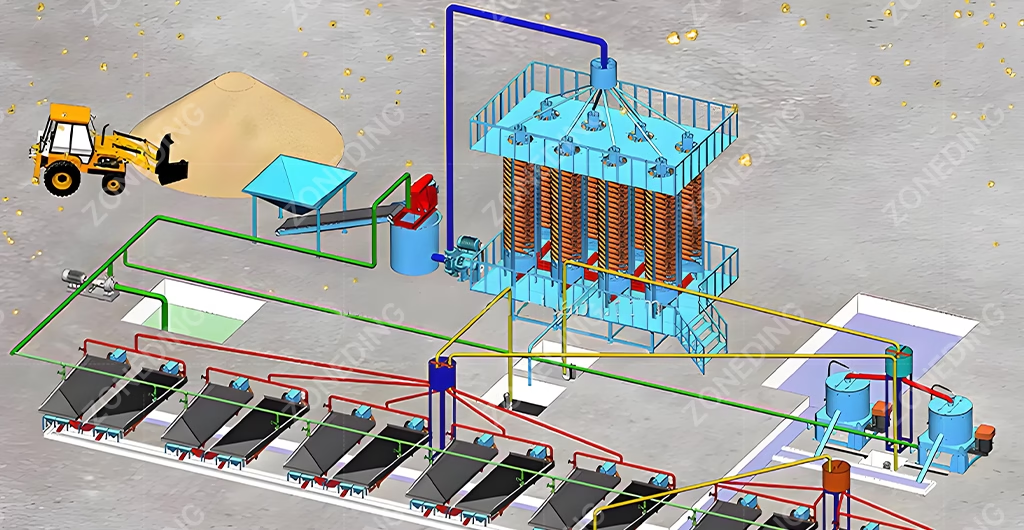

Gravity separation is one of the oldest and most fundamental mineral ore dressing processes. This method separates minerals based on differences in their specific gravity (density). It is particularly effective for minerals with high specific gravity. Gold, tin, tungsten, and some heavy sands are good examples. Gravity separation is environmentally friendly. This is because it primarily uses water and physical force.

Key mineral processing equipment used in gravity separation includes:

Gravity separation is often an economical first step. It is used in many mineral ore dressing processes. It can pre-concentrate ore before more complex methods like flotation.

Choosing the right partner for mineral ore dressing processes is crucial. ZONEDING offers significant advantages as a mineral processing equipment manufacturer.Its commitment to quality and service stands out. ZONEDING boasts deep industry experience. The company was founded in 2004. This long history ensures refined designs and optimized production. A team of 15 professional engineers guarantees strict quality control. They also ensure innovative design in every piece of crushing equipment and mineral processing machine.

ZONEDING provides a comprehensive product range. This includes essential crushing, grinding, flotation, magnetic separation, and gravity separation equipment. These are crucial for efficient mineral recovery. As a direct manufacturer, ZONEDING offers competitive pricing. It eliminates intermediary markups. Full-service support covers scheme design, manufacturing, installation guidance, and operator training. Reliable after-sales service includes part supply. ZONEDING exports to over 120 countries. This demonstrates extensive international logistics expertise. Choosing ZONEDING means investing in proven efficiency, durability, and a dedicated partner for successful mineral ore dressing processes.

Mineral ore dressing processes are fundamental to the mining industry. They transform raw ore into valuable concentrates. Understanding the principles of crushing, grinding, flotation, magnetic separation, and gravity separation is crucial. Each method plays a distinct role. It contributes to efficient mineral liberation and separation. The selection of precise mineral processing equipment for each stage is critical. Maximizing recovery while minimizing operational costs leads to profitable outcomes.

The right partner provides effective solutions for these complex processes. ZONEDING offers a comprehensive range of high-quality mineral processing equipment. Its expertise spans design, manufacturing, and full-service support. Whether for crushing equipment or specialized beneficiation equipment, ZONEDING ensures optimal performance. This commitment helps clients achieve their production goals. It also promotes sustainable resource utilization.

Last Updated: June 2025

How much gold remains underground? While about 212,000 tonnes are above ground, the USGS estimates only 59,000 tonnes of proven reserves are left to mine.

View detailsExplore the 10 most common minerals, from Quartz to Halite. Discover their fascinating and essential uses in technology, construction, and your daily life.

View detailsFrom panning to separation, get ultimate guide on how to process black sand for gold. Learn tips to improve yield and identify gold-rich black sand deposits.

View detailsFollow a step-by-step guide to vermiculite processing. Understand this unique mineral's definition, properties, and wide range of applications.

View details