全站搜索

Search the entire website

Search the entire website

Placer gold processing involves extracting gold from alluvial deposits. These deposits are accumulations of gold particles. They are found in riverbeds, valleys, and beaches. This guide explores various placer gold processing methods. It covers traditional gravity concentration techniques. It also includes modern gold separation technologies. Businesses aim to optimize mineral processing machine setups. This achieves maximum gold recovery efficiently. Understanding the geology and suitable technologies is crucial. This ensures a profitable placer mining operation.

This guide provides a complete overview. It covers everything from basic principles to advanced machinery. It also addresses crucial optimization strategies. This helps operations achieve better returns.

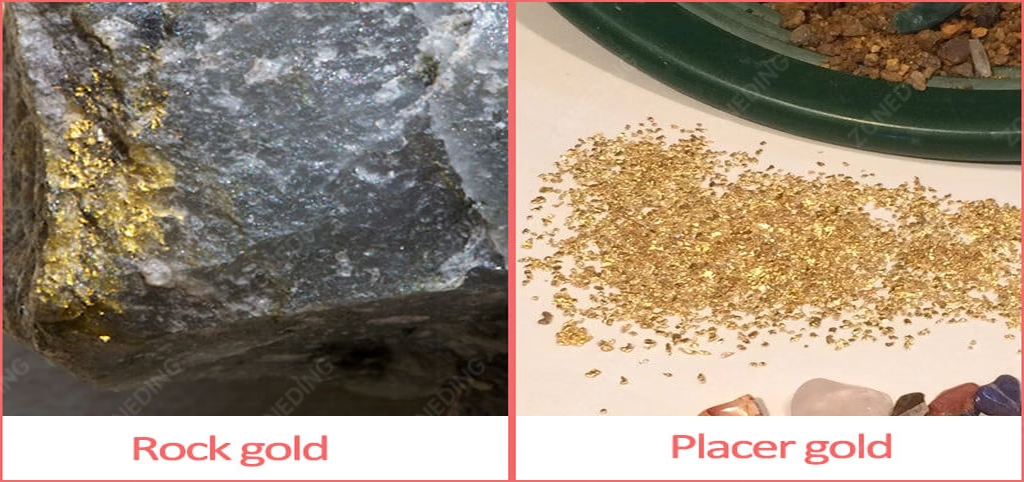

Placer gold refers to gold concentrated by natural processes. Water currents carry gold particles. These dense particles settle in specific locations. These locations include riverbeds, floodplains, and ancient stream channels. This type of gold is often found as free-milling gold. It appears in flakes, grains, or nuggets. Processing placer gold involves physical separation. It does not use chemical methods often seen in hard rock mining.

Placer gold processing is essential for several reasons. Firstly, it recovers valuable gold resources. This contributes to economic growth. Secondly, placer deposits are often easier to mine. They require less energy-intensive methods than hard rock deposits. Thirdly, demand for gold remains consistently high. This makes placer mining a viable venture. ZONEDING offers mineral processing machines designed for efficient gold recovery. This ensures maximum value extraction from these unique deposits. Understanding these fundamentals helps in strategic planning.

Placer deposits vary significantly in their characteristics. Understanding these types helps tailor processing methods.

Knowing the deposit type influences excavation techniques. It also impacts the choice of mineral processing machines. Each type presents unique challenges. For example, clay in alluvial placers requires specific washing steps.

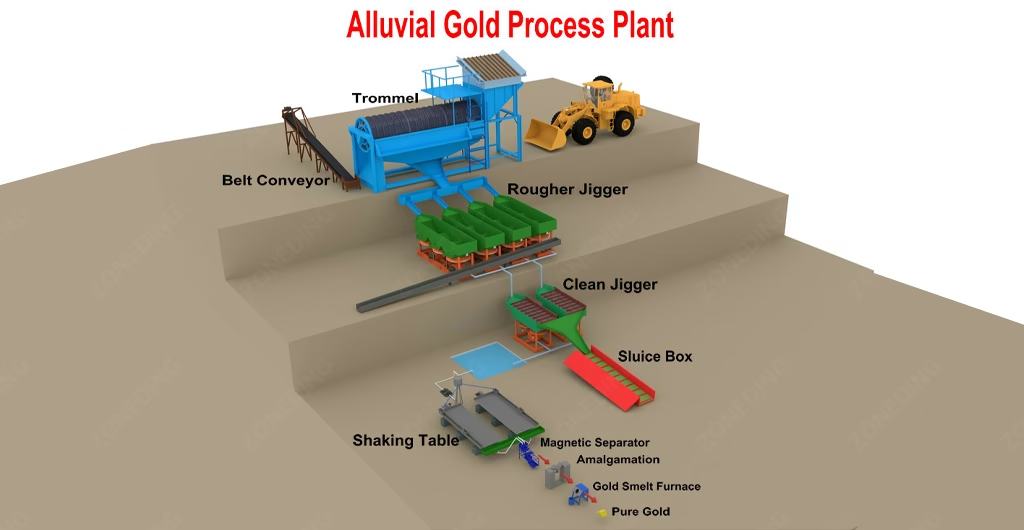

A typical placer gold processing flowchart outlines the steps involved. The goal is to separate valuable gold from inert materials. This involves a sequence of physical separation stages. Each stage refines the material, increasing gold concentration.

The general steps are:

This systematic approach ensures efficient recovery. It minimizes losses of fine gold. ZONEDING provides essential mineral processing machines for each stage. These machines streamline the entire flowchart. This helps miners achieve optimal output. Properly designed flowcharts boost operational efficiency.

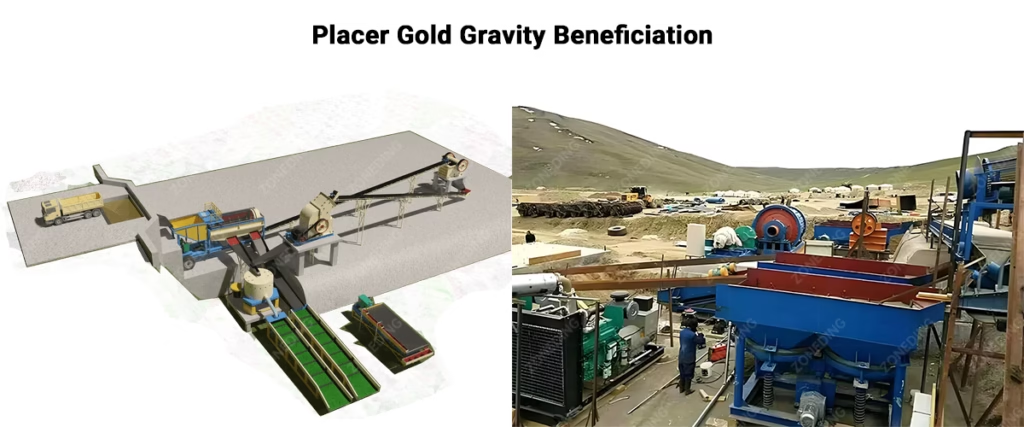

Gravity concentration is the primary method for placer gold processing. This method leverages the density difference between gold and waste material. Gold is much denser than sand, gravel, and clay. Various equipment types employ this principle effectively.

Historical methods still find limited use in small-scale mining. They provide context for modern techniques.

Modern placer gold processing relies on advanced mineral processing machines. These machines achieve higher recovery rates. They also handle larger volumes.

These methods are crucial for maximizing gold recovery. They form the backbone of modern placer gold processing operations.

Effective placer gold processing requires specific mineral processing machines. These machines perform critical functions. They prepare the ore and concentrate the gold. ZONEDING specializes in providing these vital components.

Initial processing stages focus on cleaning and sizing the raw material.

These machines ensure proper feed preparation. They are vital for subsequent gold recovery. They prevent valuable gold from washing away with waste.

After washing and screening, gravity separation equipment recovers the gold.

Choosing the right combination of these mineral processing machines is critical. It maximizes recovery and operational efficiency. ZONEDING’s expertise ensures clients select optimal equipment.

Optimizing a placer gold processing setup involves several key considerations. The goal is to maximize gold recovery while minimizing operational costs. Careful planning and equipment selection are crucial.

Optimizing these factors significantly improves the profitability of placer gold processing.

Placer gold processing faces unique challenges. Addressing these issues with effective solutions is vital for success.

Addressing these challenges ensures a more efficient operation. It also promotes environmental responsibility.

The placer gold processing industry constantly evolves. New technologies aim for greater efficiency and sustainability. These trends shape the future of gold recovery.

These trends point towards more precise, environmentally conscious placer gold processing. ZONEDING stays at the forefront of these innovations. It incorporates advanced features into its mineral processing machines. This ensures clients benefit from cutting-edge solutions. This continuous development helps address industry demands.

Choosing the right partner for placer gold processing equipment is critical. ZONEDING offers significant advantages as a mineral processing machines manufacturer. Its commitment to quality and service stands out. ZONEDING boasts deep industry experience. The company was founded in 2004. This long history ensures refined designs and optimized production. A team of 15 professional engineers guarantees strict quality control. They also ensure innovative design in every piece of crushing equipment and mineral processing machine.

ZONEDING provides a comprehensive product range. This includes essential washing, screening, and gravity separation equipment. These are crucial for efficient gold recovery. As a direct manufacturer, ZONEDING offers competitive pricing. It eliminates intermediary markups. Full-service support covers scheme design, manufacturing, installation guidance, and operator training. Reliable after-sales service includes part supply. ZONEDING exports to over 120 countries. This demonstrates extensive international logistics expertise. Choosing ZONEDING means investing in proven efficiency, durability, and a dedicated partner for successful placer gold processing.

Placer gold processing offers significant opportunities for mineral extraction. Success depends on understanding the unique characteristics of placer deposits. It also relies on selecting the right mineral processing machines. Implementing effective processing methods, primarily gravity concentration, is key. Careful optimization of the entire setup maximizes gold recovery. It also ensures operational efficiency.

By addressing challenges like clay content and fine gold loss, operations become more sustainable. Embracing future trends in automation and eco-friendly technologies helps stay competitive. Choosing a reputable manufacturer like ZONEDING is vital. This ensures high-quality crushing equipment, washing and screening equipment, and gold separation solutions. ZONEDING provides comprehensive support. This ranges from design to after-sales service. This partnership ensures successful and profitable placer gold processing ventures.

Understand how the different types of gold ore influence gold mining strategies, extraction processes, and overall recovery rates for better decision-making.

View detailsDiscover 9 most common problems on ball mill, from excessive wear to power consumption. Learn how to identify issues and implement solutions to extend lifespan.

View detailsLearn basics of gypsum production with our easy-to-follow guide. This Guide is from mining to processing so it is perfect for newcomers. Contact ZONEDING now!

View detailsThis guide tells what mineral processing is, explaining how valuable materials are extracted through essential steps like crushing, grinding, and separation.

View details