Vermiculite is a versatile mineral. It finds widespread application across many industries. This comprehensive guide outlines Vermiculite Processing. It covers its transformation from raw form to valuable finished products. Understanding Raw Vermiculite characteristics and the step-by-step Vermiculite Production process is essential. It helps you appreciate its diverse roles, from insulation to lightweight aggregates. The journey of vermiculite from mine to market showcases its unique properties.

Table of Contents

What is Raw Vermiculite?

Raw vermiculite refers to the naturally occurring mineral. We extract it directly from the earth. It possesses several key characteristics that define its nature and potential uses.

Here are the defining aspects of raw vermiculite:

- Mineral Group: It belongs to the phyllosilicate group of minerals. This means it exhibits a layered structure.

- Appearance: Raw vermiculite typically appears as flat, lustrous flakes. Its color varies. It ranges from silvery-brown to golden-brown.

- Common Impurities: These flakes often contain various impurities. These include quartz, feldspar, and other silicate minerals.

- Key Characteristic – Exfoliation: The most significant trait of raw vermiculite is its remarkable ability to expand substantially when heated. We term this expansion exfoliation. This property makes the mineral extremely useful for diverse applications.

- Chemical Composition: Chemically, raw vermiculite constitutes a hydrated magnesium-aluminum-iron silicate.

- Water Molecules: It traps water molecules explicitly within its layered crystalline structure. This interlayer water is directly responsible for the mineral’s unique expansive properties.

- Exfoliation Mechanism: When subjected to high temperatures, this trapped water rapidly vaporizes. The resulting steam forces the mineral’s layers apart. This causes the individual flakes to expand dramatically.

Vermiculite forms through a specific geological alteration process. This involves hydration and weathering. It originates from existing mica minerals. This formation process is critical for understanding its unique characteristics.

The formation of vermiculite requires specific geological conditions to occur successfully. Hot, mineral-rich groundwater or hydrothermal fluids play a significant role. These fluids interact with mica-rich rock formations. They cause the chemical changes necessary for vermiculite’s development. The resulting mineral retains the layered structure of its parent mica. However, it gains the ability to exfoliate when heated. This makes it distinct. The geological settings where vermiculite is found typically indicate these alteration zones. Large deposits are often associated with ultrabasic or basic igneous rocks. These rocks provide the necessary chemical environment. The specific conditions, such as temperature, pressure, and fluid composition, influence the purity and quality of the vermiculite formed.

What are Key Properties of Vermiculite?

Vermiculite possesses several key properties. These make it exceptionally valuable across various industries.

- Exfoliation (Expansion): Its unique feature is its expansion when we heat it rapidly to temperatures between 800°C and 1100°C. The trapped water molecules turn into steam. This forces the layers apart. This process yields a concertina-like structure. We often call the expanded product Exfoliated Vermiculite.

- Low Bulk Density: After exfoliation, vermiculite becomes extremely lightweight. Its bulk density significantly decreases. This makes it an ideal material for reducing weight in composite products. It is also beneficial for easy handling in various applications.

- Thermal Insulation: The expanded, layered structure creates numerous air pockets. These air pockets make exfoliated vermiculite an excellent thermal insulator. It resists heat transfer effectively. This property is vital for Vermiculite Insulation products.

- Fire Resistance: Vermiculite is naturally non-combustible. It does not burn or support combustion. It can withstand extremely high temperatures without melting or breaking down. This makes it a crucial component in Fire-Resistant Materials.

- Chemical Inertness: Vermiculite is chemically stable. It does not react with most acids or bases. This property makes it safe for various applications. It is particularly useful in horticulture and chemical spill containment.

- High Cation Exchange Capacity (CEC): This property allows vermiculite to absorb and store nutrients. It then gradually releases them to plants. This makes it highly beneficial in agricultural and horticultural settings.

- High Absorbency: Its porous structure enables it to absorb liquid effectively. This is useful for spill clean-up and in certain industrial processes.

Where can We Find it?

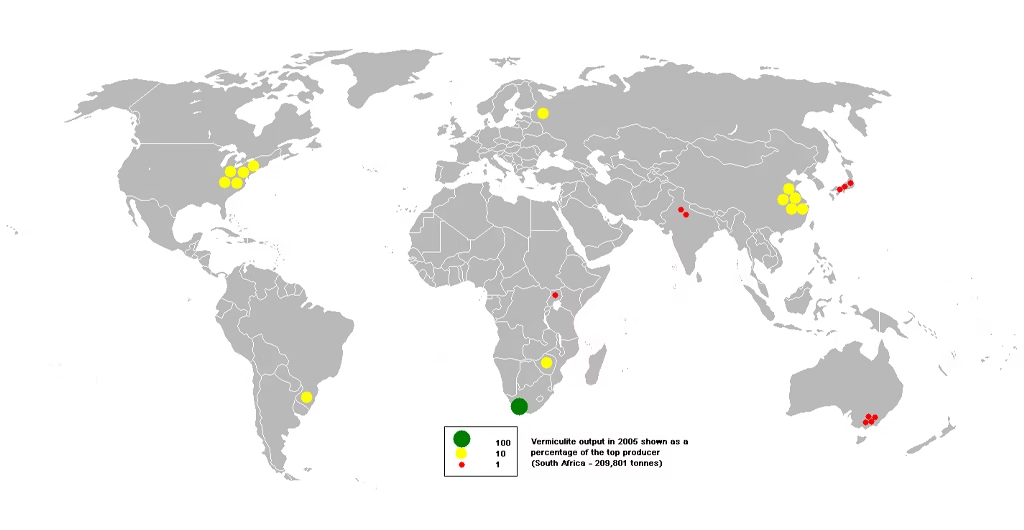

Major commercial operations concentrate in specific countries. The geological conditions required for its formation are not universally widespread. This makes it a relatively localized mineral resource. Significant sources often determine global supply. They influence international markets for Raw Vermiculite.

- South Africa: Historically, South Africa has been one of the largest producers of vermiculite. Its deposits are known for high quality and consistent supply.

- United States: The U.S. also possesses significant vermiculite reserves. Mines located in states like Montana and North Carolina have been important contributors to global supply.

- Brazil: Brazil has emerged as a key producer. It provides a reliable source of the mineral from substantial deposits.

- Russia: Russian territories also hold considerable vermiculite resources. They contribute to regional and international markets.

- China: China has its own vermiculite deposits and processing facilities. It meets both domestic demand and export needs.

- Other Countries: Smaller deposits and operations exist in countries such as Australia, Zimbabwe, and other parts of Africa. They contribute to the overall market.

What are Applications of Vermiculite as a Mineral?

Vermiculite finds a wide array of applications across diverse industries. This is due to its unique combination of properties. Its lightweight nature, excellent insulation, fire resistance, and absorption capabilities make it highly desirable. These characteristics stem directly from the Vermiculite Properties inherent in its exfoliated form. Applications range from construction and horticulture to industrial uses and environmental protection.

- Construction and Building Materials:

- Lightweight Aggregate: We use exfoliated vermiculite as a lightweight aggregate in concrete and plasters. It reduces weight while improving thermal insulation. This contributes to energy-efficient Building Material Innovation. ZONEDING’s block machines can utilize lightweight aggregates, including vermiculite. We use them to produce lightweight concrete blocks with superior insulation properties.

- Fireproofing: Its non-combustible and heat-resistant properties make it an excellent material for passive fire protection. Manufacturers incorporate it into spray-on coatings, fire-rated boards, and refractory bricks. These serve as Fire-Resistant Materials.

- Insulation: We widely use it for loose-fill insulation in attics and wall cavities. It provides effective thermal and acoustic insulation.

- Horticulture and Agriculture:

- Soil Amendment: Its high water retention and cation exchange capacity make it an ideal soil amendment. It helps aerate soil, improve drainage, and retain nutrients and moisture for plant growth.

- Soilless Growing Media: Vermiculite is a crucial component in seed starting mixes and potting soils. It provides sterile, lightweight growing environments.

- Industrial Applications:

- Packaging: Its lightweight and shock-absorbing qualities make it suitable for packaging fragile goods.

- High-Temperature Cements and Coatings: Manufacturers use it in specialized cements and coatings. These applications require resistance to extreme heat.

- Acoustic Control: Its porous structure helps absorb sound. This makes it useful in acoustic panels.

What are Problems When We Processing Vermiculite Ore?

Processing vermiculite ore presents several challenges. These relate primarily to separating the valuable mineral from impurities. They also relate to ensuring optimal exfoliation. Raw vermiculite typically occurs alongside other minerals and rocks. This demands effective beneficiation techniques. These techniques must avoid damaging the delicate layered structure of the vermiculite flakes. Ineffective processing reduces the quality and economic value of the final product. Addressing these challenges is crucial for efficient Vermiculite Production.

- Impurities: Raw vermiculite ore is rarely pure. It often contains quartz, feldspar, mica, amphiboles, and other gangue minerals. Efficiently separating these impurities is critical. We must do this without losing vermiculite or damaging its structure. Contaminants can reduce the expansion ratio. They also lower product quality.

- Friability of Vermiculite: Vermiculite flakes are relatively delicate. Excessive mechanical action during crushing or grinding can cause them to break. This reduces their size. It negatively impacts their exfoliation potential. Maintaining the integrity of the flakes throughout the initial stages of Vermiculite Processing is essential.

- Dust Control: The dry processing stages can generate significant amounts of dust. This happens particularly during crushing, screening, and drying. This poses health hazards to workers. It requires robust dust collection systems. Environmental regulations also necessitate strict dust emission controls.

- Moisture Content Variation: The moisture content of raw ore varies. This depends on mining conditions and weather. Inconsistent moisture levels affect screening efficiency. They significantly impact the drying process. Proper moisture management is necessary for uniform processing.

- Energy Consumption for Exfoliation: The exfoliation process requires high temperatures. These typically range between 800°C and 1100°C. Maintaining these temperatures consistently across large volumes of material is energy-intensive. This contributes substantially to Crusher Operating Costs. This happens if the plant uses inefficient energy sources or equipment.

What are the Essential Steps of Processing Vermiculite Ore?

Processing vermiculite ore involves several essential steps. These transform the raw mineral into useful exfoliated vermiculite. Each stage aims to purify, size, and expand the material. This ensures it meets the specific requirements for various industrial applications. The entire sequence is designed for efficiency and product quality. This multi-stage approach constitutes comprehensive Vermiculite Processing.

Mining and Extraction:

- Initial Extraction: Miners typically extract raw vermiculite ore using open-pit mining methods. This involves removing overburden to expose the ore body. Large excavators and trucks then move the raw ore to the primary processing facility.

- Pre-sorting: We sometimes perform preliminary sorting at the mine site. This removes obvious large rock fragments and waste material.

Crushing and Pre-screening:

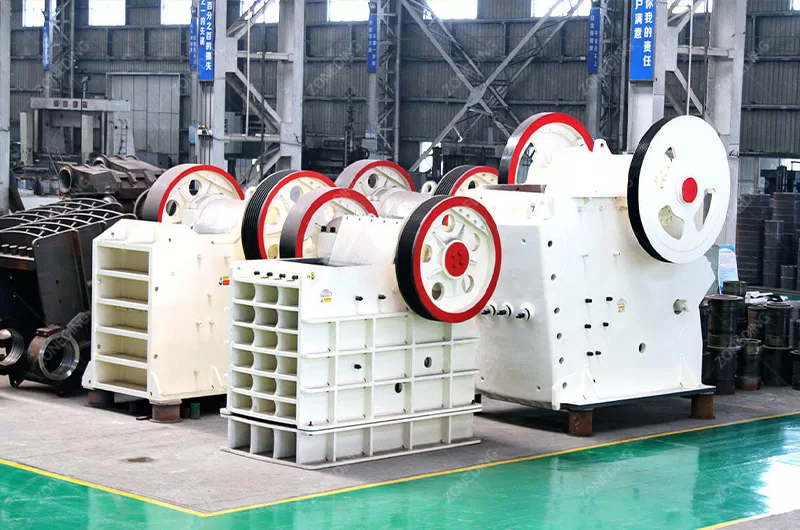

- Primary Crushing: We subject the extracted ore to primary crushing. We use jaw crushers or cone crushers. This reduces the large ore lumps to a manageable size. It prepares them for further processing. Operators take care to minimize damage to the fragile vermiculite flakes.

- Pre-screening: After primary crushing, the material passes through a grizzly or vibrating screen. This removes very fine particles (slimes) and oversized material.

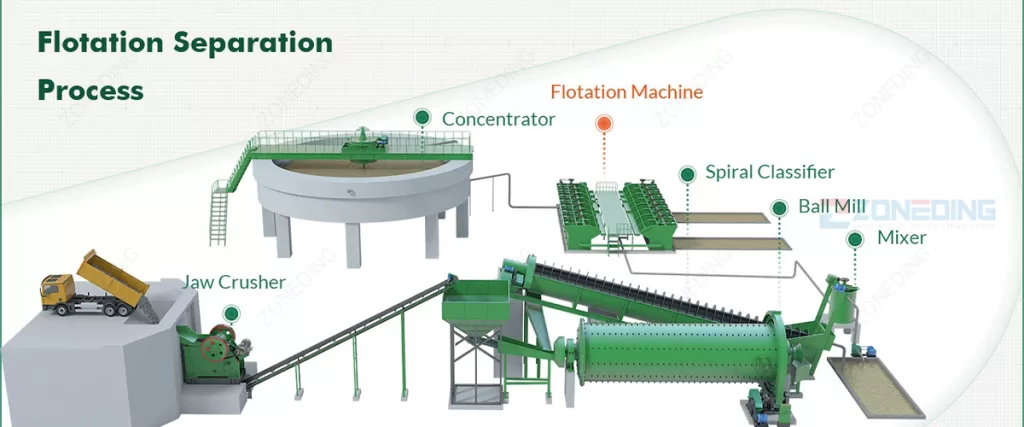

Beneficiation (Separation and Purification):

- Washing and Scrubbing: We thoroughly wash and scrub the crushed and screened ore. This removes clay, dirt, and other loose impurities attached to the vermiculite flakes.

- Wet or Dry Concentration: Depending on the nature of the ore, we employ concentration methods.

- Flotation: This common method involves adding chemical reagents to create froth. Vermiculite particles adhere to air bubbles and float. This separates them from heavier gangue minerals.

- Heavy Medium Separation: We place the ore in a liquid medium with controlled density. Vermiculite, being lighter, floats, while heavier impurities sink.

- Magnetic Separation: If the ore contains magnetic impurities (e.g., magnetite), magnetic separators remove them.

Drying:

Rotary Dryers: The concentrated vermiculite concentrate, still wet from beneficiation, enters rotary dryers. These rotate slowly. They gently tumble the vermiculite while warm air passes through. This reduces moisture content to very low levels. Efficient drying is crucial. It prevents decrepitation during exfoliation.

Sizing (Screening and Classification):

Multi-deck Screens: We subject the dried vermiculite to precise sizing. We use multiple vibrating screens. These screens separate the vermiculite flakes into various size grades (e.g., coarse, medium, fine, superfine). This sizing is critical for specific end-use applications. Different industries require different particle sizes.

Exfoliation (Expansion):

- Furnace Heating: We feed the sized vermiculite flakes into specialized high-temperature furnaces. These are often vertical shaft furnaces. Temperatures typically range from 800°C to 1100°C. The rapid heating causes the interlayer water to flash into steam. This forces the layers apart. This process yields lightweight, expanded (exfoliated) vermiculite. This is the core of How vermiculite is made.

- Cooling: Exfoliated vermiculite is very hot and lightweight. We carefully cool it before further handling.

Final Sizing and Packaging:

- Post-Exfoliation Screening: Sometimes, we perform further screening and air classification on the exfoliated material. This removes any unexfoliated particles or fines.

- Packaging: We then package the finished Exfoliated Vermiculite into bags or bulk containers. This prepares it for shipment and distribution.

What are Key Machines During this Process?

Effective vermiculite processing relies on a suite of specialized machines. Each performs a critical role in the transformation journey. These machines facilitate everything from initial size reduction and impurity removal to the final exfoliation and grading of the product. The selection of precise equipment directly impacts efficiency and the quality of the Exfoliated Vermiculite. Understanding these tools is fundamental to successful Vermiculite Production.

- Crushing Equipment:

- Jaw Crushers: We often employ jaw crushers for primary crushing of raw vermiculite ore. They reduce large rocks into smaller, more manageable sizes.

- Cone Crushers: We use cone crushers for secondary crushing. They further reduce material size. We choose them to minimize over-crushing and preserve the vermiculite flake integrity.

- Screening and Sizing Equipment:

- Vibrating Screens (Grizzly Screens, Multi-deck Vibrating Screens): These are essential for separating material based on particle size at various stages. They remove oversized material, fines, and classify vermiculite flakes into specific grades before and after exfoliation.

- Washing and Desliming Equipment:

- Scrubbers: They remove stubborn clay and dirt from the vermiculite flakes through attrition.

- Log Washers/Trommel Screens with Sprays: They thoroughly wash the ore and remove fine particulates.

- Concentration Equipment:

- Flotation Cells: Froth flotation separates vermiculite from gangue minerals based on surface properties.

- Spiral Concentrators/Jigs: These utilize gravity separation principles. They concentrate vermiculite from heavier impurities.

- Magnetic Separators: They remove magnetic impurities that might be present in the ore.

- Drying Equipment:

- Rotary Dryers: These specialized drums gently tumble the wet vermiculite concentrate. Hot air flows through. This uniformly reduces moisture content. This prevents decrepitation during the high-temperature exfoliation process.

What is the Price of a Vermiculite Ore Processing Plant?

The price of a vermiculite ore processing plant varies significantly. This reflects the complexity and scale of the operation. It is not a fixed cost. Instead, it represents an investment influenced by a range of technical and commercial decisions. Understanding these variables provides clarity on potential expenditures for Vermiculite Production.

Key factors influencing the price include:

- Plant Capacity: A larger plant, designed for higher throughput (tonnes per hour), will naturally cost more. This is due to larger equipment sizes and more extensive infrastructure. Smaller, modular plants are available at a lower entry point.

- Level of Automation: Manual or semi-automatic plants are less expensive than fully automated systems. Automation, using PLC controls and sensors, enhances efficiency. It reduces labor costs over time. But it requires a higher upfront investment. ZONEDING, for instance, integrates Siemens PLC control cabinets into its machinery. This enhances automation and efficiency. It can be a key consideration in a processing plant’s overall cost structure.

- Processing Complexity: The purity of the raw ore determines the number and type of beneficiation stages required. Highly impure ores demand more advanced and costly separation equipment. This drives up the overall plant cost.

- Location and Infrastructure: Site preparation, civil works, and environmental compliance measures vary by location. Remote sites often incur higher logistics and construction costs.

- Installation and Commissioning: Project planners must factor in the cost of installing and commissioning the plant. This includes testing and operator training.

How to Choose Suitable Supplier for Your Project?

Choosing a suitable supplier for a vermiculite processing project requires careful evaluation. Several key factors ensure project success.

- Experience and Expertise:

- Industry Track Record: Look for suppliers with a long history and proven track record in manufacturing mineral processing equipment. This applies particularly to vermiculite or similar minerals. ZONEDING, for example, founded in 1990, possesses over 30 years of experience in manufacturing.

- Technical Team: Assess the supplier’s engineering team. Professional engineers with expertise in mineral processing can provide valuable insights for plant design and optimization.

- Product Quality and Technology:

- Equipment Durability: Inquire about the materials used in manufacturing. High-wear steel and reputable component brands (e.g., Siemens PLC, Taiwan Kelly hydraulics, German Schneider inverters) indicate robust and reliable machinery. This commitment to quality is evident in ZONEDING’s Building Material Innovation.

- Customization Capabilities:

- Tailored Solutions: Can the supplier design and supply equipment or a full processing line customized to your specific ore characteristics, desired output, and site conditions? This flexibility is crucial for optimal performance. ZONEDING also highlights this strength with its ability.

- Full-Service Support:

- After-Sales Service: Check their warranty, spare parts availability, and technical support responsiveness. Long-term parts supply is vital. Wear Parts Crusher components need regular replacement.

- Global Reach and Success Stories:

- International Presence: A supplier with international export experience demonstrates a broader understanding of diverse market demands and logistical capabilities. ZONEDING, for instance, exports to over 120 countries. This indicates strong global experience.

- Client References: Ask for references or case studies. They should demonstrate successful projects, particularly those similar to yours.

- Financial Stability and Pricing:

- Competitive Pricing: While quality is paramount, evaluate if the pricing is competitive. Direct manufacturers, like ZONEDING, can offer price advantages by eliminating middlemen.

Conclusion

We transform Raw Vermiculite into Exfoliated Vermiculite through a precise Vermiculite Processing journey. This involves mining, crushing, concentration, drying, sizing, and critical exfoliation. We address impurities and friability throughout these steps. The resulting product offers valuable Vermiculite Properties: insulation, fire resistance, and a lightweight nature. Its versatile applications in construction and horticulture highlight its significant industrial importance for modern materials.

For project inquiries or to discuss how our advanced machinery can enhance your production, contact us. Explore ZONEDING’s customized block machine solutions. We design them for strong, high-quality construction using various materials.

FAQ

- Question 1: Is vermiculite dangerous for health?

- We generally do not consider naturally occurring vermiculite dangerous. However, some historical vermiculite deposits had asbestos contamination. Modern vermiculite suppliers test their product. This ensures it is asbestos-free, making it safe for most uses.

- Question 2: What is the main difference between vermiculite and perlite?

- Vermiculite exfoliates into layered, spongy flakes. These flakes retain water and nutrients well. Perlite is a volcanic glass. It expands into lightweight, porous particles. These primarily improve drainage and aeration. Both are lightweight aggregates.

- Question 3: Can vermiculite be reused?

- You can often reuse exfoliated vermiculite. This applies especially in gardening, for several seasons. You can use it to amend soil or as part of potting mixes. Its properties remain stable over time. But its structural integrity might degrade with repeated washing or handling.

- Question 4: What temperature is needed to exfoliate vermiculite?

- Vermiculite typically exfoliates at high temperatures. This is usually between 800°C and 1100°C. Rapid heating causes the trapped water molecules within its structure to flash into steam. This forces the layers apart. It creates the expanded product.

- Question 5: Is vermiculite a good insulator for homes?

- Yes, Exfoliated Vermiculite is an excellent thermal insulator for homes. Its lightweight, porous structure creates numerous air pockets. These effectively resist heat transfer. We often use it as loose-fill insulation in attics and wall cavities.