全站搜索

Search the entire website

Search the entire website

Coal is a vital source of energy for the world. But the raw coal that comes out of a mine is not ready for use. It is a mix of coal, rock, clay, and other impurities. This is where coal processing comes in. A modern coal preparation plant (CHPP) is like a refinery for coal. It is a sophisticated facility for cleaning and sorting the coal. The goal is to create a consistent, high-quality product that burns efficiently.

In this guide, we’ll take you deep “inside the process” to show you the 4 key machines that are the pillars of a profitable sand washing operation.

This guide will walk you through the entire journey. We will show you the coal preparation process step by step. You will understand how we turn a rough, raw material from the ground into the fuel that powers our industries and lights our homes. We will also explain the critical role of each piece of equipment in this transformation.

Coal is a combustible black or brownish-black sedimentary rock. It is a fossil fuel. It formed from the remains of plants that lived millions of years ago in swampy environments. Over time, layers of dead plant matter were buried under dirt and rock. Immense heat and pressure transformed this material into coal.

The main element in coal is carbon. It also contains hydrogen, sulfur, oxygen, and nitrogen. The energy in coal can release chemical energy from the ancient plants that absorbed sunlight. When we burn coal, this energy will go out as heat.

Coals are not all the same. They are classified by “rank,” which depends on how much heat and pressure the material endured. Higher rank means more carbon, more energy, and fewer impurities.

| Type of Coal | Carbon Content | Energy Content | Key Characteristics |

|---|---|---|---|

| Peat | < 60% | Low | Not actually coal. It is the first step in formation. |

| Lignite | 60-70% | Low | “Brown coal.” Crumbly, high moisture, smoky when burned. |

| Sub-bituminous | 70-80% | Medium | A dull black color. Primarily used for electricity. |

| Bituminous | 80-90% | High | Most abundant type. Used for electricity and steel. |

| Anthracite | > 90% | Very High | “Hard coal.” Lustrous, burns very cleanly and hot. |

At ZONEDING, our equipment can handle all ranks of coal. We customize our coal processing solutions based on whether we are dealing with high-moisture lignite or hard anthracite.

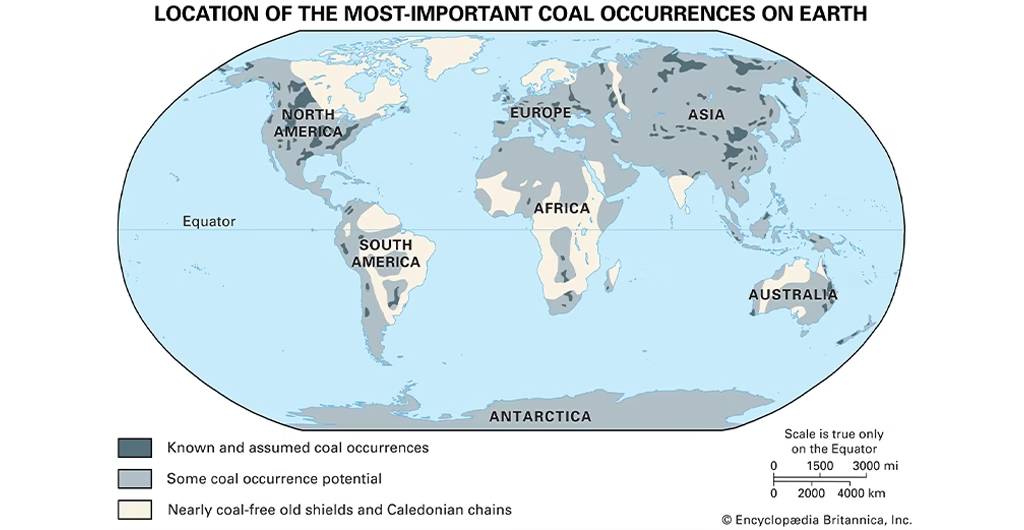

Coal can be on every continent. It is located in underground layers or “seams.” These seams can be just a few centimeters or over 30 meters thick. There are two main ways to mine it:

The largest coal reserves are in the United States, Russia, Australia, China, and India. The location and mining method can affect the raw coal’s quality and the amount of coal processing it requires.

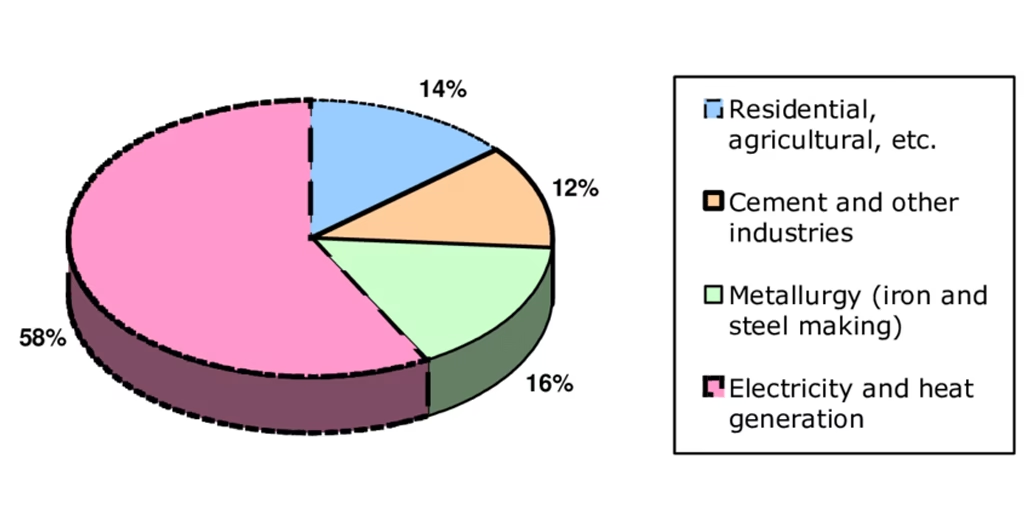

Coal has been a cornerstone of industrial society for centuries. Its primary applications fall into a few key categories:

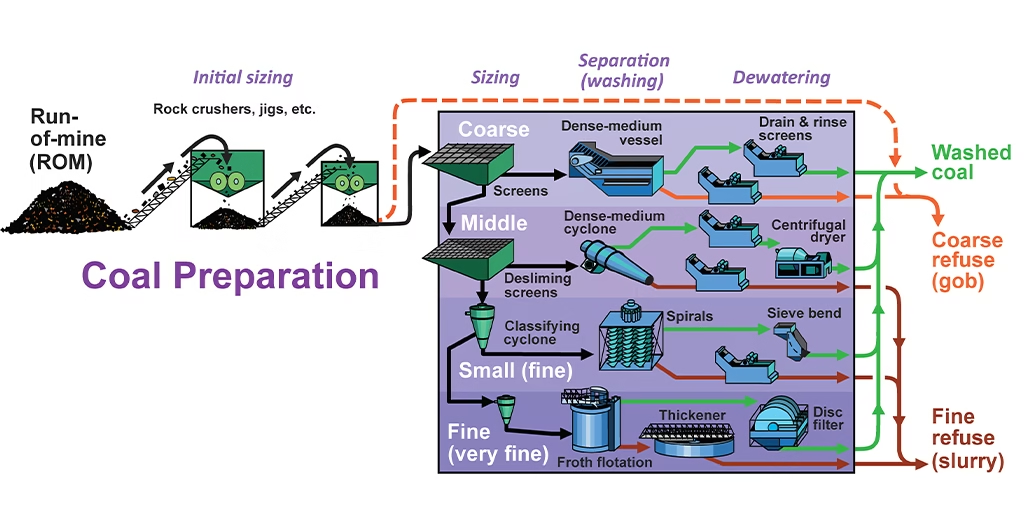

Turning raw coal into electricity is a multi-stage journey. The coal preparation plant (CHPP) is where the most critical value-adding steps happen.

Here is the coal preparation process step by step:

After mining, the raw coal is transported to the CHPP. This first stage is coal handling. It involves a series of conveyors, feeders, and stockpiles to move and store the raw coal efficiently and safely. Our ZONEDING heavy-duty belt conveyors and vibrating feeders aim to withstand the abrasive nature of raw coal.

The raw coal arrives in large, irregular lumps. It must be crushed to a more manageable and uniform size for efficient cleaning. This includes two stages:

This is the heart of the CHPP. Coal cleaning, also known as coal washing, is how you improve coal quality. The goal is to separate the valuable, low-density coal from the high-density waste rock, clay, and pyrite (which contains sulfur). This is done using processes that exploit the density difference:

After washing, the clean coal is saturated with water. It is necessary to remove the water from the coal to increase its heating value and reduce transportation weight. This involves dewatering screens, which use vibration to shake the water off, and sometimes thermal dryers, which use heat to evaporate any remaining moisture.

The clean, dry coal is then transported to the power plant. Before coal combustion, it is ground into a fine powder by a coal pulverizer. This powder, as fine as talcum powder, is then blown into the furnace. The large surface area allows it to burn almost as easily and efficiently as a gas, releasing the maximum amount of heat to create steam for electricity generation.

Selecting the correct equipment for your coal preparation plant (CHPP) is crucial for efficiency, cost-effectiveness, and reliability. As a manufacturer of this equipment, we guide our customers through a detailed selection process.

You should ask: What is the maximum feed size and hardness of my raw coal? What is the required output size for the washing circuit?

You should ask: What is the density difference between my coal and waste? What is the percentage of clay and fines?

You should ask: What is my plant’s tonnage per hour? What is my final product moisture requirement?

This is a common and important question. The price of a coal preparation plant (CHPP) varies significantly based on several key factors. There is no standard price list because every plant is a custom solution.

Here are the main elements that influence the final cost:

As a manufacturer, ZONEDING works with clients to design a plant that meets their budget and performance goals, providing a transparent and detailed quotation.

Choosing a supplier is as important as choosing the equipment. ZONEDING is a leading manufacturer of mineral processing equipment with a proven track record in the coal industry. We established our company in 2004 and have delivered solutions to over 120 countries.

Our key advantage is that we are a true one-stop solution provider for the entire coal preparation plant (CHPP). We design and manufacture the crushers, screens, feeders, conveyors, and washing components in our own advanced 80,000-square-meter factories. This means we have complete control over quality and ensure all components work together seamlessly.

Our team of 15 professional engineers works directly with you to analyze your coal and design a custom plant. Because we sell directly from our factory, we eliminate middlemen, offering competitive pricing without compromising on quality or service. We provide full-service support, from initial design and manufacturing to installation guidance, operator training, and reliable after-sales service.

This guide tells advantages, disadvantages, applications, capabilities, and maintenance considerations of Closed-Circuit and Open-Circuit crushing plant.

View detailsThink you know cone crusher liners? Our blog reveals surprising facts about selection, wear, and replacement that could save you time and money.

View detailsThis guide tells 5 critical factors for selecting right dewatering screen. Learn to evaluate feed tonnage, particle size, desired moisture content, and more.

View detailsLearn how to separate minerals by magnetic methods, covering magnetic separation properties, machine types, applicable materials, and the step-by-step process.

View details