Dolomite is a widespread mineral. It plays a vital role across numerous industries. Understanding its unique characteristics and effective processing methods proves essential for maximizing its industrial value. This guide covers dolomite properties, its formation, and diverse dolomite applications. It also highlights key processing techniques, including dolomite crushing and dolomite grinding. This information aids in optimizing its use from mining to specialized industrial uses.

Table of Contents

What Exactly is Dolomite?

Dolomite is a common rock-forming mineral. It has a specific chemical composition. Its chemical formula is CaMg(CO₃)₂. This means it is a calcium magnesium carbonate. Dolomite belongs to the carbonate mineral group. It shares similarities with calcite but includes magnesium.

Dolomite has a moderate hardness. Its Mohs hardness is between 3.5 and 4. This makes it softer than quartz but harder than calcite. Its specific gravity ranges from 2.8 to 2.9. This means it is relatively dense. Dolomite forms in vast sedimentary beds. These deposits result from altered limestone or direct precipitation from water.

Why is Dolomite Key in Industry Today?

Dolomite holds a key position in numerous industrial processes today. Its unique chemical makeup and physical properties contribute to its wide applicability. This makes it an indispensable raw material in various sectors. Industry values dolomite for its stability and versatility.

- Construction: Dolomite serves as a source for dolomite for aggregates in concrete and asphalt. Its hardness and durability make it suitable for structural applications. Crushed dolomite finds use as road base material and architectural stone. Dolomite is also a vital component in cement production. It contributes magnesium to the clinker.

- Metallurgy: Dolomite acts as a flux in steelmaking. It helps remove impurities. It also protects the refractory linings of furnaces. This enhances efficiency and extends equipment lifespan. When calcined, dolomite produces dead-burned dolomite. This material is crucial in refractory bricks. These bricks withstand high temperatures in ovens and kilns.

- Agriculture: Dolomite benefits agriculture as a soil conditioner. It neutralizes acidic soils. It replenishes both calcium and magnesium nutrients. These are essential for healthy plant growth. This dual-nutrient effect makes it more valuable than pure limestone for certain crops.

- Chemical Industry: Dolomite is for producing magnesium compounds. Magnesia from dolomite is a valuable product. It finds application in various chemical synthetics and processes.

- Glass Manufacturing: Dolomite’s role extends to glass manufacturing. It provides magnesium oxide, which improves glass durability and luster.

What are Physical Properties and Chemical Characteristics of Dolomite?

Understanding the physical properties and chemical characteristics of dolomite is essential. This guides its proper application and processing in industry. Its distinct features make it useful in various specialized roles.

Physical Properties of Dolomite:

- Color: Dolomite typically appears in shades of white, gray, pink, or green. Impurities can sometimes tint it brown or black.

- Luster: It possesses a vitreous (glassy) to pearly luster. This gives it a somewhat shiny appearance.

- Streak: The streak, or color of its powder, is always white. This remains consistent regardless of the specimen’s color.

- Hardness: Dolomite has a Mohs hardness of 3.5 to 4. This makes it harder than calcite but softer than quartz. This property affects the ease of dolomite crushing and dolomite grinding.

- Specific Gravity: Its specific gravity ranges from 2.8 to 2.9. This indicates a moderate density.

- Crystal System: It crystallizes in the trigonal system. It typically forms rhombohedral crystals.

- Cleavage: Dolomite exhibits perfect rhombohedral cleavage in three directions. This means it breaks into distinctive rhomb-shaped fragments.

- Fracture: It has a conchoidal to uneven fracture.

- Transparency: It can be translucent to opaque.

- Tenacity: Dolomite is brittle. It breaks readily under stress.

Chemical Characteristics of Dolomite:

- Chemical Composition: It is a calcium magnesium carbonate with the formula CaMg(CO₃)₂. This defines its unique chemical behavior.

- Acid Reaction: Dolomite reacts with dilute hydrochloric acid. This reaction is usually slower and less vigorous than that of calcite. It often requires powdered dolomite or heating to produce a noticeable effervescence. This slower reaction is a key distinguishing feature.

- Thermal Stability: Dolomite is thermally stable. However, upon heating to high temperatures (calcination), it decomposes. This produces calcium oxide (CaO) and magnesium oxide (MgO), releasing carbon dioxide. This process is crucial for making calcined dolomite.

- pH Buffering: In agricultural applications, dolomite acts as a pH buffer. It helps regulate soil acidity. This makes it an effective soil amendment.

- Refractory Properties: The magnesium oxide formed from calcination has high refractory properties. This makes calcined dolomite valuable in high-temperature industrial linings.

These dolomite material characteristics dictate its suitability for various industrial applications. ZONEDING recognizes the importance of precise material properties. Its equipment handles diverse materials effectively, ensuring optimal processing outcomes.

The formation of dolomite is a complex geological process. It typically involves either primary precipitation or, more commonly, secondary alteration. Understanding its origin helps geologists locate and extract dolomite ore.

- Secondary Alteration (Dolomitization): Most geologists believe dolomite primarily forms through the alteration of existing limestone. Limestone mainly consists of calcite (CaCO₃). When magnesium-rich water circulates through limestone, magnesium ions replace some calcium ions in the calcite structure. This process changes calcite into dolomite. This secondary dolomitization usually occurs at relatively low temperatures and pressures in shallow marine environments or in groundwater systems.

- Primary Precipitation: Another less common pathway is primary precipitation. This means dolomite directly precipitates from seawater or other magnesium-rich brines. These conditions were more prevalent in ancient geologic periods. For example, vast dolomite deposits formed during the Proterozoic Eon. Modern environments rarely see primary dolomite formation. It usually requires specific microbial activity or highly concentrated brines.

Where Are Dolomite’s Main Reserves Found Globally?

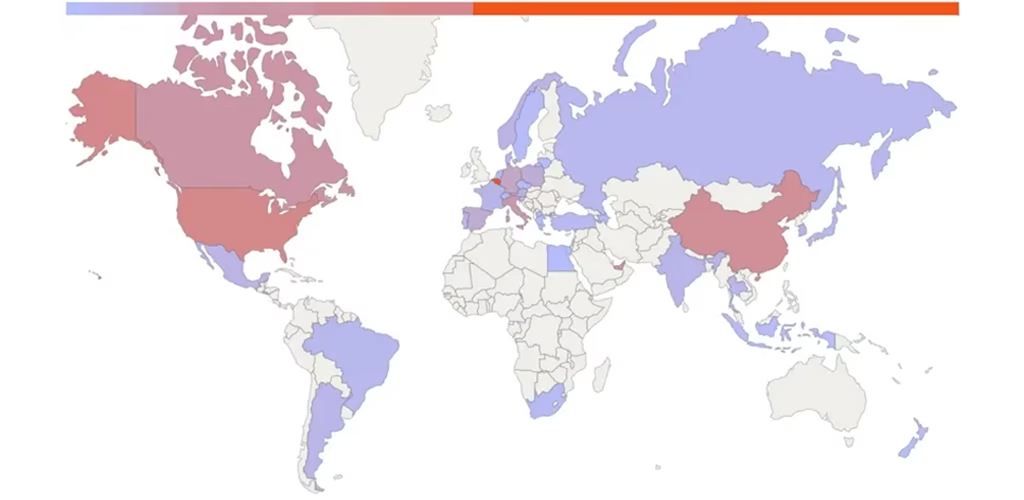

Dolomite reserves are abundant and widely distributed across the globe. This widespread availability supports significant dolomite production for industrial demands worldwide.

- North America: Holds substantial dolomite resources. The United States has significant deposits in the Appalachian region, the Great Lakes area, and parts of the Midwest. California, Illinois, Indiana, Michigan, New York, Ohio, Pennsylvania, and Wisconsin are key producing states. Canada also possesses extensive dolomite reserves, especially in Ontario and Quebec.

- Europe: Has rich dolomite reserves. Prominent deposits are in countries like Germany, Austria, Italy, Norway, and the United Kingdom. The Dolomites mountain range in Italy is famous for its geological formations primarily composed of dolomite rock.

- Asia: Another region with significant dolomite occurrences. China, India, Japan, and parts of Southeast Asia, including Vietnam and the Philippines, have notable deposits. China, in particular, is a major global producer and consumer of dolomite.

- Other Continents: Australia has significant reserves in states like Western Australia and South Australia. South America and Africa also feature various deposits.

What are Applications of Dolomite?

The versatile nature of dolomite allows it to serve many important industrial applications. Its unique dolomite properties of calcium and magnesium make it a valuable resource. It finds use across various sectors.

Construction Industry:

- Aggregates: Crushed dolomite is as an aggregate. It forms a key component in concrete mixes and asphalt pavements. Its hardness and durability provide strength to these construction materials.

- Road Base: It serves as a base material for roads and highways. This ensures stability and drainage.

- Building Stone: Dimension stone applications use natural dolomite. It serves for facades, walls, and decorative elements.

- Cement Production: Dolomite is a fluxing agent in the production of Portland cement. It provides magnesium oxide.

- Block Production: Dolomite for block production often involves using crushed dolomite as a aggregate component. This provides strength and density to concrete blocks.

- Flux in Steelmaking: Dolomite acts as a flux in blast furnaces and steel converters. It removes impurities like silica and alumina from molten metal.

- Refractory Material: When calcined to dead-burned dolomite, it produces a highly refractory material. This material lines furnaces, kilns, and crucibles. These linings withstand extreme temperatures in iron, steel, and non-ferrous metal industries.

Agricultural Industry:

- Soil Conditioner: Agricultural grade dolomite neutralizes acidic soils. It provides essential nutrients: calcium and magnesium. This improves soil structure and promotes healthy plant growth.

- Livestock Feed Supplement: Dolomite is sometimes as a calcium and magnesium supplement in animal feed.

Chemical Industry:

- Magnesium Compounds: Dolomite is a primary source for manufacturing various magnesium compounds. This includes magnesium oxide (MgO), magnesium sulfate, and magnesium hydroxide. These compounds have diverse chemical uses.

- Magnesia Production: The process of extracting magnesia from dolomite is crucial. This provides raw material for many industrial applications.

Glass and Ceramics:

Dolomite adds magnesium oxide to glass batches. This improves glass durability, brilliance, and reduces devitrification. In ceramics, it acts as a flux and a source of magnesia.

Environmental Applications:

- Water Treatment: It can be used for pH adjustment and removing impurities in water treatment processes.

- Flue Gas Desulfurization: Dolomite helps remove sulfur dioxide from power plant emissions. This reduces air pollution.

These multifaceted dolomite applications highlight its broad economic significance. The continued demand underscores the need for efficient dolomite processing methods.

What Essential Steps Are Involved in Dolomite Processing?

Effective dolomite processing transforms raw dolomite ore into valuable industrial products. This process involves several key stages, each designed to refine the material for specific dolomite applications.

- 1. Crushing: Raw dolomite first undergoes dolomite crushing. Primary crushers, like jaw or gyratory crushers, reduce large rocks from the mine. Secondary and tertiary crushers (e.g., cone, impact, or VSI crushers) further refine the material’s size. This multi-stage crushing prepares the dolomite for subsequent steps.

- 2. Screening and Classification: After crushing, vibrating screens sort the dolomite into various size fractions. This ensures consistent product sizing required for specific uses, such as dolomite for aggregates. For fine powders, air classifiers separate particles by fineness.

- 3. Washing (Optional): If impurities like clay are present, dolomite may be washed to enhance its purity. This is crucial for high-grade applications and ensures cleaner aggregates.

- 4. Drying (Optional): Wet dolomite, whether from the mine or after washing, is often dried using rotary dryers. This prevents clogging in subsequent dry processes and ensures material flow.

- 5. Grinding (for fine products): For applications requiring fine or ultrafine material, the crushed dolomite is fed into grinding mills. Ball mills, Raymond mills, or Vertical Roller Mills (VRMs) achieve specific fineness for industrial powders. This dolomite grinding is essential for chemical or filler applications.

- 6. Calcination (for specialized products): To produce calcined dolomite, material is heated to high temperatures in a rotary kiln. This thermal process releases CO₂, leaving behind reactive calcium and magnesium oxides.

- 7. Conveying and Storage: Throughout these stages, conveyor belts efficiently move materials. Silos and stockpiles store raw, intermediate, and finished dolomite products.

ZONEDING provides robust and efficient equipment for each of these essential dolomite processing stages, ensuring high-quality output for demanding dolomite production needs.

What Equipment Do We Need to Process Dolomite?

Effective dolomite processing requires specialized equipment. This machinery transforms raw dolomite ore into value-added products. The choice of equipment depends on the desired end product and its specific applications, such as dolomite for aggregates or calcined dolomite. ZONEDING provides a range of robust solutions for mineral processing equipment suitable for dolomite.

- Crushing Equipment:

- Primary Crushers: Jaw crushers or gyratory crushers handle the initial size reduction. They process large rocks from the mine.

- Secondary Crushers: Cone crushers or impact crushers further reduce material size. They prepare it for fine crushing or grinding. This dolomite crushing stage is essential for various product specifications.

- Tertiary Crushers: VSI (Vertical Shaft Impact) crushers can achieve even finer crushing. They also improve the cubical shape of aggregates.

- Grinding Equipment:

- Ball Mills: These mills achieve fine grinding after crushing. They reduce dolomite to powder form. This is suitable for applications like fillers or chemical processes.

- Raymond Mills or Vertical Roller Mills (VRMs): These mills are commonly used for ultrafine dolomite grinding. They produce powders with specific fineness for industrial applications.

- Screening and Classification Equipment:

- Vibrating Screens: These separate crushed dolomite into different size fractions. They ensure product consistency for specific uses, such as aggregates.

- Washing Equipment:

- Sometimes, dolomite requires washing to remove clay or impurities. Sand washing machines can perform this task effectively.

- Drying Equipment:

- While dolomite is often processed dry, if moisture content is high or if it has been washed, rotary dryers may be needed to prepare it for subsequent steps like calcination.

- Calcination Equipment:

- Rotary Kilns: For producing calcined dolomite (dolime or dead-burned dolomite), rotary kilns are essential. They heat the dolomite to high temperatures. This causes thermal decomposition, releasing CO₂ and leaving behind MgO and CaO.

ZONEDING offers advanced solutions for each of these stages, ensuring high efficiency and reliability in dolomite processing.

What are Specific Challenges During Dolomite Processing, and Solutions?

Dolomite processing involves several unique challenges. Addressing these effectively ensures efficient operation and high-quality output for various dolomite applications. Careful planning and appropriate technology offer solutions.

- Hardness and Abrasiveness: Dolomite has a moderate to high hardness (3.5-4 Mohs) and can be abrasive. This leads to significant wear on crushing and grinding equipment.

- Solution: Crushers and mills designed for abrasive materials are used. These are equipped with wear-resistant components. Parts typically use manganese steel, high-chrome alloys, or ceramic liners. Regular maintenance and timely replacement of wear parts extend equipment life. ZONEDING utilizes high-wear steel in its machinery to combat this issue.

- Dust Generation: Crushing and grinding dry dolomite generates abundant fine dust. This poses environmental and health concerns.

- Solution: Comprehensive dust control systems are implemented. These include baghouse filters, cyclones, and wet scrubbers. Transfer points are enclosed. Water sprays are used at strategic locations. This minimizes airborne dust.

- Controlling Particle Size and Purity: Different dolomite applications demand specific particle sizes and purity levels. Achieving these while maintaining high throughput can be challenging.

- Solution: Advanced screening and classification equipment are employed. Multi-stage crushing and grinding circuits are used. These circuits tailor to meet precise product specifications. Material beneficiation techniques like washing or sorting are incorporated if high purity is required.

- Variability in Raw Material: The quality and composition of dolomite ore can vary within a deposit. This impacts processing efficiency and final product quality.

- Solution: Rigorous quality control measures are implemented from the mining stage. Raw material is blended to create a consistent feed to the processing plant. Processing parameters are adjusted to account for variations.

By proactively addressing these challenges, dolomite processing plants achieve higher operational efficiency. They also ensure superior product quality and maintain environmental compliance.

What Key Factors You Should Consider When Selecting Dolomite Processing Equipment?

Selecting the right equipment for dolomite processing is crucial for operational success. This decision impacts efficiency, costs, and the quality of the final product. Many key factors need careful consideration. ZONEDING offers comprehensive consultation to help clients make informed choices for their mineral processing needs.

- Raw Material Characteristics:

- Hardness and Abrasiveness: This influences the choice of crusher type (jaw, cone, impact) and grinding mill (ball, vertical roller). It also dictates the selection of wear-resistant components.

- Moisture Content: High moisture may necessitate pre-drying equipment or different crushing techniques to prevent clogging.

- Feed Size: The maximum size of ROM (Run-of-Mine) dolomite determines the primary crusher’s opening size.

- Chemical Composition: Purity levels and mineralogical associations can impact beneficiation requirements.

- Desired Product Specifications:

- Fineness and Particle Size Distribution: This is perhaps the most critical factor. Different dolomite applications (e.g., dolomite for aggregates, fine powder for chemicals) require various size ranges. This dictates the entire crushing, grinding, and screening circuit design.

- Purity Requirements: Some applications demand very high purity. This might require additional washing, sorting, or beneficiation steps.

- Capacity:

- The required processing capacity (tons per hour or tons per day) determines the size and number of machines. It influences equipment sizing across all stages, from dolomite crushing to dolomite grinding.

- Manufacturer Reputation and After-Sales Support:

- A reputable manufacturer with a proven track record should be chosen. It is important to ensure they offer comprehensive full-service support, including installation, commissioning, training, and readily available spare parts. ZONEDING excels in providing this level of support.

Careful evaluation of these factors ensures the selection of a dolomite processing system that meets technical, economic, and environmental objectives. This maximizes the value of dolomite production.

Maintenance and Safety Considerations for Dolomite Processing Plant

Operating a dolomite processing plant efficiently requires strict adherence to maintenance and safety protocols. Implementing robust programs minimizes downtime, extends equipment life, and protects personnel. ZONEDING emphasizes safety and durability in its equipment design.

Maintenance Considerations:

- Preventive Maintenance: A regular preventive maintenance schedule is established. This includes inspections, lubrication, and adjustments. It covers all equipment from dolomite crushing units to grinding mills and calcination kilns.

- Wear Part Management: Dolomite is abrasive. Crushers, screens, and mill liners experience significant wear. Wear parts are monitored closely. An inventory of critical spares is maintained. Timely replacement schedules are implemented to avoid unexpected breakdowns. ZONEDING uses high-quality, wear-resistant steel for its components. This reduces the frequency of replacements.

- Lubrication: Manufacturer guidelines for lubrication of bearings, gears, and other moving parts should be followed. Proper lubrication prevents premature wear and overheating.

- Vibration Analysis: Equipment should be regularly monitored for abnormal vibrations. This can indicate misalignment, worn bearings, or structural issues. Early detection prevents catastrophic failures.

- Dust Control System Checks: Dust collectors, filters, and ventilation systems must function optimally. Filter bags should be regularly cleaned or replaced. Ductwork should be checked for leaks. This maintains air quality and prevents equipment damage from dust.

- Electrical Systems: Electrical panels, wiring, and motor controls are inspected. Proper grounding and insulation are ensured. Preventative checks reduce the risk of electrical failures and fires.

- Conveyor Belt Care: Conveyor belts are inspected for wear, tears, and proper tension. Rollers and idlers must operate smoothly. This prevents material spillage and belt damage.

Safety Considerations:

- Lockout/Tagout Procedures: Strict lockout/tagout procedures are implemented during maintenance or repair. This prevents accidental startup of machinery. It protects workers from moving parts.

- Personal Protective Equipment (PPE): The use of appropriate PPE for all personnel is mandated. This includes hard hats, safety glasses, hearing protection, dust masks or respirators, and steel-toed boots.

- Dust Exposure Control: Beyond dust collection, local exhaust ventilation (LEV) is implemented at crushers and transfer points. Respiratory protection is provided in dusty areas. This minimizes exposure to airborne silica particles.

- Noise Control: Processing plants generate high noise levels. Hearing protection is provided. Noise dampening measures for equipment are implemented. Designated quiet zones are established.

- Emergency Procedures: Emergency response plans are developed and practiced. These plans cover fire, accidents, and equipment failures. Staff are trained in first aid and emergency protocols.

- Machine Guarding: All moving parts of machinery must have proper guards. These prevent contact with rotating shafts, belts, and gears.

- Training: Regular safety training is conducted for all employees. It covers equipment operation, hazard recognition, and emergency procedures. A strong safety culture is promoted within the plant.

- Slope Stability: In dolomite mining operations, pit wall stability is regularly assessed and maintained. This prevents landslides or rockfalls.

Proactive maintenance and a strong safety culture contribute significantly to the smooth, profitable, and safe operation of any dolomite production facility.

How Can ZONEDING Enhance Your Dolomite Processing Efficiency and Quality?

ZONEDING, as a leading manufacturer of block machines and mineral processing equipment, offers significant advantages for enhancing dolomite processing efficiency and quality. The company’s expertise and robust solutions help clients achieve superior results in their dolomite production.

- Customization Capabilities: The company designs equipment and complete plant layouts specifically for client needs. This involves considering unique dolomite properties, desired output fineness, and production capacity. Tailored solutions ensure optimal performance and integration. This reduces bottlenecks and maximizes throughput. ZONEDING’s engineering team possesses deep knowledge of material characteristics. They develop precise configurations for efficient particle size optimization in dolomite processing.

- Durability and Quality Components: Recognizing the abrasive nature of dolomite, ZONEDING prioritizes durability. The company manufactures its equipment using high-wear steel as a primary material. Key components, like hydraulic systems (e.g., Taiwan Kelly) and control units (e.g., Siemens PLC, Schneider inverters), come from internationally renowned brands. This commitment to quality materials and components ensures longer operational lifespans and reduced maintenance frequency. This significantly lowers overall dolomite processing plant cost and enhances reliability.

- Full-Service Support: ZONEDING provides comprehensive support. This covers initial project consultation and scheme design. It includes equipment manufacturing, installation, commissioning, and personnel training. The company’s experienced engineers offer on-site guidance. This ensures a smooth setup and optimal calibration of the processing line. After-sales service ensures continuous operational excellence. It guarantees clients receive prompt support and spare parts. This end-to-end service ensures high efficiency and sustained quality in dolomite production.

By partnering with ZONEDING, clients benefit from decades of experience, advanced technology, customizable solutions, and comprehensive support. This enhances both the efficiency and the quality of their dolomite processing operations.

What Future Trends Are Shaping Dolomite’s Role in Sustainable Industrial Development?

The role of dolomite in industry is evolving. Several future trends point towards more sustainable dolomite production and utilization. These trends emphasize efficiency, environmental responsibility, and new applications for its unique dolomite properties.

- Emphasis on Energy Efficiency: The drive for reduced energy consumption is paramount. Future dolomite processing plants will prioritize energy-efficient grinding technologies. This includes advanced vertical roller mills and high-pressure grinding rolls (HPGRs). These technologies optimize particle size reduction with less power input. This lowers operational costs and reduces carbon footprint.

- Advanced Beneficiation Techniques: Increasing demand for higher purity dolomite will push for advanced beneficiation. Technologies like optical sorting, froth flotation, and magnetic separation will become more common. These methods upgrade dolomite ore quality. They remove impurities before crushing and grinding. This maximizes the value extracted from deposits.

- Circular Economy and Waste Utilization: There is growing interest in using dolomite in circular economy initiatives. This includes exploring its potential for treating industrial wastewater or as a component in novel building materials that incorporate recycled waste. Its use in waste-to-aggregate applications will expand.

- New and Niche Applications: Research continues into new applications for dolomite. This includes its use in advanced ceramics, specialized absorbents, and even as a reactant in emerging chemical processes. The unique calcium-magnesium composition offers potential for innovative uses.

- Digitalization and Automation: Dolomite processing plants will leverage digitalization. This includes IoT sensors, data analytics, and artificial intelligence. These tools optimize plant operations. They predict maintenance needs. They also ensure precise quality control. Automated systems improve efficiency and reduce human error.

These trends highlight a future where dolomite’s role remains pivotal. The focus shifts towards maximizing its industrial benefits while minimizing its environmental footprint. Companies like ZONEDING continually adapt their equipment and solutions to align with these evolving sustainable development goals.

Finally, A Summary of Dolomite’s Impact

Dolomite is a critical mineral. It holds immense value across many industries. This guide has explored its natural properties, formation, and vital applications in construction, metallurgy, agriculture, and more. Effective processing methods, from crushing and grinding to advanced calcination, are key to harnessing its full potential. Addressing challenges like abrasiveness and dust generation through robust solutions and high-quality equipment ensures efficient and safe operations. ZONEDING plays a crucial role. It provides the advanced machinery and comprehensive support necessary for optimal dolomite production. As industries move towards sustainability, dolomite’s role will continue to evolve, with a focus on energy efficiency, advanced processing, and environmental responsibility. Its importance will only grow in sustainable industrial development.

FAQ

- Question 1: What is the primary difference between dolomite and limestone?

The primary difference lies in their chemical composition. Limestone is predominantly calcium carbonate (CaCO₃). Dolomite is a calcium magnesium carbonate (CaMg(CO₃)₂). This magnesium content gives dolomite distinct properties and applications.

- Question 2: How is calcined dolomite different from raw dolomite?

Calcined dolomite results from heating raw dolomite to high temperatures. This process drives out carbon dioxide. It leaves behind a mixture of calcium oxide (CaO) and magnesium oxide (MgO). This material has significant refractory and chemical uses.

- Question 3: What safety precautions are important when processing dolomite?

Safety precautions include robust dust control systems due to fine particle generation. Workers must use appropriate PPE, especially respirators. Strict lockout/tagout procedures are crucial during maintenance. Noise control and emergency preparedness also remain vital.

- Question 4: Why is precision in dolomite grinding important?

Precision in dolomite grinding ensures the desired particle size distribution. This is critical for specific dolomite applications. For example, fine powders for chemical reactions or accurate aggregate sizes for optimal concrete mixes. This directly impacts product quality and performance.