This guide provides a comprehensive look at jaw crushers, covering everything from their core mechanics and common uses to the latest advancements and essential selection criteria, equipping you with the knowledge to leverage this technology effectively in the years to come.

Table of Contents

What is a Jaw Crusher?

The Jaw Crusher is the backbone of the crushing industry. At my company, ZONEDING, we consider it the most important machine in any quarry or recycling operation. It is a primary crusher, which means it does the heavy lifting. It takes the largest rocks from a blast or demolition site and breaks them into a manageable size. Think of it as a giant mechanical nutcracker for stone.

What are Jaw Crushers Used For?

A jaw crusher is used for primary crushing. Its main job is to reduce large, tough materials into smaller pieces. This is the first step in most crushing processes. After the jaw crusher, the smaller rocks are sent to secondary crushers, like cone or impact crushers, for further processing. You need a jaw crusher to handle the biggest and hardest materials right from the start.

It creates a consistent feed for the rest of the plant. This makes the entire operation more efficient. Without a reliable primary crusher, your whole production line stops.

What are Advantages and Disadvantages of Jaw Crushers?

Every machine has its strengths and weaknesses. Understanding them helps you make the right choice.

Advantages:

- Robust and Simple: The design is straightforward. It has few moving parts, which makes jaw crusher maintenance relatively easy.

- Handles Hard Materials: It is excellent for crushing very hard and abrasive rocks like granite and basalt.

- High Crushing Ratio: It can handle very large feed sizes compared to its overall size.

- Low Operating Cost: Because it is simple, the cost per ton is usually lower than more complex crushers.

Disadvantages:

- Produces Flaky Product: The crushing action can create elongated or flaky particles. This is not ideal for high-spec concrete.

- Not for Fine Crushing: It is a coarse crusher. It cannot produce sand or very small aggregate sizes.

- Can Clog: Wet and sticky materials can pack in the crushing chamber, causing blockages.

What Are Applications of Jaw Crusher?

You will find a jaw crusher in almost any industry that needs to break down large, hard materials. It is a true workhorse.

- Mining: This is the most common application. It is the first step in processing ore from the mine.

- Quarrying: It is used to produce aggregate for construction, roads, and concrete.

- Construction Waste Recycling: A rock crusher is perfect for breaking up demolished concrete and asphalt.

- Metallurgy: It is used to crush slag and other materials in metal processing.

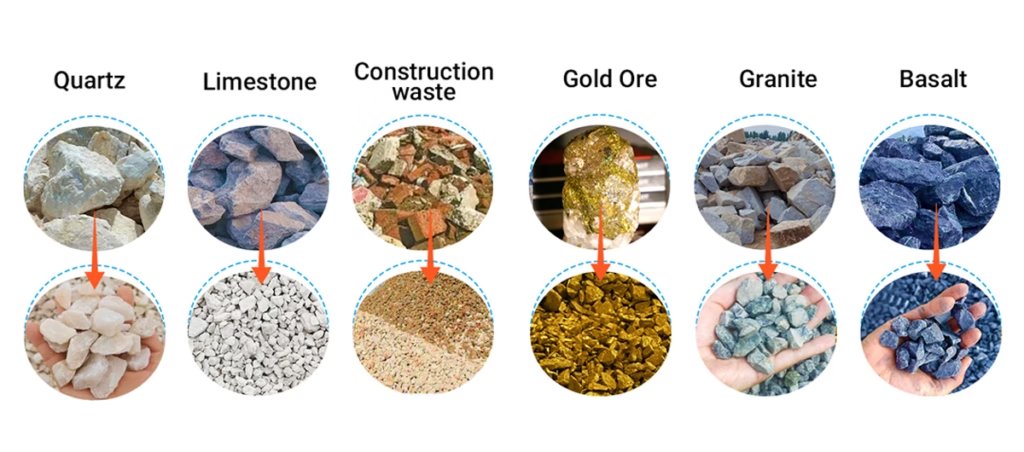

What Materials can use Jaw crushers?

Jaw crushers are designed for the toughest jobs. They can handle a wide variety of hard and abrasive materials.

- Hard Rock: Granite, basalt, gabbro, quartzite.

- River Stone: Hard, rounded, and very abrasive.

- Ores: Iron ore, copper ore, gold ore.

- Recycled Materials: Demolished concrete, asphalt chunks.

Classifications of Jaw Crusher

There are two main types of jaw crushers, based on how the swing jaw moves.

- Blake (Double Toggle): In this design, the pivot point is at the top of the swing jaw. It produces a “swinging” motion. This type can handle very large and hard feed materials. It is the most common design for large primary crushers.

- Dodge (Single Toggle): The pivot point is at the bottom. This creates a more complex, elliptical motion. This motion pushes material through the chamber more aggressively. It produces a more uniform product but is more prone to choking and has a lower capacity. It is less common today.

At ZONEDING, most of the crushers we build are Blake-type, as they are more reliable for heavy-duty primary crushing.

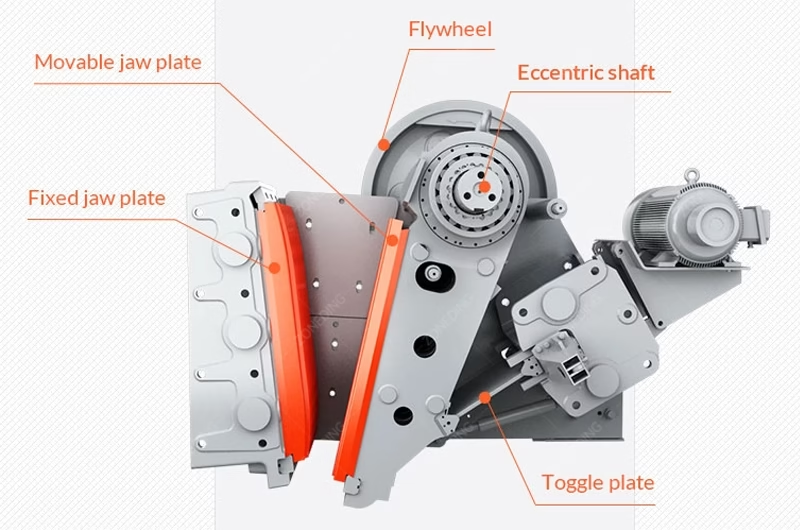

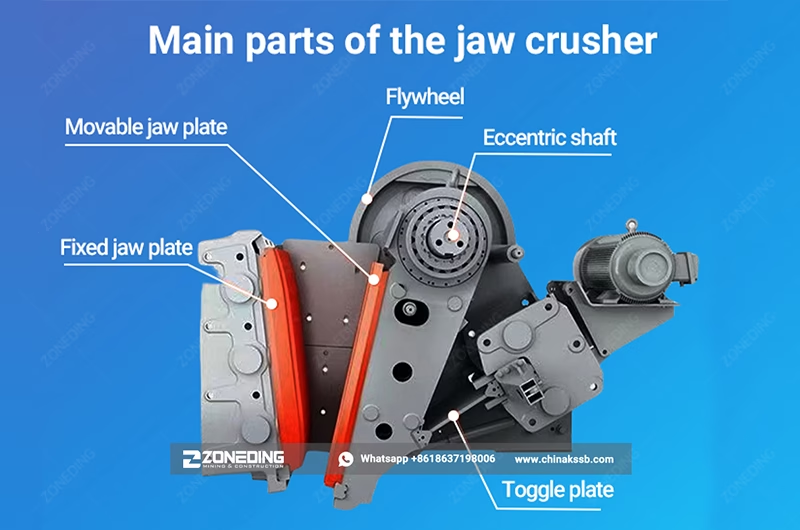

Jaw Crusher Components & Spare Parts

Understanding the main parts helps with operation and maintenance.

- Fixed Jaw Plate: The stationary plate that the material is crushed against.

- Swing Jaw Plate: The moving plate that applies the crushing force.

- Pitman: The large component that holds the swing jaw and moves up and down.

- Eccentric Shaft: The shaft that drives the Pitman’s motion.

- Flywheel: A heavy wheel that stores energy to provide smooth, continuous crushing power.

- Toggle Plate: A small but critical part. It holds the bottom of the Pitman in place and acts as a safety fuse, breaking if uncrushable material enters the chamber.

How Do Jaw Crushers Work?

The jaw crusher working principle is simple but very effective.

- Material is fed into the top of a V-shaped crushing chamber.

- The flywheel, powered by a motor, spins the eccentric shaft.

- The eccentric shaft causes the Pitman to move up and down.

- This motion forces the swing jaw to move back and forth, like a chewing motion.

- Rock is squeezed and compressed between the fixed jaw and the swing jaw until it breaks.

- The broken pieces move down the chamber and are crushed again until they are small enough to fall out of the bottom opening.

What is a Complete Crushing Process?

A jaw crusher is just the beginning. A complete Crushing process solution involves multiple stages.

- Primary Crushing: A jaw crusher takes the largest rock and breaks it down to a manageable size (e.g., 6-10 inches).

- Secondary Crushing: A cone crusher or impact crusher takes the output from the jaw crusher and breaks it down further (e.g., 1-3 inches).

- Screening: A vibrating screen separates the material into different sizes (e.g., sand, 1/2 inch stone, 1 inch stone).

- Tertiary Crushing (Optional): If even smaller sizes or better shape is needed, a VSI or cone crusher is used for a final reduction.

ZONEDING can design and supply these complete crushing plants for any application.

How to Choose a Right Jaw Crusher?

Choosing the right jaw crusher for sale is critical. Here is what you need to consider:

- Material Hardness: How hard is your rock? Get a lab test if you are not sure. This affects the wear life of the jaw plates.

- Maximum Feed Size: What is the largest piece of rock you will put into the crusher? This determines the required opening size.

- Required Capacity: How many tons per hour (TPH) do you need to produce? This determines the overall size of the machine.

- Desired Output Size: What size do you need the material to be after crushing? This determines the “Closed Side Setting” (CSS).

What is the Cost of a Jaw Crusher Price?

The jaw crusher price varies widely.

- A small, used jaw crusher might cost around $20,000.

- A medium-sized, new stationary crusher from a reputable manufacturer like ZONEDING could be in the range of $50,000 to $150,000.

- A large, high-capacity mobile jaw crusher can cost over $500,000.

The price depends on size, brand, quality of components (like bearings and steel), and any extra features. As a direct manufacturer, we offer competitive pricing by eliminating the middleman.

What Size Products can be Produced by A Jaw Crusher?

The output size is controlled by the gap at the bottom of the crushing chamber. This is called the Closed Side Setting (CSS). It is the narrowest distance between the two jaw plates. The CSS determines the maximum size of the product that comes out. For example, with a CSS of 4 inches, most of the material will be smaller than 4 inches.

Operation tips of Jaw Crushers

- Consistent Feeding: Do not dump huge loads all at once. Feed the crusher steadily for best performance.

- Avoid Choke Feeding: Do not overfill the chamber. This reduces efficiency and increases wear.

- Remove Tramp Metal: Use a magnet or a spotter to remove any steel before it enters the crusher. Tramp metal can cause serious damage.

- Listen to the Machine: Experienced operators can hear changes in the crusher’s sound that indicate a problem.

How to Maintain Your Jaw Crushers?

Proper jaw crusher maintenance is the key to a long and productive life.

- Daily: Check the lubrication of bearings. Check the tension of the V-belts. Check for any loose bolts.

- Weekly: Inspect the jaw plates for wear. Most jaw plates are reversible, so you can flip them to get double the life.

- Monthly: Check the condition of the toggle plate and its seating.

- Greasing: Follow the manufacturer’s schedule. Over-greasing can be as bad as under-greasing.

What are Mobile Jaw Crushers?

A mobile jaw crusher is a complete primary crushing unit mounted on tracks or wheels. It includes the crusher, a feeder, a discharge conveyor, and a power unit. The biggest advantage is flexibility. You can move it directly to the material, saving a huge amount on hauling costs. They are very popular for contract crushing and recycling jobs.

What are Differences Between Jaw Crushers and Other Crushers?

- Jaw Crusher vs. Cone Crusher: A jaw crusher is a primary crusher for large feed. A cone crusher is a secondary or tertiary crusher for smaller feed and produces a better-shaped product.

- Jaw Crusher vs. Impact Crusher: A jaw crusher uses compression for hard rock. An impact crusher uses high-speed impact for softer rock and recycling, producing a superior cubical product.

2025 Jaw Crusher Developments and Trends

The jaw crusher is an old design, but it continues to improve.

- Automation: Modern crushers have sensors that can automatically adjust the setting and detect blockages, improving efficiency.

- Improved Wear Parts: New manganese steel alloys for jaw plates are lasting longer than ever, reducing downtime. We offer these advanced jaw crusher wear parts.

- Hybrid Power: Mobile crushers are now available with diesel-electric drives, which are more fuel-efficient and better for the environment.

Common Questions about Jaw Crushers

How long do jaw crusher plates last?

This depends entirely on the material being crushed. In soft limestone, they might last for thousands of hours. In hard, abrasive granite or river gravel, they might need to be replaced after only a few hundred hours.

Can a jaw crusher handle wet and sticky material?

It can be a problem. Wet, sticky material like clay can pack in the V-shaped chamber and cause blockages. A special “slab-breaker” jaw plate design can help, but it is not ideal. A different type of feeder might be needed.

Conclusion

The jaw crusher is the essential starting point for almost any crushing operation. It is a simple, powerful, and reliable machine designed to handle the toughest jobs. Choosing the right one depends on your material, feed size, and capacity needs. Proper operation and consistent jaw crusher maintenance will ensure it remains a profitable workhorse for your business for many years.

If you are looking for a new stone crusher or need advice on your current operation, our team at ZONEDING is here to help. Contact us today for a free consultation and let our experience work for you.