全站搜索

Search the entire website

Search the entire website

The demand for construction aggregates is skyrocketing globally. From infrastructure projects like highways and bridges to residential housing, quality material is the foundation of development. However, transforming raw geological deposits into specification-grade construction material is not a simple task. Processing crushed stone and gravel requires precise engineering, robust machinery, and a strategic plant layout.

Inefficiency in the production line leads to wasted energy, excessive wear on parts, and poor product shape. This guide provides a comprehensive overview of the modern aggregate production process. It explores the differences in handling blasted rock versus river deposits and outlines the essential machinery required for a profitable operation.

As a leading manufacturer of mineral processing equipment, ZONEDING provides the technology and expertise to turn raw stone into valuable commercial assets.

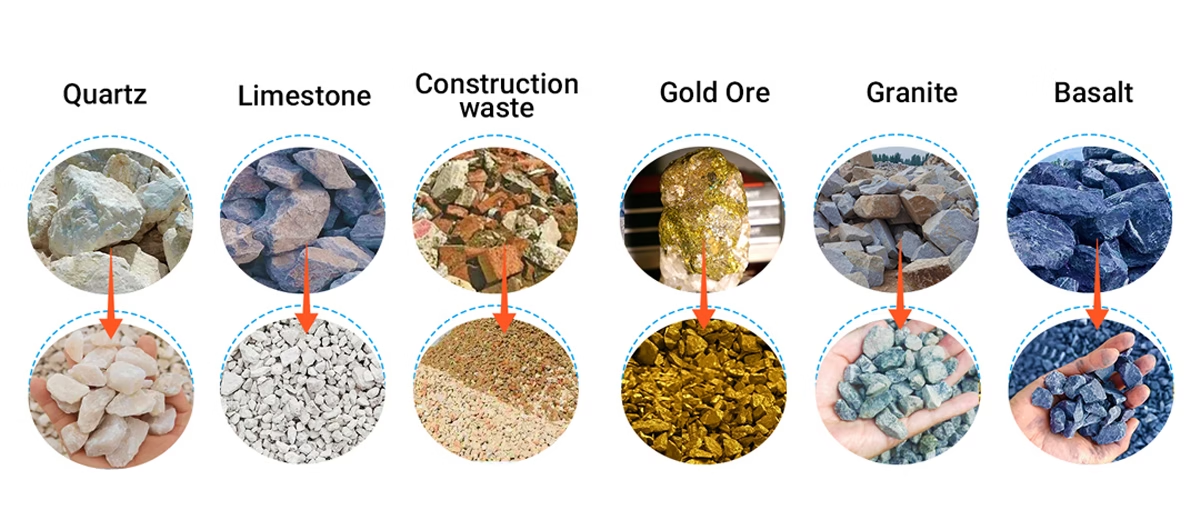

Before investing in machinery, it is vital to clearly define the raw material. While often grouped together as “aggregates,” crushed stone and gravel have distinct geological origins and physical characteristics that dictate how they must be processed.

Understanding this distinction is the first step in processing crushed stone and gravel. A plant designed for soft limestone will suffer catastrophic wear if used to process abrasive silica-rich river gravel.

Why is the global market for these materials so massive? It is because almost every construction sector relies on them. The specific use depends heavily on the size (gradation) and the shape of the aggregate produced by the ZONEDING crushers.

This is the primary consumer of aggregates.

Large, heavy, and angular crushed stone (typically granite or trap rock) is used to support railroad ties. The sharp edges lock together to hold the tracks in place under the immense weight of passing trains, while allowing water to drain away freely.

Pea gravel (small, rounded river stones) is popular for driveways, walkways, and garden beds because it is aesthetically pleasing and comfortable to walk on.

| Aggregate Size | Common Name | Typical Application |

|---|---|---|

| 0-5 mm | Stone Dust / Sand | Paver bedding, asphalt filler, block making. |

| 5-10 mm | 1/4 Inch Chip | Surface dressing, driveways, drainage. |

| 10-20 mm | 3/4 Inch Stone | The industry standard for concrete mix and asphalt. |

| 20-40 mm | Ballast / Railroad | Railway tracks, heavy drainage, road base. |

| 40mm+ | Riprap / Base | Foundations, stabilization, erosion control. |

A modern aggregate plant functions as a synchronized system rather than individual machines. The objective is to reduce particle size gradually while maintaining consistent throughput. A typical line for processing crushed stone and gravel follows four main stages.

The process begins with the raw feed. Extensive blasted rocks or large river boulders are fed into a primary crusher via a vibrating feeder. The goal here is simple bulk reduction. The output size usually ranges between 150mm and 300mm. The primary crusher must be robust enough to handle shock loads and massive input sizes.

Once the material is reduced to a manageable size, it moves via conveyor belts to secondary crushers. This stage defines the product.

You cannot sell a mixed pile of rocks. The market demands specific gradations (e.g., 0-5mm sand, 5-10mm gravel, 10-20mm stone). Vibrating screens separate the crushed material into these categories. Oversized material that does not pass through the screen screens is returned to the crusher for another cycle (closed circuit).

For high-grade applications, cleanliness is non-negotiable. Dust, clay, and organic matter compromise the strength of concrete. Washing systems, such as screw washers or bucket wheels, remove these impurities to ensure the final product meets strict construction standards (ASTM or local equivalents).

The hardness and abrasiveness of the rock dictate the equipment selection. ZONEDING engineers emphasize matching the crusher type to the geological properties to minimize operational costs (OpEx).

Limestone is relatively soft and low in silica.

These materials are tough and often contain high silica content, which acts like sandpaper on metal.

ZONEDING manufactures a complete range of equipment tailored for these specific applications. Here is an analysis of the core machinery found in top-tier plants.

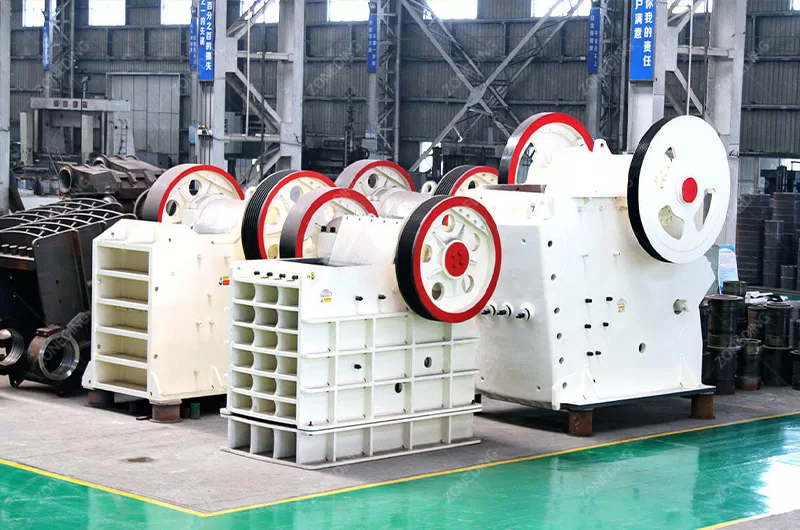

The Jaw Crusher is the universal starting point. The ZONEDING PE and PEW series utilize a deep crushing cavity and a heavy-duty eccentric shaft. This machine mimics a chewing motion to break large boulders. It is favored for its simplicity, reliability, and ease of maintenance. It handles the roughest work, protecting the finer downstream equipment.

For crushing manufacturing of hard materials, the Cone Crusher is indispensable. ZONEDING offers hydraulic cone crushers (HPT/HST series) that provide high crushing efficiency. These machines feature hydraulic operational controls, allowing operators to adjust the discharge opening (CSS) with a button press. They produce a uniform product size and are essential for large-scale granite or basalt quarries.

When processing crushed stone and gravel for road surfaces or concrete, particle shape is vital. Theoretically, a Cone Crusher can leave some elongated particles. The Impact Crusher (PF/PFW series) solves this. By impacting the stone against curtain liners, it “trims” the edges, creating a perfect cube. It is the preferred secondary crusher for softer rocks or a tertiary shaper for harder rocks.

With natural sand becoming scarce, manufactured sand is in high demand. Vertical Shaft Impact (VSI) crushers smash rocks against rocks (stone-on-stone crushing). This produces a fine, graded sand product that serves as an excellent eco-friendly alternative to river sand.

For detailed specifications on these machines, refer to the Crushing Equipment page.

A critical decision in plant design is mobility. Should the plant be fixed in one location, or should it be movable? This depends on the project duration and site conditions.

| Feature | Stationary Crushing Plant | Mobile Crushing Station | Considerations for Choice |

|---|---|---|---|

| Installation | Requires concrete foundations (1-2 months setup). | Hydraulic legs or tracks (1-3 days setup). | How fast do you need to start production? |

| Initial Cost | Lower equipment cost, higher civil work cost. | Higher equipment cost, zero civil work cost. | What is your budget structure? |

| Logistics | Trucks must haul rock to the crusher. | Crusher drives directly to the rock face. | How far is the extraction point? |

| Capacity | Scalable to massive outputs (1000+ TPH). | Generally limited to 50-400 TPH per unit. | What is your target daily metric tonnage? |

| Resale | Difficult to relocate or sell. | High demand for used mobile units. | Is this a short-term project? |

For a dedicated commercial quarry with reserves for 20 years, a stationary plant offers the best ROI. However, for highway construction, tunnel excavation, or construction waste recycling, a mobile crushing station is superior. It follows the project progress and eliminates material transport costs.

When calculating the budget for processing crushed stone and gravel, smart investors look beyond the purchase price. The Total Cost of Ownership (TCO) determines profitability.

The aggregate industry is evolving. Processing crushed stone and gravel involves more technology and environmental responsibility than ever before.

Environmental regulations are tightening globally. Modern plants must minimize their footprint.

Sensors and IoT (Internet of Things) are entering the quarry. ZONEDING equipment is increasingly compatible with monitoring systems that track bearing temperatures, vibration levels, and oil pressure. This allows for predictive maintenance—fixing a machine before it breaks—preventing costly unplanned downtime.

Recycling is a booming sector. Crushing demolition concrete, brick, and asphalt to create recycled aggregate is highly profitable. Mobile crushing stations are the primary tool for this application, turning city waste into road base on-site.

ZONEDING stands as a premier partner for aggregate producers worldwide. Established in 2004, the company combines manufacturing prowess with engineering expertise.

Processing crushed stone and gravel successfully requires a balance of geological knowledge and mechanical engineering. Whether the goal is to produce road base from limestone or high-strength concrete aggregate from river cobbles, the equipment selection determines the profitability.

Investors must consider not just the initial price, but the long-term efficiency, energy consumption, and maintenance costs. By partnering with a manufacturer like ZONEDING, producers gain access to customizable, factory-direct solutions that are built to withstand the rigors of the mining environment. From the first blast to the final screen, the right technology turns rock into revenue.

To discuss specific project requirements or obtain a customized flow chart design, visit Complete Production Line or contact the ZONEDING engineering team for a consultation.

Last Updated: July 2025

Facing a choice between a ball mill and a rod mill? Feeling confused? It's very important to select the right grinding equipment. Ball mills and rod mills are both grinding equipment, but they differ in grinding media, mechanism, product size, ...

View detailsLearn the process of buying Crushers from China, from finding reliable suppliers to managing customs. Your all-in-one guide for sucessful imports.

View detailsThis blog tells what a concrete crusher is, its work principle, and the purpose, process, and benefits in turning construction waste into valuable resources.

View detailsDiscover 9 most common problems on ball mill, from excessive wear to power consumption. Learn how to identify issues and implement solutions to extend lifespan.

View details