全站搜索

Search the entire website

Search the entire website

Silver is rarely found in its pure native form in nature. It is typically locked away in complex ores, often associated with lead, zinc, copper, or gold. For mining companies and mineral processing plants, the challenge isn’t just finding the ore—it is separating the valuable metal from the waste rock efficiently and profitably. Selecting the correct silver extraction methods is the difference between a highly profitable operation and a failed project.

The choice of processing technology depends entirely on the mineralogy of your ore body. Is the silver “free” and coarse? Is it associated with sulfides? Or is it oxidized? This guide details the three industry-standard techniques: Gravity Separation, Froth Flotation, and Cyanidation Leaching.

ZONEDING explores the mechanics, advantages, and ideal applications of each to help you determine the best path for your processing plant.

Before diving into the specific separation methods, you must understand the preparation stage. You cannot extract silver from a large boulder. The rock must be liberated.

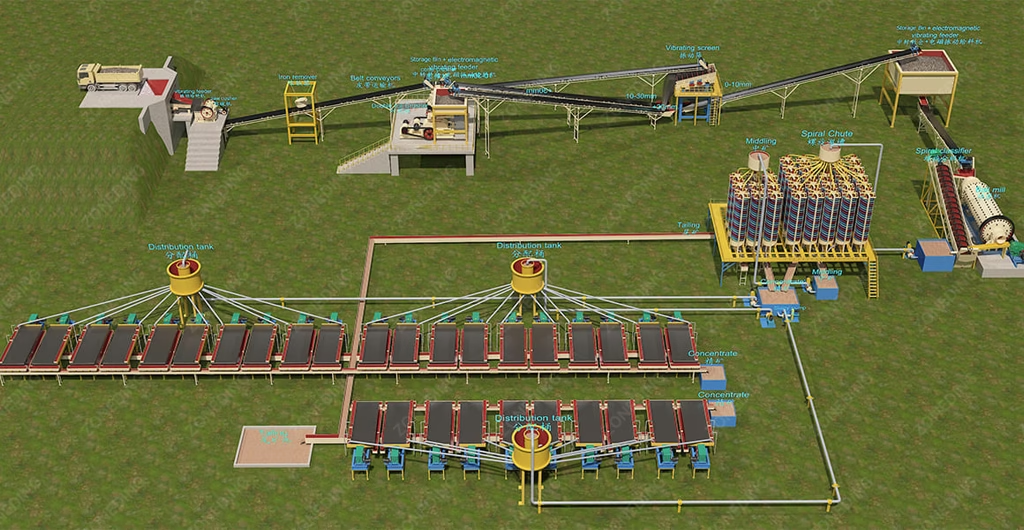

The silver extraction process begins with comminution—crushing and grinding. Large rocks extracted from the mine are fed into a Jaw Crusher for primary reduction. They are then passed to a Cone Crusher for fine crushing. Finally, the material enters a Ball Mill, where it is ground into a fine powder (often 200 mesh).

This stage is critical. If the grind is too coarse, the silver remains locked inside the waste rock, and you lose it to the tailings. If the grind is too fine, you waste energy and create “slimes” that are hard to process. ZONEDING engineers design this comminution circuit to ensure the particle size is perfect for the specific extraction method chosen.

Gravity separation is the oldest and most cost-effective method in mineral processing. It relies on a simple physical principle: silver is much heavier than the surrounding rock (gangue).

When you suspend ground ore in water and agitate it, the heavier silver particles sink to the bottom faster than the lighter silica or limestone. By controlling the flow of water and the vibration of the equipment, you can separate the heavy concentrate from the light tailings.

This method does not use expensive chemicals, making it environmentally friendly and cheap to operate. However, it only works if the silver particles are coarse and dissociated (free) from the rock.

Froth Flotation is the dominant technique for processing complex sulfide ores. Since most of the world’s silver comes as a byproduct of Lead-Zinc or Copper mining, flotation is the most widely used industrial method.

Flotation separates minerals based on their surface chemistry (hydrophobicity), not their weight. The process involves treating the ground ore slurry with specific chemical reagents.

A typical ZONEDING flotation line involves three stages:

When silver is associated with gold, or when the ore is oxidized (weathered), flotation often fails because the minerals do not float well. In these cases, Cyanidation Leaching is the standard. This is a chemical/hydrometallurgical process.

Ground ore is mixed with a dilute cyanide solution. The cyanide dissolves the silver (and gold) into a liquid form (Pregnant Solution).

ZONEDING provides complete CIL/CIP plant designs, including the thickeners, leaching tanks, and electrolysis systems needed for the final stage.

Choosing the correct silver extraction methods is a balance of cost, recovery rate, and mineralogy.

| Feature | Gravity Separation | Froth Flotation | Cyanidation Leaching |

|---|---|---|---|

| Target Ore | Native Silver, Coarse grains | Silver Sulfides (Argentite) | Oxidized Silver, Ag-Au Ores |

| Operating Cost | Low | Medium | High |

| Complexity | Simple | Moderate | Complex |

| Chemical Use | None | Collectors & Frothers | Cyanide |

| Typical Recovery | 40-60% (as pre-treatment) | 80-90% | 90-95% |

| Environmental | Clean | Needs Water Treatment | Strict Controls Needed |

ZONEDING does not just sell machines; the company designs flowcharts. Because silver ore is rarely uniform, a “Combined Process” is often the best solution.

Many modern plants use Flotation first to create a high-grade concentrate. Then, that concentrate is re-ground and treated with Cyanidation. This reduces the volume of material that needs leaching, saving massive amounts of chemical costs and tank space.

The industry is moving toward efficiency and environmental stewardship.

Due to the toxicity of cyanide, the industry is researching non-toxic alternatives. Reagents based on Thiosulfate are gaining traction. These are less harmful to the environment and can be effective for certain silver ores.

New technology allows for the flotation of coarser particles. This means you do not have to grind the rock as fine. Coarser grinding reduces electricity consumption in the Ball Mill significantly, lowering the biggest OpEx cost in the plant.

ZONEDING is integrating smart sensors into flotation cells. These sensors monitor the froth color and bubble size in real-time, automatically adjusting the air flow and reagent dosage to maintain peak recovery without human intervention.

Maximizing the return on a silver mine requires more than just digging; it requires a scientific approach to silver extraction methods. Whether your deposit demands the simplicity of Gravity Separation, the chemical precision of Froth Flotation, or the intensive recovery of Cyanidation, the equipment must be tailored to the rock.

There is no “one-size-fits-all” solution. The most profitable plants often combine these methods—using gravity to catch the coarse silver early, and flotation or leaching to capture the rest.

ZONEDING provides the mineral processing expertise and the heavy machinery to build these circuits. From the initial crusher to the final filtration, ZONEDING ensures your production line is efficient, durable, and optimized for high recovery rates.

Effective metallurgy starts with a conversation. Reach out to the ZONEDING engineering team today to analyze your ore and design a flowchart that turns geology into profit.

Last Updated: January 2026

Learn what makes copper most useful metals. We learn its properties—conductivity, malleability, corrosion resistance—and the essential applications they enable.

View detailsThe ultimate guide to stone washing machines. Covers wheel vs. spiral washers, process flow, pricing factors, and maintenance tips. Master sand washing today.

View detailsLearn how to separate minerals by magnetic methods, covering magnetic separation properties, machine types, applicable materials, and the step-by-step process.

View detailsExplore the machinery behind crushed stone and gravel production. From crushing blasted rock to washing river deposits, we provide complete plant solutions.

View details