全站搜索

Search the entire website

Search the entire website

In the world of mineral processing, selecting the right crushing equipment is the most critical decision a plant manager makes. Two machines often cause confusion due to their visual similarities and shared mechanics: the Gyratory Crusher and the Cone Crusher. Both utilize a rotating mantle to crush rock against a stationary liner. Both are vertical compression crushers. However, treating them as interchangeable is a costly mistake.

Understanding the Gyratory crusher vs. cone crusher distinction is essential for optimizing plant layout, estimating capital expenditure (CapEx), and ensuring operational efficiency. This guide by ZONEDING breaks down the definitions and seven fundamental differences to help you make an informed investment.

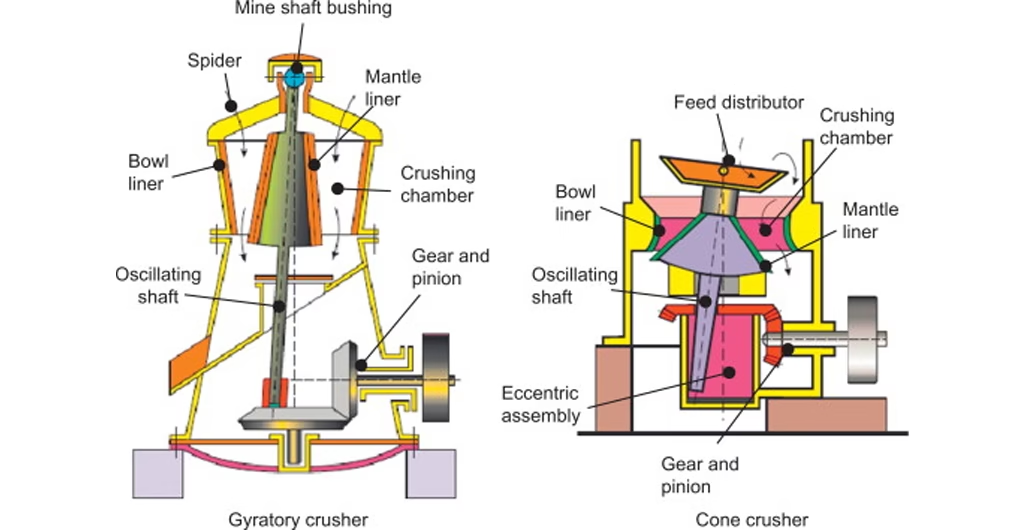

A Gyratory Crusher is a heavy-duty primary crushing machine engineered to process raw, blasted rock directly from the mine face. It is essentially a crushing giant. Physically, it consists of a massive steel conical head (mantle) sitting on an eccentric shaft. This head gyrates (wobbles) inside a funnel-shaped outer shell lined with concave plates.

When rock enters the top, it is trapped between the moving mantle and the stationary concave. As the mantle gyrates, it squeezes the rock until it shatters. The unique feature of a gyratory crusher is its continuous crushing action. Unlike a Jaw Crusher, which crushes only on the “close” stroke, the Gyratory crushes efficiently around the entire 360-degree chamber. It is defined by its steep crushing chamber and “spider” suspension system at the top, allowing it to handle high capacities and blocky materials typical of large-scale open-pit mines.

A Cone Crusher is a compression machine designed for the secondary, tertiary, and quaternary stages of crushing. While it shares the same eccentric “wobble” mechanic as the gyratory, its design is optimized for specific sizing rather than bulk reduction.

ZONEDING Cone Crushers (such as the HPT and HST series) feature a flatter crushing chamber and operate at much higher speeds. The goal of a cone crusher is not just to break rock, but to shape it. By using a high crushing frequency and a large stroke, it encourages “inter-particle crushing” (rock crushing against rock). This produces a finer, more uniform output with a high percentage of cubical products, which is essential for high-quality concrete and asphalt aggregates. It is the workhorse of the modern aggregate plant, sitting downstream from the primary station.

The most defining difference lies in where the machine sits in your flowchart.

The Gyratory Crusher is exclusively a Primary Crusher. It is the first machine the rock meets after being blasted from the mine face. It competes directly with the Jaw Crusher. Its job is bulk reduction. It takes run-of-mine (ROM) ore and reduces it to a size that a conveyor belt can handle (usually 150-300mm). You will almost never see a Gyratory Crusher used for fine crushing.

The Cone Crusher is a Secondary or Tertiary Crusher. It occupies the middle or end of the production line. It takes the output from a primary crusher (like a Jaw or Gyratory) and reduces it further. ZONEDING Cone Crushers are designed to produce final product sizes (like 20mm or 40mm) or to prepare material for a ball mill.

Because their roles are different, their physical capacity to accept rock varies immensely. This is often the deciding factor for mine operators.

Gyratory Crushers are designed with a massive, circular feed opening. They generally do not need a feeder to regulate the flow; trucks dump rock directly into the crusher (choke feeding).

Cone Crushers have a much smaller, stricter feed opening.

While both use a “cone” shape, the geometry of the crushing chamber dictates how the rock is broken. This affects efficiency and wear.

The Gyratory Crusher features a steep, vertical crushing chamber.

The Cone Crusher features a flatter, shallower crushing chamber.

Speed and “throw” (how far the mantle moves) determine the throughput and the fineness of the product.

The Gyratory Crusher operates at a relatively low speed (rpm).

The Cone Crusher operates at a much higher speed.

How is the massive central shaft supported? This is a major mechanical difference that affects maintenance and installation height.

In a Gyratory Crusher, the main shaft is suspended from the top of the machine by a specialized spider bearing assembly.

| Feature | Gyratory Crusher | Cone Crusher |

|---|---|---|

| Shaft Support | Suspended from the top (Spider) | Supported from the bottom |

| Height | Very Tall (requires deep foundation) | Low Profile |

| Adjustment | Raise/Lower Shaft | Rotate Bowl or Hydraulic Cylinder |

In a Cone Crusher, the movable cone is supported from the bottom.

When planning a plant, the volume of material you need to move (Tons Per Hour – TPH) often dictates the choice between a Gyratory and a Jaw, but it also highlights the scale difference with Cones.

Budget allocation is the final hurdle. The cost difference between these two machines is substantial.

You need a Gyratory Crusher if:

You need a Cone Crusher if:

The debate of Gyratory Crusher vs. Cone Crusher is not really a debate about which is “better,” but rather which is “correct” for the stage of production.

The Gyratory is the hungry giant, sitting at the entrance of the world’s largest mines, consuming massive boulders. The Cone Crusher is the precision athlete, sitting downstream, refining that rock into valuable, usable commodities. For 90% of aggregate producers and quarries, the ideal combination is a Jaw Crusher (Primary) followed by a ZONEDING Cone Crusher (Secondary).

Understanding these seven differences prevents costly engineering mistakes. If you are ready to design a crushing circuit that balances capacity with logical investment, contact the ZONEDING engineering team today for a custom flowchart and quote.

Last Updated: January 2026

This guide tells the step-by-step processes from ore mining to final purification for Nickel Extraction, to Learn how nickel is brought to market.

View detailsThis expert guides you key factors: rock hardness (Ai), feed size, capacity requirements, and operational costs to tell how to choose right primary crusher.

View detailsLooking for everything you need to know about screening machine? We break down inclined vs horizontal screens, trommels, and how to choose right screen media.

View detailsOur "Antimony 101" guide covers everything from its basic definition and properties to the detailed industrial processing techniques. Read More Now!

View details