全站搜索

Search the entire website

Search the entire website

Starting a stone crushing business or upgrading an existing aggregate line is a massive capital undertaking that requires precision, foresight, and engineering expertise. A common misconception among new investors is that a crushing plant is merely a single machine that breaks rocks. In reality, it is a complex, synchronized industrial system. The difference between a highly profitable plant and a maintenance nightmare often comes down to one thing: equipment selection and configuration. You cannot treat high-abrasion granite with the same equipment you use for soft limestone; doing so would bankrupt your operation through wear costs alone.

Designing a complete stone crushing plant requires a logical hierarchy of capacity, input size, and output quality. It functions like an orchestra; every machine must play its part in perfect rhythm. A bottleneck at the screening stage can choke the primary crusher, and a failure in the feeding stage can starve the entire line.

As a manufacturer with over 20 years of experience, ZONEDING has designed thousands of flowcharts for clients across 120 countries. We have distilled the complex process down to the absolute essentials. Here is a detailed breakdown of the 9 key machines you need to construct an efficient, high-yield, and durable production line in 2025.

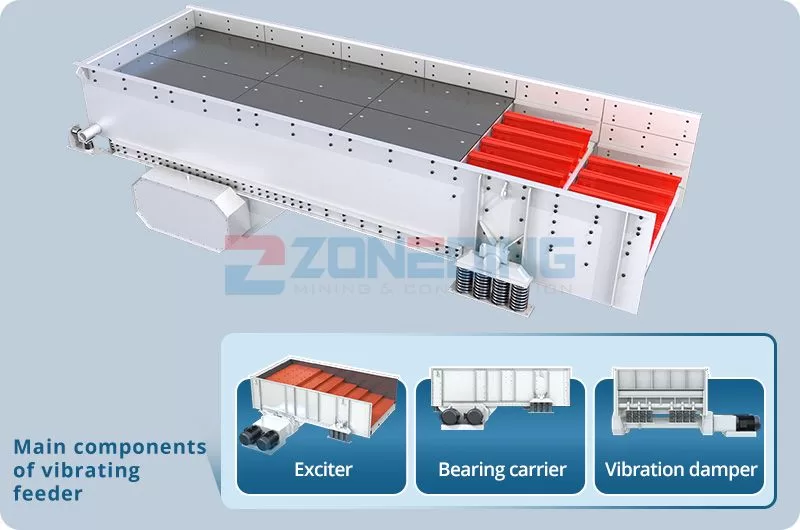

The production process begins here. While often overlooked as a simple hopper, the Vibrating Feeder is critically important for the longevity of your primary crusher. Its role is not just to drop rocks into a hole; it is to regulate the flow of raw material evenly and continuously.

If you were to dump a truckload of blasted rock directly into a Jaw Crusher, two major problems would occur:

The feeder acts as the gatekeeper, using strong vibration to move rocks forward in a uniform stream. This ensures the crusher operates at a constant load (amp draw), which is the key to energy efficiency.

Our feeders are equipped with a specialized “Grizzly Bar” section at the discharge end. This acts as a pre-screen before the crusher even touches the rock.

The Jaw Crusher is the undisputed king of primary crushing. For 95% of stone crushing plants, this is the first machine the rock encounters. Aptly nicknamed the “tiger’s mouth,” its primary function is massive reduction ratio. It takes massive, run-of-mine boulders—sometimes as large as 1200mm in diameter—and breaks them down into manageable chunks (typically 150-300mm).

The mechanism is simple but incredibly powerful:

Because it handles the rawest, hardest, and most irregular feed, robustness is the only metric that matters. At ZONEDING, our PE and PEW Series Jaw Crushers are engineered for this exact purpose. We utilize high-quality manganese steel castings for the jaw plates and a heavy-duty eccentric shaft to withstand extreme shock loads.

Unlike impact crushers, jaw crushers are distinctively not picky about rock hardness. Whether you are mining abrasive quartzite or soft limestone, the Jaw Crusher provides the reliable foundation required for a stable plant. Without a properly sized jaw crusher, your secondary machines would be overwhelmed by oversized rocks, leading to immediate blockages. It is the machine that sets the maximum throughput potential (Total TPH) for your entire business.

Once the rock leaves the primary station, it needs further reduction and shaping. If you are processing soft to medium-hard materials like Limestone, Coal, Gypsum, or Concrete Waste, the Impact Crusher is your ideal secondary solution.

Unlike the Jaw or Cone crusher which uses compression (squeezing), the Impact Crusher uses kinetic energy. Fast-spinning rotors equipped with heavy-duty blow bars strike the falling rock, throwing it against steel impact curtains. The rock shatters along its natural fissures.

Key Strategic Advantages:

A Crucial Warning:

Impact crushers are not suitable for highly abrasive rocks like granite or silica. The wear on the blow bars would be too rapid, forcing you to stop production every few days for replacements. However, for limestone quarries, the Impact Crusher is the absolute profit-maker due to its low initial cost and high-quality output.

If your geological survey indicates hard, abrasive materials like Granite, River Stone, Basalt, or Iron Ore, you must switch your secondary crusher to a Cone Crusher. Using an Impact Crusher on these materials would result in changing wear parts constantly, which is operationally unsustainable.

The Cone Crusher operates on “lamination crushing” principles:

We focus on advanced HPT (Multi-cylinder) and HST (Single-cylinder) hydraulic cone crushers. These are vastly superior to old spring cones:

As natural river sand supplies dwindle globally due to environmental regulations, the Vertical Shaft Impact (VSI) Crusher has become an essential component for modern plants. It acts as a tertiary or quaternary stage machine.

The VSI operates like a rock centrifuge:

ZONEDING’s VSI crusher are designed with optimized rotor tips to extend wear life, allowing you to upgrade your output to premium-grade material that sells for a higher price point.

The Vibrating Screen is effectively the cash register of your plant. This is where your mixed crushed stone is separated into distinct, sellable products. Without efficient screening, you have no product definition.

How it works:

The screen consists of multiple layers of mesh (decks) with different aperture sizes (e.g., 20mm on top, 10mm in the middle, 5mm on the bottom). An eccentric shaker motor causes the entire body to vibrate violently.

Our Vibrating Screens utilize a circular vibration trajectory which is highly efficient for heavy-duty screening. Structure is critical here—screens endure millions of stress cycles. We use rivet-connected side plates rather than welded ones to prevent cracking under constant g-force stress. Selecting the correct screen surface area is vital; if the screen is too small, good material carries over into the reject pile, and you lose production volume.

In the crushing process, rock flour and dust are inevitable. In the past, this was waste. However, modern construction standards place strict limits on the “silt content” of sand used in concrete, as dust weakens the structural bond. This is where the Sand Washing Machine adds value.

Typically placed after the VSI or the final screen, the Sand Washer (commonly the XSD Wheel Bucket type) cleans the product:

For ZONEDING clients, adding a washing module can often double the market price of the sand fraction. It turns low-grade “crusher dust” into premium “washed construction sand.” In regions where water is scarce, we also integrate water recycling systems and thickeners to minimize consumption, ensuring environmental compliance.

While they are not “crushing” equipment, no plant can function without a robust network of Belt Conveyors. They are the arteries of the site, transporting material from feeder to crusher, crusher to screen, and screen to stockpile.

Investors often try to cut costs on conveyors, but this is a critical mistake. A conveyor failure stops 100% of production immediately. Real efficiency depends on three factors:

We design conveyor systems using high-grade rubber belts (often nylon or EP reinforced) and heavy-duty idler rollers. Furthermore, in 2025, dust control is non-negotiable. We frequently design simple covers or fully enclosed gallery conveyors to prevent dust emissions and protect your final product from rain saturation.

Running a crushing plant involves managing hundreds of kilowatts of power and multiple independent motors. Attempting to start and stop these machines manually is dangerous and inefficient. You need a centralized Electric Control System.

A crushing plant cannot just be turned on. It must follow a strict logic:

Our plants are equipped with PLC (Programmable Logic Controller) systems featuring touch screens. These smart panels allow operators to:

Investing in a high-end control cabinet reduces labor costs (fewer operators needed) and prevents catastrophic human error that could burn out expensive motors.

You rarely need all 9 machines in a single line. The correct combination depends entirely on your raw material hardness and your market requirements.

| Configuration Goal | Primary Stage | Secondary Stage | Tertiary Stage | Shaping/Cleaning |

|---|---|---|---|---|

| Hard Rock (Granite/Basalt) | Vibrating Feeder + Jaw Crusher | Cone Crusher (Single/Multi-Cylinder) | VSI Crusher (Optional) | Vibrating Screen + Sand Washer |

| Soft Rock (Limestone) | Vibrating Feeder + Jaw Crusher | Impact Crusher (PFW Series) | Impact Crusher (Recirculation) | Vibrating Screen (No washer needed) |

| Sand Making Line | Vibrating Feeder + Jaw Crusher | Fine Jaw or Cone Crusher | VSI Sand Maker (Essential) | Vibrating Screen + XSD Sand Washer |

Building a stone crushing plant is an exercise in systems engineering. It is not enough to simply buy high-quality machines; you must ensure they are sized to work together. A massive Jaw Crusher adds no value if the downstream Conveyor Belt is too narrow to take the rocks away. From the brute force of the primary station to the delicate precision of the washing circuit, each of these 9 machines holds a key to your profitability.

At ZONEDING, we don’t just sell machinery; we sell production capacity. We calculate the mass flow balance, the energy consumption, and the expected wear life to provide you with a turnkey solution that works from day one. Whether you are building a 100 TPH aggregate line or a 1000 TPH mining project, getting these 9 components right is the foundation of your success.

Ready to visualize your plant layout? Contact the ZONEDING engineering team today for a customized flowchart design and ROI analysis.

Last Updated: January 2026

Explore the typical price range of jaw crushers and understand the main factors influencing their cost, such as size, capacity, features, and machine quality.

View detailsDon't select the wrong crusher for your circuit. Learn to avoid costly mistakes in secondary, tertiary, & quaternary crushing stages from this ZONEDING's Blog.

View detailsOur practical guide tells differences on jaw crushers vs. impact crushers. Learn how to choose the right machine for your materials and budget. Get expert tips!

View detailsLooking to improve your sand and gravel making process? This guide provides practical tips on optimizing your operations, reducing waste, and increasing output.

View details