Antimony is a semi-metallic element that holds a unique and critical place in modern industry. While not as well-known as copper or gold, it is indispensable for manufacturing flame retardants, batteries, and high-tech alloys. However, extracting antimony is a complex process with different technical challenges.

At my company, ZONEDING, we have specialized in engineering and building complete mineral processing plants since our founding in 1990. We have successfully designed solutions for some of the world’s most challenging antimony deposits. This guide will cover everything you need to know about this strategic mineral, from its basic properties to the advanced techniques used in its processing.

Table of Contents

What is Antimony?

Antimony (symbol Sb, atomic number 51) is a brittle, silvery-white semi-metal, also known as a metalloid. This means it has properties of both a true metal and a non-metal. It is a poor conductor of heat and electricity and is most famous for its ability to impart strength and hardness to other metals, particularly lead and tin. In its pure form, antimony is crystalline and easily broken. Its most important commercial form is the mineral stibnite (antimony sulfide, Sb₂S₃), which is the source of virtually all the world’s antimony production.

Where Can We Find Antimony Deposits?

Antimony is a relatively rare element, making its deposits geographically concentrated. Over 90% of the world’s primary antimony production is from these three countries:

- China: For decades, China has been the world’s largest producer, with significant deposits in the Hunan, Yunnan, and Guangxi provinces.

- Russia: Russia holds substantial reserves and is a major global supplier.

- Tajikistan: This Central Asian nation has emerged as a key player in the antimony market.

Other countries with notable antimony production include Bolivia, Australia, and Myanmar. The deposits come through hydrothermal activity, where hot, mineral-rich fluids deposit stibnite in veins and fractures within rock formations.

What are the Properties of Antimony?

Understanding antimony’s properties is key to appreciating its uses and processing challenges.

- Appearance: Silvery, bluish-white and very brittle.

- Hardness: It is quite soft, with a Mohs hardness of 3 to 3.5, similar to a copper coin.

- Density: It has a specific gravity of 6.69, making it moderately heavy.

- Melting Point: Antimony has a relatively low melting point of 630°C (1,167°F).

- Key Characteristic: Its most valuable property is that it expands slightly when it cools and solidifies, which is unusual for metals. This makes it excellent for creating high-resolution castings and alloys.

Extracting a high-grade antimony concentrate is crucial for economic viability. A “high-grade” concentrate is one where the percentage of antimony is as high as possible, and the concentration of undesirable impurities (penalty elements) is as low as possible.

- Higher Payout from Smelters: Smelters pay more for concentrates that are rich in antimony because they are more efficient to process into pure metal.

- Lower Transportation Costs: Shipping a high-grade concentrate means you are not paying to transport worthless rock.

- Avoiding Penalties: Impurities like arsenic and lead are common in antimony ores. If the levels of these penalty elements are too high in your concentrate, the smelter will pay you significantly less or may even reject the shipment.

What are the Applications of Antimony?

Antimony’s unique properties make it a critical, often irreplaceable, component in several key industries.

- Flame Retardants: This is its largest use. Antimony trioxide is a powerful synergist with halogenated materials (like plastics and textiles) to stop them from catching fire. It’s in everything from electronics and clothing to aircraft and car seats.

- Lead-Acid Batteries: Antimony is alloyed with lead to create the plates in lead-acid batteries. It strengthens the lead, improves its performance, and reduces the need for maintenance.

- Alloys: It is mixed with tin and lead to create pewter, Babbitt metal (for bearings), and solder.

- High-Tech Applications: Ultra-high purity antimony applies in the semiconductor industry for infrared detectors and diodes. It also applys in next-generation high-capacity batteries.

What are Different Types of Antimony Ore?

Understanding your ore type is the first step in designing an effective processing plant.

- Simple Sulfide Ore: The easiest to process. The primary mineral is stibnite (Sb₂S₃) with few other interfering sulfides. Froth flotation is highly effective.

- Complex Sulfide Ore: This is very common. The stibnite often comes with other sulfide minerals like arsenopyrite (arsenic), pyrite (iron), galena (lead), and sphalerite (zinc). This requires a more complicated differential flotation process.

- Oxidized Ore: This ore has been weathered, and the original stibnite has been converted into antimony oxides like stibiconite. Standard flotation and often require gravity separation or leaching methods can not process these ore.

- Gold-Bearing Antimony Ore: In these “refractory” ores, microscopic gold is inside the stibnite. Extracting the gold requires a specialized pre-treatment step after the initial antimony concentration.

The extraction method is based on the ore type.

- Froth Flotation: This method is the most common for sulfide ores. It uses chemical reagents and air bubbles to selectively separate stibnite particles from the waste rock.

- Gravity Separation: Best suited for coarse, high-density oxidized ores. Equipment like shaking tables and jigs is helpful for this method.

- Hydrometallurgy (Leaching): This involves using a chemical solution (like sodium sulfide) to dissolve the antimony from the ore. It is more complex and costly but can be effective for some complex or oxidized ores.

- Pyrometallurgy (Smelting): This is the final step where the high-grade concentrate is heated in a furnace to produce crude antimony metal.

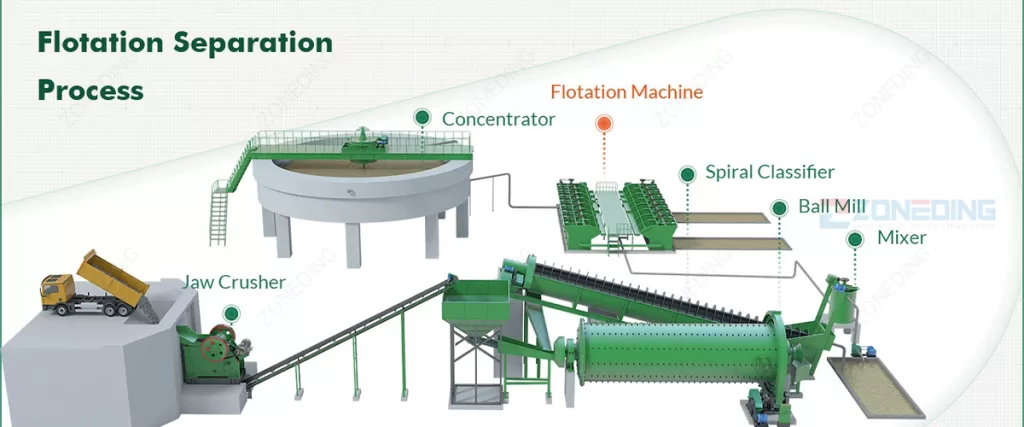

A typical antimony processing plant, like the ones we design at ZONEDING, follows a specific flow:

- Crushing & Grinding: The run-of-mine ore is first crushed into small rocks and then fed into a ball mill, which grinds it with steel balls into a fine powder, creating a slurry with water.

- Flotation: The slurry is pumped to flotation cells. We add specific reagents and air. The stibnite particles attach to the bubbles and float to the surface, forming a froth that is collected.

- Dewatering: The froth (concentrate) is sent to a thickener to settle the solids and then to a filter to remove most of the water, creating a dense cake.

- Smelting: The dewatered concentrate is heated in a furnace, where it melts and separates into crude antimony metal and a waste product called slag.

How to Solve the Challenges When Processing Antimony?

Every antimony deposit is unique, but most present a set of common processing challenges. Overcoming these is the key to a profitable operation. At ZONEDING, we solve these problems through a combination of smart process design and robust equipment. Here is our approach to the most frequent issues.

Solution for High Arsenic Content: Selective Depression

The challenge is that arsenic-bearing minerals like arsenopyrite float just as easily as stibnite. Our solution is to use specific chemical depressants, such as lime, in a high-pH environment. These reagents essentially “blind” the arsenic minerals, preventing them from attaching to air bubbles, while the stibnite floats normally. This produces a clean, high-value antimony concentrate with very low arsenic penalties.

Solution for Fine Particle Slime: Stage Grinding and Classification

The challenge is that stibnite is soft and easily over-ground into ultra-fine “slime,” which is very difficult to recover. Our solution is a two-stage grinding circuit. After initial grinding in a ball mill, we use a hydrocyclone to classify the slurry. Only the coarse, unliberated particles are back for further grinding. The fine, liberated particles bypass the second grind and go straight to flotation, which prevents over-grinding and maximizes recovery.

Solution for Oxidized Ore: Surface Activation

The challenge is that weathered or oxidized stibnite has a surface layer that repels flotation collectors. Our solution is to add an activating agent, typically sodium sulfide (Na₂S), to the slurry before flotation. This chemical effectively strips away the oxidized layer, exposing a fresh sulfide surface that the collectors can easily attach to.

Solution for Complex Minerals (Lead/Zinc): Differential Flotation

The challenge is when antimony comes with other valuable sulfides like galena (lead) and sphalerite (zinc). Our solution is to design a differential flotation circuit. In the first stage, we create chemical conditions to float only the stibnite. The tailings from this stage then go to a second flotation circuit, where we change the chemistry (e.g., adjust the pH and add different activators) to float the next mineral, like galena. This allows for the production of separate, clean concentrates for each metal.

How to Refine Antimony?

The crude antimony metal produced by a smelter is not pure enough for most high-tech applications. It must be refined to remove remaining impurities like arsenic, lead, and iron.

- Pyrometallurgical Refining: This is the most common method. The molten crude antimony is treated with reagents that react with the impurities, which then form a slag on the surface that can be skimmed off.

- Electrolytic Refining: For producing ultra-high purity antimony (99.999% or higher) for the electronics industry, an electrolytic process similar to copper refining is used. This is a more expensive and complex process.

What are the Key Equipment for an Antimony Processing Plant?

A complete antimony processing plant requires a series of integrated machines.

- Jaw Crusher & Cone Crusher: For primary and secondary crushing of the ore.

- Ball Mill: To grind the ore into a fine powder.

- Flotation Cells: The core of the separation process.

- Thickener & Filter: For dewatering the concentrate.

- Reagent Mixing Tanks & Pumps: For preparing and dosing the process chemicals.

- Smelting Furnace: For the final conversion to metal.

How Much Money Should You Prepare for an Antimony Processing Plant?

The cost of setting up an antimony processing plant varies dramatically based on several factors:

- Plant Capacity: A small 50-ton-per-day plant will be far cheaper than a large 1,000-ton-per-day operation.

- Ore Complexity: A complex ore requiring multiple flotation circuits and specialized reagents will need a more expensive plant than a simple ore.

- Location: Costs for labor, construction, and logistics vary greatly by country.

As a rough estimate, a small to medium-sized plant could range from a few hundred thousand to several million dollars. At ZONEDING, as a factory-direct manufacturer, we help clients manage these costs by providing efficient, right-sized equipment without dealer markups.

What are the Environmental Impacts of Antimony Processing?

The primary environmental concerns are related to the toxicity of antimony and its common associated element, arsenic.

- Water Contamination: If process water is not properly managed, it can release dissolved antimony and arsenic into the environment. A closed-loop water recycling system is the best solution.

- Air Pollution: The smelting process can release sulfur dioxide (a cause of acid rain) and toxic dust. Modern smelters must have advanced gas scrubbing and dust collection systems.

- Tailings Management: The waste rock (tailings) must be stored in a secure, lined facility to prevent long-term leaching of heavy metals into the soil and groundwater.

Antimony Processing Future Trends

The antimony industry is evolving in response to market demands and environmental pressures.

- Processing Low-Grade Ores: As high-grade deposits are depleted, new technologies are being developed to economically process lower-grade and more complex ores.

- Hydrometallurgy Growth: There is growing research into hydrometallurgical (leaching) processes that are more environmentally friendly and can better handle complex ores compared to traditional smelting.

- Recycling: Recycling antimony from spent lead-acid batteries and other end-of-life products is becoming an increasingly important source of supply.

FAQ

- Is antimony toxic?

- Yes, antimony and its compounds are toxic. Exposure, particularly through inhalation of dust, must be strictly controlled with proper personal protective equipment (PPE) and ventilation.

- What is the difference between antimony and stibnite?

- Antimony is a chemical element (Sb). Stibnite is a mineral (antimony sulfide, Sb₂S₃), which is the primary ore where we find antimony metal.

- Why is antimony called a strategic mineral?

- It is strategic because it is essential for military and industrial applications (especially flame retardants) and its supply is in just a few countries, making it vulnerable to geopolitical disruptions.

Why Choose ZONEDING?

Navigating the complexities of antimony processing requires a partner with deep expertise and a proven track record. Since 1990, ZONEDING has been delivering complete, one-stop solutions for the global mining industry. Our team of 15 professional mining engineers doesn’t just sell machinery; we conduct a thorough analysis of your ore to design a fully customized and optimized processing plant. As a factory-direct manufacturer, we eliminate middleman costs, providing robust, high-efficiency equipment built with durable materials and components from trusted global brands like Siemens and Schneider.

Contact our expert team today for a free consultation and let’s discuss how we can build a profitable solution for your antimony deposit.