全站搜索

Search the entire website

Search the entire website

Have you ever wondered what the world around you is truly made of? From the smartphone in your hand to the roads you drive on, our modern lives are built upon a foundation of processed minerals. Understanding the 10 common minerals and their uses reveals a fascinating story of how we transform simple rocks into the essential products we rely on every day. These materials are the silent partners of human progress.

Quartz (Silicon Dioxide, SiO₂) is the second most abundant mineral in Earth’s crust. Its primary role is in glassmaking and electronics. When you look through a window or at your phone screen, you’re looking through melted and reformed quartz sand. Its unique piezoelectric property, which allows it to generate an electric charge under pressure, makes it essential for watches, clocks, and radio transmitters.

At ZONEDING, we frequently design processing lines for silica sand, which is primarily quartz. The goal is to purify the sand to glass-grade quality by removing impurities like iron. This often involves washing, sizing with our Vibrating Screens, and sometimes magnetic separation. It’s a perfect example of how a common mineral is processed to become a high-value industrial material.

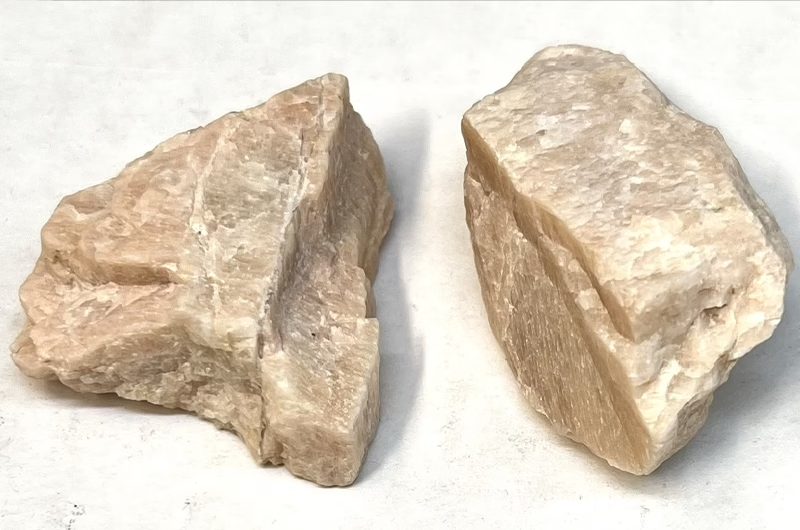

Feldspar is a group of minerals that makes up over 50% of the Earth’s crust. And Feldspar is the most important ingredient in ceramics and is also a key flux in glassmaking. It acts as a melting agent, lowering the melting temperature of other materials. This is why it’s essential for creating everything from your bathroom tiles and dinner plates to the ceramic insulators on power lines.

Processing feldspar involves crushing it to a fine powder. Our Ball Mills are perfectly suited for this task, grinding the hard mineral into the consistent, flour-like powder required by the ceramics industry. The quality of the final product, whether it’s a delicate teacup or a durable floor tile, starts with perfectly ground feldspar.

Calcite (Calcium Carbonate, CaCO₃) is the primary mineral in limestone and marble. Its most significant use is in the production of cement. When limestone is heated in a kiln, it turns into lime, the key ingredient that binds sand and gravel together to make concrete. Without calcite, our cities, bridges, and dams simply could not be built. It is quite literally the building block of modern infrastructure.

ZONEDING provides complete production lines for the cement industry, from the massive Jaw Crushers that handle quarried limestone to the enormous Rotary Kilns that transform it into clinker. We also supply equipment for producing ground calcium carbonate (GCC), which is used as a filler in plastics, paper, and paints.

Iron is rarely found in pure form; it’s extracted from iron ores, most commonly Hematite (Fe₂O₃) and Magnetite (Fe₃O₄). The overwhelming use of iron ore is to make steel. Roughly 98% of all iron ore mined is used for this purpose. From cars and ships to appliances and the rebar in buildings, steel is the most important structural metal in the world.

Our expertise at ZONEDING is deeply rooted in iron ore processing. We design and build entire beneficiation plants that crush, grind, and upgrade low-grade iron ore. For magnetite, our powerful Magnetic Separators are essential for concentrating the ore. For hematite, we often employ gravity separation methods. Our work helps turn raw, rocky ore into the high-grade concentrate needed by steel mills.

While over 160 copper minerals exist, Chalcopyrite (CuFeS₂) is the most important source of copper. Copper’s primary use is for electrical wiring and electronics due to its excellent conductivity. It is the mineral that powers our homes, businesses, and an increasingly electric world, from power grids and electric motors to the tiny circuits in your phone.

Copper ore processing is a classic example of froth flotation. After crushing and grinding the ore, we use Flotation Machines to separate the valuable chalcopyrite particles from waste rock. ZONEDING’s flotation cells are designed for high efficiency, ensuring our clients can recover the maximum amount of this vital metal from their ore.

You know Halite (Sodium Chloride, NaCl) by its common name: rock salt. While its most familiar use is for seasoning food, over 80% of salt is used in the chemical industry. It is a primary source of chlorine and sodium hydroxide, which are fundamental chemicals used to manufacture plastics (like PVC), paper, soaps, and detergents. It is also used for de-icing roads in winter.

| Mineral Name | Chemical Formula | Key Industry | What It Helps You Do |

|---|---|---|---|

| Quartz | SiO₂ | Electronics, Glass | See through your phone screen and windows. |

| Feldspar | KAlSi₃O₈ | Ceramics, Glass | Drink from a ceramic mug, use a dinner plate. |

| Calcite | CaCO₃ | Construction | Live in a sturdy building, drive over a bridge. |

| Hematite | Fe₂O₃ | Steel Manufacturing | Drive a car, use steel appliances. |

| Halite | NaCl | Chemical, Food | Season your food, de-ice your roads. |

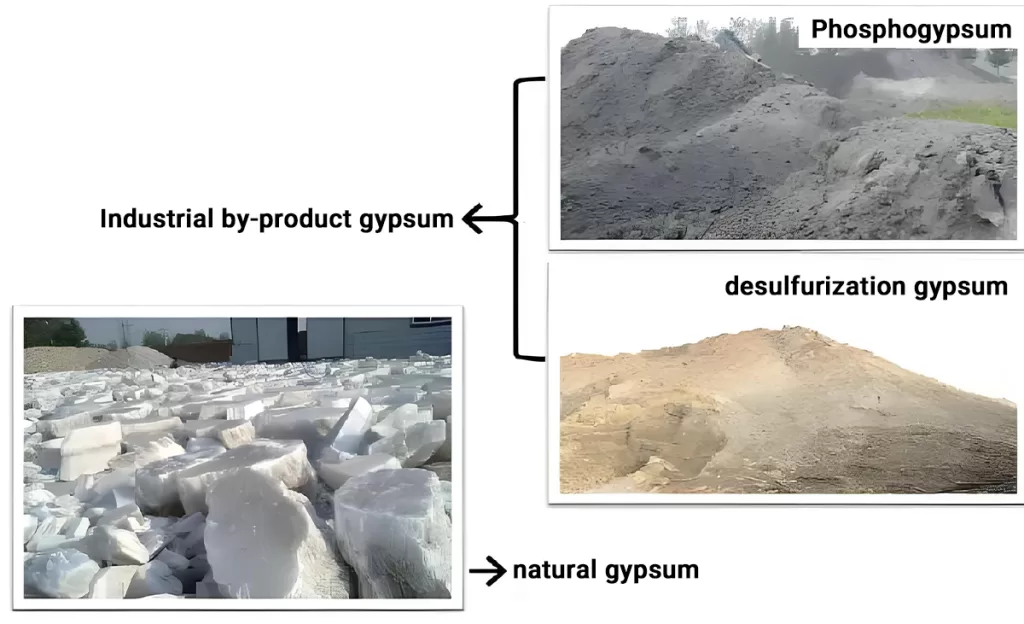

Gypsum (Calcium Sulfate Dihydrate, CaSO₄·2H₂O) is a soft mineral with a crucial role in construction. Its primary use is to make plaster and wallboard (drywall). When gypsum is heated, it loses water, and when water is added back, it re-hardens into a solid mass. This property makes it perfect for creating the smooth interior walls of our homes and offices. It’s also used as a fertilizer and as an ingredient in cement to control the setting time.

Kaolinite is the main mineral in kaolin, or “china clay.” Its number one use is in the paper industry, where it provides gloss and opacity. It fills the tiny spaces between paper fibers, crea ting a smooth, bright surface that is ideal for printing. It is also the key ingredient in porcelain and fine china, and is used in cosmetics, paints, and even medicines as an active ingredient in stomach-soothing remedies.

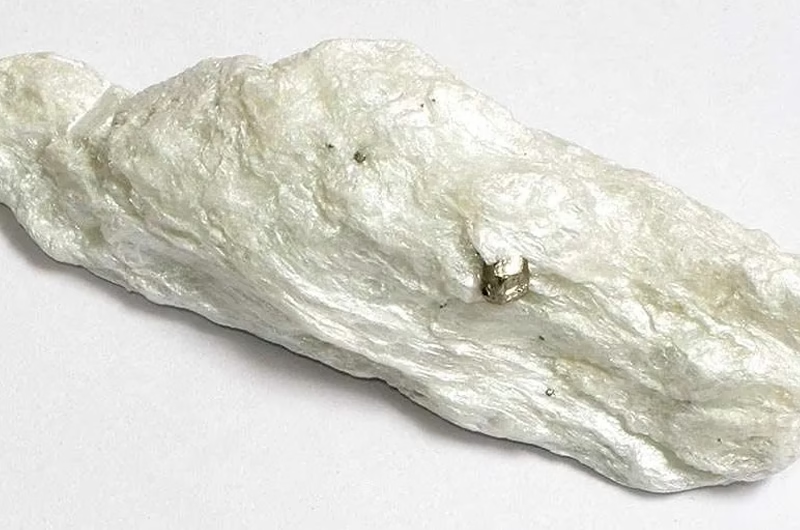

Talc is the softest mineral on Earth, famous for its greasy, soapy feel. Its softness and inertness make it a versatile filler material. It is ground into talcum powder, but its main industrial uses are in plastics, ceramics, and paints. In plastics, it increases stiffness and heat resistance. In paints, it improves the suspension of solids. It is the invisible ingredient that enhances the properties of many everyday products.

Bauxite isn’t a single mineral, but a rock primarily composed of aluminum hydroxide minerals like Gibbsite. It is the one and only significant source of aluminum. The process of turning bauxite into aluminum metal is energy-intensive but results in a metal that is lightweight, strong, and corrosion-resistant. This makes aluminum essential for aircraft, vehicles, beverage cans, and construction materials.

The 10 common minerals and their uses are a testament to human ingenuity. We take these raw materials, often found in low concentrations, and transform them into the very fabric of our modern world. From the calcite in our buildings to the quartz in our computers, these minerals are the unrecognized heroes of our daily lives.

Understanding this connection is the first step. The next is recognizing the complex engineering required to make it happen. The journey from a raw rock to a finished product depends on precise, efficient, and reliable mineral processing technology.

Ideally, the slurry agitator tank is key equipment ensuring full reaction between chemicals and ore. Learn how it prevents sedimentation and boosts recovery.

View detailsMaximize yield with Gold Gravity Separation Equipment. From Centrifugal Concentrators to Shaking Tables, we offer a complete solution to recover fine gold.

View detailsWhat is iron ore used for? Discover the top 5 uses including steel production, cast iron, powdered iron magnets, radioactive shielding, and coal washing.

View detailsHow much gold remains underground? While about 212,000 tonnes are above ground, the USGS estimates only 59,000 tonnes of proven reserves are left to mine.

View details