全站搜索

Search the entire website

Search the entire website

Are you tired of watching your profits flow out into the tailings pond? Are you looking for a way to recover gold efficiently without navigating the complex and expensive regulations of chemical leaching? Gold Gravity Separation Equipment is the backbone of responsible, high-yield mining operations worldwide. It utilizes the simple yet powerful law of physics—specific gravity—to separate valuable gold particles from waste rock.

At ZONEDING, we advocate for a “Gravity First” approach. By implementing a complete verified circuit, from Centrifugal Concentrators to Shaking Tables, you can recover both coarse nuggets and fine “flour” gold purely mechanically. This guide deep-dives into how you can maximize your yield, reduce your environmental footprint, and build a profitable plant using our proven technology.

Gold Gravity Separation is a physical mineral processing technique that separates gold from gangue (waste) minerals based on their significant differences in specific gravity (density).

To understand why this works so well, you have to look at the numbers. Pure gold is incredibly dense, with a specific gravity (SG) of approximately 19.3. In contrast, common waste minerals found in gold ore, such as quartz, silica sand, or limestone, usually have a specific gravity between 2.6 and 2.7. This massive difference—gold being roughly seven times heavier than the rock holding it—is the “loophole” that gravity equipment exploits.

When you suspend crushed ore in a liquid medium (usually water) and apply specific movements—like vibration, flowing, or centrifugal spinning—the laws of physics take over. The heavy gold particles overcome the fluid resistance and sink rapidly to the bottom. Meanwhile, the lighter waste particles are kept in suspension by the water and are washed away as tailings.

Understanding the nature of your deposit is the first step in successful mining, as “Placer” (Alluvial) gold and “Rock” (Lode) gold require completely different machinery setups to be profitable.

This gold has already been liberated by nature. Over millions of years, erosion has worn away the host rock, leaving loose gold mixed with sand, gravel, and heavy clay in riverbeds or ancient channels. The primary challenge here isn’t crushing rock; it is washing and scrubbing. Clay is the enemy of placer mining because it traps gold and floats it away.

This gold is still trapped inside solid veins of quartz or sulfide minerals. You cannot simply wash it; you have to unlock it. The process requires high energy to break the rock down to the point of “liberation”—where the gold particle is free from the surrounding stone.

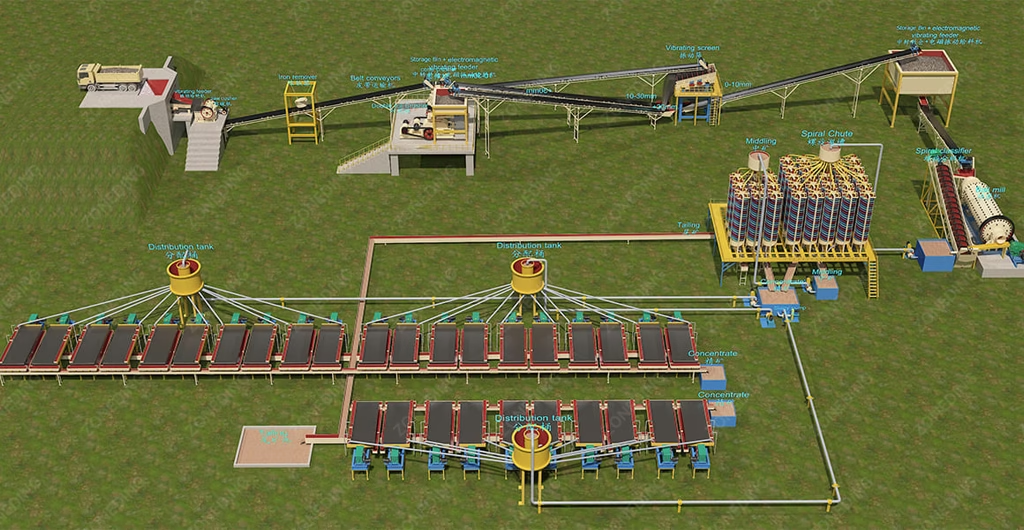

A high-recovery plant is like a well-organized team; each machine has a specific role, targeting a specific size of gold particle. To ensure you catch every grain, ZONEDING typically integrates the following core technologies into a unified circuit.

This is the workhorse for modern recovery. Traditional gravity methods rely on 1G (Earth’s gravity), which works for nuggets but loses fine dust. The Centrifugal Concentrator spins at high speeds to generate 60G to 80G of force. This intensified gravity forces even microscopic gold particles (down to 20 microns) to stick to the capture cone, while the lighter sand is ripped away by the water. ZONEDING units feature an automated fluidized water jacket, which keeps the concentrate bed loose and prevents compaction, ensuring high recovery rates for “flour gold.”

Once you have a concentrate from the centrifuge, it is still mixed with some heavy black sands. You need to upgrade it to pure gold. The Shaking Table (often the 6-S model) is the ultimate precision tool. As the table shakes back and forth, water flows across it. You can visually see the separation happen: a clear gold line forms at the top, followed by other minerals. It produces a high-grade product (up to 95% purity) that can go directly to the smelting pot.

The Jig is an older but reliable technology that uses pulsating water through a screen bed. It is excellent requires less water than other methods. We often place Jigs early in the circuit (after crushing but before fine grinding) to catch coarse gold nuggets before they get flattened or smeared in the ball mill.

Never let your waste go unchecked. The sluice box is a simple, inclined channel with riffles and carpet. ZONEDING installs these at the end of the process to treat the “tailings” (waste) coming from the other machines. It acts as a safety net, catching any stray gold that might have escaped due to process surges.

For decades, the standard for gold extraction involved hazardous chemicals. However, the industry is undergoing a massive shift toward “Green Mining,” and Gravity Separation is leading this charge. There are compelling reasons—financial, environmental, and operational—to eliminate or minimize chemical use in your plant.

Cyanide is highly toxic. If a cyanide leach pad leaks, it can destroy local rivers and ecosystems. Because of this risk, environmental protection agencies in most countries make obtaining a permit for a cyanide plant extremely difficult, expensive, and slow. Mercury, often used by artisanal miners, is a neurotoxin that causes severe health issues and is banned by international treaties (like the Minamata Convention). Gravity separation uses only water and physics. It is clean. Governments issue permits for gravity plants much faster, allowing you to start production months or years sooner than a chemical plant.

Chemical plants are thirsty for consumables. You must constantly purchase cyanide, activated carbon, lime for pH control, and acids for stripping. These costs fluctuate with the market and eat into your monthly profits. With a gravity plant, your main consumable is electricity and water. You are not dependent on chemical suppliers or supply chain disruptions.

Running a chemical plant requires highly trained chemists and strict safety protocols to prevent fatal accidents. A gravity plant is mechanical. It is safer for your workforce and easier to manage. Mechanics can fix a Shaking Table; you don’t need a chemical engineer on every shift. Furthermore, gravity separation recovers coarse gold that cyanide actually struggles with (coarse gold takes too long to dissolve), making gravity not just an eco-friendly choice, but a necessary technical step for efficiency.

Designing a gravity circuit is not about randomly picking machines; it is about creating a balanced flow where every particle gets a chance to be separated. At ZONEDING, we follow a strict sequential logic to design our High Recovery Plants, primarily for hard rock applications.

The goal here is “Liberation.” You must break the rock until the gold particle is free.

Now that the gold is free, we need to catch it quickly.

The waste (tailings) from the Centrifugal Concentrator runs over a Sluice Box or Chute before going to the tailings pond. This is a low-cost insurance policy to catch any nuggets that might have skipped the centrifuge during a power surge or flush cycle.

If you buy the best equipment in the world but ignore the operational variables, you will still lose gold. Optimizing a gravity circuit requires constant attention to specific physical parameters. ZONEDING engineers always train operators to monitor the following four critical factors.

This is the number one reason for lost gold. If you do not grind the rock fine enough, the gold remains encapsulated inside the quartz. A gravity separator sees “light quartz,” not “heavy gold,” and washes it away. Conversely, if you grind it too fine (“slimes”), the gold becomes so tiny that it floats on water tension and won’t sink. You must find the “Sweet Spot” for your specific ore—usually between 60% and 80% passing 200 mesh.

The ratio of water to solids is vital. If the slurry is too thick (too many solids), the particles overcrowd each other. The gold particles cannot physically find a path to settle through the thick mud. If the slurry is too thin (too much water), the flow velocity is too high, and the valuable fine gold is flushed out of the machine before it can settle. A typical shaking table performs best at roughly 25% to 30% solids.

Gravity equipment hates surges. If you dump a massive load of ore onto a shaking table all at once, the table gets swamped, and gold is washed into the tails. You need a steady, consistent feed rate. ZONEDING uses slurry pumps with VFD (Variable Frequency Drives) and buffer tanks to ensure the flow to the gravity concentrators is smooth and constant, 24/7.

In Centrifugal Concentrators, pressurized water pushes back against the capture rings to keep the bed fluidized. If the pressure is too high, you blow the gold out. If it is too low, the sand packs hard like concrete, and the gold bounces off. Tuning this water pressure is the key skill of a good operator.

The investment required for a gold gravity plant varies significantly based on scale (Tons Per Hour – TPH) and complexity. However, compared to a Cyanide CIL/CIP plant, the capital expenditure (CAPEX) is substantially lower.

For artisanal miners or pilot testing, a basic setup is very affordable. This usually includes a small Jaw Crusher, a Hammer Mill (instead of a ball mill for lower cost), and a Shaking Table.

This is the most common range for established junior mining companies. It involves a full professional circuit: Hopper, Vibrating Feeder, Jaw Crusher, Fine Crusher, Ball Mill, Spiral Classifier, Centrifugal Concentrators, and Shaking Tables.

Gravity separation equipment is mechanically tough, involving fewer delicate parts than chemical pumps, but “tough” does not mean “maintenance-free.” To keep your recovery rates high and your plant running continuously, a strict maintenance schedule is required.

The most critical component here is the fluidization water system. You must ensure the water fed into the concentrator is clean. If dirty river water is used without filtration, the tiny holes in the concentrate cone will clog. Once clogged, the capture bed hardens (“packs doubt”), and gold simply slides over it and is lost. Check and clean the water filters every shift. Also, inspect the concentrate cone liner for wear; abrasive sand will eventually wear down the capture ribs.

The Shaking Table relies on a generic gearbox often called the “Head Motion.” This contains internal gears that create the differential stroke (slow forward, fast back). This box is filled with oil. You must check the oil level weekly and change it seasonally to prevent the gears from grinding. Additionally, keep the table surface clean. Algae or calcium scale can build up on the deck, disrupting the smooth flow of water and ruining the separation. Scrub the deck gently with a soft brush during shutdowns.

Moving crushed rock and water is like sandblasting the inside of your pipes. The impellers and rubber liners of your slurry pumps are high-wear items. ZONEDING recommends keeping at least one spare “Wet End” kit (Impeller, Volute, Liner) for every pump on site. Do not wait for a pump to fail before ordering spares, or your entire production line will stop for weeks.

The field of gravity separation is not stagnant; it is evolving rapidly as technology improves and ore grades decline. As we move through 2025, ZONEDING is observing and integrating several key trends that are defining the future of the industry.

Gold Gravity Separation is not just a mining method; it is a business strategy that prioritizes profitability, sustainability, and simplicity. It allows miners to recover the majority of their gold at a fraction of the cost of chemical plants, free from the burdens of toxic waste management. By understanding the physics of the process and selecting the right combination of equipment—balancing the brute force of the Ball Mill with the precision of the Shaking Table—you can build a processing line that delivers consistent wealth. Whether you are dealing with ancient riverbeds or deep rock veins, the fundamental truth remains: Gold is heavy, and with the right equipment, you can use that weight to your advantage.

Contact ZONEDING today for a free consultation and let us help you turn your rock into revenue!

Last Updated: January 2026

Discover 9 most common problems on ball mill, from excessive wear to power consumption. Learn how to identify issues and implement solutions to extend lifespan.

View detailsNew to construction materials? This guide breaks down 5 basic types of sand, from Pit Sand to M-Sand, explaining their properties in easy-to-understand terms.

View detailsDid you know your house is full of nonferrous metals? This 8 examples, from the nickel in your coins to the titanium in your glasses, you probably use everyday.

View detailsThis guide tells advantages, disadvantages, applications, capabilities, and maintenance considerations of Closed-Circuit and Open-Circuit crushing plant.

View details