全站搜索

Search the entire website

Search the entire website

If you are operating a quarry or a mine, you are not just managing machines; you are managing physics. Every time you turn on a crusher, you are waging a war against the geological strength of the rock.The profitability of your entire operation often comes down to one fundamental choice: The Crushing Method.

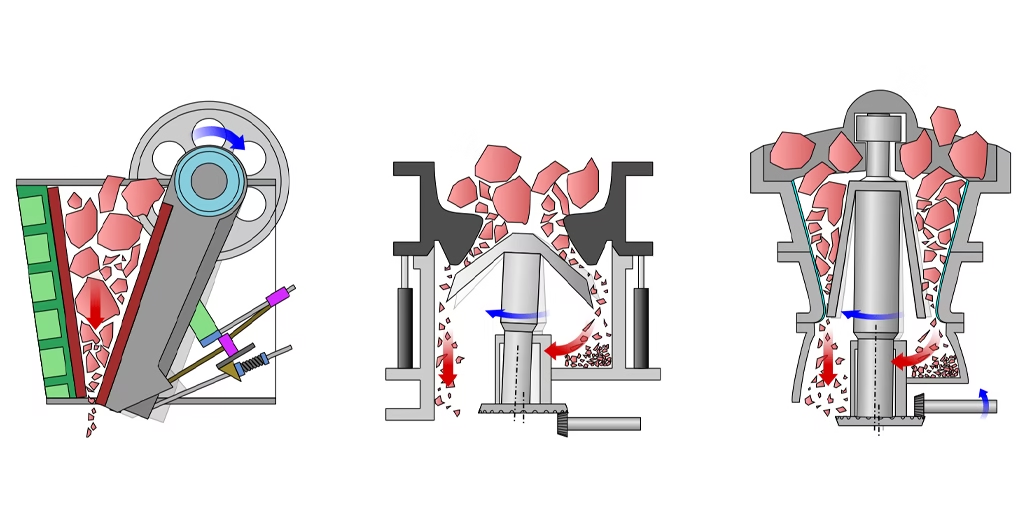

Understanding the three core principles of rock reduction—Compression, Impact, and Shear—is the secret to efficiency. It determines the quality of your aggregate, the lifespan of your liners, and your electricity bill.

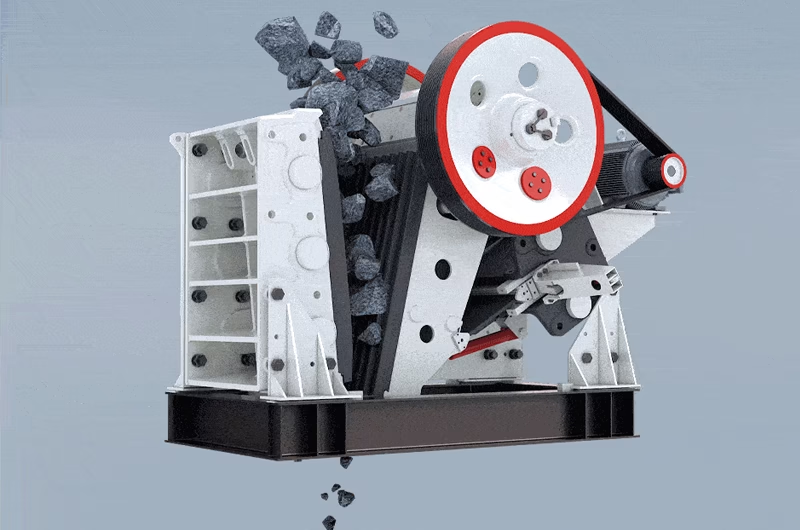

Compression crushing is the brute force method of the mining world. It is the most reliable technique for handling the hardest materials on earth.

Imagine a giant nutcracker. This is the essence of compression. Two surfaces mechanically approach each other. The rock is trapped between them. As the surfaces close in, the crushing force builds up inside the rock structure.

Rock is brittle. It has high compressive strength, but it has a limit. When the mechanical pressure exerted by the machine exceeds the internal bond strength of the mineral, the rock shatters. This method does not rely on speed; it relies on high torque and immense pressure. It creates a “slow” but unstoppable breaking action.

The two champions of compression are the Jaw Crusher and the Cone Crusher, both staples in the ZONEDING product line.

Compression is the only viable option for abrasive, hard rock like Granite, Basalt, Iron Ore, and River Pebbles. Why? Because these rocks contain Silica. Silica is like glass; it cuts metal. If you rub silica against metal at high speed, the metal vanishes. Compression crushing minimizes this rubbing. It presses directly down. This drastically extends the life of your wear parts (Jaw plates and Mantles). If you are mining hard rock, compression is your lifeline.

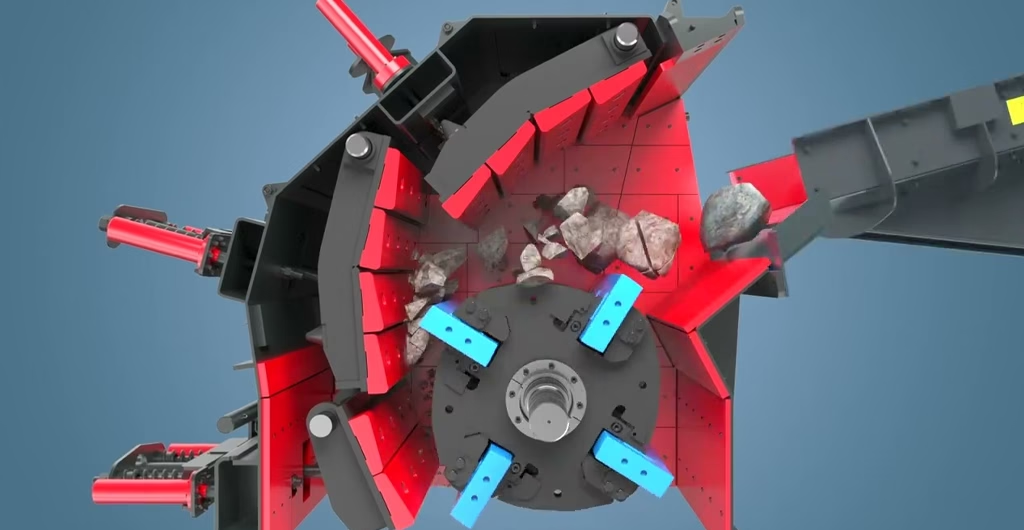

Impact crushing is the complete opposite of compression. If compression is a hydraulic press, impact crushing is a sledgehammer. It is all about kinetic energy, speed, and collision.

In this method, the machine does not squeeze the rock. Instead, it hits the rock with incredible speed.

According to physics, Energy equals Mass times Velocity squared (E=1/2mv2). By spinning a rotor at high RPM, we generate massive kinetic energy.

The greatest benefit of impact crushing is the particle shape. Compression crushers tend to create flat, needle-like (flaky) stones because they squeeze the rock. Impact crushers break the rock where it wants to break—along natural fissures. This results in a cubic (square) shape.

For modern construction, cubic aggregate is gold. It locks together better in concrete and requires less cement paste. If your client demands high-grade aggregate for highways or skyscrapers, you need impact crushing.

The major machine here is the Impact Crusher (HSI) and the VSI (Sand Maker).

However, you must be careful. Because the rock slides and strikes the metal at high speed, friction is high. If you use this method on abrasive rock (like Granite) with high silica content, your blow bars will wear out in days. It is financially disastrous. Impact crushing is best suited for soft to medium-hard, low-abrasion materials like Limestone, Coal, or Calcium Carbonate.

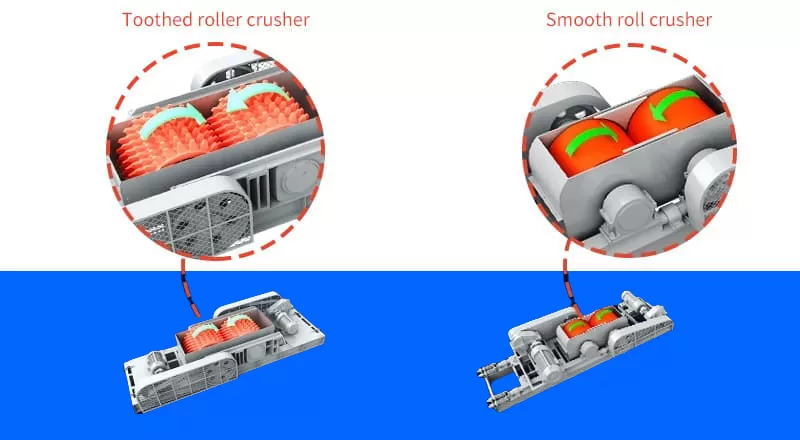

Shear crushing is the least discussed but highly specialized method. It works on the principle of cutting, cleaving, or tearing the material.

Think of a pair of scissors or a cheese grater. Shear force applies stress in a parallel direction to the surface of the material. It pulls the material apart rather than squeezing it or hitting it.

Machines that use shear force usually have two rolls or drums spinning towards each other. Unlike compression, which just pushes, shear crushing relies on friction to “grab” the material and pull it through the gap.

The biggest enemy of mining machinery is moisture. If you put wet clay or chalk into a Compression Crusher (Jaw), it packs tight. It creates a solid “pancake” of mud that blocks the machine.

Shear crushing solves this. Because the rollers are constantly turning and “tearing” the feed, the sticky material cannot build up. It is pulled through forcibly. This makes shear crushing the standard for handling Coal, Clay, Salt, and Soft Shale.

Another unique feature of shear crushing is that it produces very little dust (fines).

When you impact rock, you create a cloud of dust. When you compress rock, you create some powder at the contact points. But when you shear or cut rock, you get clean breaks.

This is vital for industries like Coal. Coal power plants need lumps of coal to burn efficiently. If the crusher turns the coal into dust, it is wasted. Therefore, Double Roller Crushers or Toothed Rollers (which prioritize shear force) are the industry standard for friable materials where you want to minimize waste.

| Feature | Compression (Jaw/Cone) | Impact (HSI/VSI) | Shear (Roller) |

|---|---|---|---|

| Physics | Squeezing / Pressure | Striking / Velocity | Cutting / Tearing |

| Best Rock Type | Hard & Abrasive (Granite, Iron Ore) | Soft & Non-Abrasive (Limestone) | Soft & Sticky (Coal, Clay) |

| Wear Cost | Low (Best for hard rock) | High (Only for soft rock) | Low (Non-abrasive only) |

| Product Shape | Flaky (Needle-like) | Cubic (Excellent) | Blocky (Low fines) |

| Reduction Ratio | Medium (3:1 to 5:1) | High (10:1 to 20:1) | Low/Medium (4:1) |

| Moisture Tolerance | Low (Blocks easily) | Medium | High (Handles mud) |

Now that you know the physics, how do you apply this to your purchase? At ZONEDING, we advise clients to look at three specific data points in their geological report before signing a contract.

This is the single most important number. It refers to how much silica (quartz) is in your stone.

This is measured in MPa.

Crushing is an old industry, but the technology is moving fast. In 2025, we are seeing the integration of smart tech with these traditional mechanical principles.

The biggest trend is Mobile Crushing. We mount these massive Jaw, Cone, or Impact crushers on crawler tracks.

This allows you to take the crushing method directly to the blasting face. You no longer need to truck raw rock 2 kilometers to a fixed plant. You drive the crusher to the rock.

ZONEDING has developed mobile units that combine methods. For example, a single mobile chassis can carry a Feeder and a Jaw Crusher. A second chassis carries a Cone Crusher and a Screen. This gives you a complete “Hard Rock” factory that you can drive with a remote control.

In the past, if a piece of uncrushable iron entered a Cone Crusher (Compression), the machine would break. The shaft would snap.

Today, ZONEDING Cone Crushers use intelligent hydraulic release systems. Sensors detect the pressure spike. The hydraulics instantly drop the mantle, letting the iron pass through, and then reset the pressure automatically. This happens in seconds. It allows for continuous operation and protects your investment from catastrophic failure.

Adjusting the discharge opening used to take hours of manual labor. Now, with a touch screen, you can adjust the “Closed Side Setting” (CSS) of your crusher. This lets you change the product size instantly to meet changing market demands without stopping the machine.

ZONEDING MACHINE stands as a leader in China’s mineral processing industry for a reason.

There is no “perfect” crusher. There is only the right crushing method for your specific geology.If you fight the physics, you lose money.

At ZONEDING, we don’t just sell steel machinery; we sell engineered solutions. When you contact us, we ask for your stone analysis first. We look at your silica content, your moisture, and your market goals. Then, we design a flow chart that uses the correct balance of Compression, Impact, and Shear forces.

Contact ZONEDING today for a free consultation and customized crushing circuit design.

Last Updated: January 2026

Get the ultimate guide to crushers vs. breakers. Understand differences, applications, and key selection criteria. Make informed decisions with confidence.

View detailsUnlock economic potential of gabbro deposits. Learn what gabbro is and how the crushing plant can turn gabbro into valuable resource for construction projects.

View detailsFrom panning to separation, get ultimate guide on how to process black sand for gold. Learn tips to improve yield and identify gold-rich black sand deposits.

View detailsLearn to produce ceramsite sand. This guide covers raw materials, crushing, pelletizing, calcining, screening, and machinery. Start manufacturing today!

View details