全站搜索

Search the entire website

Search the entire website

Producing ceramsite sand, a lightweight ceramic aggregate, constitutes a crucial process in modern construction and various other industries. This material features high strength, low density, and excellent insulation properties. It becomes invaluable for lightweight concrete, horticultural substrates, and filtration. Understanding the entire ceramsite sand production process, from raw material preparation to final screening, helps ensure efficient and high-quality output. This guide provides a comprehensive overview of the ceramic sand production line, detailing each essential step and the machinery involved.

The demand for sustainable and high-performance construction materials continues to grow. This places ceramsite sand at the forefront of innovative solutions. Mastering the leca production process allows manufacturers to meet market needs while optimizing operational efficiency. This guide offers insights into machinery, process optimization, and quality control.

Ceramsite sand is a lightweight, porous ceramic aggregate. Manufacturers produce it by firing various natural or artificial materials at high temperatures. Its unique properties, including low bulk density (typically 300-900 kg/m³), high compressive strength, and excellent thermal insulation, make it highly valuable across numerous industries.

These characteristics address critical needs in construction, horticulture, and environmental applications. Businesses recognize its potential for cost reduction and performance enhancement, directly contributing to a profitable ceramsite line.

For businesses, ceramsite sand offers distinct advantages. Its light weight reduces transportation costs and structural loads in buildings. This allows for lighter designs and lower foundation costs. The material’s durability and chemical inertness contribute to long-lasting products, increasing customer satisfaction. In construction, it leads to improved thermal and acoustic insulation, supporting energy-efficient buildings.

ZONEDING’s versatile grinding solutions facilitate the initial processing of raw materials for this valuable product.

Selecting the optimal ceramsite raw materials is fundamental for producing high-quality ceramsite sand. The choice of materials directly impacts the final product’s density, strength, and expansion characteristics. Common raw materials include clay, shale, fly ash, and certain industrial sludges. Each material possesses specific properties that influence the ceramsite manufacturing process. Understanding these properties helps ensure consistent product quality, crucial for any profitable ceramsite line.

Clay ceramsite production often uses plastic clays, which expand well under heat. Shale ceramsite manufacturing utilizes argillaceous rocks, providing good strength and expansion. The fly ash ceramsite process leverages industrial waste, offering an environmentally friendly and cost-effective option. Some processes also incorporate coal gangue or other mineral byproducts. Careful material analysis and testing determine the best material mix for desired lightweight aggregate production. ZONEDING specializes in customization mineral processing. This assists in the selection and preparation of diverse ceramsite raw materials for optimal output specifications.

Ceramsite sand, a versatile lightweight aggregate, finds extensive use across numerous industries. This occurs due to its unique physical properties. Understanding these diverse applications highlights its economic value and broad market potential. Its characteristics make it ideal for demanding situations like light weight, insulation, or filtration. This makes it a valuable component in many diverse products.

Key applications include:

These applications underscore the importance of consistent ceramsite quality control. ZONEDING’s grinding solutions ensure raw materials are perfectly prepared for these varied applications. This contributes to a profitable ceramsite line.

The complete ceramsite manufacturing process involves a series of meticulously controlled stages. Each step transforms raw materials into the high-quality expanded clay aggregate known as ceramsite sand. This intricate sequence ensures the final product possesses the desired lightweight, porous, and strong characteristics. These characteristics are required for various applications. Understanding this chain helps in planning and optimizing a ceramic sand production line.

This comprehensive process starts with raw material handling. It proceeds through shaping, heat treatment, and final classification. Efficient operation of each stage is critical for overall productivity and product quality. ZONEDING provides essential ceramsite machinery for each stage. This supports the entire ceramsite sand production chain.

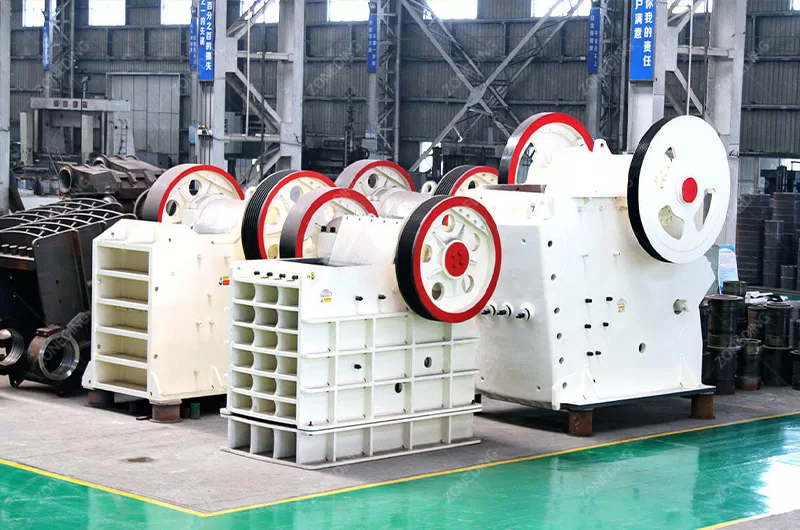

The initial stage involves preparing ceramsite raw materials. This includes crushing, grinding, and mixing stages. Large lumps of clay, shale, or fly ash undergo size reduction using crushing equipment like jaw or impact crushers. These machines reduce material to a uniform size, typically within a few millimeters.

Fine grinding often follows, using ball mills or rod mills. This process creates a powder suitable for pelletizing. A precise moisture content is then achieved through mixing with water and binders in pugmills or mixers. This preparation ensures suitable plasticity for subsequent processes, critical for successful clay ceramsite production or fly ash ceramsite process.

ZONEDING’s crushing equipment and milling equipment are designed for high efficiency in these initial stages.

Pelletizing transforms the prepared, moistened raw material powder into small, spherical green pellets. This stage uses ceramsite pelletizing equipment such as disc pelletizers (granulators) or rotary drum granulators. As these machines rotate, the powder agglomerates. It gradually forms uniform pellets through a rolling and compaction action. The size and consistency of these green pellets significantly influence the quality of the final expanded product. Controlled feed rates, moisture levels, and equipment settings are crucial for achieving optimal pellet formation. Variations in pellet size lead to inconsistent expansion during calcination.

Calcining is the most vital step in the ceramsite manufacturing process. Green pellets are rapidly heated to high temperatures (1100-1300°C) inside a rotary kiln for ceramsite. This intense heat causes the raw material to soften and melt. Simultaneously, gases trapped within the material expand, creating the characteristic porous, lightweight structure. This rapid expansion process is known as bloating.

Precise temperature control, retention time, and atmosphere within the rotary kiln determine the final density, strength, and structure of the expanded clay aggregate. ZONEDING’s advanced rotary kiln technology offers superior temperature control and energy efficiency.

After calcination, the hot, expanded ceramsite must undergo controlled cooling. Cooling occurs in rotary coolers or grate coolers. This process stabilizes the internal porous structure and prevents thermal shock. Thermal shock could compromise the material’s strength. Once cooled, ceramsite screening separates the material. Screening machines, typically vibrating screens, classify the ceramsite sand into various size fractions. This precise size grading produces different grades of ceramsite, from fine powders to coarse aggregates. This final classification makes the material suitable for specific applications, completing the lightweight aggregate production process.

A modern ceramic sand production line relies on a specialized suite of ceramsite machinery. Each machine fulfills a critical role in transforming raw materials into finished ceramsite sand. The selection and configuration of this equipment directly impact the line’s efficiency, output quality, and overall profitable ceramsite line operation. Understanding the function of each component is vital for anyone looking to build ceramsite plant.

Essential ceramsite machinery includes:

ZONEDING offers a comprehensive portfolio of these machines. This provides full ceramsite equipment supplier services. Its expertise ensures seamless integration and optimal performance for the entire ceramsite sand production process.

Ensuring ceramsite quality control is paramount for a profitable ceramsite line. It needs to meet client specifications. Strict adherence to quality standards at every stage of the ceramsite manufacturing process guarantees a consistent and high-performance product. This protects a company’s reputation and expands market opportunities. Effective quality management systems are crucial for anyone who wants to build ceramsite plant.

Key aspects of ceramsite quality control include:

ZONEDING’s customization mineral processing solutions integrate advanced monitoring tools and offer precise equipment. This directly aids in the achievement of stringent ceramsite quality control.

Operating a ceramsite manufacturing process involves several common challenges. These can impact efficiency and product quality. Addressing these issues proactively is essential for maintaining a profitable ceramsite line. Understanding potential pitfalls allows for effective planning and troubleshooting. Anyone who wants to build ceramsite plant needs to pay attention to these issues.

Anticipating these challenges and implementing robust solutions ensures smoother and more efficient ceramsite sand production.

Planning and investing in a successful ceramsite sand plant requires careful consideration of numerous factors. A well-executed plan ensures a profitable ceramsite line and long-term operational success. The initial investment decision significantly impacts future returns. A strategic approach is critical for anyone looking to build ceramsite plant.

Key steps for effective planning and investment include:

A meticulous approach to these planning stages forms the foundation for a highly efficient and profitable ceramsite line.

ZONEDING MACHINE stands as a dedicated ceramsite equipment supplier. The company commits to supporting clients throughout their ceramsite sand production journey. Expertise in mineral processing equipment and a comprehensive service offering ensure a robust and profitable ceramsite line. ZONEDING’s full-service approach minimizes client complexity and maximizes operational efficiency.

ZONEDING’s support includes:

Partnering with ZONEDING provides a reliable foundation for achieving success in ceramsite sand production.

We clearly explain what andalusite is, its thermal properties, and the essential steps used to process it for applications in steel, ceramics, and foundries.

View detailsAre you struggling with inefficient mineral separation, leaving valuable materials behind? Are you experiencing low recovery rates and high operating costs? This comprehensive guide will give all the details about shaking tables. Shaking...

View detailsLearn how to identify gold in the ground by its color, luster, and shape. We explain why raw gold doesn't sparkle like glitter and how to spot it in dirt.

View detailsLooking to improve your sand and gravel making process? This guide provides practical tips on optimizing your operations, reducing waste, and increasing output.

View details