Andalusite may not be a household name like gold or copper, but this powerful mineral is a hidden hero in the world of high-temperature industries. My company, ZONEDING, has engineered mineral processing solutions since 1990, and we understand that every industrial mineral has a unique path from raw ore to a valuable final product. Andalusite is a perfect example. Its value lies in its incredible ability to withstand extreme heat, a property that can only be unlocked through precise andalusite processing. This guide will explain what andalusite is, its key andalusite properties, its most important uses, and the essential steps needed to process it effectively.

Table of Contents

What Exactly is Andalusite?

Andalusite is a naturally occurring aluminosilicate mineral. In simpler terms, it is a rock-forming mineral made up of aluminum, silicon, and oxygen. It belongs to a special group of minerals known as polymorphs, which also includes kyanite and sillimanite. Polymorphs are like siblings—they have the exact same chemical formula (Al₂SiO₅) but different crystal structures. This difference in structure gives each mineral unique physical properties. Andalusite’s specific crystal structure is what gives it the exceptional ability to convert into mullite, a highly refractory material, at high temperatures with very little volume change.

Andalusite is a metamorphic mineral. This means it is formed deep within the Earth’s crust when existing rocks, typically clay-rich shales or slates, are subjected to relatively low pressure but high temperatures. This process, called contact metamorphism, often happens when hot magma intrudes into the surrounding rock. The intense heat from the magma “cooks” the existing rock, causing the minerals within it to recrystallize and form new minerals, like andalusite. The specific combination of low pressure and high heat is the key to forming andalusite instead of its cousins, kyanite or sillimanite.

What is the Composition of Andalusite?

The chemical formula for andalusite is Al₂SiO₅. When you break this down, it tells you what the mineral is made of.

- Aluminum Oxide (Al₂O₃): This makes up about 63% of andalusite by weight. This high alumina content is the primary source of its refractory properties.

- Silicon Dioxide (SiO₂): This makes up the remaining 37% of the mineral.

Pure andalusite has this exact composition. However, in nature, it is common for small amounts of other elements, like iron or manganese, to substitute for aluminum. The amount of these impurities can affect the mineral’s color and its performance in high-temperature applications, which is why the beneficiation process to remove them is so important.

What is the Properties of Andalusite?

Andalusite’s value comes from a unique set of physical and thermal characteristics. These andalusite properties make it a premium material for specific industrial uses.

- Excellent Thermal Stability: This is its most important feature. When heated above 1,380°C (2,516°F), andalusite converts directly into mullite (3Al₂O₃·2SiO₂), a strong, needle-like crystal. This conversion happens with only a very small (about 3-5%) and predictable volume expansion. This stability means that refractory bricks made from andalusite do not crack or deform when heated.

- High Refractoriness: “Refractory” means it can withstand very high temperatures without melting or breaking down. Andalusite can resist temperatures up to 1,850°C (3,362°F), making it perfect for lining industrial furnaces.

- Good Thermal Shock Resistance: Because of its stable conversion to mullite, andalusite can handle rapid changes in temperature without cracking. This is crucial in industries like steel manufacturing, where furnaces are heated and cooled frequently.

- High Creep Resistance: At high temperatures, some materials will slowly deform under pressure. Andalusite’s strong mullite structure provides excellent resistance to this “creep,” ensuring that furnace linings maintain their structural integrity.

Where Can We Find It?

Andalusite is found in metamorphic rocks around the world, but large, economically viable deposits are relatively rare. The world’s leading producer of andalusite is South Africa, which accounts for the majority of global supply. Other significant producers include France, Peru, and Spain. China also has significant andalusite resources. These deposits are typically mined using open-pit methods, where the andalusite-bearing rock is extracted for processing.

What are Applications of Andalusite?

The unique properties of andalusite make it almost exclusively used in one major industry: refractory products. An andalusite refractory is a ceramic material designed to withstand extreme heat.

- Steel Industry: This is the largest consumer of andalusite. It is used to make refractory bricks that line blast furnaces, ladles, and tundishes—the containers used to hold and transport molten steel. The uses of andalusite in the steel industry are critical for safety and efficiency.

- Cement Industry: Andalusite is used to line the high-temperature zones of rotary kilns where clinker is produced.

- Glass Industry: It is used in the furnaces and tanks where glass is melted.

- Ceramics Industry: Andalusite is used to make high-quality “kiln furniture”—the shelves and posts used to support ceramic products during firing. Its stability ensures the furniture does not warp or break at high temperatures.

What are the Main Steps in Processing Andalusite Ore?

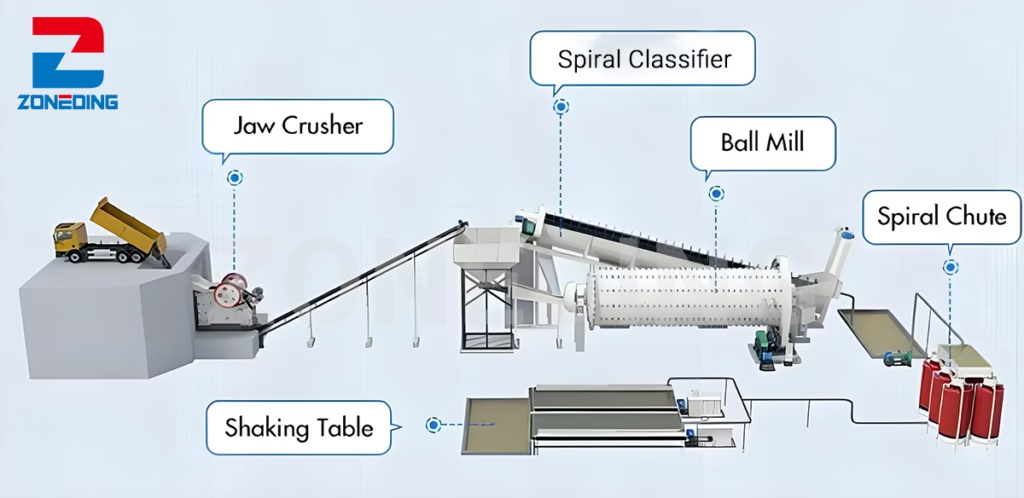

Transforming raw andalusite ore from the mine into a high-purity industrial product requires a precise, multi-stage process. As a manufacturer of mineral processing equipment, ZONEDING designs complete lines to handle these andalusite mineral processing steps.

- Comminution (Crushing & Grinding): The process starts by crushing the large ore rocks into a smaller, more uniform size using jaw crushers and cone crushers. The goal is not to create a fine powder but to liberate the andalusite crystals from the surrounding waste rock (gangue).

- Screening and Washing: The crushed ore is then screened to separate it into different size fractions. A washing stage is used to remove fine clays and slimes that can interfere with the later separation stages.

- Beneficiation (Separation): This is the most critical step. Various techniques are used to separate the valuable andalusite crystals from the waste rock. This is often a combination of methods.

- Dewatering and Drying: The final andalusite concentrate is dewatered and then dried in a rotary dryer to produce the final, ready-to-ship product.

How Does Andalusite Compare to Kyanite and Sillimanite?

While all three minerals have the same chemical formula, their different crystal structures affect how they behave when heated. This makes them suitable for different refractory applications.

- Andalusite: Expands by about 3-5% when heated. This conversion is done “in-situ,” meaning the andalusite can be put directly into the refractory brick mix and it will convert to mullite during the first firing. This makes it very energy and cost-efficient.

- Kyanite: Undergoes a large and rapid volume expansion of about 16-18% when heated. Because of this, kyanite must be pre-calcined (heated) to convert it to mullite before it can be used to make bricks. This adds an extra step and cost to the process.

- Sillimanite: Is the most stable of the three. It expands by only about 2-3% when heated, and this conversion happens at a higher temperature. It is often used in high-end refractory applications.

The choice between andalusite vs kyanite often comes down to cost and the specific technical requirements of the refractory product.

How Do You Separate Andalusite from Waste Rock? (Beneficiation)

Andalusite beneficiation is the process of concentrating the valuable mineral. Because andalusite is not magnetic and does not respond well to flotation, the separation process relies on its physical properties, primarily its density and shape.

- Heavy Media Separation (HMS): This is the most common method. The crushed ore is placed in a tank containing a dense liquid (a slurry of water and ferrosilicon). The lighter waste rock floats to the top and is removed, while the denser andalusite crystals sink to the bottom and are collected.

- Magnetic Separation: While andalusite itself is not magnetic, many of the impurity minerals found with it (like mica and tourmaline) are weakly magnetic. High-intensity magnetic separators are used to remove these impurities and improve the purity of the final product.

- Gravity Separation: Jigs and spirals can also be used to separate andalusite based on density differences, especially for finer particle sizes.

What are the Key Equipment for This Process?

A typical andalusite mining and processing plant uses a range of specialized machinery.

- Crushers: Jaw crushers for primary crushing and cone crushers for secondary crushing.

- Vibrating Screens: To size the material accurately for the separation stages.

- Heavy Media Separation (HMS) Drums or Cyclones: The core equipment for the main beneficiation step.

- Magnetic Separators: High-intensity roll or drum separators to remove iron-bearing impurities.

- Jigs and Spiral Concentrators: For gravity-based separation.

- Rotary Dryers: To dry the final concentrate to the required moisture content.

How to Choose the Right Supplier for Your Project?

Choosing the right partner for your andalusite processing project is critical. You need more than just an equipment seller.

- Experience and Expertise: Look for a supplier with proven experience in designing and building industrial mineral processing plants. Ask for case studies and references.

- One-Stop Solution: A supplier who can provide a complete, integrated processing line—from crushing to final product—will save you time, money, and coordination headaches.

- Customization: Every ore deposit is different. Your supplier should be able to analyze your ore and design a custom flowsheet that is optimized for your specific needs.

- After-Sales Support: A reliable supplier will provide support for installation, commissioning, operator training, and spare parts to ensure your plant runs smoothly for years to come.

FAQ

- Is andalusite a gemstone?

- Yes, a rare, transparent variety of andalusite called Chiastolite can be used as a gemstone. It is known for its distinctive dark, cross-shaped inclusions of carbon or clay. However, the vast majority of andalusite is opaque and used for industrial purposes.

- What color is andalusite?

- Industrial-grade andalusite is typically pinkish-brown, grayish, or reddish. The color is often influenced by small amounts of impurities like iron and manganese.

- Is andalusite valuable?

- Yes, high-quality andalusite is a valuable industrial mineral. Its price is significantly higher than that of raw materials like bauxite but lower than more processed synthetic refractory materials. Its value comes from its unique performance in high-temperature applications.

Conclusion and Final Advice

Andalusite is a critical industrial mineral whose importance is directly tied to its remarkable performance at extreme temperatures. Its stable and predictable conversion to mullite makes it a superior and cost-effective material for the refractory industry, especially in steel and cement manufacturing. Successfully producing high-purity andalusite requires a deep understanding of its properties and a carefully designed andalusite processing flowsheet that focuses on liberation and efficient physical separation.

For anyone looking to develop an andalusite deposit, the key takeaways are:

- Thoroughly test your ore to understand its liberation characteristics.

- Design a process flow that relies on proven, robust technologies like Heavy Media Separation.

- Partner with an experienced equipment supplier who can provide a complete, customized solution.