Gold extraction is the industrial process of separating pure gold from the rock, or ore, that holds it captive.

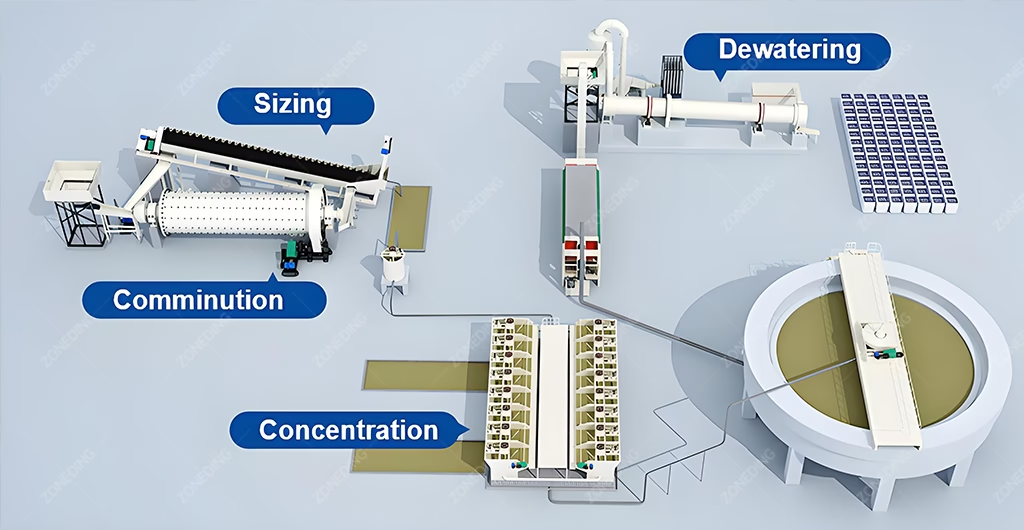

At my company, ZONEDING, we have been building the specialized machinery for this complex process since our founding in 1990. You must first crush massive amounts of rock to access the tiny, often microscopic, particles of gold locked inside. Then, you use a specific scientific method to persuade that gold to separate from the worthless rock. This is the essence of metallurgical science, how the modern mining industry transforms rugged stone into a valuable, pure metal.

Table of Contents

What Exactly is Gold Ore?

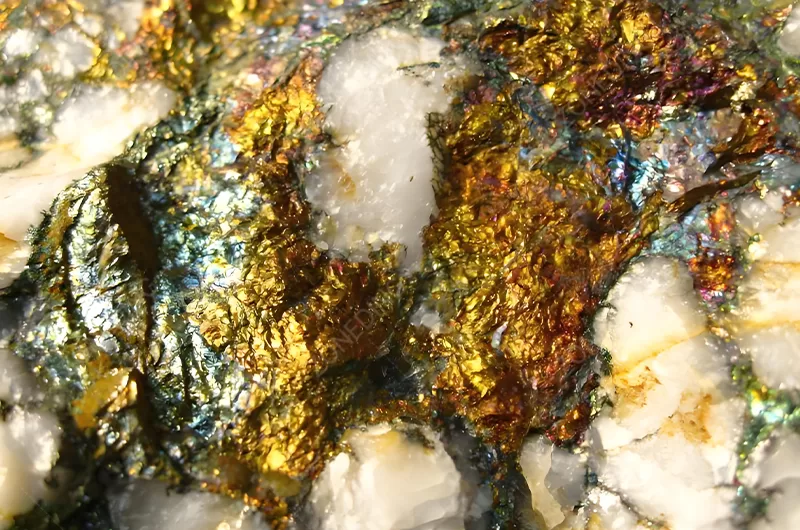

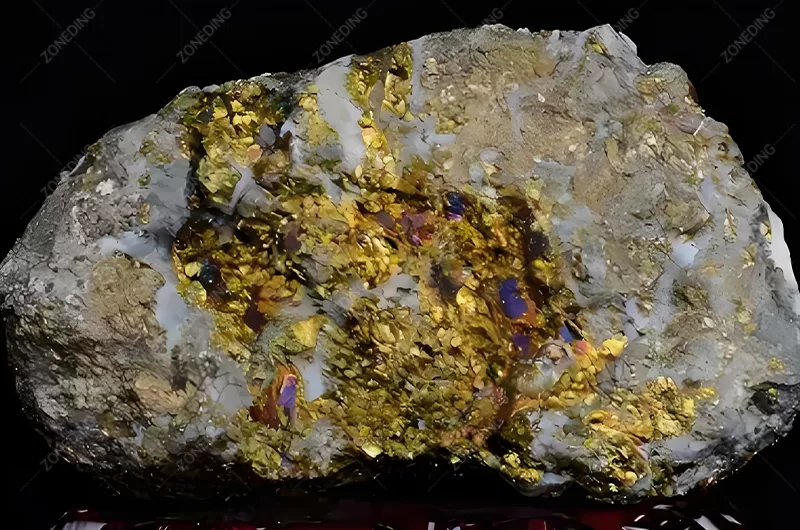

Gold ore is any rock that contains a high enough concentration of gold to make its extraction economically viable.

The gold itself is often completely invisible to the naked eye. You could be holding a piece of high-grade gold ore and not see a single speck of yellow. Its value is determined by the “grade,” a precise measurement of how much gold exists per ton of rock.

For a massive open-pit mine, a grade as low as 0.5 g/t might be profitable because they process millions of tons.

For a smaller underground mine, grades of 5 g/t or higher are typically needed to cover the higher operational costs. Before any major investment, mining companies perform extensive drilling and send rock samples for “assaying,” a chemical analysis that determines the exact gold content. This data is the single most important factor in deciding whether to build a mine.

Most of the world’s primary gold ore deposits are formed by a geological process involving extremely hot, mineral-rich water circulating deep within the Earth’s crust. This is known as a hydrothermal process. This superheated fluid acts as a solvent, picking up dissolved minerals, including gold, as it forces its way through cracks and fissures in the rock.

As this fluid travels towards the surface, it begins to cool, or the pressure drops dramatically. When this happens, it can no longer hold all its dissolved minerals. They begin to crystallize and deposit themselves on the walls of the fissures, often forming the quartz veins that miners treasure. Different temperature and depth conditions create different types of deposits, such as epithermal (formed close to the surface) or mesothermal (formed deeper down). Over millions of years, geological uplift and erosion push these ancient rock formations closer to the surface, where we can finally access them.

Where Can We Find Gold Ore?

You can find gold ore on every continent, but it tends to be concentrated in specific geological environments. The two main categories of deposits dictate the entire approach to mining:

- Lode Deposits (Hard Rock): This is gold that is still encased in its original host rock. It is the primary source of most of the world’s gold. Mining these deposits requires heavy industrial equipment for drilling, blasting, and then hauling the broken rock to a processing plant. At ZONEDING, we manufacture the crushers and grinding mills that are the first critical step in processing this hard rock ore.

- Placer Deposits: This is “secondary” gold that has been weathered and eroded out of a lode deposit by wind, rain, and ice over geological time. Because gold is so heavy, these liberated particles get carried downstream and settle in predictable locations like riverbeds, stream banks, and beaches. This type of mining is generally simpler and less capital-intensive because nature has already done the hard work of freeing the gold from the rock. The equipment needed here focuses on separation, not crushing.

Why is Gold So Difficult but Important to Separate?

Separating gold is a significant technical challenge for two main reasons. First, gold is one of the most chemically inert or “noble” metals. It strongly resists reacting with other elements, which is why it never rusts or tarnishes. This makes it perfect for jewelry and critical electronics, but it also means we can’t use simple, cheap chemical reactions to coax it out of the rock. We have to use very specific and carefully controlled processes.

Second, gold exists in extremely low concentrations, even in high-grade ore. Imagine grinding up a car and then trying to find a single grain of salt within the pile of metal dust—that’s the scale of the challenge. You must process an enormous volume of waste material to recover a tiny amount of valuable product. The process remains critically important, however, because gold’s immense and stable economic value justifies the massive investment in technology and energy required for its extraction.

Is Small-Scale Gold Mining Profitable?

Yes, absolutely. Small-scale gold mining can be a very profitable venture, provided you approach it as a serious business. Success hinges on two critical factors: the quality of your gold ore (the grade) and the efficiency of your processing equipment. A small, well-run operation with high-grade ore can easily be more profitable than a massive mining corporation struggling with a low-grade deposit.

The financial key is balancing your initial investment (CAPEX) with your ongoing operational costs (OPEX). Your biggest expenses will be fuel, labor, and equipment maintenance. This is where choosing the right technology from the start is paramount. At ZONEDING, we specialize in providing complete, modular small scale gold mining equipment that is designed for high recovery rates and low energy consumption, helping you maximize your return on investment.

What Are Different Types of Gold Ore?

Understanding your specific ore type is essential because it dictates your entire extraction strategy. You simply cannot use the wrong process and expect good results. The main categories are:

- Free-Milling Ore: This is the ideal type of ore for miners. The gold particles, even if small, are physically distinct and can be easily liberated from the host rock through simple crushing and grinding. Once liberated, the gold can be recovered efficiently using straightforward methods like gravity separation, which are both cheap and environmentally friendly.

- Refractory Ore: This is the most challenging and increasingly common type of ore. The term “refractory” means the gold resists simple extraction methods. The gold particles are often microscopic (sub-micron in size) and are physically encapsulated or chemically bonded within other minerals. The most common varieties include:

- Sulfide-Encapsulated: Gold is locked inside sulfide minerals like pyrite (“fool’s gold”) or arsenopyrite. The cyanide solution cannot reach the gold without first breaking down the sulfide host.

- Carbonaceous: The ore contains natural carbon, which is “active” and will re-adsorb the gold from the leaching solution, effectively stealing it back before you can recover it.

Once the ore is crushed to the consistency of sand or fine powder, you must choose a method to separate the gold. Here are the four primary techniques used in the industry today. At ZONEDING, we manufacture the key equipment for all of them.

1. Chemicals Dissolve Gold (Gold Leaching)

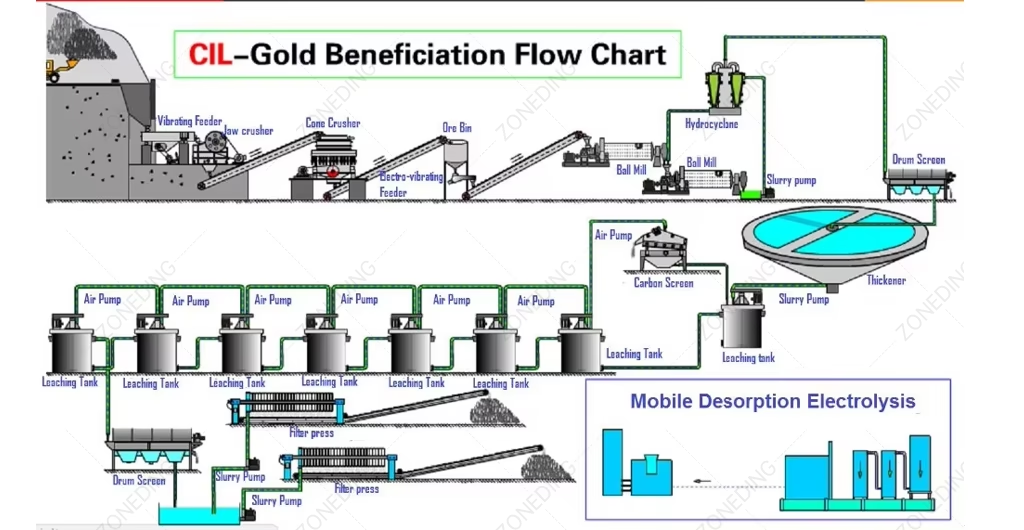

- Principle: This process uses a chemical solution to selectively dissolve the gold from the ore, creating a gold-rich liquid from which the metal can be recovered. The most widespread and efficient technique is the cyanide leaching process for gold.

- Process Flow: For low-grade ore, this is often done via Heap Leaching, where crushed ore is piled on a large impermeable liner and the cyanide solution is dripped over it for weeks or months. For higher-grade ore, a more intensive process called Vat Leaching is used. The finely ground ore is mixed with the solution in large Leaching Tanks and constantly agitated. From there, the dissolved gold is typically adsorbed onto activated carbon in what is known as a Carbon-in-Pulp (CIP) circuit.

- Advantages: It is highly effective, capable of recovering over 90% of the gold, making it the only viable choice for many large-scale, low-grade deposits.

- Key Equipment: Crushers, Grinding Ball Mills, Leaching Tanks, Agitators, Carbon Screens, Electrowinning Cells.

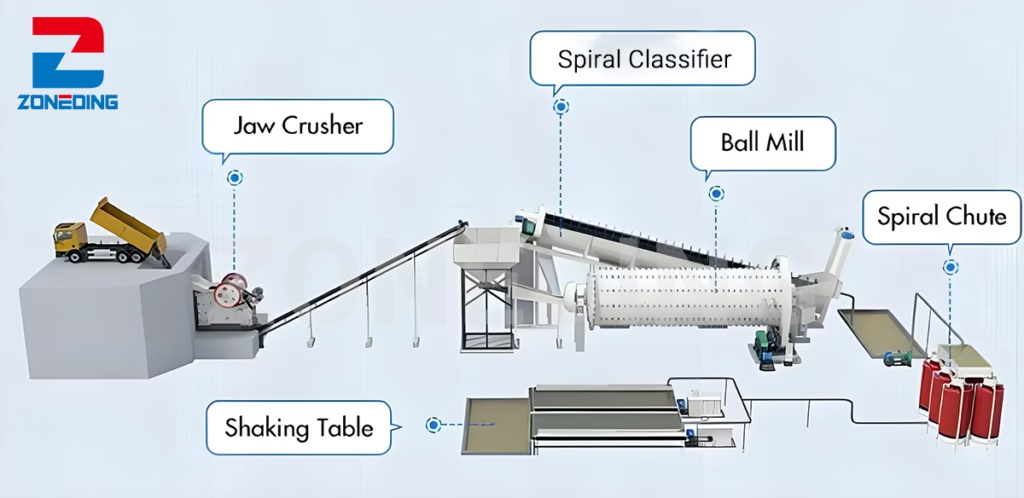

2. Gravity Separation

- Principle: This is the oldest, simplest, and most environmentally friendly method. It works entirely based on the physical principle of density. Gold is incredibly heavy—its specific gravity is 19.3, meaning it’s 19.3 times heavier than an equal volume of water. Most rock minerals (quartz, feldspar) have a specific gravity of only 2.5-3.0. This huge difference allows for easy separation.

- Process Flow: Crushed ore is mixed with water to create a slurry. This slurry flows over a device like a shaking table, sluice box, or spiral concentrator. These devices use a combination of water flow, vibration, and riffles to trap the super-heavy gold particles while allowing the much lighter waste rock (gangue) to wash away.

- Advantages: It has a very low operational cost, uses no harmful chemicals, and is highly effective for recovering coarse particles in free-milling and placer gold deposits.

- Key Equipment: Gravity Separation Tables, Sluice Boxes, Spiral Concentrators, Jigs.

3. Froth Flotation

- Principle: This elegant method is the workhorse for treating refractory ores where gold is attached to sulfide minerals. It works by chemically modifying the surface of the sulfide mineral particles to make them hydrophobic (water-repellent). These waterproof particles will then attach to air bubbles and float to the surface, creating a gold-rich froth.

- Process Flow: The ore is ground to a very fine powder and mixed into a slurry with water inside a flotation cell. Specific chemical reagents are added. A “collector” makes the target mineral waterproof, a “frother” creates stable bubbles, and sometimes a “depressant” is used to prevent other minerals from floating. Air is pumped through the mixture, and the valuable froth is skimmed off the top as a high-grade concentrate.

- Advantages: It is a highly efficient way to concentrate value from low-grade and complex sulfide ores, turning uneconomic material into a valuable feedstock for a smelter or a specialized leaching circuit.

- Equipment and Reagents: Flotation Cells, Grinding Mills, Reagent Dosing Systems.

4. Melting Method (Smelting)

- Principle: Smelting uses extremely high temperatures—often above 1,200°C (2,200°F)—to melt a high-grade gold concentrate. In this molten state, the different materials separate according to their density. The incredibly heavy liquid gold sinks to the bottom, while the much lighter molten rock and fluxing agents form a worthless layer called “slag” on top.

- Process Flow: The gold concentrate (from flotation or gravity separation) is mixed with fluxing agents like borax and silica. The flux acts like a cleaning agent, helping to lower the melting point and chemically gather the impurities into the slag. This mixture is heated in a furnace until everything is liquid. The slag is poured off, and the molten gold is then poured into molds to create semi-pure doré bars.

- Advantages: It is a direct and relatively fast method to produce a tangible, high-purity gold product directly from a concentrate.

- Key Equipment: Smelting Furnaces, Crucibles, Pouring Molds.

Choosing the correct method is the single most important technical decision you will make. It absolutely must be based on a professional metallurgical test of your specific ore.

- For placer deposits or hard rock with coarse, free-milling gold, your primary method should be Gravity Separation. It is the cheapest and greenest way to recover the bulk of your value.

- If your gold is locked in sulfide minerals like pyrite, you will need Froth Flotation. This is not an optional step; it is the only way to effectively concentrate that type of ore before further treatment.

- For vast, low-grade deposits with finely disseminated gold, Cyanide Leaching (often Heap Leaching) is the global industry standard. It is the most economically viable technology at that scale.

- If you have produced a high-grade concentrate from flotation or gravity, Smelting is the final step to turn that powder into a solid, transportable metal bar.

No extraction process is 100% efficient; some gold is always lost to the waste stream, known as “tailings.” The recovery rate is a key performance indicator for any mine. A modern, well-run cyanide leaching plant can achieve recovery rates of 95% or higher. A simple gravity circuit might recover 60-80% of the gold in a suitable free-milling ore. The goal of a well-designed processing plant, like the complete solutions we engineer at ZONEDING, is to maximize this recovery rate. Even a 1% improvement in recovery can translate into millions of dollars in additional revenue for a large mining operation.

What’s the Environmental Cost of These Methods?

The environmental impact of gold mining is a significant global concern that requires rigorous engineering and management.

- Leaching: Cyanide is highly toxic, so modern operations are built as zero-discharge systems. This includes using heavy-duty impermeable liners for heap leach pads and having a dedicated detoxification circuit to neutralize the cyanide in the tailings before they are stored.

- Waste Rock: Mining can expose rock that contains sulfides. When these sulfides react with air and water, they can create sulfuric acid, a phenomenon known as Acid Rock Drainage (ARD). This must be carefully managed through water treatment and proper storage of waste rock.

- Water Usage: Processing ore uses a lot of water. Sustainable mines invest heavily in water recycling systems to minimize their demand for fresh water.

The doré bars produced at the mine site are not pure gold. They are an alloy containing gold, silver, and other trace metals. These bars are securely transported to a specialized, high-security refinery. There, advanced processes like the Miller Process (using chlorine gas to remove impurities) or the Wohlwill Process (using electrolysis) are employed to separate the metals. This final refining step is what produces the investment-grade gold bars that are 99.9% or even 99.99% pure.

What’s the Safest and Most Sustainable Gold Extraction Method?

Unquestionably, gravity separation is the safest and most sustainable gold extraction method. It operates purely on the physical principle of density, using only water and mechanical motion. It completely avoids the use of hazardous chemicals like cyanide or mercury, which eliminates the primary source of environmental risk in gold processing. However, its major limitation is that it only works effectively on free-milling ores where the gold particles are coarse enough to be liberated. It cannot recover microscopic gold. Therefore, the most sustainable overall strategy is often an integrated one: use gravity separation as the first step to recover as much gold as possible, thereby reducing the volume of material that requires more energy and chemical-intensive treatment later.

FAQ

- What is the difference between gold mining and extraction?

- Gold mining refers to the entire activity of getting the ore out of the ground (e.g., digging, blasting, hauling). Gold extraction, also called processing or metallurgy, refers specifically to the technical steps taken after the ore is mined to separate the valuable gold from the waste rock.

- Can you attempt gold extraction from rock at home?

- While you can try panning (a basic form of gravity separation) in a stream as a hobby, it’s not practical or safe for hard rock. Chemical methods are extremely dangerous, require industrial controls, and are heavily regulated. It is not recommended to attempt this at home.

- What is the minimum gold grade that is profitable to mine?

- This is the “million-dollar question” with no single answer. It depends on the price of gold, the depth of the ore, the type of ore (free-milling is cheaper to process), local labor costs, and the scale of the operation. A huge open-pit mine in a low-cost jurisdiction might be profitable at 0.4 g/t, while a small underground mine in a remote, high-cost area might need 8 g/t to break even.