全站搜索

Search the entire website

Search the entire website

Choosing the wrong crusher is a costly mistake that can lead to production bottlenecks, high operating costs, and a final product that doesn’t meet specifications. A roll crusher is a powerful and versatile machine, but it’s not a one-size-fits-all solution. It excels in specific situations where other crushers might struggle, especially for less abrasive materials and when you need to minimize the creation of fine particles.

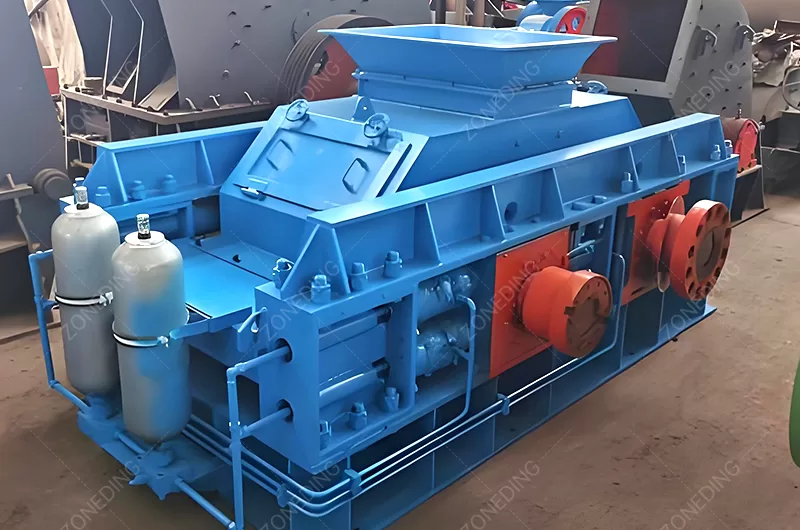

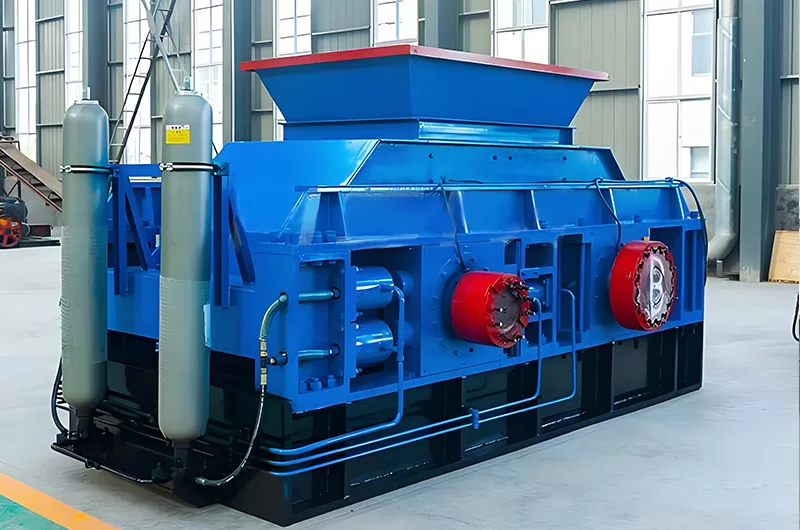

So, how do you know if a roll crusher is the right choice for you? And if it is, how do you select the perfect configuration? As a manufacturer that has designed and delivered these machines to over 120 countries, we’ve guided hundreds of clients through this exact process. It all comes down to asking the right questions before you buy. This checklist of 10 essential questions will give you the confidence to select a machine that perfectly matches your goals and delivers maximum value.

At its core, a roll crusher is a machine that reduces the size of materials through compression. Imagine a giant, industrial-strength pasta maker. Instead of dough, you feed it rock, coal, or other materials. The material is caught and squeezed between one or two heavy, rotating cylinders (rolls) until it fractures and passes through. This simple, robust mechanism is its greatest strength.

The crushing action is purely compressive. The rolls grip the material and pull it into the narrowing gap between them, where immense pressure is applied. This is fundamentally different from an impact crusher (like a hammer crusher) which shatters rock through high-speed collisions. The key benefit of this gentle compression is that it creates very few fine particles (dust). This is vital in industries like coal, where fines are less valuable, or in producing specialized aggregates.

There are two main types you will encounter:

The surfaces of these rolls can be smooth, corrugated, or toothed, which is a critical design choice tailored to the specific material being processed.

In the world of mineral processing and aggregate production, every equipment choice is an investment that directly impacts your profitability. Choosing a crusher isn’t like buying a standard vehicle; it’s a strategic decision. The wrong roll crusher can become a drag on your entire operation, leading to a cascade of negative financial consequences that ripple through your entire business.

Here’s why getting it right is so critical:

Work through this checklist with your team and potential suppliers. The answers will directly lead you to the ideal machine for your operation.

This is the most important question. You must know your material’s hardness, abrasiveness, and moisture content. A roll crusher’s performance is entirely dependent on its compatibility with your feed. At ZONEDING, we always start here, often requesting a material sample for analysis.

Hardness (Mohs Scale): Roll crushers excel with soft to medium-hard materials. Pushing them to crush very hard rock leads to extreme wear and potential damage.

| Mohs Hardness | Material Example | Suitability for Roll Crusher |

|---|---|---|

| 1-3 | Talc, Gypsum, Coal, Clay | Excellent |

| 3-5 | Limestone, Phosphate, Shale | Very Good (Ideal Application) |

| 5-6 | Apatite, Softer Ores | Good (Requires durable rolls) |

| 7+ | Quartz, Granite, River Rock | Not Recommended (Use Jaw/Cone) |

Abrasiveness: A material can be soft but highly abrasive (like some sandstones). High abrasiveness will rapidly wear down the roller surfaces, increasing your maintenance costs. Be honest with your supplier about this.

Moisture & Stickiness: High moisture can cause fine, sticky material to “cake” or build up on smooth rolls, reducing efficiency. If your material is sticky, a toothed roll crusher is often a better choice as the teeth provide a positive grabbing and self-cleaning action.

You need to know your maximum feed particle size and the exact product size you want. This determines the crusher’s required “reduction ratio” and roll diameter. Roll crushers are typically secondary or tertiary crushers with a reduction ratio of 3:1 to 4:1. This means if your max feed is 120mm, you can reliably crush it to 30-40mm.

A key technical concept here is the Nip Angle. This is the angle formed by the tangents to the roll surfaces at the point where they first grip a particle. If this angle is too large, the rolls will slip and fail to pull the material down. A larger roll diameter creates a smaller, more favorable nip angle, allowing it to grab a larger piece of feed. This is why knowing your maximum feed size is critical for the supplier to select the right roll diameter for you.

Your required throughput (TPH) dictates the physical size (width and diameter) of the crusher. The theoretical capacity can be estimated, but it’s crucial to understand it’s only a starting point.

The actual capacity you achieve will be lower and depends heavily on:

Always give your supplier your target average TPH and your required peak TPH. At ZONEDING, our engineers use this information to size a machine with a comfortable safety margin, ensuring it never becomes a production bottleneck.

This is a critical customization decision. The roller surface must match your material and crushing goal.

While the double roll crusher is used in over 90% of applications due to its superior control and efficiency, the single roll crusher has a specific niche. It excels with extremely sticky materials that might pack and bridge the gap in a double roll design. The action of the single roll against a stationary plate helps shear and break up these challenging materials more effectively. For most mining and aggregate applications, however, the double roll configuration is the correct choice.

Your crusher must have a robust protection system to handle “tramp” metal (like an excavator tooth) or uncrushable rock. Without it, you are risking catastrophic failure.

All ZONEDING roll crushers are equipped with one of these robust systems as a standard feature.

The roller surfaces (shells) are your primary wear components. Their material composition dictates their lifespan and your long-term operating cost. High-manganese steel (14% Mn and higher) is the industry standard because it work-hardens. The constant impact and pressure from crushing makes the surface harder and more wear-resistant over time.

However, for specific applications, other materials might be better. For highly abrasive but low-impact scenarios, high-chromium iron shells can offer superior wear life. As a manufacturer, we consult with you on your specific material to recommend the optimal alloy, ensuring you get the best balance of performance and cost-per-ton.

The mechanism for adjusting the gap between the rolls should be precise, safe, and easy to use.

A roll crusher is relatively simple, but disciplined maintenance is key to its longevity. Regular lubrication of the bearings is the most critical task. You need a clear schedule from your supplier.

| Frequency | Task | Why It’s Important |

|---|---|---|

| Daily | Visual inspection for cracks, loose bolts. Listen for unusual noises. | Catches small problems before they become major failures. |

| Weekly | Grease all bearings per manufacturer’s specifications. | Prevents bearing failure, the most common cause of major downtime. |

| Weekly | Check drive belt tension and condition. | Ensures efficient power transmission and prevents slippage. |

| Monthly | Inspect roller shell surfaces for wear patterns. | Helps you plan for rotations or replacements and spot uneven feed issues. |

| Monthly | Check oil levels in gear reducers (if applicable). | Protects the drivetrain from premature failure. |

For a B2B buyer importing from China, this question is about long-term partnership and trust. A machine is only as good as the support behind it. When a wear part needs replacing, you cannot afford to wait weeks for a shipment.

As a factory-direct global supplier, ZONEDING maintains detailed records of every machine sold. We know your exact roller shell specifications and bearing types. We maintain a stock of critical spares and have a streamlined logistics process to get them to you quickly. Before you buy, ask the supplier: “If I need a new set of roller shells in 18 months, what is the process and how long will it take?” The answer will reveal their commitment to your long-term operational success.

As a factory-direct manufacturer with experience in over 120 countries, we provide more than just a machine; we provide a complete, customized solution. At ZONEDING, our engineers work with you to answer these very questions. We analyze your material and guide you to the perfect configuration—smooth or toothed, with the right alloy for your roller shells. Our robust construction, use of stress-relieved frames, and commitment to high-quality wear parts ensure you receive a durable, high-performance machine that delivers a fast return on your investment. We don’t just sell mineral processing equipment; we build long-term production partnerships.

Selecting the right roll crusher is a strategic decision that pays dividends for years. By systematically working through these 10 questions, you transform yourself from a simple buyer into an informed partner in the specification process. You ensure that the machine you invest in is perfectly aligned with your material, your production goals, and your operational realities.

Ready to find the perfect crushing solution for your plant? Contact our engineering team today to start the conversation.

Learn the working principle of a vibrating screen. This guide lists key components, the process of stratification and sizing, and how it separates materials.

View detailsLooking for the best rock crusher for gold? Our guide compares Jaw, Cone, and Hammer Mill crushers to maximize your gold recovery from hard rock.

View detailsFeeling overwhelmed by vibrating feeder options? Follow 7-step checklist to select the perfect model based on material size, capacity, and operating conditions.

View detailsLearn the secrets to maximizing profit for Stone crushing business, from choosing the right crusher equipment to managing logistics and wear parts costs.

View details