全站搜索

Search the entire website

Search the entire website

A vibrating screen stands as a fundamental piece of equipment in the mineral processing and aggregate industries. Its primary function is to separate materials based on size. Understanding how this machine operates is key to optimizing production and ensuring product quality. This guide provides a simple, clear explanation of the vibrating screen working principle. It covers its core components and the precise steps involved in the material separation process.

ZONEDING designs these machines for maximum efficiency and reliability in demanding environments.

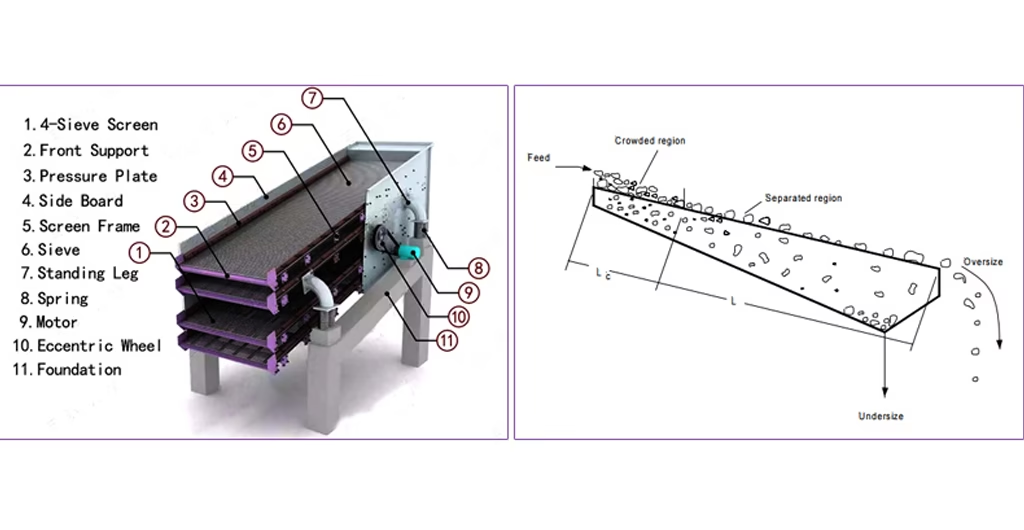

To understand how a vibrating screen works, it is essential to first know its main components. Each part plays a specific role in creating the motion and separation needed for effective sizing. A robust design of these components ensures long service life and consistent performance.

The coordinated action of these parts allows the vibrating screen to perform its sizing function with high precision. ZONEDING engineers its vibrating screens with durable materials and advanced engineering. This ensures that each component can withstand the high-stress conditions of continuous operation in mining and aggregate production, delivering reliable performance day after day.

The screen box, or screen deck, is the main frame that holds the screen mesh. It is a rigid, rectangular structure built to endure constant vibration and the impact of heavy materials. The design of the screen box is critical for distributing vibrational forces evenly across the entire screening surface.

The screen mesh is the surface where material separation actually occurs. It is made of woven wire, polyurethane, or rubber and has precisely sized openings (apertures). Material smaller than the apertures passes through, while larger material is retained on top. The choice of mesh material depends on the application, abrasiveness of the material, and required sizing accuracy.

The vibration system is the heart of the vibrating screen. This component, also known as an exciter or vibrator, generates the rapid motion needed to separate materials. It typically consists of an eccentric shaft or unbalanced weights that rotate at high speed. This rotation creates a powerful centrifugal force, causing the entire screen box to vibrate in a specific pattern (linear or circular).

The screen box is mounted on a set of heavy-duty springs. These springs serve two critical purposes. First, they isolate the intense vibrations of the screen box from the support structure, preventing this energy from transferring to the surrounding plant and foundation. Second, they allow the screen box to move freely in its intended pattern, enhancing screening efficiency.

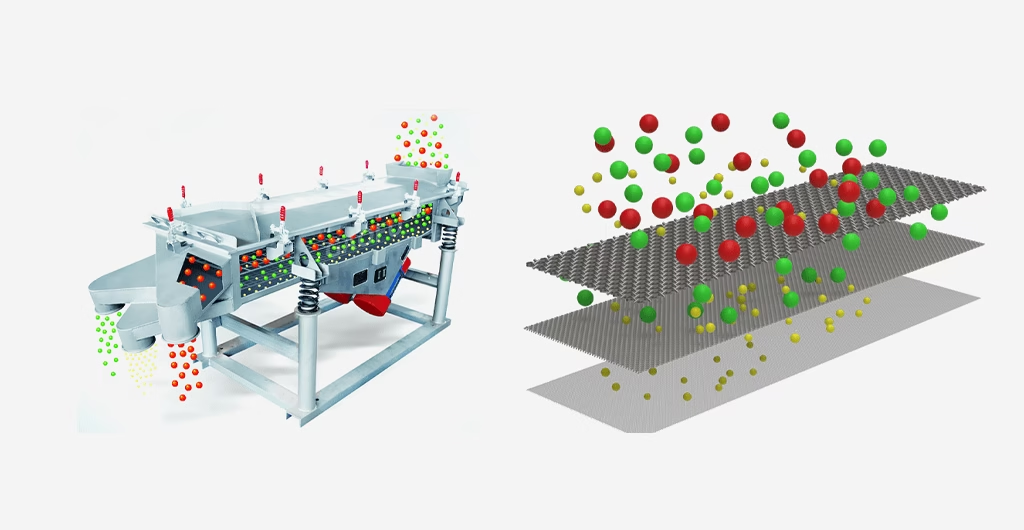

The vibrating screen working principle can be broken down into a simple, three-stage process. This sequence ensures that materials are classified accurately and efficiently based on their size. Each step is a direct result of the machine’s controlled vibration.

The entire process happens in a continuous flow, allowing a vibrating screen to process large volumes of material quickly. The efficiency of this process depends on factors like the vibration frequency, amplitude, and the angle of the screen deck. ZONEDING designs its vibrating screens with adjustable parameters. This allows operators to fine-tune the machine for specific materials and achieve optimal separation performance in any application.

The process begins when material is fed onto the upper end of the inclined screen deck. As soon as the material contacts the screen, the powerful vibration forces it to move. This rapid agitation causes the material bed to expand and stratify. Stratification means the smaller particles work their way down through the gaps between larger particles, moving closer to the screen mesh surface. The larger particles rise to the top of the material bed. This natural segregation is critical for efficient screening.

As the stratified material travels down the length of the screen deck, the smaller particles at the bottom encounter the screen mesh openings. Particles smaller than the apertures pass through the screen and are collected as fines or undersize product. Particles larger than the apertures cannot pass through. They are retained on the screen surface and continue to travel down the deck. This is the core sizing or separation step. The probability of a particle passing through the mesh depends on it having multiple opportunities to encounter an opening.

The vibration not only causes stratification and sizing but also serves to convey the material along the screen deck. The angle of the vibration and the incline of the deck work together to move the oversized material steadily toward the discharge end. Once at the end, the oversized particles fall off the screen into a separate chute or onto a conveyor belt. The machine effectively separates the initial feed into at least two products: undersize (fines) and oversize (coarse). Multi-deck screens can produce several sized products simultaneously.

Achieving optimal performance from a vibrating screen depends on several key operational factors. Properly managing these variables ensures high throughput, accurate sizing, and a long service life for the equipment. A well-tuned screen directly translates to a more profitable operation.

Adjusting these factors is crucial for adapting to different types of rock, sand, or ore. For instance, screening moist, sticky material requires a different setup than screening dry, free-flowing aggregates. The experts at ZONEDING provide technical guidance to help customers configure their vibrating screens for specific operational challenges. This ensures the mineral processing equipment delivers maximum efficiency and productivity.

| Factor | Description | Impact on Efficiency | How to Optimize |

|---|---|---|---|

| Vibration Characteristics | Includes amplitude (stroke), frequency, and type of motion (linear vs. circular). | Determines how aggressively the material is agitated and conveyed. | Adjust exciter settings based on material type and desired throughput. |

| Deck Angle (Incline) | The angle at which the screen box is installed. | A steeper angle increases material travel speed but reduces screening efficiency. | Find the optimal angle that balances throughput with sizing accuracy. |

| Material Properties | Includes particle size, shape, density, and moisture content. | Sticky or wet material can blind the screen mesh, reducing efficiency. | Use appropriate screen media (e.g., polyurethane) and consider water sprays. |

| Feed Rate | The volume of material fed to the screen per hour. | Overloading the screen reduces stratification and sizing accuracy. | Maintain a consistent feed rate that matches the screen’s capacity. |

| Screen Media Selection | The type of mesh and the size/shape of its apertures. | Incorrect aperture size leads to inaccurate product. Worn media reduces efficiency. | Choose the right media for the application and conduct regular inspections. |

Vibrating screens come in various designs, each tailored for specific applications and stages in the processing circuit. Choosing the right type of screen is essential for building an efficient workflow. The primary distinction lies in the motion they generate.

ZONEDING offers a comprehensive portfolio of both circular and linear motion vibrating screens. This allows the company to provide the ideal screening solution for any application, whether it’s for heavy-duty primary scalping in a mine or fine sizing in a sand washing plant. The selection process always starts with a analysis of the customer’s material and production goals, ensuring the your screening equipment is a perfect fit.

A circular vibrating screen is often for primary and secondary screening applications. Its exciter is mounted in the center of the screen box, generating a circular or elliptical motion. This motion is very effective at moving heavy loads and handling coarse materials. It is a robust and simple design, making it a popular choice for scalping (removing oversized rock before primary crushing) and classifying aggregates, coal, and various ores.

A linear vibrating screen uses two exciters that rotate in opposite directions. This synchronized movement cancels out horizontal forces and produces a straight-line, reciprocating motion. This linear action propels material forward effectively, making it ideal for applications that require high drainage rates, such as dewatering sand or classifying fine, wet materials. They are also used for fine sizing where high accuracy is paramount.

Even with robust construction, the demanding nature of screening means that operational issues can arise. Identifying and addressing these problems quickly is crucial for minimizing downtime and maintaining productivity. Most issues can be traced back to maintenance, operation, or component wear.

A proactive maintenance schedule is the best defense against unexpected breakdowns. Regular inspections of the screen mesh, springs, and motor are essential. ZONEDING not only supplies durable vibrating screens but also provides comprehensive after-sales support and spare parts services. This commitment helps clients maintain their complete production line at peak performance, ensuring long-term operational success.

ZONEDING stands as a leading manufacturer of mineral processing equipment, offering unmatched expertise in screening technology.

For a screening solution that delivers on reliability and efficiency, choose ZONEDING.

The vibrating screen is an indispensable tool in modern material processing. Its working principle, though based on simple mechanical motion, is highly effective for classifying vast quantities of material with precision. By understanding its key components and the factors that influence its performance, operators can maximize their plant’s efficiency and profitability.

From the robust screen box to the powerful exciter, each part works in harmony to stratify, size, and convey material. Proper selection, installation, and maintenance are critical for achieving consistent results. Whether for coarse scalping in a quarry or fine dewatering of sand, the vibrating screen is a testament to powerful, efficient engineering.

For any operation looking to improve its screening process, partnering with an experienced manufacturer is key. The right equipment and expert support can make all the difference.

A clear guide to the coal mining. Learn key stages: mining, preparation (cleaning), transportation, pulverization, and combustion for electricity generation.

View detailsThis essential guide clarifies the 7 most common types, their pros, cons, and ideal uses to help you make an informed decision for your processing operations.

View detailsEverything about the two main types of mining. This guide covers the definitions, techniques, pros, cons,methods of both surface mining and subsurface mining.

View detailsHow does it really work? We go beyond the basics to detail the roles of the vibrating screen, sand washer, hydrocyclone, and dewatering screen in the process.

View details