全站搜索

Search the entire website

Search the entire website

Dive into the detailed steps of a sand washing process. Understand how sand washers, dewatering screens, and other machinery work together to achieve optimal sand cleaning and classification.

ZONEDING designs and builds machines. These machines ensure our customers get the best sand possible. This guide explains the sand washing process. It covers the essential steps. It also shows the equipment and technology we use. We focus on transforming raw sand into a clean, classified product. This helps you understand how we achieve optimal sand quality.

Sand washing plays a vital role in producing high-quality construction materials. Raw sand, directly extracted from natural deposits, often contains a mixture of impurities. These include clay, silt, dust, and organic matter. If you use unwashed sand in concrete or asphalt, these contaminants can severely compromise the strength and durability of the final product. Imagine building a structure with weak foundations – that is the risk with impure sand. Sand cleaning eliminates these harmful substances. It ensures the sand meets stringent specifications required by engineers and builders. This process directly impacts the safety and longevity of infrastructure projects. ZONEDING MACHINE provides the specialized equipment that makes this essential cleaning possible. The company helps ensure the foundational quality of construction materials.

Clean sand offers significant benefits. It creates stronger concrete because it binds effectively with cement. It also ensures better compaction in asphalt mixes. This prevents premature wear and tear on roads. Additionally, clean, well-graded sand commands a higher market value. Aggregates producers can charge more for a superior product. This boosts profitability. By investing in an efficient sand washing process, you invest in product quality and business sustainability. ZONEDING’s solutions focus on maximizing both your output quality and operational efficiency. The company offers solutions that deliver superior sand production for your projects.

Raw sand often carries various undesirable elements. Clay and silt particles, which are very fine, adhere to sand grains. They can prevent proper adhesion between aggregate and cement in concrete. This leads to reduced strength and increased porosity. Organic matter interferes with the curing process of cement, causing delays and weaknesses. Other materials like mica or shells can also impact durability. These impurities can absorb water, affecting the water-cement ratio in concrete. This results in inconsistent mixes. Effective sand cleaning removes these detrimental components. This leaves behind only the strong, inert sand grains required for reliable construction materials.

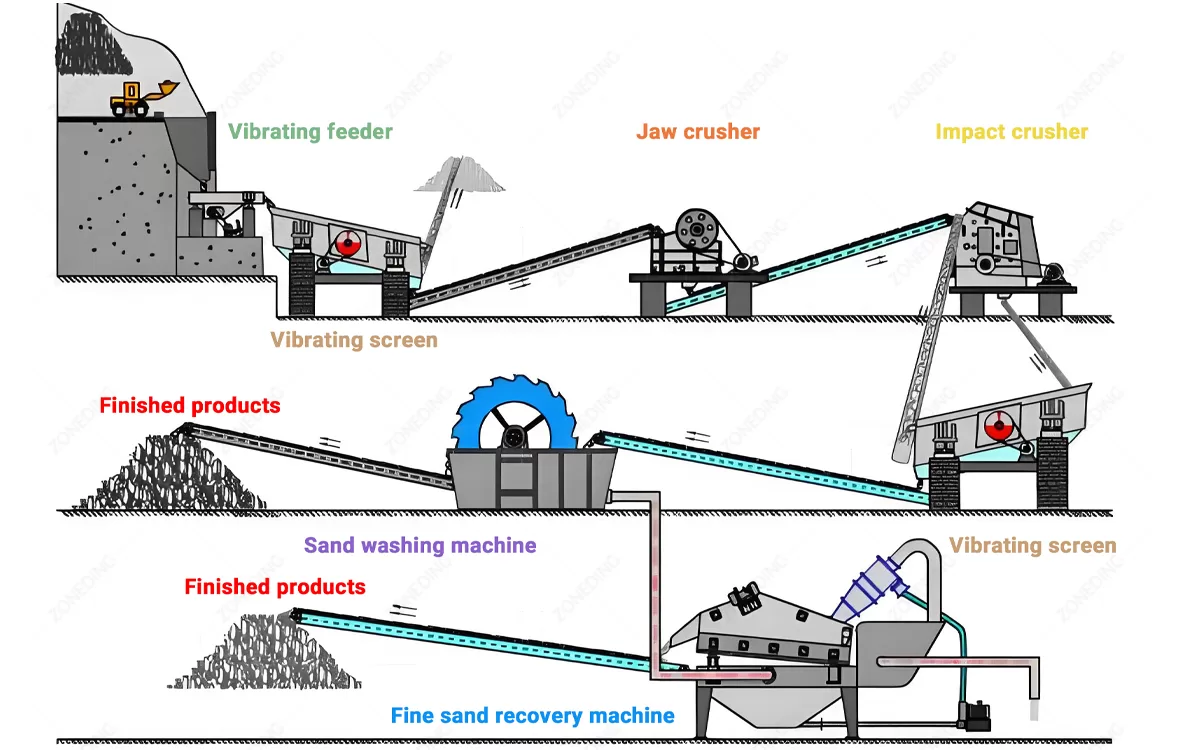

The sand washing process follows a systematic sequence of steps. Each step plays a crucial role in transforming raw, impure sand into high-quality, usable material. This journey typically begins with feeding the raw sand into the system. Next, it undergoes vigorous washing to remove contaminants. After washing, the sand needs efficient dewatering. This reduces its moisture content. Finally, it may pass through an additional classification stage. This organizes it into specific size grades. This integrated approach ensures thorough sand cleaning and optimal final product quality. ZONEDING provides robust machinery for every stage of this process. The company designs complete production line solutions that ensure a continuous and efficient flow from raw material to finished product.

This structured workflow is vital for any successful aggregate production operation. Bypassing any step can compromise the sand’s quality. For instance, insufficient washing leaves impurities. Poor dewatering makes the sand too wet for immediate use. ZONEDING helps you engineer a seamless workflow. This maximizes both efficiency and the quality of your output. We ensure your sand washing process meets industry standards.

The sand washing process begins with feeding raw sand into the system. This often involves using a hopper and a feeder. The feeder regulates the flow of raw material into the subsequent washing equipment. Consistent and controlled feeding is essential. It prevents overloading the washing machinery. It also ensures efficient processing. An uneven feed reduces both the quality of sand cleaning and the overall production capacity. ZONEDING offers various feeding solutions. These guarantee a steady supply of raw material for your aggregate production. This sets the stage for an effective washing operation.

At the heart of the sand washing process lies the sand washer. ZONEDING offers a range of high-performance sand washers, primarily screw sand washers and wheel sand washers. These machines are engineered to effectively agitate raw sand with water. This action separates fine impurities like clay and silt from the heavier sand particles. The impurities then mix with water. They are carried away as slurry. This leaves behind cleaner sand. A screw sand washer, for instance, uses a rotating screw to continuously move material upwards, against a flow of water. This creates intense scrubbing action.

Wheel sand washers use rotating buckets or paddles to scoop, tumble, and discharge sand while constantly exposing it to cleaning water. Both types provide excellent sand cleaning. Your choice depends on factors like the raw material characteristics, desired output quality, and specific capacity requirements. ZONEDING’s robust designs ensure maximum cleaning efficiency. They also provide minimal wear and tear. This means more uptime and lower operational costs for your aggregate production. We custom-tailor solutions to match your exact project needs.

Choosing between screw and wheel sand washers depends on your specific sand cleaning needs. Consider the table below:

| Feature | Screw Sand Washer | Wheel Sand Washer | Your Advantage |

|---|---|---|---|

| Capacity | Higher capacity, ideal for continuous large-scale | Medium capacity, good for various applications | Matches your scale, ensures consistent output |

| Fines Recovery | Excellent for recovering fine sand | Good for recovering fine sand, less susceptible to loss | Maximizes valuable sand recovery, minimizes waste |

| Water Content | Produces slightly wetter sand post-wash | Slightly lower water content post-wash | Reduces subsequent dewatering needs |

| Maintenance | Robust design, simple maintenance | Easy to maintain, fewer moving parts in water | Ensures longer lifespan, lower operational costs |

| Application | Best for very fine sand, sand production | Versatile for various sand types and classification | Meets diverse project requirements, enhances flexibility |

After the sand washing process, the sand contains a significant amount of water. This makes it unsuitable for immediate use in many construction applications. Efficient dewatering becomes critical at this stage. It reduces moisture content to an acceptable level. This ensures the sand is dry enough for transport, storage, and use. High moisture content adds unnecessary weight for transportation. It also affects mixing properties in concrete production. Dewatering screens are specifically designed for this purpose. They represent a key part of the modern sand washing process.

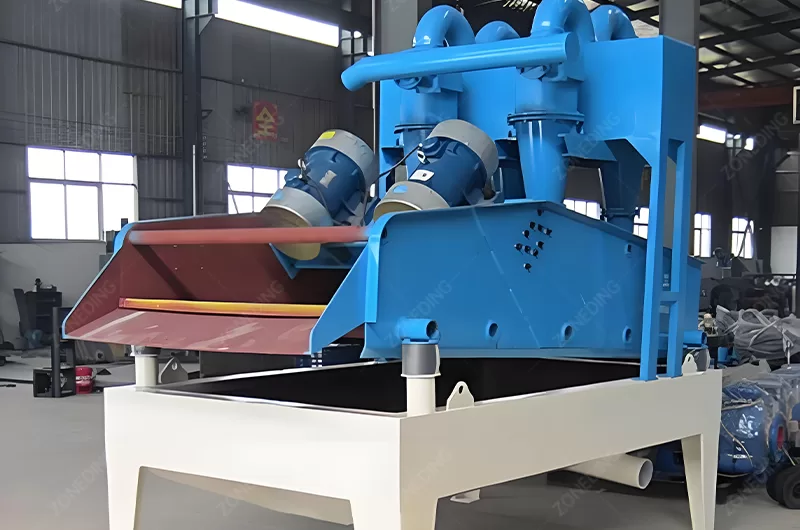

These machines effectively separate water from the clean sand. This prepares the sand for its next destination. ZONEDING provides advanced dewatering solutions. These include vibratory dewatering screens. These solutions help you achieve optimal moisture levels. This ensures your final sand product is ready for use. It enhances the overall efficiency of your sand production.

Dewatering screens operate using high-frequency vibration. This motion allows water to drain rapidly through the screen mesh. Vibrations consolidate the sand particles. This results in a drier product. These screens significantly reduce the moisture content of washed sand. Typical moisture levels can drop from 20-30% down to 10-15%. This impacts the cost efficiency of your sand production. It saves on transportation costs and prepares the sand for immediate use. ZONEDING’s dewatering screens are built for durability and high performance. They integrate seamlessly into your sand washing process. This maximizes your plant’s throughput.

After washing and dewatering, the sand is clean. However, it still needs classification into specific size ranges. Different construction applications require different aggregate sizes. For example, fine sand works best for plastering, while coarser sand suits concrete mixes. This classification stage ensures the sand meets precise project specifications. It maximizes the value of your output. Effective classification uses specialized screening equipment. This separates the sand into distinct grades. ZONEDING offers a variety of high-efficiency screening equipment for this crucial final step in the sand washing process.

Efficient classification directly impacts the usability and marketability of your sand. Properly graded sand leads to superior performance in its end application. It also prevents waste. You can effectively utilize all valuable fractions for different purposes. ZONEDING’s solutions help you achieve precise grading results. This enhances the overall quality and versatility of your sand production.

Vibrating screens are primarily used for sand classification. These machines feature multiple decks, each with a different mesh size. As washed sand vibrates across these decks, smaller particles pass through finer meshes. Larger particles retain on coarser meshes. This separates the sand into distinct factions. For example, a three-deck screen might produce three different sand grades simultaneously. Selecting the correct mesh sizes requires consideration of the desired final product specifications. Factors like screen amplitude, frequency, and inclination are also optimized for precise classification. ZONEDING designs and supplies robust efficient screening equipment: vibrating screens. These provide reliable and accurate sand grading for any construction requiremen

The sand washing process constantly evolves with new technologies and sustainability initiatives. In 2025, several key trends shape the future of sand production. These advancements aim for greater efficiency, reduced environmental impact, and higher product consistency. Staying updated helps you maintain a competitive edge and optimize your operations. ZONEDING continuously integrates these innovations into its mineral processing equipment and complete production line designs.

These trends focus on smarter, more flexible operations. They address challenges like escalating energy costs and increased environmental regulations. Technology plays an increasingly vital role in achieving better sand cleaning and classification.

The sand washing process stands as a non-negotiable step for producing high-quality sand. This material is crucial for a wide range of construction materials. We have explored each critical stage, from initial feeding and intensive sand cleaning to efficient dewatering and precise classification. Understanding these steps helps you appreciate the engineering behind superior sand. Investing in the right sand washers, dewatering screens, and associated equipment means investing in the strength and longevity of your construction projects. It also boosts your operational profitability.

To maximize your success, choose a supplier who understands the nuances of sand processing. A good partner offers robust, efficient, and technologically advanced solutions. They also provide comprehensive support throughout your project life cycle. Embrace the latest trends like automation and water recycling. This ensures your sand production remains both competitive and sustainable.

To build or upgrade your sand washing process for optimal efficiency and output, contact ZONEDING today for expert advice and a customized equipment solution!

Learn how stone crushers are operated to convert rocks into uniform sand. This guide covers setup, material flow, and control strategies for sand production.

View detailsExplore the main types of vibrating screens. Learn how to choose the right screening equipment for mining & aggregate project. ZONEDING is your expert supplier.

View detailsKeep your plant running efficiently. This crusher maintenance checklist covers critical daily inspections, weekly lubrication, and monthly wear part checks.

View detailsThis article explains origins and unique properties of perlite, applications, industrial perlite processing chain from mining to final screening & grading.

View details