Recycled concrete aggregate (RCA) transforms waste concrete into valuable raw material. This process is crucial for sustainable construction. It reduces landfill burden. It also conserves natural resources. Efficient RCA processing enhances material quality. It ensures compliance with industry standards. This guide covers the complete workflow. It includes crushing, screening, grading, and quality control. It explains how to produce high-quality eco-friendly aggregate.

The construction industry generates vast amounts of concrete waste. Recycling this waste offers significant environmental and economic benefits. Waste concrete can become a viable alternative to natural aggregate. ZONEDING supplies robust crushing and screening equipment. This equipment is essential for efficient recycled concrete aggregate production.

Table of Contents

What is Recycled Concrete Aggregate (RCA) and Why is it Important?

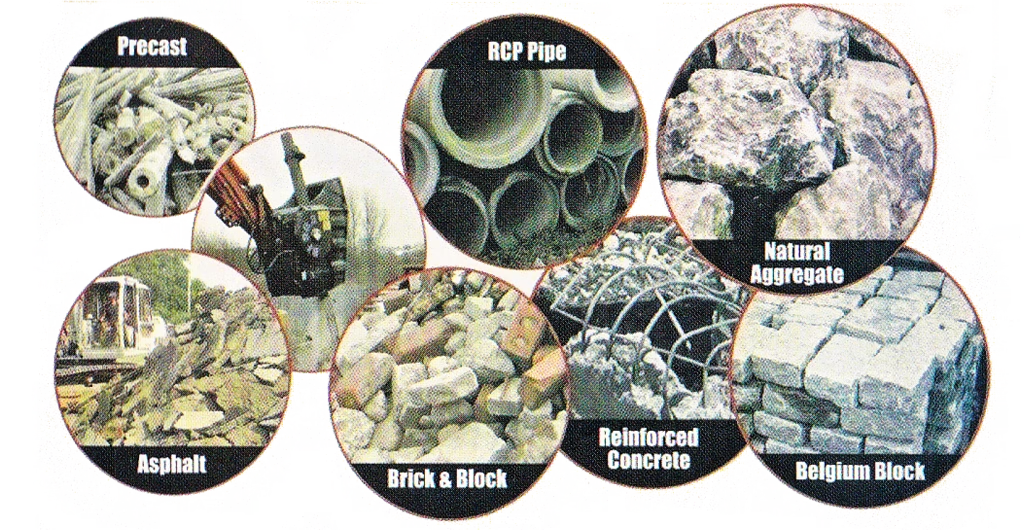

Recycled concrete aggregate (RCA) is a granular material. It comes from crushed, processed concrete demolition waste. This waste often includes rubble from buildings, roads, and bridges. RCA serves as a sustainable substitute for natural aggregate. It is used in construction projects. Its production is a key part of the circular economy.

The importance of RCA grows steadily. Natural aggregate sources deplete. Environmental concerns over quarrying increase. RCA offers a practical solution. It reduces virgin material demand. It also minimizes waste disposal in landfills. Proper RCA processing is vital. It guarantees the quality and performance of the recycled product.

Benefits of Using Recycled Concrete Aggregate (RCA)

Using RCA offers multiple advantages for various projects.

- Environmental Impact Reduction: RCA minimizes landfill waste. It lowers the demand for virgin aggregate. This protects natural landscapes. It also reduces carbon emissions from quarrying and transportation.

- Cost Savings: Sourcing RCA locally can reduce material costs. It also cuts transport expenses compared to new aggregate. The availability of waste concrete is widespread.

- Resource Conservation: Recycling concrete conserves finite natural resources. It supports a more sustainable construction industry. This aligns with global ecological goals.

- Performance: High-quality RCA performs well in many applications. It can be used for road bases, fills, and even some concrete mixes. Its properties are carefully controlled by RCA processing.

ZONEDING’s mobile crushing stations are ideal for RCA production. They process waste concrete on-site. This maximizes benefits. It reduces transportation costs. This provides an eco-friendly aggregate solution.

What are Applications of Recycled Concrete Aggregate?

Recycled Concrete Aggregate (RCA) offers many applications across the construction sector. It serves as a sustainable, eco-friendly aggregate alternative. RCA is widely used in road construction and for drainage. It is also common as fill material. With proper quality control, it even finds its way into new concrete production. This broad utility supports resource recycling efforts. It transforms waste concrete into valuable materials for infrastructure and building projects. ZONEDING’s crushing and screening equipment processes waste concrete. This enables the production of versatile RCA for these essential uses.

Diverse Uses of Eco-Friendly Aggregate

RCA’s versatility stems from its re-engineered properties. This occurs after careful RCA processing. Its primary application lies in infrastructure development. It forms robust base and sub-base layers for roads, highways, and pavements. Its interlocking characteristic provides excellent stability. Beyond roads, RCA serves as an effective fill material for site leveling. It also backfills trenches and excavations. It offers good compaction and drainage capabilities. ZONEDING’s advanced crushing and screening equipment enables high-quality processing. This ensures versatile RCA production.

Properly processed RCA can replace a portion of virgin aggregate in certain new concrete mixes. This supports construction waste recycling. It turns demolition debris into a valuable structural component. RCA’s permeability makes it valuable for drainage systems and landscaping projects too. This reinforces its role as a truly eco-friendly aggregate.

The Complete RCA Processing Flow: From Waste to Valuable Aggregate

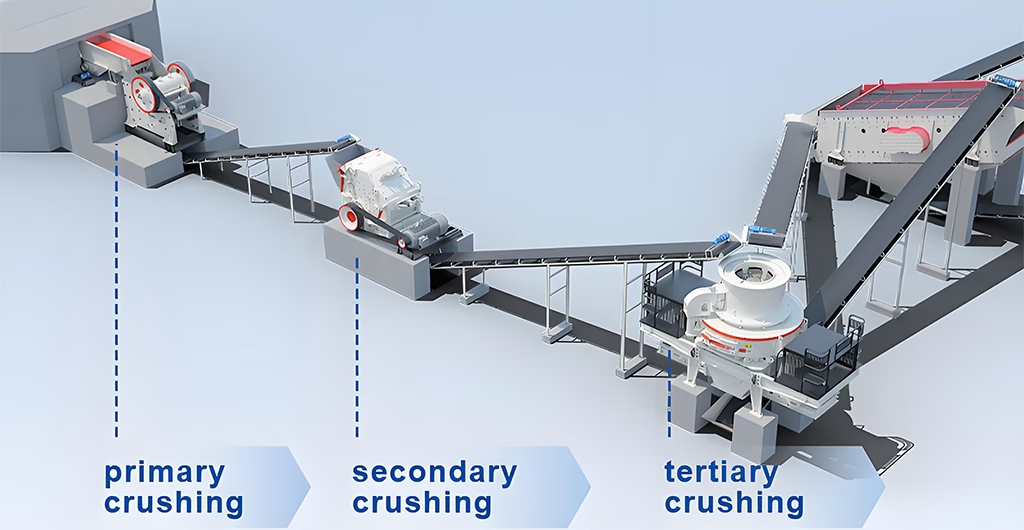

The RCA processing flow transforms demolition waste into reusable aggregate. This multi-stage process ensures material quality. It also optimizes product specifications. Each step is critical for producing reliable recycled concrete aggregate.

A well-designed RCA processing flow maximizes throughput. It minimizes energy consumption. It also maintains environmental standards. ZONEDING designs and supplies complete processing lines. These lines handle various types of waste concrete. They produce high-quality eco-friendly aggregate.

1. Demolition and Collection

This initial stage involves gathering materials needed for RCA processing.

- Source Material: Waste concrete comes from old buildings, bridges, and pavements. Demolition activities produce it.

- Pre-sorting: Large debris, steel rebar, wood, plastics, and other contaminants are removed. This step improves processing efficiency. It also protects crushing equipment from damage. Manual or mechanical sorting can occur at the demolition site. It can also happen at the processing plant feed area.

2. Primary Crushing

The collected waste concrete undergoes primary size reduction. This step is fundamental to RCA processing.

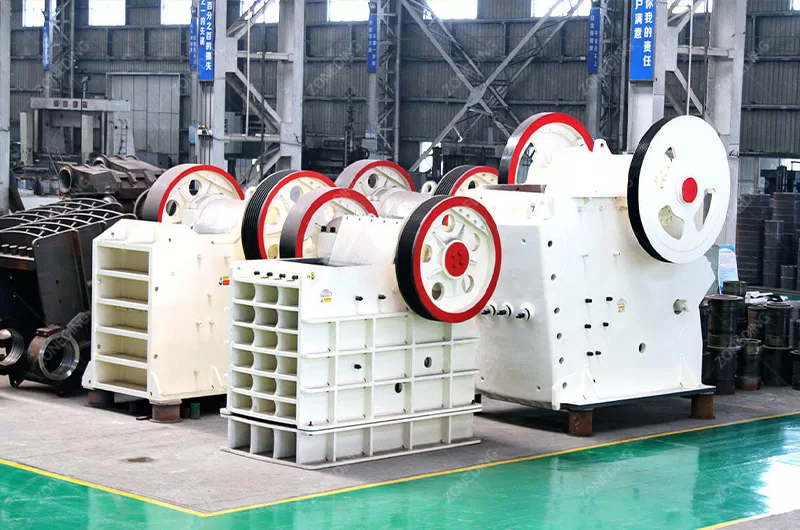

- Equipment: Large jaw crushers are commonly used here. They handle the initial breaking of large concrete pieces. They produce a more manageable size. ZONEDING’s jaw crushers are robust. They process tough waste concrete effectively.

- Purpose: Primary crushing reduces large concrete blocks. It prepares them for secondary crushing. This stage typically produces material up to 100-200 mm in size.

3. Secondary Crushing

Further size reduction occurs in this stage of the RCA processing flow.

- Equipment: Impact crushers or cone crushers are frequently employed. Impact crushers are excellent for producing cubical-shaped aggregate. Cone crushers are effective for harder concrete. ZONEDING offers both types. These machines are integral to recycled concrete aggregate production.

- Purpose: Secondary crushing reduces material to a finer, more uniform size. It helps achieve the desired particle shape. This is critical for aggregate performance. The goal is to produce material closer to the final aggregate size.

4. Screening and Separation

Material classification and contaminant removal happen concurrently in RCA processing.

- Screening: Vibrating screens separate the crushed material into different size fractions. This creates various graded aggregate products. Multi-deck screens are used for precise sizing.

- Contaminant Removal: Magnets remove steel rebar. Air classifiers or water flotation devices remove lighter contaminants. These might include wood, plastic, or foam. Efficient RCA processing ensures these impurities are minimized. ZONEDING’s vibrating screens are highly efficient. They provide accurate grading for high-quality recycled concrete aggregate.

- Purpose: This stage ensures the RCA meets grading requirements. It also removes remaining contaminants. This improves the quality of the eco-friendly aggregate.

5. Final Grading and Stockpiling

The final products are sorted and stored efficiently.

- Grading: Screened material is typically graded into different sizes. These range from fine sand to coarse aggregate. Each grade suits specific applications.

- Stockpiling: Graded RCA is stockpiled. It is ready for sale or immediate use. Careful management prevents cross-contamination.

- Purpose: This final stage ensures that the production of recycled concrete aggregate results in commercial products. These products meet various construction needs.

Key Equipment for RCA Processing

ZONEDING provides key equipment for the entire RCA processing flow.

- Mobile Crushing Plants: These integrate multiple crushing stages and screens onto one mobile chassis. They are highly flexible. They allow on-site processing of waste concrete. This significantly reduces transport costs. This is beneficial for construction waste recycling.

- Jaw Crushers: For primary crushing of large concrete blocks.

- Impact Crushers: For secondary crushing, producing well-shaped aggregate.

- Cone Crushers: For secondary/tertiary crushing, especially for harder concrete or high-volume production.

- Vibrating Screens: For accurate sizing and classification of RCA.

- Magnetic Separators: To remove ferrous metals (rebar).

- Feeders and Conveyors: To ensure continuous material flow throughout the plant.

Quality Control and Standards for RCA

Maintaining high quality in recycled concrete aggregate is essential. It ensures the aggregate’s performance. It also encourages widespread adoption. Stringent quality control measures are applied throughout the RCA processing flow. These measures ensure the final product meets specified standards.

Various national and international standards govern RCA use. These standards determine suitability for different applications. Effective RCA processing directly impacts compliance. ZONEDING equipment contributes to consistent, high-quality RCA production.

Key Quality Parameters for Recycled Concrete Aggregate

Several parameters evaluate RCA quality. These are crucial for its successful use.

- Particle Size Distribution (Gradation): This measures the proportions of different particle sizes. It must meet project specifications. RCA processing includes precise screening for this.

- Impurities Content (Contaminants): The presence of rebar, wood, plastic, or gypsum is controlled. These impurities negatively affect performance. ZONEDING’s screening and separation technologies help minimize these.

- Density and Water Absorption: RCA typically has lower density and higher water absorption than natural aggregate. These properties impact concrete mix designs.

- Compressive Strength and Durability: These properties assess the aggregate’s ability to withstand loads and weathering. They are crucial for structural applications.

- Sulfate Content: High sulfate levels can cause expansion problems in concrete. This is monitored carefully.

- Alkali-Silica Reactivity (ASR): If reactive silica is present in the original concrete, ASR can occur. This causes expansion and cracking. This is an important consideration for long-term stability.

Ensuring Compliance with Standards

Adhering to standards ensures RCA reliability. This is vital for widespread acceptance.

- Regular Testing: Samples of RCA are tested at every stage of RCA processing. This includes input material, crushed products, and final stockpiles.

- Standard Specifications: RCA must meet specific national or regional standards. Examples include ASTM or EN regulations. These standards dictate acceptable limits for various properties.

- Process Control: Consistent operation of crushing and screening equipment is vital. It maintains product quality. ZONEDING’s control systems ensure stable performance.

- Material Selection: Initial demolition waste sorting reduces contaminants. This simplifies RCA processing and improves output quality.

High-Efficiency Strategies for RCA Processing

Optimizing RCA processing leads to greater profitability. It also ensures sustainability. High-efficiency strategies focus on maximizing material recovery. They also aim to reduce operational costs. Each step in the workflow can be refined for better results.

Implementing these strategies requires careful planning and the right equipment. ZONEDING provides solutions designed for maximizing efficiency in recycled concrete aggregate production.

Maximizing Material Recovery and Minimizing Waste

Focus on getting the most out of every ton of waste concrete.

- Advanced Pre-sorting: Investing in advanced sorting technologies at the demolition site or feed area reduces non-concrete contaminants. This improves crushing efficiency. It also prolongs equipment lifespan.

- Closed-Loop Systems: Integrating water recycling systems for washing concrete reduces water consumption. It also minimizes wastewater discharge.

- Optimized Crushing Ratios: Adjusting crusher settings minimizes fines production. Fines often have lower value. ZONEDING impact crushers are known for producing cubical, well-graded aggregate with minimized fines.

Reducing Operational Costs

Cost control is vital for profitability in RCA processing.

- Energy Efficiency: Choosing energy-efficient crushing and screening equipment reduces power consumption. ZONEDING’s equipment is designed for optimal power usage.

- Wear Parts Management: Regular maintenance and using high-quality wear parts extend equipment life. This reduces replacement costs and downtime. ZONEDING’s parts are robust.

- On-Site Processing: Deploying mobile crushing stations drastically reduces transportation costs. It brings the processing plant to the source of the waste concrete. This is a core part of construction waste recycling.

- Automation: Implementing automated controls for feeders and crushers optimizes throughput. It reduces labor requirements.

Enhancing Product Value

Quality and specialized products command better prices.

- Precise Grading: Producing a wide range of accurately graded RCA products expands market opportunities. This includes specific sizes for fine aggregate or specialty fills.

- Contaminant-Free Product: Investing in effective magnetic separation and air classification ensures a cleaner RCA. A cleaner product achieves higher market value.

- Certification: Obtaining product certification demonstrates quality. This increases customer confidence. It expands market access for recycled concrete aggregate.

ZONEDING’s Solutions for RCA Processing

ZONEDING offers comprehensive solutions for RCA processing. These solutions transform waste concrete into high-quality eco-friendly aggregate. The company’s expertise covers all stages of the RCA processing flow. They contribute to sustainable and profitable recycling operations.

ZONEDING’s commitment to innovation and customer support ensures successful project implementation. They provide robust and efficient crushing and screening equipment. This equipment meets the demanding requirements of recycled concrete aggregate production.

Integrated and Mobile Processing Plants

ZONEDING specializes in flexible solutions for RCA processing.

- Full Processing Lines: ZONEDING designs and supplies complete RCA production lines. These lines integrate primary and secondary crushing. They also include multi-stage screening. They incorporate contaminant removal.

- Mobile Crushing Stations: These are a flagship product for RCA processing. They combine feeders, crushers, and screens on a single chassis. They offer unparalleled mobility. This facilitates on-site construction waste recycling. They minimize logistics and environmental impact.

Advanced Crushing and Screening Equipment

ZONEDING provides high-performance machinery for optimal RCA processing.

- Jaw Crushers: Robust and high-capacity for primary reduction of bulky concrete.

- Impact Crushers: Efficient for secondary crushing. They produce desirable cubical shapes. They are ideal for road bases.

- Cone Crushers: Durable for hard concrete. They ensure consistent particle size distribution.

- Vibrating Screens: Multi-deck screens for precise sizing and classification of RCA. They ensure graded products meet strict specifications.

Comprehensive Service and Support

ZONEDING offers extensive support for its RCA processing solutions.

- Customized Design: Engineers design tailored RCA processing flowsheets. They optimize solutions based on feed material, required output, and site conditions.

- Manufacturing Excellence: Advanced production facilities ensure high-quality, durable equipment.

- Installation and Commissioning: Expert teams provide guidance for efficient setup and startup.

- After-Sales Service: Long-term support, spare parts availability, and technical assistance maximize uptime. They ensure continuous, efficient recycled concrete aggregate production.

2025 Latest Trends in RCA Processing

The field of RCA processing continues to evolve. Advancements focus on greater efficiency, higher product quality, and enhanced sustainability. These trends shape the future of recycled concrete aggregate production. They offer new opportunities for resource recycling.

Staying updated on these trends helps operators maintain competitiveness. ZONEDING integrates these innovations into its crushing and screening equipment. The company ensures its solutions remain at the forefront of the industry.

Key Technological Developments

- Smart Sorting Technologies: Advances in sensor-based sorting (e.g., optical sorters, X-ray transmission) allow for automated and more precise removal of contaminants. This improves RCA quality significantly.

- Enhanced Crushing Techniques: Development of crushers with improved wear resistance reduces maintenance. They also offer better aggregate shape control for specific applications.

- Digitalization and AI in Plant Operations: Automation and remote monitoring systems optimize feeder rates, crusher settings, and screen performance. This maximizes throughput and minimizes energy use in RCA processing.

- Advanced Contaminant Removal: Innovations in air classification and washing systems reduce non-inert materials and fines. This allows for higher-grade RCA suitable for concrete mixes.

Market and Sustainability Drivers

- Circular Economy Mandates: Governments increasingly mandate the use of recycled concrete aggregate. This promotes a circular economy in construction. Such mandates boost demand for high-quality RCA.

- Carbon Footprint Reduction: Using RCA significantly lowers a project’s carbon footprint. This is due to reduced virgin material extraction and transportation. Companies prioritize eco-friendly aggregate for sustainability goals.

- Standardization Evolution: Standards for RCA use in structural applications continue to develop. This increases confidence in recycled concrete aggregate performance. It expands its market.

- Urban Mining: The concept of “urban mining” views demolition waste as a valuable resource. It drives investment in efficient on-site RCA processing facilities.

Common Questions About RCA Processing

- Question 1: What is the main benefit of RCA processing?

- The main benefit is environmental sustainability. It reduces landfill waste. It also conserves natural aggregate resources. and It promotes resource recycling in construction.

- Question 2: Can RCA be used in new concrete production?

- Yes, high-quality RCA can replace some virgin aggregate in new concrete. This requires rigorous RCA processing. It ensures the aggregate meets specific quality and performance standards.

- Question 3: What types of equipment are essential for RCA processing?

- Essential equipment includes jaw crushers for primary crushing, impact crushers or cone crushers for secondary crushing, and vibrating screens for sizing. Mobile crushing stations integrate these for flexibility.

- Question 4: How does ZONEDING ensure the quality of RCA produced by its equipment?

- ZONEDING provides robust crushing and screening equipment. This equipment is designed for precise sizing and optimal shape. It minimizes impurities. They offer integrated solutions for contaminant removal. This ensures the production of high-quality recycled concrete aggregate.

- Question 5: Is on-site RCA processing more cost-effective?

- Yes, on-site RCA processing is often more cost-effective. It uses mobile crushing stations. This eliminates transportation costs for waste concrete to a central plant. It also reduces costs for bringing in new aggregate.

Conclusion and Recommendations

RCA processing represents a pivotal shift towards sustainable construction. Converting waste concrete into valuable recycled concrete aggregate offers profound environmental and economic benefits. It ensures efficient resource recycling. A well-executed RCA processing flow is essential. It delivers high-quality, compliant aggregate products.

ZONEDING is a leader in providing robust crushing and screening equipment. The company’s solutions specialize in recycled concrete aggregate production. They are designed for maximum efficiency and superior product quality. Leverage ZONEDING’s expertise and advanced machinery. This ensures successful and sustainable RCA processing operations. Contact ZONEDING today to discuss specific needs. They can help transform waste concrete into an eco-friendly aggregate.