Slag processing transforms industrial by-products into valuable resources. This guide covers everything you need to know. It starts with understanding different slag types. It then moves to effective slag treatment methods and specialized slag processing equipment. We explore diverse slag utilization pathways and applications. This process helps achieve efficient resource transformation. It turns what was once waste into economically viable, eco-friendly aggregate.

The steel and non-ferrous metal industries generate millions of tons of slag globally. This waste material has significant potential. Proper processing unlocks its value. It also reduces environmental impact. ZONEDING MACHINE provides robust solutions for efficient slag processing. Our machinery helps you recover valuable metals. It also produces high-quality construction materials.

Table of Contents

What is Slag and Why Does it Need Processing?

Slag is a glassy, stony by-product. It forms during the smelting or refining of metals. It often contains oxides of various metals. and It also contains fluxes used in the furnace. Slag varies significantly based on its origin and composition. Proper slag processing is crucial for various reasons.

Raw slag can pose environmental challenges. It can leach heavy metals. It also occupies large landfill spaces. Processing transforms this waste material. It converts it into a safe, usable product. It also allows for the recovery of valuable metals still present in the slag. This makes slag processing a key part of resource recycling.

Different Types of Slag

Slag types vary widely depending on the metallurgical process.

- Blast Furnace Slag: This comes from iron production. It is typically granular or air-cooled. It is rich in silicates and aluminates.

- Steel Slag: This is a by-product of steelmaking. It is denser and can contain higher levels of free lime. Basic Oxygen Furnace (BOF) slag and Electric Arc Furnace (EAF) slag are common forms.

- Non-Ferrous Slag: These slags originate from copper, lead, zinc, and other non-ferrous metal production. Their composition is highly variable. They often contain higher concentrations of remaining target metals.

Benefits of Slag Processing

Processing slag offers significant advantages.

- Resource Recovery: It reclaims valuable metals like iron, copper, or zinc. These metals are otherwise lost in the slag. This acts as effective resource recycling.

- Environmental Protection: It reduces landfill waste. It minimizes potential for environmental contamination from raw slag. This contributes to better ecological management.

- Economic Value: Processed slag becomes a marketable product. It can be used as an eco-friendly aggregate for construction. It also finds use in cement production. This generates new revenue streams.

- Reduced Natural Resource Demand: Utilizing processed slag lowers the need for virgin aggregates. It decreases the environmental impact of quarrying.

The Essential Slag Processing Methods

Slag processing involves several key methods. These methods transform raw slag into marketable products. The chosen methods depend on the slag type. They also depend on the desired final application. Each step aims to refine the material. This enhances its value and safety.

A well-designed slag treatment method must be efficient. It needs to recover valuable components effectively. It should also produce high-quality materials. ZONEDING MACHINE provides tailored solutions. Our technology optimizes each processing step.

Crushing and Screening

This is the primary stage for most slag processing operations.

- Purpose: Raw slag usually comes in large, irregular lumps. Crushing reduces these to smaller, manageable sizes. Screening then separates the crushed material into specific size fractions. This prepares it for further processing or direct use.

- Process: Initial crushing uses robust equipment like jaw crushers. Secondary crushing might involve cone crushers or impact crushers. These machines produce finer, more cubical particles. Vibrating screens ensure precise size classification.

- ZONEDING Advantage: Our crushers are designed for high wear resistance. They handle the abrasive nature of slag. Our screens offer high efficiency. They ensure accurate sizing for various applications.

Magnetic Separation

This method is crucial for recovering ferrous metals from slag.

- Purpose: Steel slag often contains residual iron or steel particles. These are valuable. Magnetic separators effectively extract them. This improves the quality of the non-ferrous slag portion. It also provides a recovered metal product.

- Process: The crushed slag passes under powerful magnets. These can be drum magnets or suspended electromagnets. Ferrous materials are attracted and separated from the main stream. This is a vital step in resource recycling.

Air Classification and Jigging

These methods separate materials based on density differences.

- Air Classification: Lighter contaminants or fine particles are removed using air currents. This improves the purity of the aggregate product.

- Jigging: This water-based method separates particles by density. It uses pulsating water flows. It is particularly effective for recovering non-ferrous metals from slag. And It separates denser metal particles from lighter slag.

Grinding and Milling

This stage prepares slag for fine powder applications.

- Purpose: Some advanced applications require very fine slag powders. These include cement additives or specialized fillers. Grinding and milling reduce the material to a fine particle size.

- Equipment: Ball mills or vertical roller mills are used for this process. They achieve the required fineness for high-value products.

Key Equipment for Efficient Slag Processing

Efficient slag processing relies on specialized, robust equipment. The abrasive nature of slag demands machinery built for durability. ZONEDING MACHINE provides a comprehensive range of slag processing equipment. These machines ensure high performance, reliability, and precision.

Our equipment selection covers every stage of the slag treatment methods. From primary size reduction to fine grinding. We ensure optimal resource transformation. Our solutions are designed to deliver consistent quality and maximum metal recovery.

Primary Crushing: Jaw Crushers for Slag

- Function: Jaw crushers are essential for initial size reduction. They handle large, hard chunks of raw slag. Their powerful jaws break down the material efficiently.

- ZONEDING’s Offerings: Our PE and JC series jaw crushers feature heavy-duty construction. They have wear-resistant manganese steel plates. This ensures long service life in abrasive slag processing environments. They provide high throughput for primary reduction.

Secondary Crushing: Cone and Impact Crushers for Finer Slag

- Function: After primary crushing, secondary crushers further reduce particle size. Cone crushers are suitable for hard slags. They produce a consistent, cubical product. Impact crushers are ideal for softer slags. They yield a well-shaped, high-quality aggregate.

- ZONEDING’s Offerings: Our hydraulic cone crushers offer high efficiency. Our impact crushers are known for excellent product shape. These machines are key to producing suitable eco-friendly aggregate from slag.

Screening and Classification: Vibrating Screens and Sizers

- Function: Precise sizing is critical for various slag applications. Vibrating screens separate crushed slag into desired particle sizes. Multi-deck screens allow for simultaneous separation into multiple fractions.

- ZONEDING’s Offerings: Our YK and ZSW vibrating screens feature innovative designs. They ensure high screening efficiency. They offer accurate classification for different slag utilization pathways.

- Function: Magnetic separators are non-negotiable for recovering ferrous metals. They remove iron and steel particles from slag. This effectively enhances the value of both the recovered metal and the remaining slag.

- Importance: This step in slag processing is vital for maximizing resource recycling. It contributes significantly to the economic viability of the operation.

Grinding Equipment: Ball Mills and Roller Presses

- Function: For applications requiring fine slag powder, grinding is necessary. Ball mills grind slag to micron sizes. Roller presses offer energy-efficient fine grinding.

- Applications: Fine slag powder is used as an additive in cement. It finds use in road construction or as mineral fillers.

Integrated/Mobile Slag Processing Plants

- Functionality: ZONEDING offers integrated mobile crushing stations. These combine crushing, screening, and sometimes magnetic separation on a single mobile chassis.

- Benefits: They provide flexibility for on-site slag processing. They reduce transportation costs. They adapt easily to changing site conditions or material sources.

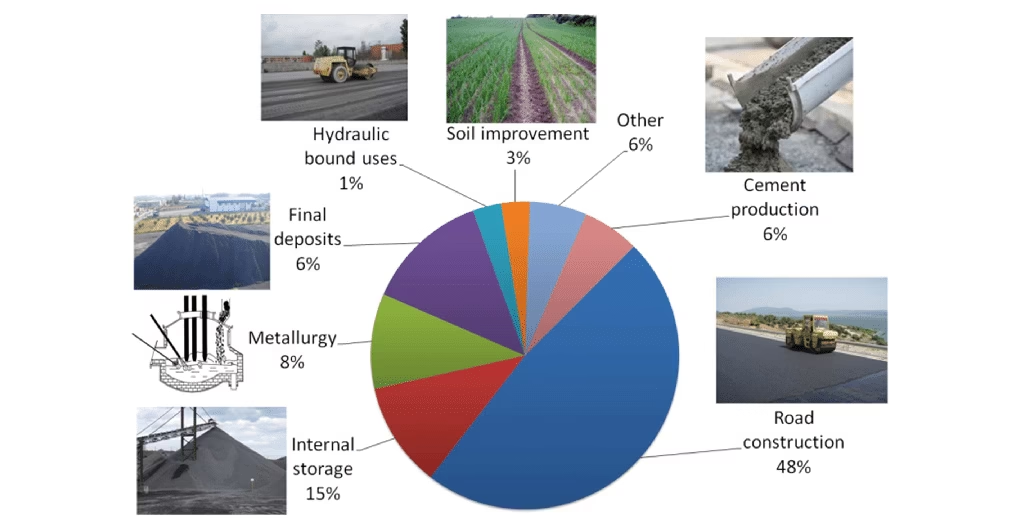

Diverse Applications and Utilization Pathways of Processed Slag

Processed slag, transformed into a valuable eco-friendly aggregate, offers extensive utilization pathways. Its unique properties make it suitable for various industries. This contributes significantly to resource recycling and sustainable development. ZONEDING’s efficient slag processing equipment enables the production of high-quality slag products. These products meet specific requirements for diverse applications.

Understanding these slag utilization pathways is key. It helps you maximize the economic and environmental benefits. It unlocks the full potential of this industrial by-product.

Road Construction and Pavements

- Application: Processed slag, particularly blast furnace slag and steel slag, is widely used. It serves as sub-base, base, and even wearing courses in road construction. Its high abrasion resistance and stability are beneficial.

- Benefits: It provides excellent structural support. It reduces the need for virgin aggregates. This makes it an eco-friendly aggregate choice for infrastructure projects.

Cement and Concrete Production

- Application: Granulated blast furnace slag (GBFS) is a common supplementary cementitious material (SCM). It replaces a portion of Portland cement. Ground GBFS (GGBS) enhances concrete durability and strength.

- Benefits: Using slag in cement reduces energy consumption and CO2 emissions. It improves concrete properties. This includes resistance to sulfates and chlorides.

Agricultural Applications

- Application: Certain types of processed slag, especially basic steel slag, can serve as soil conditioners. They can also act as slow-releasing fertilizers. They provide essential nutrients. And They also help neutralize acidic soils.

- Benefits: This offers a sustainable way to improve soil health. It increases crop yields. This creates another valuable slag utilization pathway.

Environmental Applications

- Application: Processed slag shows promise in various environmental projects. It can be used for wastewater treatment filters. It also finds use in heavy metal immobilization. Its porous structure and chemical properties are advantageous.

- Benefits: It provides cost-effective solutions for environmental remediation. It reduces pollution. This demonstrates its value beyond traditional construction.

Other Industrial Uses

- Application: Slag can be used as raw material in glass and ceramic production. It serves as a lightweight aggregate for concrete blocks. It is also used as railway ballast.

- Benefits: These specialized uses further expand the market for processed slag. They contribute to a fully circular economy. ZONEDING’s precise slag processing equipment can produce materials tailored for these diverse needs.

Quality Control and Standards in Slag Processing

Achieving economic value from slag demands strict quality control. It ensures the finished product meets specific industrial standards. The effectiveness of slag treatment methods directly impacts product quality. ZONEDING’s slag processing equipment is designed to support these rigorous quality requirements.

Implementing comprehensive quality control throughout the slag processing flow is essential. It guarantees the reliability and performance of materials. This, in turn, boosts confidence and market acceptance for processed slag.

Key Parameters for Processed Slag

Several critical parameters define the quality of processed slag:

- Chemical Composition: Analyzing the levels of oxides (e.g., CaO, SiO2, Al2O3) and trace elements. This is crucial for its use in cement or agriculture. Undesirable elements like heavy metals are monitored.

- Physical Properties: Measuring properties like density, porosity, abrasion resistance, and water absorption. These are vital for aggregate and construction applications.

- Particle Size Distribution: Ensuring the processed slag meets grading specifications. Vibrating screens provide precise control over this.

- Stability and Reactivity: For steel slag, understanding free lime content and potential for expansion is critical. This ensures long-term performance in applications like road bases.

Ensuring Compliance with Standards

Adherence to established standards is paramount for market acceptance.

- Industry Standards: Compliance with international and national standards (e.g., ASTM, EN) for aggregates or cementitious materials is mandatory.

- Regular Testing: Consistent sampling and testing at various stages of slag processing are vital. This includes raw slag, intermediate products, and final stockpiles.

- Process Optimization: ZONEDING’s automated systems help maintain stable operating conditions. This minimizes variations in product quality. Our engineers provide expert guidance on optimizing the slag treatment methods.

2025 Latest Trends in Slag Processing

The field of slag processing is continuously evolving. New demand drivers and technological advancements are emerging. These trends focus on maximizing value. They also enhance the sustainability of resource transformation. Staying informed about these developments is crucial. It helps maintain a competitive edge.

ZONEDING integrates these innovations into its slag processing equipment. We ensure our solutions remain at the forefront of the industry. We help clients achieve efficient slag utilization pathways.

Key Technological Developments

- Advanced Sensor-Based Sorting: New technologies use optical, X-ray, or laser sensors. They identify and separate non-ferrous metals or fine impurities from slag. This boosts recovery rates and product quality.

- Enhanced Grinding and Activation: Development of ultra-fine grinding technologies. These include vertical roller mills or stir-mill systems. They increase the reactivity of slag. This makes it a more effective cementitious material.

- Digitalization and AI in Plant Operations: Automation and artificial intelligence optimize operational parameters. These include feeder rates and crusher settings. They monitor equipment health. This leads to higher energy efficiency and reduced downtime in slag processing.

Market and Sustainability Drivers

- Circular Economy Mandates: Governments are increasingly promoting circular economy principles. This drives demand for recycled materials like processed slag. Strict regulations reduce landfill and encourage resource recycling.

- Carbon Footprint Reduction: Using processed slag, especially in cement, significantly reduces CO2 emissions. This supports global sustainability goals. Companies prioritize eco-friendly aggregate for greener construction.

- Expanded Slag Utilization: Research continues to uncover new, high-value slag utilization pathways. These include applications in geopolymers, lightweight construction materials, and specialized ceramics.

- Regional Demand Variations: Growth in certain regions, like Asia and Africa, is driving demand for both steel and non-ferrous slags. This creates new markets for slag processing technologies.

Common Questions About Slag Processing

- Question 1: What are the main types of slag processed by ZONEDING equipment?

- We primarily process blast furnace slag and various steel slag types (BOF, EAF). We also handle non-ferrous slags. Our slag processing equipment adapts to different compositions and physical properties.

- Question 2: How does slag processing contribute to environmental sustainability?

- Slag processing reduces landfill waste. It minimizes potential pollution. It also conserves natural resources by turning slag into an eco-friendly aggregate. This actively promotes resource recycling.

- Question 3: Can processed slag be used as an alternative to natural aggregate?

- Yes, properly processed slag is an excellent alternative. It is used in road bases, sub-bases, and railway ballast. Its properties often meet or exceed natural aggregate standards for many applications.

- Question 4: What ZONEDING equipment is vital for recovering metals from slag?

- Magnetic separators are crucial for recovering ferrous metals. For non-ferrous metals, jigging and advanced sorting technologies are also effective. Our tailored solutions optimize metal recovery.

- Question 5: What quality parameters should I consider for processed slag?

- You should consider chemical composition, physical properties (density, abrasion), and particle size distribution. Stability and reactivity are also important. These parameters ensure slag suitability for its intended slag utilization pathways.

Conclusion and Recommendations

Slag processing is a critical industrial practice. It holds immense potential for resource transformation. It turns waste material into valuable eco-friendly aggregate. Understanding slag types, effective slag treatment methods, and specialized slag processing equipment is vital. It underpins successful slag utilization. This approach reduces environmental impact. It also generates significant economic value.

ZONEDING MACHINE stands as your reliable partner. We provide cutting-edge slag processing equipment. We offer comprehensive solutions from design to after-sales support. Our expertise ensures efficient resource recycling and maximum value recovery from slag. Contact ZONEDING today. Let us help you unlock the full potential of your waste material.