Perlite is a unique volcanic glass. It possesses an incredible ability to expand greatly when heated. This makes it an incredibly versatile material. Its unique properties allow for a wide range of uses. Understanding perlite processing is key. It helps transform raw material into usable products. This guide explores everything about perlite. It covers its origins, processing, and many perlite applications.

When considering perlite, its magic-like transformation often comes to mind. It starts as a simple rock. It then “pops” into a lightweight, white material. This happens through careful industrial processing. This process requires specific equipment. ZONEDING MACHINE provides much of the specialized machinery used.

Table of Contents

What is Raw Perlite and Why is it Unique?

Raw perlite is a naturally occurring volcanic glass. It forms when molten lava cools rapidly. This rapid cooling traps water molecules within its structure. This internal water gives perlite its unique characteristic. It looks similar to obsidian in its raw state. However, it usually has a more dull, light-colored appearance.

Its uniqueness lies in its structure. It holds between 2% and 6% combined water. This water is physically trapped inside minute, concentric layers. When heated rapidly, this trapped water turns into steam. This steam causes the rock to expand. This expansion process is truly remarkable.

Unique Properties of Expanded Perlite

After perlite processing, specifically expansion, the material gains several valuable properties:

- Extremely Lightweight: Expanded perlite can weigh as little as 3-15 lbs per cubic foot. This makes handling and transport easy. It significantly reduces structural loads in construction.

- Excellent Thermal Insulation: Its cellular structure contains numerous air pockets. These trap heat effectively. This makes it a superior insulating material.

- High Porosity and Absorbency: The tiny, interconnected cells absorb and hold water or liquids. This is crucial for horticulture and filtration uses.

- Sterile and Inert: It does not host insects, bacteria, or fungi. It is chemically stable. It does not react with most common chemicals.

- Fire Resistant: Being volcanic glass, it is naturally non-combustible. It can withstand high temperatures.

- Sound Absorption: Its porous nature helps dampen sound, making it useful in acoustic applications.

Where Does Perlite Come From?

Perlite originates from specific volcanic regions around the world. These deposits are typically found in areas with past volcanic activity. Major deposits are present in the United States, Greece, Turkey, and Japan. The perlite mining process extracts these vast reserves of raw material.

The perlite mining process is similar to other industrial mineral quarrying. It typically involves open-pit mining methods. Raw perlite is extracted from large surface deposits. The aim is to obtain the material cost-effectively. This prepares it for subsequent perlite processing steps.

Typical Perlite Deposits

Raw perlite deposits form when silica-rich volcanic lava flows into water. Or when it cools quickly in a water-saturated environment. This rapid cooling prevents crystallization. It traps volcanic water. Over time, weathering and alteration can further modify these deposits. This results in the characteristic hydration and onion-skin-like fractures. These deposits are often massive, providing a stable supply for future perlite applications.

Mining operations start by removing overburden, the soil and rock covering the perlite seam. Then, the raw perlite itself is extracted. This usually involves blasting or mechanical excavation. The raw material is carefully assessed. This ensures it meets quality standards for expansion. ZONEDING’s crushing equipment can be used at this initial stage. It helps size the raw perlite for easier transport.

The Industrial Perlite Processing Chain: From Mine to Market

The transformation of raw perlite into its expanded form involves a series of industrial steps. This constitutes the core of perlite processing. Each stage utilizes specific equipment. These steps are crucial for creating the valuable material. The entire chain focuses on efficiency and quality.

This perlite processing chain turns a simple rock into a versatile product. It relies on precise thermal treatment and mechanical separation. ZONEDING MACHINE provides robust machinery for these transformations. Its equipment ensures high-quality output for various perlite applications.

1. Raw Perlite Crushing & Sizing

The first step in perlite processing involves reducing the raw material size.

- Purpose: Raw perlite comes in various sizes from the mine. It requires uniform sizing to ensure efficient drying and consistent expansion.

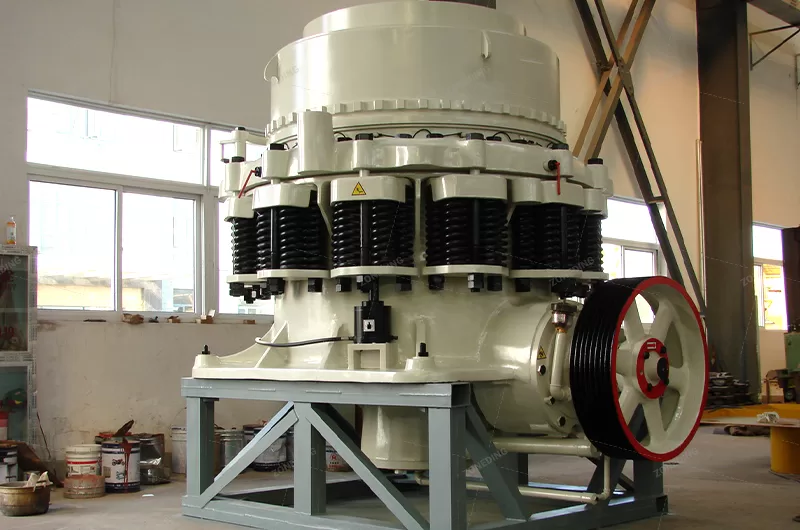

- Process: Large chunks of raw perlite enter primary crushers. Jaw crushers are typical for this initial reduction. They break down the material into smaller pieces. Then, secondary crushers, like cone crushers or impact crushers, further refine the size. These systems achieve the desired particle range, usually between 0.1 to 3 mm.

- ZONEDING Solutions: ZONEDING crushers are built for consistency. They provide precise sizing. This prepares the perlite for optimal downstream processing.

2. Drying Raw Perlite

After crushing, the raw perlite must be dried.

- Purpose: Raw perlite often contains surface moisture, which can interfere with the expansion process. Drying removes this external water. This ensures only the internal, structural water facilitates expansion.

- Process: Rotary dryers are commonly used. They gently tumble the perlite while applying heat. This removes excess moisture. Careful control of temperature and residence time is important to prevent premature expansion.

- ZONEDING Solutions: ZONEDING rotary dryers are efficient. They ensure uniform drying. This optimizes the perlite expansion phase.

3. Perlite Expansion (Furnace)

This is the most critical stage of perlite processing.

- Purpose: The dried raw perlite is rapidly heated. This causes the trapped water to vaporize. The material then expands significantly. It creates a lightweight, cellular structure.

- Process: Perlite is fed into a specialized furnace. Temperatures range between 850°C and 1100°C. The rapid heating softens the glass. The internal water turns to steam. This forces millions of tiny bubbles into the softened material. The particles “pop” like popcorn, increasing 4 to 20 times their original volume. This produces expanded perlite.

- Equipment: Vertical furnaces or rotary kilns are specifically designed for this high-heat, short-duration process.

4. Expanded Perlite Screening & Grading

After expansion, the expanded perlite must be classified.

- Purpose: The expanded material varies in size and density. Screening separates it into different grades. Each grade suits specific perlite applications.

- Process: Expanded perlite moves to vibrating screens. These screens use multiple decks. They sort the material by particle size. This creates uniform products. Common grades include fine, medium, and coarse, tailored for horticulture, construction, or filtration.

- ZONEDING Solutions: ZONEDING vibrating screens are highly efficient. They provide precise separation. This ensures consistent product quality and market readiness.

5. Dust Collection & Packaging

The final steps involve preparing the perlite for distribution.

- Purpose: Dust is a natural by-product during processing. It must be collected for environmental and safety reasons. The final product requires proper packaging.

- Process: Dust collectors capture airborne particles. This ensures a clean working environment. It also prevents waste. The graded expanded perlite is then packaged. This can be in large bulk bags or smaller sacks. This makes it ready for shipping.

Where is Perlite Used?

Expanded perlite is an incredibly versatile material. Its unique combination of properties makes it valuable across many industries. From gardens to construction sites, perlite applications are diverse. These applications take advantage of its lightweight, insulating, and porous nature.

The wide range of perlite applications highlights its importance as an industrial mineral. Its ability to solve different problems makes it a preferred choice. ZONEDING’s perlite processing lines enable the production of material precisely for these varied uses.

Perlite in Horticulture & Agriculture

This represents one of the most well-known perlite applications.

- Soil Amendment: Perlite mixes with potting soil. It improves drainage and aeration. It prevents compaction, helping plant roots access oxygen. and It also reduces the risk of root rot.

- Hydroponics: It acts as an inert growing medium in hydroponic systems. It provides excellent moisture retention and aeration. It delivers nutrients efficiently to plants.

- Seed Starting: Its sterile nature and fine texture are perfect for germinating seeds. It helps prevent damping-off diseases, improving seedling success rates.

- Landscaping: Lightweight perlite can reduce the weight of rooftop gardens. It improves drainage in heavy clay soils.

Perlite in Construction & Insulation

Perlite is a key material in modern construction. Its insulating properties are highly valued.

- Lightweight Aggregate: It replaces sand in lightweight concrete and plaster. This reduces structural loads. It improves thermal and fire resistance.

- Loose-Fill Insulation: Expanded perlite fills easily into cavity walls and attics. It forms an effective thermal barrier. Its granular form fills irregular spaces well.

- Insulating Concrete: Used in roof decks and floor fills, it provides lightweight insulation. It minimizes heat transfer.

- Fire-Rated Applications: Perlite plasters and ceiling tiles offer superior fire resistance, protecting structures.

Perlite in Filtration

Perlite serves as an effective filter medium in many processes.

- Filter Aid: Perlite filter aids are used to clarify liquids. This includes beverages like beer and wine. It also filters fruit juices, sugars, and edible oils. Its porous structure traps fine particles, providing a clean filtrate.

- Processing: It is common in pharmaceuticals and chemicals. It filters industrial waste as well. Its inert nature ensures no unwanted chemical reactions.

Other Niche Perlite Applications

Perlite has even more specialized uses.

- Cryogenics: Its excellent insulative properties make it ideal for storing super-cold liquids. It insulates tanks for liquid oxygen, nitrogen, and natural gas.

- Absorbents: It can absorb oil, chemicals, and other spills. Its porous nature makes it highly effective.

- Abrasives: Fine grades of perlite are used in polishes, cleaners, and other abrasive products. It provides gentle scrubbing action.

ZONEDING’s Role in Perlite Processing

ZONEDING MACHINE plays a vital role in the perlite processing industry. It provides the robust machinery needed to transform raw perlite into its valuable expanded forms. Its expertise covers key stages of the industrial perlite processing chain.

ZONEDING designs and manufactures specific equipment. This equipment supports efficient perlite mining and processing operations. It focuses on durability and performance. This ensures clients can produce high-quality perlite products consistently.

How ZONEDING Supports Perlite Processing

- Crushing and Sizing: ZONEDING provides high-performance jaw crushers and cone crushers. These machines efficiently reduce raw perlite to precise sizes. This prepares it for optimal expansion.

- Drying Equipment: ZONEDING’s rotary dryers are critical for removing surface moisture. This ensures the raw perlite is perfectly conditioned for the expansion furnace.

- Screening and Grading: ZONEDING’s vibrating screens are essential. They classify expanded perlite into various grades. This allows producers to capture different market segments.

- Complete Production Lines: ZONEDING can design and supply entire perlite processing plant solutions. These include all necessary equipment. They integrate it into an efficient, customized system.

- Full-Service Support: ZONEDING’s commitment extends beyond equipment. It offers full-service support. This includes planning, installation, training, and maintenance.

Common Questions About Perlite Processing

- Question 1: What makes perlite expand?

- Perlite expands due to trapped water within its structure. When heated rapidly to over 850°C, this water turns into steam. This causes the glassy material to soften and “pop”, increasing its volume significantly.

- Question 2: Is perlite considered eco-friendly?

- Yes, perlite is largely considered eco-friendly. It is a natural mineral. Its extraction uses open-pit mining. However, its use reduces the need for less sustainable materials. Its lightweight nature also reduces transportation energy.

- Question 3: What ZONEDING equipment is vital for perlite processing?

- ZONEDING supplies jaw crushers, cone crushers, rotary dryers, and vibrating screens. These are crucial for efficient perlite processing. They cover the crushing, drying, and grading stages.

- Question 4: Can perlite replace sand in concrete?

- Yes, expanded perlite can replace sand or other aggregates in concrete mixes. It creates lightweight concrete. This type of concrete is insulating. It is also fire-resistant. It significantly reduces the overall weight of structures.

- Question 5: How does ZONEDING ensure the quality of processed perlite?

- ZONEDING provides precision screening equipment. This ensures accurate grading of expanded perlite. Its crushing and drying equipment also delivers consistent quality. This supports the production of high-standard perlite.

Conclusion and Recommendations

Perlite stands out as a remarkable natural material. Its unique ability to expand creates a lightweight, versatile product. Understanding its properties and the perlite processing chain is essential. It helps producers harness its full potential across many perlite applications. From sustainable agriculture to efficient construction, perlite offers innovative solutions.

ZONEDING MACHINE is a trusted partner. It offers specialized equipment and comprehensive solutions for every stage of perlite processing. Producers should consider how perlite could benefit operations. Exploration of its uses as a lightweight filler, insulator, or filter aid is recommended. Contact ZONEDING today to discuss specific perlite processing needs. It can help design a tailored production line.