全站搜索

Search the entire website

Search the entire website

Aggregate forms the backbone of construction. It provides strength and stability to structures. Selecting the right aggregate rock types determines a project’s success. Different common aggregate rocks possess unique properties. These properties impact durability, workability, and cost. This guide compares eight prevalent aggregate rock types. It helps choose efficient aggregate for construction projects. Engineers often analyze properties, pros, and cons. This ensures selection of durable and efficient aggregate.

Construction success depends heavily on material quality. Aggregate comprises a large volume of concrete and asphalt. Its characteristics directly influence the final material’s performance. Understanding these distinctions is crucial. It supports informed material specification and procurement. ZONEDING manufactures crushing and screening equipment. This equipment processes various aggregate rock types. It meets strict quality standards for durable aggregate.

Aggregate is fundamental to modern construction. It serves as a filler in concrete and asphalt. It also forms bases for foundations, roads, and railways. Its structural role is indispensable. Sound construction aggregate properties are vital for long-lasting infrastructure.

Aggregate contributes up to three-quarters of the volume in concrete. It influences strength, thermal conductivity, and volumetric stability. Proper selection directly impacts crack resistance and freeze-thaw durability. High-quality aggregate minimizes maintenance costs over time. ZONEDING’s aggregate production lines ensure consistent quality. They produce various common aggregate rocks. This meets the stringent demands of any construction project. The company’s technology helps producers deliver superior aggregate for construction projects.

Aggregate performs several critical functions. These functions support structural integrity.

Choosing the right rock types directly impacts these functions. Properties like hardness, density, and shape dictate performance. An efficient aggregate choice optimizes both structural integrity and budget constraints.

Engineers evaluate several key properties of common aggregate rocks. It ensures optimal performance.

Eight common aggregate rock types find widespread use in construction. Each presents a unique set of properties. These properties make them suitable for specific applications. Understanding these differences is crucial. It helps in selecting the most efficient aggregate.

This section details the characteristics, advantages, and disadvantages of each rock type. This information assists in making informed decisions. ZONEDING’s crushing equipment can process all these materials. It transforms them into construction-ready durable aggregate.

| Aggregate Type | Key Properties | Typical Uses | Considerations (Pros/Cons) |

|---|---|---|---|

| Granite | Very hard, dense, high strength | High-strength concrete, roads, railway ballast | Costly to crush, good durability |

| Basalt | Extremely hard, dense, strong | Road surfaces, asphalt, railway ballast | Very hard to crush, unmatched hardness |

| Limestone | Moderate hardness, porous, calcium carbonate | General concrete, road base, subbase | Widespread, affordable, susceptible to acids |

| Sandstone | Variable hardness, cemented grains | General fill, some concrete applications | Availability varies, strength varies, adaptable |

| Quartzite | Extremely hard, high silica, durable | High-strength concrete, abrasion-resistant uses | Very hard to crush, ASR potential |

| Gneiss | Good strength, banded, moderate to high density | General construction, road bases | Properties vary, can produce flaky particles |

| Dolerite | Very dense, high strength, tough | Heavy-duty pavements, railway ballast | Difficult to crush, excellent durability |

| River Gravel | Rounded, various compositions | General concrete, non-structural fill | Good workability, lower strength, requires washing |

Granite is an intrusive igneous rock. It is very hard and dense. Its crystalline structure contributes to high strength. Granite aggregate properties make it one of the most reliable choices.

Granite aggregate offers excellent mechanical strength. It resists abrasion and weathering very well. Its hardness makes it ideal for heavy-duty applications. Pavements and high-strength concrete often use granite. Its dark, variegated appearance can also be aesthetically pleasing. However, granite often requires significant energy for crushing. This increases production costs. Its sharp, angular fragments can also make concrete less workable. ZONEDING’s specialized crushing equipment for aggregate, like jaw crushers and cone crushers, efficiently processes granite. This ensures optimal particle shape and gradation.

Pros of Granite Aggregate:

Cons of Granite Aggregate:

Basalt is a fine-grained extrusive igneous rock. It is extremely hard and dense. Basalt aggregate characteristics include high resistance to impact and abrasion.

Basalt aggregate exhibits exceptional strength. It holds superior resistance to wear. It is ideal for road bases, asphalt concrete, and railway ballast. Its dark color can be beneficial for specific asphalt applications. Similar to granite, its hardness makes crushing challenging. This results in higher wear on crushing equipment. Fine basalt dust can also sometimes affect asphalt adhesion. ZONEDING designs its crushing equipment for aggregate with robust wear parts. This ensures efficient processing of hard rock types like basalt. The company delivers consistently sized and shaped durable aggregate.

Pros of Basalt Aggregate:

Cons of Basalt Aggregate:

Limestone is a sedimentary rock. It consists primarily of calcium carbonate. It is one of the most common and versatile aggregate rock types.

Limestone aggregate is relatively softer than igneous rocks. This makes it easier to crush. Its affordability and wide availability contribute to its popularity. It provides good workability in concrete mixes. Limestone can also react with acidic environments. This leads to deterioration over time. Its strength and abrasion resistance are moderate. This limits its use in high-performance applications. ZONEDING’s impact crushers are highly effective for processing limestone. They produce cubical and well-graded aggregate for construction projects. This ensures material consistency.

Pros of Limestone Aggregate:

Cons of Limestone Aggregate:

Sandstone is a sedimentary rock. It forms from cemented sand grains. Its properties vary widely. They depend on grain size, cementing material, and mineral composition.

Sandstone for construction is often locally abundant. This makes it an attractive cost option. Its moderate hardness makes it relatively easy to crush and shape. However, some sandstone varieties show lower strength and durability. They can degrade due to weak cementing materials. The presence of clay minerals can also impact performance. Project specifications must carefully consider sandstone aggregate advantages.

ZONEDING’s comprehensive aggregate production lines handle diverse sandstone types. Mobile crushing and screening solutions are particularly effective for remote sandstone quarries. They provide flexible and efficient aggregate production.

Pros of Sandstone Aggregate:

Cons of Sandstone Aggregate:

Quartzite is a metamorphic rock. It forms from sandstone under intense heat and pressure. It is extremely hard and durable. Quartzite aggregate strength is very high.

Quartzite aggregate offers exceptional compressive strength. It provides superior abrasion resistance. It closely rivals granite and basalt in performance. This makes it suitable for demanding applications. Its high silica content can be an issue. It can react with alkalis in cement. This causes alkali-silica reaction (ASR). ASR leads to cracking and expansion. Crushing quartzite also requires robust crushing equipment. ZONEDING supplies heavy-duty jaw crushers and highly durable cone crushers. These units are specifically designed for processing very hard and abrasive aggregate rock types like quartzite.

Pros of Quartzite Aggregate:

Cons of Quartzite Aggregate:

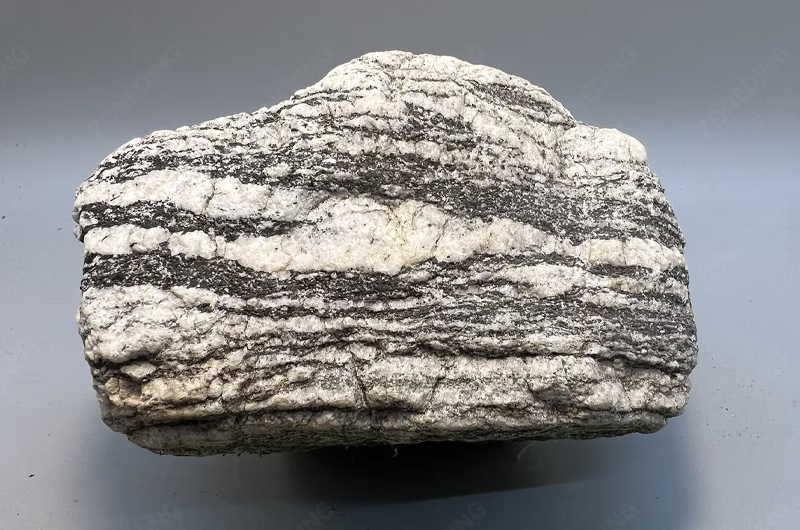

Gneiss is a high-grade metamorphic rock. It features distinct bands of different minerals. Its properties are somewhat variable. They depend on mineralogy and banding.

Gneiss aggregate often exhibits good to very good strength. Its layered structure can offer a degree of flexibility. This makes it resilient in some applications. Its density and abrasion resistance are typically strong. However, its banded structure can sometimes lead to planes of weakness. This affects impact resistance. The crushing process must be carefully controlled. This prevents excessive flakey or elongated particles. ZONEDING offers customized crushing and screening equipment solutions. These solutions optimize particle shape and gradation for complex aggregate rock types like gneiss. Their expertise ensures clients get the most efficient aggregate.

Pros of Gneiss Aggregate:

Cons of Gneiss Aggregate:

Dolerite is a fine-to-medium-grained intrusive igneous rock. It is often dark-colored and very dense. Dolerite aggregate characteristics include high strength and durability.

Dolerite aggregate offers excellent mechanical properties. It resists crushing and abrasion very well. Its high density provides good bulk strength in concrete. It is suitable for heavy-duty pavements and railway ballast. Crushing dolerite can be challenging. Its toughness requires powerful crushing equipment. This leads to higher wear rates on machinery. Availability might also be localized. ZONEDING specializes in robust aggregate production lines. These lines effectively handle tough materials like dolerite. They deliver consistent quality of durable aggregate.

Pros of Dolerite Aggregate:

Cons of Dolerite Aggregate:

River gravel consists of naturally rounded rock fragments. Water transportation smooths and rounds these particles. They usually compose of various rock types.

River gravel aggregate is readily available in many regions. Its natural rounded shape improves concrete workability. This reduces the amount of water needed in mixes. It can also reduce cement content. However, the rounded shape results in less inter-particle locking. This can decrease the ultimate strength of concrete. Its properties depend heavily on the source rock. It often requires thorough washing and screening. This removes organic matter and fines. ZONEDING provides comprehensive screening machines and washing equipment. These prepare river gravel. They ensure it meets specific construction aggregate properties.

Pros of River Gravel Aggregate:

Cons of River Gravel Aggregate:

Choosing the ideal aggregate rock types for a construction project involves a systematic approach. Several factors guide this decision. These factors include project requirements, budget, and local availability. Owners should prioritize durable aggregate that meets all technical specifications.

A careful evaluation prevents costly failures and delays. This framework helps navigate the selection process. It ensures the chosen aggregate delivers optimal performance. ZONEDING advises clients on aggregate production lines. These lines process specific common aggregate rocks. This ensures they achieve desired material characteristics.

Consider these points when choosing aggregate:

ZONEDING is a leading manufacturer of mineral processing equipment. The company specializes in solutions for aggregate production. It helps clients create high-quality, durable aggregate from diverse rock types. ZONEDING’s commitment to efficiency and customization supports successful construction projects.

ZONEDING’s core business involves designing and manufacturing robust equipment. This equipment processes raw stone into specification-compliant aggregate. They offer full-service support. This ensures smooth project delivery. ZONEDING offers technologically advanced machinery. They focus on delivering cost-effective and efficient aggregate solutions.

ZONEDING provides a comprehensive range of machinery. This machinery covers all stages of aggregate production.

ZONEDING offers extensive support. This extends from initial consultation to after-sales service.

Choosing the right aggregate rock types is a cornerstone of successful construction projects. Understanding the distinct properties of common aggregate rocks is essential. These properties include strength, durability, and workability. Each rock type offers unique advantages and disadvantages. These aspects must align with project-specific demands.

Making informed decisions leads to durable aggregate and efficient aggregate use. This contributes to long-lasting structures. ZONEDING offers comprehensive solutions for aggregate production. The company’s advanced crushing and screening equipment processes a wide array of rock types. ZONEDING’s expertise helps maximize quality and efficiency. Partner with ZONEDING for customized equipment and full-service support. They ensure your construction aggregate properties meet the highest standards.

This blog tells what a concrete crusher is, its work principle, and the purpose, process, and benefits in turning construction waste into valuable resources.

View detailsHow much gold remains underground? While about 212,000 tonnes are above ground, the USGS estimates only 59,000 tonnes of proven reserves are left to mine.

View detailsLearn essential machines and solutions for talc beneficiation. Know about crushers, mills, flotation cells & dryers that form an efficient talc processing plant.

View detailsUnderstand dry grinding process: definition, workprinciple, advantages, and common applications in various industries. Get a complete overview here.

View details