Mobile Crushing Plant FAQs: Your Complete Guide

Are you looking for a more flexible and cost-effective way to process rock, ore, or construction waste? A mobile crusher could be the perfect solution. Instead of hauling materials to a fixed machine, a mobile crushing plant brings the processing power directly to your job site. This guide will help you understand this technology, its benefits, and whether it is the right investment for your operation.

Table of Contents

What Exactly is a Mobile Crusher?

A mobile crusher is a complete crushing machine mounted on a wheeled or tracked chassis. Think of it as a self-contained factory on the move. This setup includes the crusher itself, a power system (usually a diesel engine), feeders, and conveyors all integrated into one unit. The main purpose of a portable crushing plant is to provide maximum operational flexibility. You can easily move it around a large site or transport it between different projects, which is impossible with a traditional static plant.

What are Main Benefits of Mobile Crushing Plant?

Using a mobile crusher offers several powerful advantages that can directly impact your project’s efficiency and profitability. These benefits are why more and more operations are choosing mobile solutions.

- Reduced Transport Costs: This is the biggest benefit. You crush materials on-site, eliminating the huge expense of trucking rock or demolition waste to an off-site facility. This saves you money on fuel, trucks, and labor.

- Fast Setup and Relocation: You can have a mobile plant up and running in a matter of hours, not weeks or months like a static plant. This speed is crucial for short-term projects or jobs with tight deadlines.

- Operational Flexibility: You can move the crusher directly to the rock face in a quarry or next to a demolition pile. This minimizes the need for extra loaders to re-handle material, making your entire workflow more efficient.

- Smaller Footprint: Mobile units are compact. They can work in tight spaces where building a large static plant would be impossible, making them ideal for urban demolition or smaller quarry sites.

What are Applications of Mobile Crushers?

The versatility of mobile crushers makes them useful in a wide range of industries. They are designed to handle tough conditions and diverse materials, making them a go-to solution for many applications.

- Quarrying and Mining: For primary, secondary, and tertiary crushing of hard rock like granite and basalt, directly at the source.

- Construction and Demolition: A mobile impact crusher for concrete recycling is perfect for processing old concrete and asphalt into reusable aggregate on-site.

- Road Construction: Crushing and screening materials for road base and sub-base right where the road is being built.

- Contract Crushing: For businesses that provide crushing services to various clients at different locations.

What are Types of Mobile Crushers?

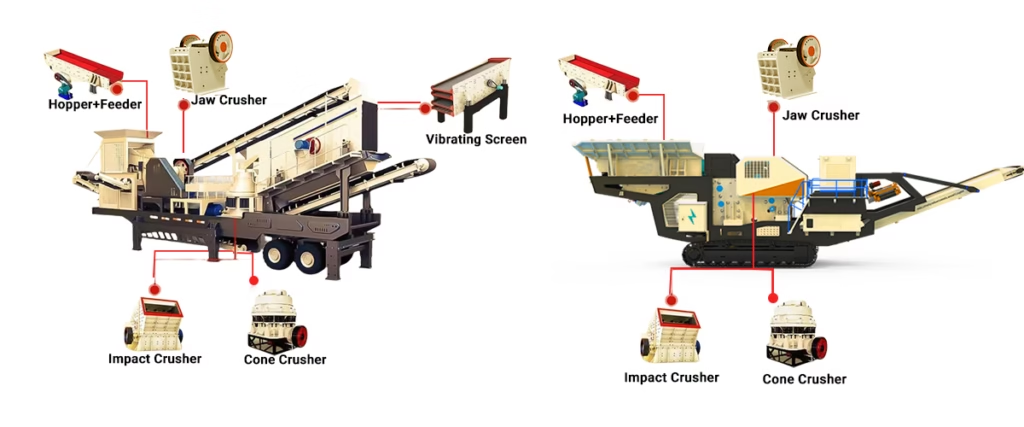

Mobile crushers are categorized by the type of crushing unit they carry and the chassis they use. At ZONEDING, we manufacture a full range to meet different material and project needs.

Based on the Crusher Type:

- Mobile Jaw Crusher: This is a primary crusher. It is perfect for breaking down large, hard, and abrasive rocks like granite. Its aggressive crushing action makes it the first step in most processing lines.

- Portable Impact Crusher: Excellent for secondary crushing and for recycling applications like concrete and asphalt. It produces a more cubical, well-shaped final product.

- Moveable Cone Crusher: Used for secondary and tertiary crushing of hard and medium-hard materials. It is known for producing high-quality, uniform aggregate.

Based on the Chassis Type:

- Track-Mounted Crusher: These units move on their own tracks, like a tank. They are ideal for rugged terrain in quarries and can be easily repositioned on-site without extra equipment.

- Wheeled Crusher: These are mounted on a semi-trailer chassis and are towed by a truck. They are faster to transport between different job sites on public roads.

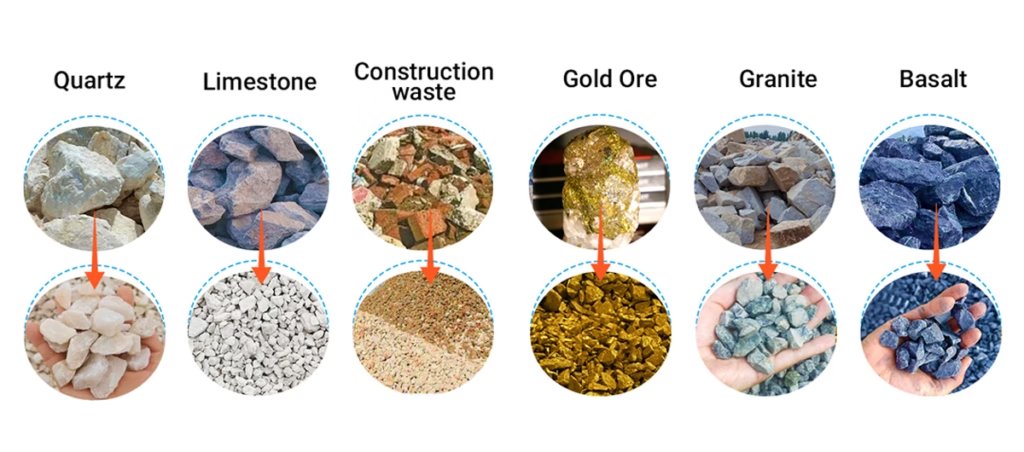

What Common Materials Can a Mobile Crusher Process Effectively?

A well-designed mobile rock crusher can handle a huge variety of materials. The key is to match the right type of crusher to the material you are processing.

- Hard Rock: Granite, basalt, gabbro, and river stone.

- Medium-Hard Rock: Limestone, dolomite, and sandstone.

- Mining Ores: Iron ore, copper ore, and gold ore.

- Recycled Materials: Concrete with rebar, asphalt pavement, and construction debris.

- Soft Materials: Coal and gypsum.

What are Features of Mobile Crushers from ZONEDING?

We design our mobile crushing plants with the operator in mind, focusing on durability, efficiency, and ease of use. Our experience since 1990 has taught us what matters most in the field.

- High-Durability Components: We use high-manganese and high-chromium steel for wear parts like jaw plates and blow bars, ensuring a longer service life and less downtime.

- Intelligent Control Systems: Our plants feature Siemens PLC control systems. This allows for one-touch startup and shutdown, real-time performance monitoring, and advanced diagnostics to prevent issues.

- Fuel Efficiency: We optimize our diesel engines and hydraulic systems to deliver maximum crushing power with lower fuel consumption, reducing your operational costs.

- Integrated Design: Our units are not just a crusher on a frame. They are fully integrated systems where the feeder, crusher, and conveyors are perfectly matched for balanced and efficient material flow.

Mobile vs. Static Crushing Plant: Which is the Better Investment?

This is a critical question. The answer depends on the scale and duration of your operation.

- A Mobile Crushing Plant is Better For:

- Short to medium-term projects (less than 5 years).

- Operations with multiple sites or changing locations.

- Projects with space limitations.

- When you need to be operational very quickly.

- A Static Crushing Plant is Better For:

- Long-term, high-volume operations (more than 5 years).

- A single, permanent location with a consistent feed source.

- When you need the highest possible production capacity (over 1000 TPH).

How Do You Choose The Right Mobile Crusher?

Selecting the right mobile crusher requires you to answer a few key questions about your project.

- What is your material? Its hardness and abrasiveness will determine if you need a jaw, impact, or cone crusher.

- What is the feed size? The maximum size of the rocks you will feed into the machine.

- What final product size do you need? This will influence the type of crusher and whether you need a screening unit.

- What is your required capacity? How many tons per hour (TPH) do you need to process?

- What are the site conditions? Is it a rugged quarry (needs tracks) or a flat recycling yard (wheels might work)?

Choosing a Supplier: What to Consider?

Your supplier is your long-term partner. Look beyond the initial price.

- Experience and Reputation: Choose a manufacturer with a long history in the industry. A supplier with global experience, like ZONEDING, understands different operational conditions and material types.

- After-Sales Support: Where will you get spare parts? Do they have technicians who can provide on-site support? Fast support is critical to minimizing downtime.

- Quality of Components: Ask about the brands of key components like the engine, hydraulics, and electronics. Reliable components mean a reliable machine.

- Factory Direct Sales: Buying directly from the manufacturer often means a better price and direct access to engineering expertise.

What are the Main Factors Influencing the Price of a Mobile Crusher?

The cost of a mobile crusher can range from $100,000 to over $800,000. Several factors determine the final price.

- Crusher Type and Size: A large primary jaw crusher will cost more than a smaller secondary impact crusher.

- Engine Brand and Power: Reputable engine brands like Cummins or CAT will increase the cost but offer reliability and better service.

- Chassis Type: Track-mounted systems are generally more expensive than their wheeled counterparts due to the complex undercarriage.

- Additional Features: The price will increase if you add options like a pre-screen, magnetic separator, or side conveyors.

What are the Key Maintenance Checks to Prevent Downtime?

Regular maintenance is the best way to ensure your mobile crusher runs reliably and profitably.

- Daily Checks: Check engine oil, coolant, and hydraulic fluid levels. Inspect conveyor belts for damage or misalignment. Listen for any unusual noises.

- Weekly Checks: Check the tension of all belts. Inspect the wear parts (jaw plates, blow bars) and measure the wear. Grease all lubrication points.

- Monthly Checks: Change engine and hydraulic oils and filters as per the manufacturer’s schedule. Check the structural integrity of the frame and chassis.

2025 Trends in Mobile Crushing Technology

The world of mobile crushing is constantly evolving. The latest trends are focused on making machines smarter, cleaner, and more efficient.

- Electrification and Hybrid Power: More machines are offering all-electric or diesel-electric hybrid options. These reduce fuel consumption, lower emissions, and are quieter to operate, which is important for urban sites.

- Advanced Telematics: This technology allows you to monitor your machine’s performance remotely from your computer or phone. You can track fuel usage, production rates, and upcoming maintenance needs.

- Increased Automation: Modern control systems are making machines easier to operate. Features like automatic feed control and blockage clearing reduce the need for constant operator intervention and improve efficiency.

Common Questions Answered

- How is Mobile Crusher Capacity Measured in Tons Per Hour (TPH)?

- Capacity is the amount of material a crusher can process in one hour. It is affected by the material type, its moisture content, the feed size, and the desired output size. TPH ratings are usually given as a range.

- How Quickly Can You Set Up and Operate a Mobile Crusher On-Site?

- A single track-mounted crusher can often be unloaded from a trailer and be ready to crush in under 30 minutes. A multi-unit wheeled plant might take a few hours to set up and connect.

- Can You Combine Different Mobile Units for a Complete Processing Line?

- Yes, absolutely. This is a very common practice. You can create a complete mobile crushing and screening plant by combining a mobile jaw crusher (for primary crushing), a mobile cone or impact crusher (for secondary), and a mobile screen to separate the final products.

- What After-Sales Support is Essential When Buying a Mobile Crusher?

- Essential support includes 24/7 access to technical advice, a reliable supply of genuine spare and wear parts, and the availability of trained field service engineers who can help with installation, training, and complex repairs.

Conclusion

A mobile crusher is a powerful tool that offers unmatched flexibility and can significantly reduce your operational costs. The right machine can transform your quarrying, mining, or recycling operation, turning logistical challenges into a competitive advantage. The key is to carefully assess your material, site conditions, and production goals.

By choosing a reliable machine from an experienced supplier, you are not just buying equipment; you are investing in a more efficient and profitable future for your business. If you are ready to explore your options, our team is here to help you configure the perfect mobile crushing solution.