全站搜索

Search the entire website

Search the entire website

Starting a limestone processing plant is a big project, but it can be very profitable. The process involves taking large rocks from a quarry and turning them into valuable products like construction aggregate or lime. You need a solid plan, the right equipment, and a good location. This guide will walk you through the key steps, from crushing the first stone to choosing the best machines for the job.

Limestone is a common type of rock found all over the world. It is a sedimentary rock, which means it formed from layers of sediment over millions of years. Most limestone is made of a mineral called calcium carbonate (CaCO₃). This calcium carbonate often comes from the shells and skeletons of ancient sea creatures like coral and shells. It is relatively soft compared to rocks like granite, which makes it easier to crush and process.

You cannot use the huge boulders that come out of a quarry directly. Limestone processing is necessary to break the rock down into specific, usable sizes and to improve its purity. For construction, you need different sizes of stone, known as limestone aggregate, for making concrete or building roads. For other industries, you might need to grind it into a fine powder to create a calcium carbonate plant product or heat it in a kiln to produce lime. Processing turns a raw, low-value material into a range of high-value products.

Once processed, limestone and its derivatives are used almost everywhere. The market for these products is huge and stable.

The journey from a giant rock to a finished product involves several key stages. The exact steps depend on whether you want to make aggregate, powder, or lime.

The first step is getting the limestone out of the ground. This usually happens in a quarry. Workers use controlled blasting or heavy machinery to break large sections of rock away from the quarry wall. These large boulders are then loaded into heavy-duty dump trucks to be transported to the processing area.

This is where the real processing begins. The large boulders from the quarry are too big for most machines. They are fed into a primary crusher, which is a powerful machine that breaks them down into smaller, more manageable rocks. A jaw crusher for primary limestone crushing is the most common choice for this job. After crushing, the material moves onto vibrating screens that separate the stones by size.

Sometimes, the crushed stone is mixed with dirt, clay, or other unwanted materials. To create a high-quality product, you need to clean it. A washing plant uses water jets and scrubbers to remove these impurities. This step is especially important if the limestone aggregate will be used to make high-strength concrete.

If your goal is to produce lime, you need an extra step called calcination. This involves heating the crushed limestone to a very high temperature (over 900°C or 1650°F) in a large industrial oven called a kiln. The heat causes a chemical reaction that removes carbon dioxide (CO₂) from the stone, turning it into calcium oxide (CaO), also known as quicklime.

The final steps depend on your end product. For construction aggregate, the sized and washed stones are ready to be sold. For quicklime, it might be sold as is or mixed with water in a controlled process called hydration. This creates calcium hydroxide (Ca(OH)₂), or hydrated lime, a fine white powder. If you are following the limestone powder manufacturing process, the crushed stone is fed into large mills that grind it into a fine powder.

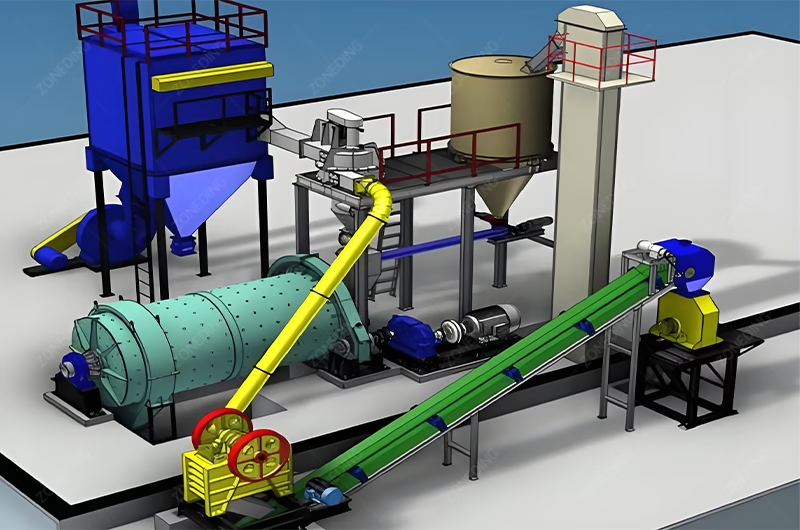

A successful plant needs a series of reliable machines working together.

A typical setup includes:

At ZONEDING, we understand that your equipment is the heart of your operation. We provide complete, reliable solutions for your limestone crushing plant.

limestone crusher machine to the final conveyors. This ensures all the parts work together perfectly.Choosing the right partner is just as important as choosing the right equipment. Here is what you should look for in a supplier:

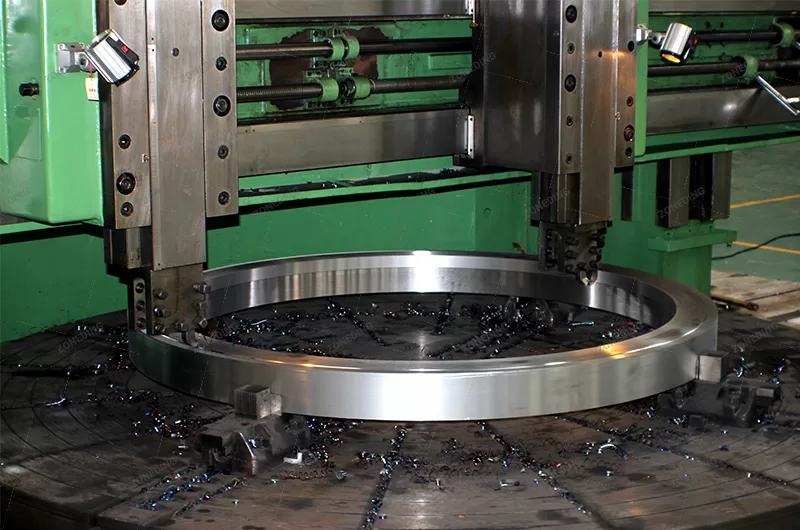

At ZONEDING, we have over 30 years of experience in manufacturing machinery for the construction and processing industries. We provide complete, one-stop solutions, from designing your entire limestone crushing plant to manufacturing every piece of equipment in-house. Our focus is on creating durable, efficient machines that provide the best value for your investment. We have delivered solutions to clients in over 120 countries, and our team of engineers is ready to help you build your successful processing operation from the ground up.

The cost of setting up a limestone processing plant varies widely. A small, basic crushing plant for aggregate might cost around $100,000 to $300,000. A large, fully automated plant that includes a kiln for lime production can cost over $2 million.

Key factors that influence the price are:

Starting a limestone processing plant is a complex but rewarding venture. Your success depends on a clear understanding of the process, a smart business plan, and choosing the right equipment from a reliable partner. By breaking down large rocks into valuable materials, you can build a strong and durable business.

The key steps are securing a quarry, designing an efficient plant, and investing in high-quality machinery. A good supplier will not just sell you a crusher; they will work with you to ensure your entire operation runs smoothly and profitably for years to come.

Contact us today to discuss your project and get a customized quote from our experts.

Learn how to transform waste concrete into aggregate. This guide covers the complete RCA processing workflow: crushing, screening, grading, and quality control.

View detailsA complete diagnostic chart for hammer crusher. We break down 9 common fault symptoms, explain the root causes, and provide effective, field-tested solutions.

View detailsThis guide covers the essential stages: crushing, grinding, and various beneficiation methods like gravity separation, magnetic separation, and flotation.

View detailsExplore detailed insights into limonite's extraction, beneficiation, and treatment methods.Learn its roles as an iron ore & pigment source in modern industries.

View details