The efficiency of a ball mill directly impacts production and profitability. Grinding media, such as steel or ceramic balls, perform the heavy lifting inside these machines. The quantity, size, and management of these balls make a significant difference. Too many or too few balls, or an incorrect size mix, can waste energy, increase wear, and reduce product quality. This guide aims to stop the guesswork. It provides clear strategies for improving mill performance.

ZONEDING has been manufacturing robust industrial machinery for decades. The company understands the precise requirements for optimal operational efficiency.

Table of Contents

Grinding media load is central to a ball mill’s performance. It dictates how effectively the mill breaks down material. It impacts overall operational costs. The amount of grinding media inside the mill, often called the “charge,” directly affects the grinding action. This action includes impact, attrition, and abrasion. Getting this charge right means processing material to the desired fineness efficiently. Getting it wrong leads to significant problems.

An optimized grinding media load ensures several vital operational benefits:

- Maximizes Grinding Efficiency: The correct charge provides the optimal number of impact and abrasion events per unit of material. This ensures material breaks down effectively and maximizes the specific energy consumption for grinding.

- Controls Power Consumption: An undercharged mill might spin too fast or cause metal-on-metal wear, wasting energy. An overcharged mill requires excessive power to rotate the heavier mass, drawing more electricity than necessary. Proper loading balances these needs.

- Minimizes Liner and Media Wear: A properly loaded mill reduces unnecessary impact on liners. It ensures grinding media wears down efficiently. Incorrect loading, however, can accelerate both liner and media degradation.

- Ensures Consistent Product Quality: The right media load helps achieve the target particle size distribution and fineness. This prevents both over-grinding and under-grinding of material.

- Supports Equipment Durability: ZONEDING emphasizes engineering solutions that support optimal operational conditions. This includes machinery designed to withstand critical grinding parameters. It ensures components like full automatic production lines run with peak performance when media load is optimized.

How to Calculate and Determine Initial Ball Load?

Calculating and determining the initial ball load for a ball mill is a foundational step. It sets the baseline for efficient grinding operations. A starting point is necessary. This initial calculation helps avoid major inefficiencies from the outset. It ensures enough grinding balls are present to begin effective material processing.

Understanding Fill Level

The fill level refers to the volumetric percentage of the mill occupied by the grinding media. For most ball mills, the optimal fill level ranges between 30% to 45% of the mill’s internal volume. This percentage includes the voids between the balls. A common industry starting point is often around 35-40% for general applications. This provides enough media to create effective impact and attrition zones without overfilling the mill.

Factors in Initial Calculation

Several factors play into the initial calculation, guiding users to a sensible starting point.

- Mill Dimensions: The internal diameter and length of the ball mill are essential. These dimensions determine the total internal volume. Once the volume is known, the volume for the target fill level can be calculated.

- Density of Grinding Media: Different materials used for grinding balls (e.g., steel, ceramic, cast iron) have different densities. Density is crucial for converting volume to weight. This helps determine the total weight of grinding media needed. High-density media offer more impact energy.

- Specific Application: The type of material being ground (its hardness, friability) and its desired fineness also influence the initial ball charge. Harder materials often require a higher percentage fill or larger, heavier balls for sufficient impact.

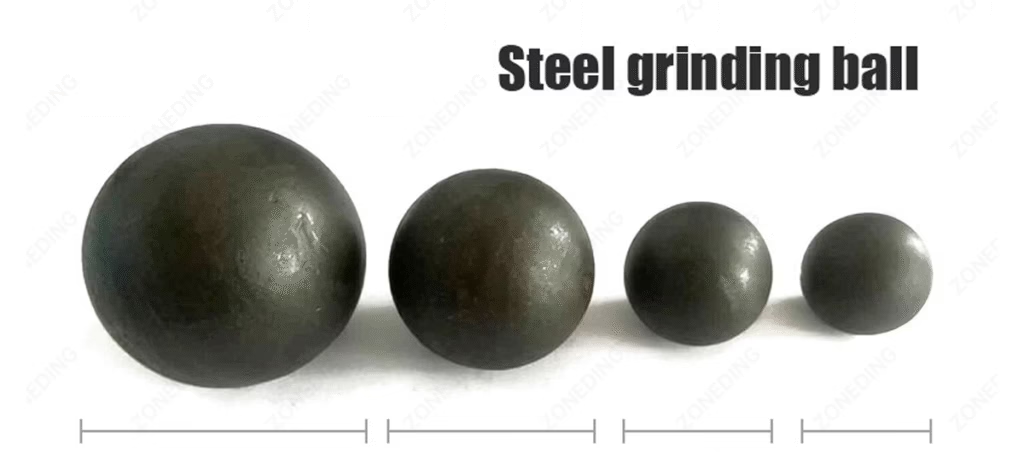

- Initial Ball Size Distribution: Grinding balls are not typically of one size. A mix of large, medium, and small balls is generally required from the start. Larger balls break coarser particles. Smaller balls grind finer particles. A common starting distribution might be 30-50% large, 30-40% medium, and 10-30% small.

The general approach involves:

- Calculating the mill’s internal volume.

- Deciding on a target volumetric fill percentage (e.g., 35%).

- Calculating the volume of balls needed based on this percentage.

- Factoring in the bulk density of the grinding media to convert this volume into the total weight of balls.

- Then, distributing this total weight across the chosen initial ball size distribution.

Optimal ball load and media distribution are not static. Many dynamic factors influence them. Understanding these helps fine-tune a mill for peak performance. The ideal charge changes with specific material and operational goals.

Material Properties

- Hardness and Abrasiveness: Tougher, harder materials need more impact energy. This often means a higher ball charge percentage. It also means larger, heavier grinding balls. More abrasive materials can accelerate ball wear. This needs to be accounted for in the media top-up strategy.

- Feed Material Size: If incoming material is coarse, more larger balls are needed in the media distribution. These larger balls are better for breaking down bigger chunks. A finer feed requires more emphasis on medium and small balls for attrition grinding.

- Desired Product Fineness: Achieving a very fine product requires longer grinding time. It might imply a higher surface area of grinding media (more smaller balls) or a slightly higher fill level to maximize grinding action.

Mill Characteristics

- Mill Diameter and Length: Larger diameter mills generate greater impact forces. This affects the required ball size distribution and speed. Mill length influences retention time and grinding intensity.

- Liner Design: The profile of mill liners (e.g., wave, step, smooth) affects how the grinding media cascades or tumbles. This influences the needed ball charge to achieve optimal media movement. Worn liners change this dynamic.

- Mill Speed: This is a crucial control. Operating speed, often expressed as a percentage of critical speed, affects grinding media trajectory. Varying mill speed impacts the required ball charge and media size.

Operational Parameters

- Mill Speed (Critical Speed Percentage): As noted, mill speed directly influences ball trajectory and impact energy. Adjustments to speed might necessitate adjustments to the ball charge. Higher speeds generally require fewer total balls for optimal action.

- Feed Rate: The rate at which material enters the mill significantly affects the “cushion” for the grinding balls. A higher feed rate requires a corresponding adjustment in ball load to maintain efficient grinding.

- Pulp Density (for Wet Grinding): The solids-to-water ratio in wet grinding impacts slurry viscosity. This affects media movement. Optimal pulp density ensures the balls are properly suspended and can move freely to grind effectively.

Media size distribution is not just about the total number of balls. It is about the mix of different-sized balls. This mix is crucial for achieving effective and efficient grinding results. A balanced distribution ensures that all particle sizes in feed material receive the right treatment. This prevents energy waste and optimizes product fineness.

Coarse vs. Fine Grinding

Grinding should be thought of as a multi-stage process happening simultaneously.

- Larger balls (typically 60-100 mm in diameter) are primarily responsible for impact grinding. They crush the coarser particles in the feed material. They provide the high energy needed to break down larger chunks. If the feed is very coarse, a higher proportion of these larger balls will be needed.

- Medium balls (typically 30-60 mm) perform a combination of impact and attrition. They work on intermediate-sized particles, further reducing them.

- Smaller balls (typically 10-30 mm) are crucial for attrition and abrasion grinding. They work on the finer particles. They produce the desired fineness and surface area. If the goal is a very fine product, these smaller balls are indispensable.

Achieving the Right Mix

The goal is to match ball size distribution to the feed material size distribution and the target product fineness. A common approach is a “graded charge” where balls of various sizes are included. As balls wear down, they move through the size hierarchy. Larger balls become medium, and medium become small. This natural wear process helps maintain a dynamic graded charge.

Key considerations for achieving the right mix:

- Regular Top-Up Strategy: Only adding small balls is not the strategy. Larger balls are typically added during top-ups. These larger balls then wear down. This helps maintain the overall size distribution.

- Continuous Evaluation: Regular screening of the grinding media inventory within the mill, or analyzing wear patterns, helps understand if distribution is optimal. The largest balls should not wear down too fast. The mill should not run out of small balls at discharge.

- Avoid Monosize Charges: A charge with balls of only one size is inefficient. It leaves gaps in the grinding action. Large particles will not get enough impact. Fine particles will not get enough attrition.

Optimizing ball load is an ongoing process, not a one-time calculation. It involves continuous monitoring and strategic adjustments to ensure peak mill performance. Moving beyond initial values is necessary. This systematic approach ensures a mill always operates at its best, adapting to changing conditions.

Monitoring and Analysis

- Power Draw Analysis: This is a primary indicator. Monitor the motor’s amperage or kWh consumption. Changes in power draw can signal an underloaded or overloaded mill. A mill running efficiently will have a stable power draw within its optimal range.

- Sound Analysis: The sound of a mill provides clues. A “hollow” or “rattling” sound often indicates an undercharged mill (metal-on-metal impact). A “muffled” or “sluggish” sound can suggest an overcharged mill.

- Particle Size Analysis (PSA): Regularly test the particle size distribution of a mill’s product. This directly indicates if the desired fineness is being achieved and if the grinding action is effective. Deviations might require ball load adjustments.

- Liner Wear Rates: Excessive liner wear can indicate an undercharged mill where balls impact the liners too aggressively. Uneven wear patterns can suggest poor media movement.

- Media Consumption Rates: Track how quickly grinding media is consumed. High consumption can point to inefficient grinding or issues with ball size distribution.

Adjusting the Charge

Based on monitoring, calculated adjustments will be made.

- If power draw is low and product is coarse: The mill might be undercharged. Add grinding media, typically the larger sizes, to increase the impact.

- If power draw is high and product is over-fine, or significant liner wear: The mill might be overcharged. Reduce the total media. Check the balance of ball sizes.

- If product is too coarse and power draw is normal: Media size distribution might be off. More larger balls might be needed for impact.

- If power draw is normal but there is over-grinding: The mix might need adjustment (more larger balls, fewer smaller ones) or the mill speed might need reduction.

Automation and Smart Systems

Modern mills increasingly use automation and smart systems for optimization.

- PLC Control: Programmable Logic Controllers can monitor power draw, feed rate, and other parameters. They can automatically adjust ball top-up systems or feed rates to maintain optimal grinding. ZONEDING incorporates advanced Siemens PLC control cabinets in its equipment. This provides precise control and data for optimization. It ensures machinery, such as customized block machine solutions, operates with high efficiency.

- Mill Load Sensors: Acoustic sensors or torque meters can provide real-time feedback on mill load. This allows for immediate adjustments.

- AI and Machine Learning: Some advanced systems use AI to analyze multiple data points. They predict optimal grinding media additions and recommend operational changes.

What Happens with Too Many or Too Few Grinding Balls?

The ball mill operates efficiently within a narrow optimal range for grinding media load. Deviating from this range, either by underloading or overloading, leads to distinct and costly problems. Understanding these consequences helps reinforce the importance of meticulous load management.

Effects of Underloading

When a ball mill has too few grinding balls, several negative outcomes occur:

- Reduced Grinding Efficiency: There are not enough balls to effectively break down the material. Many particles escape without sufficient impact or attrition. This results in coarser products and lower throughput.

- Increased Power Consumption per Ton: The mill still consumes significant power to rotate, but less material is being ground per unit of energy. Specific energy consumption skyrockets, making the operation less economical.

- Excessive Liner Wear: With fewer balls, there is less cushioning material. This leads to more direct metal-on-metal contact between the grinding balls and the mill liners. The balls impact the liners too aggressively, causing faster wear and damage.

- High Grinding Media Wear: The balls also suffer. Without enough material to grind, they impact each other more often, causing unnecessary wear on the balls themselves.

- “Hollow” Sound: The mill will often produce a distinct “hollow” or “rattling” sound. This indicates inefficient grinding and potential damage.

Effects of Overloading

Conversely, when a ball mill has too many grinding balls, different challenges are faced:

- Reduced Grinding Efficiency: An overcharged mill becomes too dense. The media cannot cascade or tumble effectively. Instead, they “slide” or “float” within the dense charge. This reduces impact and attrition. The material might not move freely through the media.

- Increased Power Consumption: A heavier charge requires more power to rotate. This increases the electricity bill without a corresponding increase in grinding efficiency. The motor has to work harder.

- Reduced Throughput: The material’s movement through the mill is restricted by the excessive ball volume. This decreases the rate at which finished product can be discharged.

- Excessive Stress on Drive System: The heavier load puts immense strain on motors, gearboxes, and bearings. This can lead to premature failure of these expensive components.

- “Muffled” or “Sluggish” Sound: An overloaded mill often sounds muffled. The grinding action is subdued. This indicates that the media is not impacting effectively.

The world of grinding media optimization is constantly evolving. 2025 brings exciting developments. These trends aim to make ball mill operations even more efficient, sustainable, and intelligent. They reflect a global push for better resource utilization and reduced environmental impact.

- Advanced Materials for Grinding Media and Liners: New alloys and composite materials are emerging. These materials offer superior hardness and toughness. They extend the life of both grinding balls and mill liners. This reduces consumption and maintenance. These materials also allow for more aggressive grinding cycles.

- AI and Predictive Models for Ball Charge Management: Artificial Intelligence and machine learning are revolutionizing how ball charges are managed. These systems analyze real-time data from sensors (power draw, acoustics, vibration). They predict optimal top-up times and ball size distributions. This ensures the mill operates at peak efficiency continuously.

- Focus on Sustainability and Circular Economy: There’s a growing emphasis on grinding media made from recycled materials. Also, processes for recycling worn-out media are improving. This reduces the carbon footprint of grinding operations. Energy-efficient grinding media designs also contribute to this sustainable shift.

- Integrated Smart Grinding Circuits: Ball mills are becoming part of larger, interconnected industrial ecosystems. IoT (Internet of Things) integration allows mills to communicate with other stages of the processing circuit. This enables holistic optimization from feed preparation to final product.

- Customized Media Solutions: Suppliers are increasingly offering highly customized grinding media solutions. These are tailored to specific ore bodies and grinding objectives. This precision engineering means less media waste and better grinding results.

FAQ

- Question 1: How often should a ball mill’s media load be checked?

- Visual checks of the load and listening to the mill should occur daily. For detailed analysis (power draw, sound), a weekly or bi-weekly check is advisable. Media top-ups are often daily or every few days.

- Question 2: What is the “critical speed” of a ball mill?

- Critical speed is the rotational speed at which centrifugal force pins the outermost grinding media against the mill shell. This prevents cascading action. Ball mills typically operate at 65-80% of critical speed.

- Question 3: Does the shape of the grinding media matter?

- Yes, the shape matters. While most often spherical, non-spherical shapes like cylinders can impact grinding. Spherical balls are standard for their consistent impact and wear properties.

- Question 4: Can different materials of grinding media (e.g., steel and ceramic) be mixed?

- Mixing different materials is generally not recommended. Different densities and wear rates can lead to an unbalanced charge and uneven grinding. It is best to stick to one material type for consistency.

- Question 5: What is the main purpose of adding fresh grinding media?

- Adding fresh grinding media (top-up) maintains the optimal ball charge volume and, crucially, the correct ball size distribution. As balls wear, they get smaller. Top-ups replenish the larger sizes.

Conclusion

Optimizing grinding media load is not just an option. It is a necessity for efficient ball mill performance. Getting the quantity and size distribution of balls right impacts everything. It affects grinding efficiency, power consumption, liner and media wear, and product quality. This guide stresses the importance of understanding influencing factors like material properties, mill characteristics, and operational parameters. This allows for continuous adjustments.

ZONEDING builds robust machinery designed to integrate these advancements. The company provides high-quality equipment, whether for concrete block production or other heavy industrial needs. It ensures its solutions support the quest for optimal efficiency and long-term success.