全站搜索

Search the entire website

Search the entire website

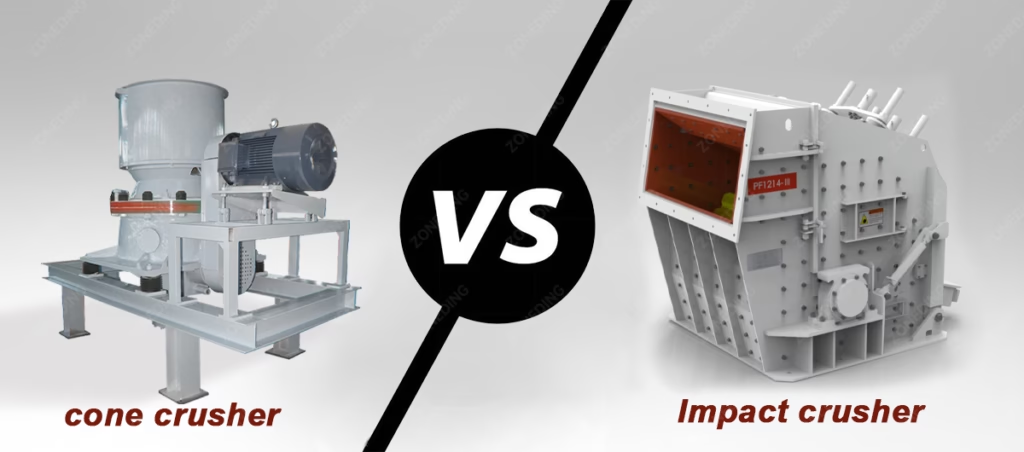

Choosing the right crushing equipment forms a crucial decision for an aggregate plant. Evaluating the merits of an impact crusher against a cone crusher often presents a challenge. Both machine types effectively reduce material size. However, their operational methods and superior applications differ significantly. An incorrect choice can lead to inefficiencies. It may also result in higher operational costs.

ZONEDING acknowledges this common dilemma. The company has manufactured high-performance crushing equipment since 2004. ZONEDING supplies both impact crushers and cone crushers globally. Expertise in aggregate production guides the company’s recommendations. This comprehensive guide details the key differences. It highlights the benefits and limitations of each type.

An impact crusher employs sharp, high-speed blows to shatter material. This dynamic breaking action effectively produces cubical, well-shaped aggregate. It is particularly effective for less abrasive feed materials. This is a key piece of equipment in many crushing operations.

The working principle involves rapidly rotating rotors. These rotors feature blow bars or hammerheads. They strike incoming feed material, causing material fragmentation. The material then propels against impact plates inside the crusher chamber, where further breakage occurs. This process repeats until the material reaches the desired size. Then, it exits the crusher.

ZONEDING offers various types of impact crushers, including horizontal shaft (HSI) and vertical shaft (VSI) models known for high reduction ratios and energy efficiency.

Impact crushers are versatile machines, defined by specific characteristics.

| Feature | Impact Crusher Advantage | Impact Crusher Limitation |

|---|---|---|

| Product Shape | Excellent cubicality | Cannot process highly abrasive feed |

| Reduction Ratio | High volume reduction | High wear on blow bars and plates |

| Versatility | Good for softer rock, recycling, sand | Not ideal for hard, sticky material |

A cone crusher uses compressive force between a moving mantle and a stationary concave to reduce material. This method ensures ideal crushing for hard, abrasive rock, specifically in secondary and tertiary stages of aggregate production. Cone crushers are known for high capacity and efficient processing of tough materials.

Continuous compression marks the working mechanism. An eccentrically rotating mantle gyrates within a fixed concave liner. Material, fed into the top, is squeezed between these surfaces. Progressive breakdown occurs as the material moves downward through the crushing chamber. Tightly packed material experiences inter-particle crushing. This produces a consistent, cubical product.

ZONEDING designs and manufactures reliable cone crushers, including hydraulic models that provide advanced automation and easy adjustment for optimizing aggregate production.

Cone crushers are indispensable for hard rock applications.

| Feature | Cone Crusher Advantage | Cone Crusher Limitation |

|---|---|---|

| Feed Material | Handles hard, abrasive rock well | Less effective with sticky material |

| Wear Costs | Lower wear parts cost per ton | Requires initial crushing to finer feed |

| Throughput | High capacity, continuous operation | Less reduction ratio than impact |

Deciding between an impact crusher and a cone crusher requires a direct comparison of their fundamental characteristics. While both reduce material, their methods and ideal applications differ significantly. Understanding these distinctions guides toward the best solution for aggregate production.

ZONEDING advises many clients on this choice, ensuring optimal crushing equipment for specific needs. The table below summarizes the key differences.

| Feature | Impact Crusher (HSI type) | Cone Crusher |

|---|---|---|

| Crushing Method | Impact, striking material with blow bars | Compression, squeezing material between two surfaces |

| Feed Material | Medium-hard to soft, less abrasive materials | Hard, abrasive materials (granite, basalt, metallic ores) |

| Product Shape | Excellent cubicality, high shape selectivity | Good cubicality, consistent particle distribution |

| Reduction Ratio | High (significant reduction in one stage) | Medium to High (suited for secondary/tertiary crushing) |

| Wear Parts | Blow bars, impact plates (higher wear rate with abrasives) | Mantle, concave (lower wear rate per ton, good for abrasives) |

| Maintenance | More frequent wear part replacement | Less frequent wear part replacement |

| Capacity | Good, but can be sensitive to sticky material | High, continuous throughput |

| Applications | Recycling, asphalt, softer aggregates, sand making (VSI) | Hard rock quarries, mining, secondary/tertiary aggregate production |

Selecting the optimal crushing equipment for an aggregate plant hinges on several key factors. Assessment of feed material properties, desired product specifications, and operational budget is necessary. A thoughtful decision ensures maximum efficiency and profitability.

ZONEDING specializes in providing tailored solutions, helping clients navigate this choice to ensure investments deliver the best return.

ZONEDING does not adhere to a one-size-fits-all solution. Engineers perform detailed analysis of client-specific site, material, and production goals. Factors like feed size analysis, desired product grading, operational hours, and maintenance capabilities receive consideration. For example, a ZONEDING mobile crushing plant could feature a jaw crusher for primary crushing, followed by either an impact crusher or a cone crusher for secondary crushing. This creates a flexible, efficient complete production line specifically suited to operational needs.

Choosing a supplier for crushing equipment involves more than just comparing machine specifications. It means finding a partner who understands your needs and supports your operation long-term. Consider these factors when making your decision.

The crushing equipment industry experiences constant evolution, aiming for greater efficiency, sustainability, and automation. Staying informed about these 2025 trends helps in making forward-looking investments. This ensures an aggregate plant remains competitive and profitable.

ZONEDING is a leading Chinese manufacturer of heavy mineral processing equipment. Focus remains on B2B solutions for mining, aggregate, and cement industries worldwide. Since its establishment in 2004, ZONEDING has built a reputation for designing and delivering robust, efficient, and customizable machinery.

The decision between an impact crusher and a cone crusher proves fundamental for an aggregate plant’s success. It relies on understanding feed material characteristics, the desired final product, and long-term operational costs. An impact crusher particularly excels with softer materials, producing highly cubical aggregate with a high reduction ratio. A cone crusher serves as the workhorse for hard, abrasive rock, offering high capacity and lower wear costs per ton.

Careful consideration of these factors allows for an informed choice. This optimizes crushing equipment investment. ZONEDING stands as an experienced partner. The company offers a comprehensive range of both impact crushers and cone crushers. Expert engineers guide clients. They analyze needs. They design the perfect complete production line. This ensures an aggregate plant thrives.

Determining whether an impact crusher or cone crusher is best for your aggregate plant? Contact ZONEDING today for a personalized consultation and a tailored equipment solution!

Learn from 9 considerations about optimal equipment, material handling, safety protocols, and quality control to maximize efficiency in basalt processing plant.

View detailsEverything you need to know about pebble sand manufacturing. From selecting the right pebbles to configuring your equipment line and calculating your ROI.

View detailsWhat is iron ore used for? Discover the top 5 uses including steel production, cast iron, powdered iron magnets, radioactive shielding, and coal washing.

View detailsWhy stop at cement? Learn how producing your own aggregates with in-house crushing plants is helping major companies cut costs and control quality.

View details