全站搜索

Search the entire website

Search the entire website

Choosing the right granite crusher represents a significant decision for any quarry or construction project. This guide provides essential tips for buying the most suitable hard rock crushing equipment to meet specific operational requirements. Readers will learn about granite properties. They will also discover how to navigate the complex world of crusher selection. The aim is to ensure an informed investment. This leads to durable, efficient machines.

Granite is a common type of intrusive igneous rock. It forms from magma slowly cooling below the Earth’s surface. This slow cooling allows large, coarse-grained crystals to form. These crystals give granite its distinctive appearance. Granite is primarily composed of four minerals. These are quartz, feldspar, mica, and amphibole. Quartz usually makes up 20% to 60% of the rock’s volume. Feldspar often comprises 10% to 65%. Mica and amphibole fill the rest. The exact proportions of these minerals determine the granite’s color and specific properties. For example, a high feldspar content gives pink or red hues. More mica often makes it darker. Equipment is to handle this variety. Manufacturers understand the different compositions.

Granite’s properties make it both valuable and difficult to crush. Understanding these characteristics is essential. This helps in selecting the right crushing equipment. Its inherent strength and composition lead to specific operational considerations. Knowing these helps design effective solutions.

Crushing granite presents several key difficulties. These challenges arise directly from granite’s robust properties. These obstacles are understood. Crushers are to overcome them. Addressing these difficulties is critical for efficient and cost-effective operations.

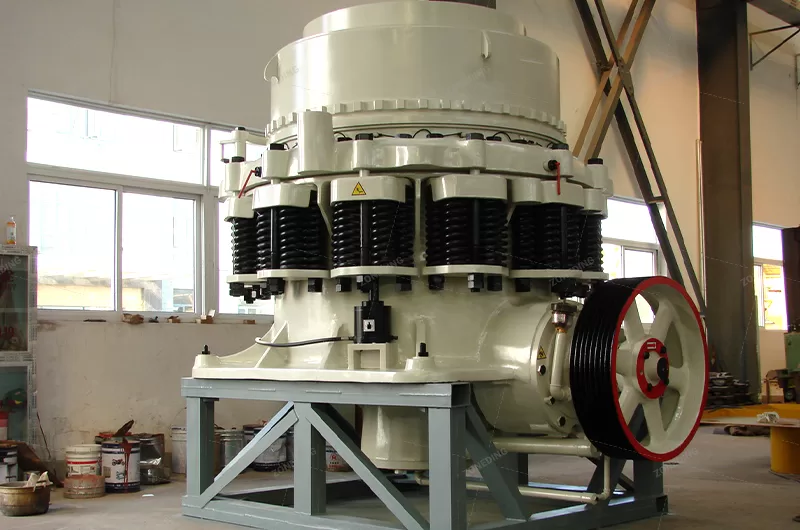

Selecting the right type of crusher is paramount for granite applications. Different crushers excel at different stages of reduction.

Buying a granite crusher represents a significant investment. A smart choice is necessary. These ten tips guide the process. They help ensure the selection of the best granite crusher for any operation. These tips focus on practical aspects. They cover every stage of the decision.

A full understanding of the granite ore is essential. Its hardness, abrasiveness, and moisture content are key. This guides the choice of hard rock crushing equipment. Different granites have varying mineral compositions. These impact wear rates. For example, high quartz content means more abrasion. Clients need to conduct detailed mineral analysis. This includes compressive strength tests. Knowing these properties helps select the right crusher type. It also helps select specific wear part materials. Using the wrong machine for the rock type leads to rapid wear. This increases operational costs. It also causes frequent breakdowns. An accurate assessment forms the foundation for proper crusher selection. This prevents expensive mistakes later.

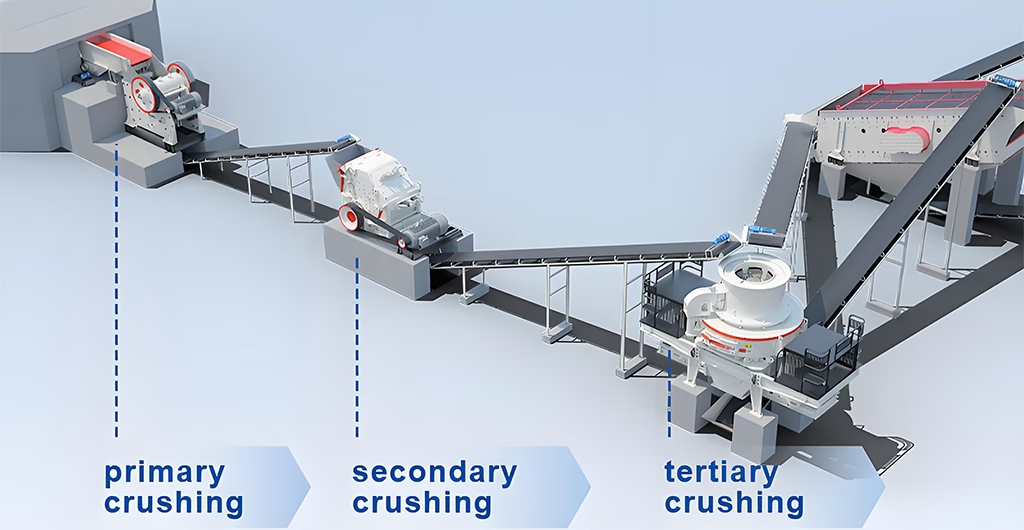

The desired output volume per hour or day is crucial. This helps size the crusher correctly. An undersized crusher struggles to meet demand. It operates inefficiently. It also wears out faster. An oversized crusher wastes capital and energy. Assistance is provided to clients in calculating their exact capacity requirements. Current needs and future growth are important. Peak demand periods also require thought. This affects the number and size of primary, secondary, and tertiary crushers. A well-matched capacity ensures smooth operation. It optimizes workflow. It maximizes crusher output efficiency. This planning step is fundamental for profitability.

The final aggregate specification is vital. Different end-products demand specific particle sizes and cubicity. Jaw crushers primarily reduce size. Cone crushers improve shape and further reduce size. Some applications need very fine aggregates. Others need a coarser product. For example, road base often requires specific angularity for compaction. Concrete aggregate needs cubical shapes for better mixing. Exact product specifications should share with manufacturers. So we can recommend The optimal crushing circuit. This includes the right type and number of crushers. It also includes screening equipment. Matching the crusher to product requirements ensures market acceptance. This boosts material value.

Granite is extremely abrasive. The quality of wear parts crusher materials directly impacts operating costs. Crushers with high-manganese steel jaws and mantles should be sought. High-chrome iron is also good for certain parts. Inferior quality parts fail quickly. This causes frequent, costly replacements. It also leads to significant downtime. Only top-grade, heat-treated alloys are for wear parts. This ensures maximum lifespan. Renowned international brands are also for key components. Examples are Siemens PLC control cabinets. Taiwan Kaili Jia hydraulic stations are also used. German Schneider inverters are installed. This commitment to quality minimizes long-term operating expenses.

Crushing granite is an energy-intensive process. A more energy-efficient crusher lowers electricity bills. This significantly improves profitability over time. Crushers with optimized crushing chambers should be considered. These chambers reduce unnecessary energy consumption. The cost of crusher maintenance and wear part replacement should also be considered. The cost of labor for repairs should be factored in. A cheaper machine might have higher operational costs. This can negate initial savings quickly. Crushers are for high efficiency. This helps contain operational costs. Parts are also for easy replacement. This reduces maintenance time and labor expenses.

Crushers operating with granite require regular maintenance. Parts need frequent checking and replacement. A machine designed for easy maintenance reduces downtime. It also keeps labor costs lower. Features like simplified wear part replacement systems should be sought. Accessible lubrication points should be considered. User-friendly hydraulic adjustment systems are also important. Maintenance accessibility is prioritized in designs. Crushers feature modular construction. This makes internal components easy to reach. This minimizes the time a crusher is offline for service. Efficient maintenance directly translates to higher uptime and production.

Modern granite crushers incorporate advanced automation. This improves efficiency and safety. PLC control systems allow for precise adjustments. They monitor operational parameters in real-time. Features like automatic tramp iron release enhance safety. They protect the crusher from damage. Variable speed drives optimize energy use. They allow fine-tuning of product gradation. Intelligent control systems, like Siemens PLC, are integrated. These systems provide comprehensive data. They allow remote monitoring and diagnostics. Automation reduces the need for constant manual intervention. It makes crushing plants more stable and productive.

Choosing a reputable manufacturer is paramount. A company with a long history in the industry should be sought. They should have proven expertise in hard rock crushing. Their customer service and after-sales support should be checked. Do they offer installation guidance? Do they provide operator training? Are spare parts readily available? ZONEDING has over 30 years of experience. Full-service support is provided. This includes design, manufacture, installation, and ongoing maintenance. A global presence exists. ZONEDING has exported to over 120 countries. This ensures reliable support no matter the location. A strong manufacturer partnership is crucial for long-term success.

Modern crushing operations must comply with strict environmental and safety regulations. Dust suppression systems are essential for granite crushing. Noise reduction features are also important. Crushers with intelligent safety interlocks should be sought. These protect operators during maintenance. Enclosed designs reduce noise emission. Crushing plants include integrated dust collection options. Water spray systems are also offered. These mitigate airborne particulate matter. Machines meet international safety standards. This ensures a safe and compliant working environment.

The initial purchase price should not be the only consideration. The total cost of ownership over the crusher’s lifespan must be considered. This includes the purchase price. It also includes energy consumption costs. Wear part replacement costs should be factored in. Maintenance labor expenses are also included. Downtime costs (lost production) are also crucial. A seemingly cheaper crusher might have very high TCO due to poor quality. A higher-quality machine from a reputable supplier might look more expensive upfront. However, it often offers a lower TCO. This is due to greater efficiency, longer lifespan, and less maintenance. The long-term value is explained. The actual cost-effectiveness of durable machines is demonstrated.

Choosing ZONEDING for granite crushing needs offers many distinct advantages. ZONEDING brings over 30 years of specialized experience to the table. ZONEDING understands the unique challenges of hard rock crushing. Solutions are for durability, efficiency, and reliability. This makes ZONEDING a trusted partner for operations.

Contact ZONEDING today to discuss granite crushing projects. Expert advice and customized solutions are ready to be provided. This helps ensure success.

This guide compares 8 common rock types, analyzing properties, pros, and cons to help you select durable and efficient aggregate for your construction project.

View detailsGet the ultimate guide to crushers vs. breakers. Understand differences, applications, and key selection criteria. Make informed decisions with confidence.

View detailsLearn how to close a mine sustainably by ecological rehabilitation. Techniques for soil restoration, water management, and repurposing land for recycle use.

View detailsExplore the machinery behind crushed stone and gravel production. From crushing blasted rock to washing river deposits, we provide complete plant solutions.

View details