Apatite is a vital mineral. It serves as the primary source for phosphorus. Phosphorus is essential for many industries, especially agriculture. Effective apatite processing ensures recovery of this critical element efficiently. This guide explores high-efficiency beneficiation for apatite ores.

Table of Contents

What is Apatite?

Apatite defines a group of phosphate minerals. It acts as the main mineral source for phosphorus. Phosphorus is a non-metallic element. It plays a crucial role in both biological systems and industrial processes. Apatite contains calcium phosphate. Its chemical formula typically appears as Ca5(PO4)3(F,Cl,OH). The mineral varies in color. One can find it in green, blue, yellow, or colorless forms. The mineral typically occurs in many different rock types.

Apatite forms in igneous, metamorphic, and sedimentary rocks. Its presence extends across the globe. It is in various geological settings. These settings significantly influence the apatite’s purity and crystal structure. Understanding its geological formation helps design effective processing methods. ZONEDING’s expertise helps tailor solutions for different apatite deposits. The company ensures its equipment can handle varied characteristics.

What are the Properties of Apatite?

Understanding apatite’s properties holds the key to processing it well. These traits guide beneficiation strategies. Different types of apatite show slightly different qualities. Knowing these helps adapt equipment and methods precisely.

- Physical Hardness: Apatite measures a hardness of 5 on the Mohs scale. This indicates a moderately hard mineral. Apatite Crushing and grinding equipment must manage this hardness efficiently.

- Specific Gravity: Its specific gravity ranges from 3.1 to 3.2. This density helps in its separation using gravity concentration methods. Distinct densities allow for more targeted and efficient separation processes.

- Luster and Fracture: Apatite usually shows a vitreous (glassy) luster. It also has an uneven to conchoidal fracture. These physical properties are important for visual identification in the field.

- Chemical Composition: Chemically, apatite is primarily calcium phosphate. This core composition influences all subsequent processing steps.

- Solubility and Reactivity: It remains mostly insoluble in water, which benefits the process by preventing significant loss during wet processing stages. However, it reacts with strong acids, a characteristic important for later chemical processing, such as phosphoric acid production.

Where Can We Find the Apatite?

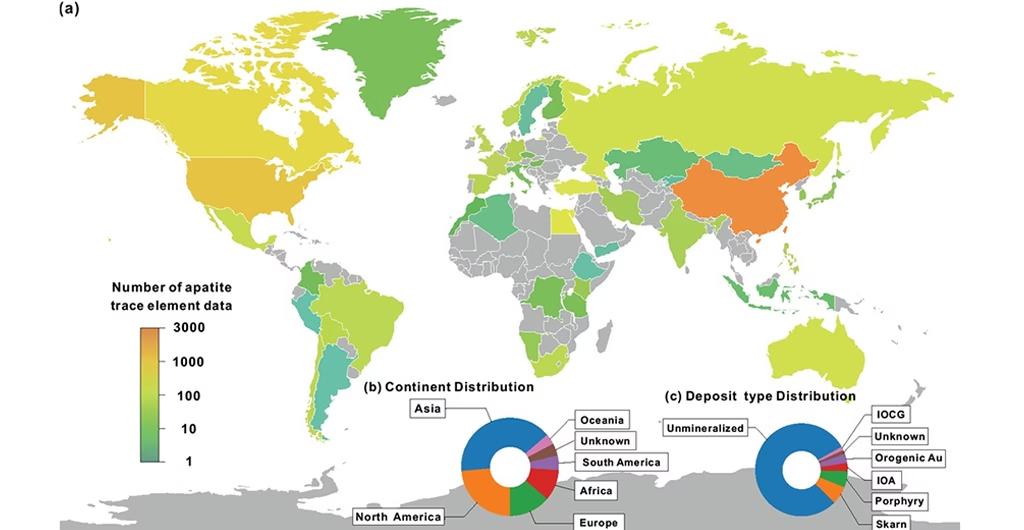

Apatite deposits exist all over the world. They are in various geological settings. These locations impact the ore’s characteristics significantly. Knowing these sources helps prepare for diverse processing needs. Experience spans many global projects. Regional differences in apatite ore compositions are understood.

- Igneous Rock Deposits: Major deposits occur in igneous rocks. These include carbonatites and alkaline intrusions. Significant deposits exist in Russia, Brazil, and Canada. These sources often present specific processing challenges.

- Metamorphic Rock Deposits: Apatite is also found in metamorphic rocks. These often occur in vein deposits. Examples include parts of Norway and Finland. These deposits typically have distinct mineral associations.

- Sedimentary Phosphorite Deposits: Furthermore, sedimentary phosphorites represent another common source. These form from marine organic matter. China holds large sedimentary deposits. The United States also possesses extensive sedimentary phosphorite reserves.

- Associated Gangue Minerals: The specific location often dictates the associated gangue minerals. These impurities must be removed during processing. For instance, apatite from igneous sources might come with silicates or carbonates. Sedimentary apatite might mix with clay or quartz. Phosphate Recovery solutions are designed to address these varying impurities effectively.

What are Applications of Apatite?

Apatite holds immense importance across numerous industries. Its diverse applications highlight its critical role in daily life. Contributions to these industries come from providing efficient processing solutions. This work directly supports the supply chain for these vital products.

- Agricultural Fertilizers: The primary use of apatite lies in fertilizer production. Around 90% of all mined phosphate rock goes into making agricultural fertilizers. These fertilizers are essential for crop growth, maintaining global food security. Apatite supplies the phosphorus needed for healthy plants.

- Phosphoric Acid Production: Beyond agriculture, apatite serves as a source for phosphoric acid production. Phosphoric acid is a base chemical with wide-ranging uses.

- Food Additives: It goes into many food additives, ensuring product quality and preservation.

- Detergents and Pharmaceuticals: Manufacturers use it in detergents and it also finds use in pharmaceuticals. These applications require high purity.

- Animal Feed Supplements: Apatite also becomes an ingredient in animal feed supplements, providing necessary phosphorus for livestock. This supports animal health and agricultural productivity.

- Steel Industry: It plays a role in the steel industry for various metallurgical processes. Phosphorus compounds improve certain steel properties.

- Specialized Applications: Some specialized applications include dental materials and certain types of lighting. The broad impact of efficient apatite beneficiation is recognized, with tailored solutions supporting these diverse applications globally.

Why is Apatite Critical for Industries?

Apatite’s criticality stems from its unique composition. It provides the world’s main source of phosphorus. Phosphorus represents an irreplaceable element. It underpins numerous industrial and biological processes. Its importance is evident every day. Work in processing apatite directly supports these critical industrial demands.

- Essential for Life: Phosphorus is a primary nutrient for all life forms. It forms a key component of DNA, RNA, and ATP (the energy currency of cells).

- Agricultural Productivity: In agriculture, phosphate fertilizers, derived from apatite, boost crop yields significantly. This ensures food security for a growing global population. Without sufficient phosphorus, crops cannot thrive. This makes high-quality phosphate rock beneficiation essential worldwide. Solutions are provided for this vital sector.

- Foundation for Industrial Chemicals: Beyond agriculture, phosphorus serves many industrial purposes. Phosphoric acid acts as a base chemical. Industries use it in detergents, food preservatives, and water treatment.

- Manufacturing and Metallurgy: It also plays a role in producing fire retardants and various industrial chemicals. The steel industry uses phosphorus compounds, applying them as alloying agents and in surface treatments. Therefore, access to consistent, high-purity apatite concentrate directly affects numerous manufacturing sectors. Specialization lies in producing efficient Mineral Processing systems that deliver the required product quality for these diverse and critical industrial needs.

What are Challenges When Processing Apatite?

Processing apatite presents various challenges. These challenges can significantly affect efficiency and cost. These issues are faced directly. The goal is to develop solutions that overcome these difficulties. The aim is always for optimal beneficiation outcomes.

- Diverse Ore Compositions: Amajor challenge involves the diversity of apatite ores. Apatite deposits vary greatly in composition. They can contain different gangue minerals, such as carbonates, silicates, or iron oxides. This necessitates highly customized processing circuits.

- Inadequate Standard Approaches: A standard approach often fails due to ore variability. Methods must be adapted for each specific ore body. This includes selecting the right equipment and choosing proper reagents for flotation.

- Fine Mineral Dissemination: Another issue relates to the fine dissemination of apatite. Often, apatite particles are very small, intergrowing finely with gangue minerals. This necessitates very fine grinding.

- Grinding Challenges: Fine grinding consumes significant energy. It also creates challenges for subsequent separation. Managing over-grinding is important, as it can lead to flotation difficulties. It may also generate excessive slimes, which reduce recovery rates.

- Environmental Concerns: Furthermore, environmental concerns always remain present. Processing can generate wastewater and tailings. Proper management of these waste streams is crucial. A focus on efficient design helps clients meet strict environmental regulations. ZONEDING has over 30 years of experience finding solutions for these complex processing challenges.

What is the Whole Process of Apatite Processing?

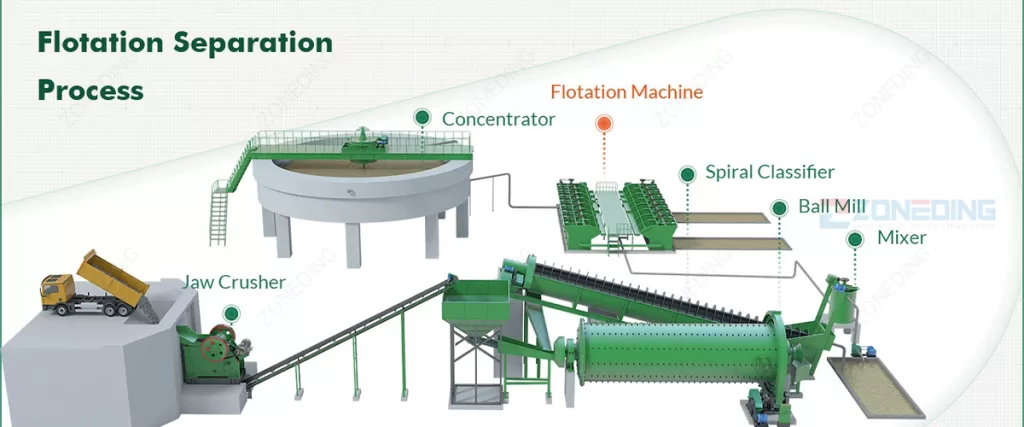

Apatite processing involves several key stages. Complete processing lines are designed for these stages. This ensures efficient recovery from start to finish. Solutions cover the entire beneficiation flow.

- Crushing: The process begins with crushing. Raw apatite ore comes in large chunks. Jaw crushers and cone crushers are used. These machines reduce the ore to a manageable size. This prepares it for subsequent grinding.

- Grinding: After crushing, the ore goes to grinding. Ball mills or rod mills grind the ore. This reduces particle size further. It liberates apatite minerals from gangue. Proper grinding is vital for effective separation. Too coarse, and minerals remain locked. Too fine, and costs increase.

- Classification: Ground pulp then moves into a classifier. Hydrocyclones or spiral classifiers separate particles by size. Coarser particles are sent back for regrinding. Finer particles move to the next stage. This ensures uniform feed for flotation.

- Flotation: Flotation represents the main separation method. Apatite particles attach to air bubbles. These bubbles rise to the surface. They form a froth. Gangue minerals remain in the pulp. Reagents (collectors, frothers) are added. These enhance selective attachment of apatite. Flotation conditions are adjusted carefully. This maximizes Apatite Flotation efficiency.

- Concentrate Dewatering: The apatite concentrate starts as a slurry. It contains a lot of water. Thickeners remove most of the water. Then, vacuum filters or press filters dewater it further. The goal is to produce a filter cake. This cake has low moisture content.

- Drying: Finally, operators often dry the filter cake. Rotary dryers or flash dryers remove remaining moisture. The dried concentrate is then ready for transport and market. This whole process ensures high-quality phosphate concentrate.

Which Equipment is Necessary for an Apatite Processing Plant?

Equipping an apatite processing plant requires specific machinery. A full range of high-quality equipment is supplied. These machines ensure efficiency and reliability. The comprehensive product line covers every stage of the process.

- Crushing Stage:

- Jaw Crushers: Handle primary reduction of large feed sizes.

- Cone Crushers: Provide secondary crushing for finer material and high capacity.

- Feeders: Ensure a steady material flow, preventing blockages and optimizing throughput.

- Grinding and Classification Circuit:

- Ball Mills: Crucial for achieving the required fineness for mineral liberation.

- Hydrocyclones: Classify the ground ore slurry by size, sending coarser material for regrinding.

- Flotation Stage:

- Flotation Cells: Designed for optimal separation, with various volumes and configurations to match specific ore characteristics. This maximizes Apatite Flotation efficiency.

- Dewatering Stage:

- Thickeners: Remove most of the water from the apatite concentrate slurry.

- Filter Presses (Vacuum/Press Filters): Dewater the thickened concentrate further, producing a low-moisture filter cake.

- Drying Stage:

- Rotary Dryers or Flash Dryers: Remove remaining moisture from the filter cake, preparing the dried concentrate for market.

- Material Handling Equipment: ZONEDING also offers various Mineral Separation equipment, including conveyors and slurry pumps. These facilities ensure smooth material handling throughout the plant.

What Are Common Apatite Processing Problems, and How to Troubleshoot Them?

Specific problems often occur during apatite processing. Recognizing these issues early helps achieve efficient processing. Practical solutions are offered to troubleshoot these common problems. Experience helps optimize plant performance.

Problem 1: Low Recovery Rates During Flotation

- Description: Not enough apatite floats into the concentrate, leading to significant mineral loss.

- Troubleshooting Steps:

- Check Pulp pH: Incorrect pH significantly affects reagent performance, which is vital for flotation.

- Verify Reagent Dosage: Too little or too much reagent (collectors, frothers) can reduce flotation efficiency.

- Assess Particle Size: If grinding is too coarse, minerals do not liberate. If too fine, excessive slimes can depress flotation. Adjustment of grinding parameters is often required.

Problem 2: Poor Concentrate Grade

- Description: The concentrate contains too many impurities (gangue minerals), reducing its market value.

- Troubleshooting Steps:

- Adjust Flotation Conditions: Modifying frother dosage might create a more stable froth for better separation.

- Examine Wash Water Rates: Insufficient wash water in cleaning stages can carry gangue into the concentrate.

- Manage Slime Contamination: Over-grinding can create slimes that contaminate the concentrate. ZONEDING engineers analyze these factors, fine-tuning the circuit. This ensures both high recovery and premium concentrate grade, improving Apatite plant optimization.

Can Sustainable Apatite Processing Practices Reduce Environmental Impact?

Yes, adopting sustainable practices in apatite processing is crucial. It definitely reduces environmental impact. Sustainable methods are integrated into plant designs. The goal is to minimize waste and conserve resources. This benefits both the environment and clients’ bottom line.

- Water Management:

- Traditional processing uses large amounts of water.

- Closed-loop water systems are proposed, which recycle water used in beneficiation.

- This significantly reduces fresh water consumption and lessens wastewater discharge.

- Tailings Management:

- Efficient tailings management is encouraged.

- Dry stacking or co-disposal methods reduce the footprint of tailings ponds.

- These methods also lower the risk of contamination.

- Energy Efficiency:

- Grinding and crushing are energy-intensive steps.

- Energy-efficient equipment, such as high-pressure grinding rolls (HPGRs), is offered. These can reduce energy consumption compared to traditional ball mills.

- Optimizing process control also saves energy. ZONEDING’s smart control systems help achieve this. Embracing these practices helps clients meet environmental regulations and build a more responsible operation. Sustainable apatite processing is not just good for the planet; it is also beneficial for long-term business viability.

How To Choose the Right Supplier for Your Project?

Choosing the right supplier for your apatite processing project is a critical decision. It directly impacts your project’s success and profitability. What makes a good partner is understood. These factors are believed to be crucial when making your choice.

- Extensive Experience:

- Look for a supplier with a long history in mineral processing.

- This experience proves their understanding of complex ores and real-world challenges.

- For instance, ZONEDING was established in 1990, bringing over 30 years of experience and successful projects worldwide.

- Comprehensive Product Range and Customization Ability:

- A good supplier offers a complete line of equipment for all processing stages.

- They should also customize solutions for your specific ore, as each apatite deposit is unique.

- ZONEDING provides full production lines and customizes every component to meet exact needs (raw materials, output, size, etc.).

- Robust Technical Support and After-Sales Service:

- A reliable supplier provides full-service support, spanning from design to installation, training, and ongoing maintenance.

- They should offer readily available spare parts and strong customer support to ensure smooth operation.

- Commitment to Quality:

- Assess their commitment to quality in materials and components.

- Good suppliers use high-quality materials and incorporate reputable components (e.g., Taiwan Kaili Jia hydraulics, German Schneider inverters, Siemens PLC). Choosing correctly ensures your plant runs smoothly and efficiently for years.

2025 Latest Apatite Processing Development and Trends

New trends in apatite processing are constantly observed. The industry keeps changing. New technologies help improve efficiency. The focus remains on innovations that make processing better.

Latest Progress at a Glance

- Enhanced Flotation Reagents: New, more selective flotation reagents are emerging. These reagents improve apatite recovery. They also reduce reagent consumption. These are being tested for better performance.

- Automated Process Control: Advanced automation systems are becoming standard. They use sensors and AI. These systems optimize flotation and grinding. They lead to more stable operation.

- Dry Processing Technologies: Research into dry beneficiation methods grows. This includes electrostatic separation. Dry methods could reduce water usage significantly. This development is carefully monitored.

The market now demands higher purity products. Environmental regulations are also stricter. This pushes for new, greener methods. Innovations in equipment design reduce energy use. They also improve waste management. These advancements are integrated into offerings. The aim is to keep clients ahead.

FAQ

- Question 1: How can an apatite concentrate grade be improved?

- Concentrate grade can be improved by optimizing flotation conditions. Check reagent dosages and pulp pH. Ensure sufficient wash water in cleaning cells. Proper classification before flotation also helps optimize the process.

- Question 2: What is the lifespan of typical apatite processing equipment?

- The lifespan of equipment varies greatly. It depends on maintenance and operating conditions. With proper maintenance and quality components, heavy mineral processing equipment can last 15-20 years or more.

- Question 3: How much water does an apatite processing plant use?

- Water usage varies greatly by plant size and process. Plants using water recycling systems significantly reduce fresh water intake. Designs prioritize water conservation.

Summary and Recommendations

Apatite processing is vital for many industries. Its importance and complex steps have been outlined. It involves crushing, grinding, flotation, and dewatering. Each step demands precise control. Challenges include diverse ore types and fine particle dissemination. Sustainable practices are emphasized. These practices prove crucial for long-term viability. This ensures responsible resource management.

You need to optimize your limonite operations. Consider a tailored solution. Review your current processing steps. Identify areas for improvement.

Choosing a knowledgeable and experienced supplier is key. Look for a partner offering comprehensive solutions. They must have customization capabilities. They should also provide full technical support. It is advisable to research well. Select a supplier committed to quality and long-term service. This choice will greatly impact your project’s success.