全站搜索

Search the entire website

Search the entire website

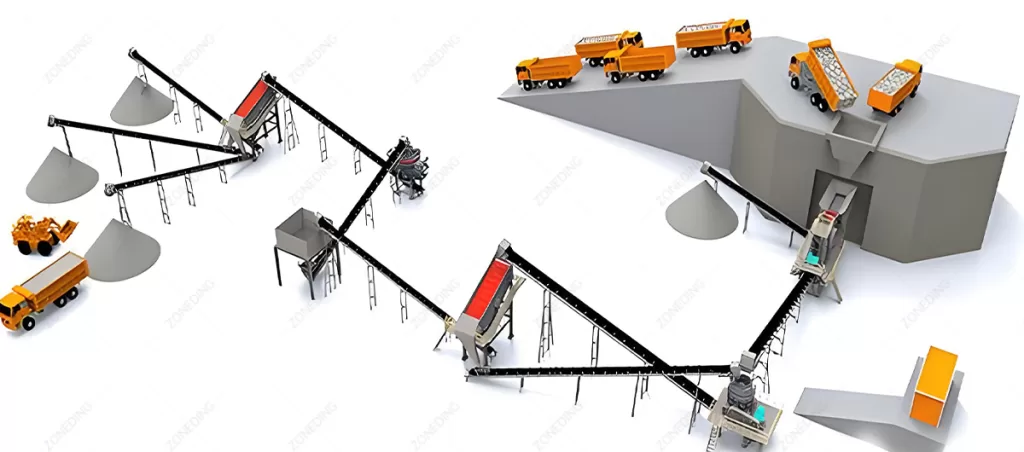

An aggregate processing plant forms the backbone of the entire construction industry. It transforms raw materials like hard rock, sand, and gravel into usable aggregates. These materials then build roads, bridges, and buildings. This guide explores the full lifecycle of an aggregate processing plant. It covers crushing, screening, washing, and every stage involved in producing aggregates. ZONEDING MACHINE provides essential mineral processing equipment and expertise. This helps build an efficient and successful aggregate plant. This also aids understanding of each critical step in aggregate production.

An aggregate processing plant operates as an industrial facility. It processes raw quarried rock or gravel into various sizes of stone, sand, and gravel. Industries call these processed materials “aggregates.” Aggregates serve as fundamental building materials. They form the core components of concrete, asphalt, and road bases. Without these plants, infrastructure development would stop. These plants ensure a consistent supply of graded materials. This helps build and maintain modern societies. ZONEDING specializes in designing and building customized aggregate plants. It delivers solutions that meet diverse material requirements and project scales. ZONEDING’s expertise helps clients get the right materials for construction needs.

Industries need aggregate processing plants because natural sources of ready-to-use aggregate diminish. Also, construction projects demand specific material sizes and qualities. A plant allows precise control over these specifications. This ensures the final building materials meet stringent engineering standards. This precision directly impacts the strength and durability of infrastructure projects. Quality aggregate production involves more than simply breaking rocks. It means creating engineered materials. ZONEDING’s complete production line solutions ensure high-quality, consistent output for projects. (178 words)

A typical aggregate plant consists of several key components. Feeders introduce raw material into the system. Crushing equipment reduces the material size. Screening equipment separates material into different fractions. Conveyors move materials between these stages. Washing equipment cleans the aggregates if necessary. Each component plays a vital role in the aggregate production process. Their efficient operation ensures the plant runs smoothly. ZONEDING helps clients select and integrate these components for maximum efficiency.

The quality of aggregates critically impacts the final construction product. Poor quality aggregates weaken concrete or destabilize roads. Engineers specify particular aggregate sizes and shapes for different applications. For example, concrete often requires cubical aggregates, while road bases might use angular, interlocking stones. An aggregate processing plant ensures compliance with these exact specifications. It produces the precise quality specific construction materials demand. This guarantees the longevity and safety of built structures.

Crushing marks the essential first step in any aggregate production process. It reduces large rocks, often from a quarry, in size. This stage is crucial because raw materials typically come in sizes too large for direct use. Effective crushing prepares the material for further processing. It enables subsequent stages to function efficiently. The type of crushing equipment used depends heavily on the hardness and size of the raw material. ZONEDING manufactures a wide range of robust crushing equipment. This ensures reliable solutions for initial size reduction.

This process involves multiple stages. Each stage refines the material further. Different crusher types perform work at each stage to optimize efficiency and product quality. This multi-stage approach allows precise control over particle size and shape. It also minimizes wear and tear on specialized machinery. ZONEDING’s engineers design complete crushing solutions. This helps clients achieve desired aggregate specifications.

Primary crushing tackles the largest raw materials. Companies commonly use jaw crushers or gyratory crushers at this stage. A jaw crusher works by compressing rock between a fixed and a moving jaw. This breaks the material. It reduces large boulders, sometimes over a meter in diameter, into sizes typically between 100mm and 250mm. This size reduction eases transportation and prepares the material for subsequent stages. ZONEDING’s jaw crushers demonstrate robust design and high crushing efficiency. They handle even the toughest rocks.

After primary crushing, the material moves to secondary crushing. Here, cone crushers usually take over. Cone crushers use a grinding and compressing action. They further reduce material size and begin to improve its shape towards a cubical form. In the tertiary stage, operators often employ impact crushers or Vertical Shaft Impact (VSI) crushers. These crushers produce fine aggregates and sand. They also further refine the particle shape. This ensures the aggregates meet strict quality standards for construction materials. ZONEDING’s advanced crushing equipment allows precise control over the final product’s characteristics.

Screening stands as a critical process in an aggregate processing plant. After crushing, the material contains various particle sizes. Screening separates these into specific size categories. This classification proves vital. Different construction applications demand different aggregate sizes. For example, fine aggregates go into concrete, while coarser ones form road bases. Effective screening ensures compliance with precise specifications. This consistency leads to higher-quality building materials. ZONEDING provides highly efficient screening equipment that precisely sorts aggregates.

This stage often involves multiple screens. Each screen has different mesh sizes. Materials pass through progressively finer screens. This separates them into distinct product streams. The result includes carefully graded aggregates. This meticulous sorting process happens within the aggregate plant. It optimizes the value of the raw material.

Operators primarily use vibrating screens for aggregate classification. These screens employ a vibrating motion to pass smaller particles through mesh openings. They retain larger particles. Single-deck, double-deck, and triple-deck screens each serve different purposes. Multi-deck screens allow simultaneous separation into several size fractions. Choosing the right screen type and mesh size depends on the desired output sizes and capacity. ZONEDING’s vibrating screens demonstrate high efficiency and durability. They ensure reliable performance in demanding aggregate production environments.

Accurate screening directly influences the quality and market value of aggregates. Precisely sized aggregates mix better in concrete. They compact more effectively in asphalt. Inaccurate screening creates inconsistent product quality. This causes issues in downstream construction processes. Proper screening also helps prevent material waste by classifying all usable fractions. It maximizes the yield from raw material. This boosts overall efficiency for aggregate producers. ZONEDING helps clients achieve precise grading results with its advanced technology.

Washing offers an optional but often crucial stage in an aggregate processing plant. It removes clay, silt, dust, and other undesirable impurities from the crushed and screened aggregates. These impurities negatively affect the quality of construction materials. For example, clay and silt weaken concrete. They can also prevent proper bonding in asphalt. Washing cleans the aggregates. It improves their physical properties. This makes them suitable for high-specification applications. ZONEDING offers advanced washing equipment to ensure aggregates meet the highest purity standards for aggregate production.

The decision to include a washing stage depends on the raw material’s cleanliness and the required aggregate quality. If raw material contains significant amounts of detrimental fine particles, washing becomes essential. This process enhances the aggregate’s value. It makes it suitable for premium market segments. ZONEDING designs effective washing solutions for specific client needs.

Washing significantly improves aggregate quality. It removes harmful organic matter and fine particles. These impurities absorb water and do not contribute to the strength of concrete. By removing them, washing improves the bond between the aggregate and cement paste. This results in stronger, more durable concrete. For road building, clean aggregates compact better and drain more effectively. This extends the lifespan of pavements. For sand production, washing removes fine silt and clays. This ensures high-quality manufactured sand for critical uses.

Operators use various methods for washing aggregates. Screw sand washers and wheel sand washers are common for sand and fine gravel. These machines use rotating screws or paddles to agitate the material. They separate the fines from the coarser particles while adding water. Water carries away the lighter impurities. Log washers handle larger, harder-to-clean aggregates. They use rotating paddles with blades to break up tough clay lumps. Choosing the appropriate washing method depends on the material type, contamination level, and desired cleanliness. ZONEDING provides a range of efficient washing equipment tailored to specific aggregate cleaning needs.

Material handling plays a central role in an aggregate processing plant. It involves the efficient movement of materials between different stages of crushing, screening, and washing. An effective material handling system minimizes downtime. It maximizes throughput. It ensures a continuous flow of raw material and finished products. This optimizes the entire aggregate production process. Without robust handling, even the best crushing equipment cannot operate at its full potential. ZONEDING designs comprehensive complete production line solutions. These include advanced material handling systems.

An efficient layout reduces operating costs. It also enhances safety. Every conveyor, feeder, and storage bin contributes to this seamless operation. ZONEDING engineers carefully plan each component’s placement. This helps clients achieve maximum efficiency in their aggregate plant.

Conveyor systems function as the arteries of an aggregate processing plant. They transport material from one process stage to another. Belt conveyors represent the most common type. They efficiently move large volumes of material horizontally or at an incline. ZONEDING carefully designs their length, width, and speed. This matches the plant’s capacity and material flow requirements. Efficient conveyor systems reduce the need for mobile equipment. They lower operational costs. They also enhance safety within the aggregate plant. ZONEDING engineers ensure seamless integration of conveyor systems into custom plant designs.

After processing, finished aggregates move to stockpiles for storage. Operators typically use radial stackers or fixed conveyors for this. Proper stockpiling prevents material segregation. It also ensures easy retrieval for loading and transportation. Different aggregate sizes often require separate stockpiles. This maintains product purity. Effective storage management optimizes logistics. It helps aggregate producers meet customer demand promptly. ZONEDING helps clients design efficient stockpiling solutions. This supports their complete aggregate production workflow.

Designing an aggregate processing plant requires careful consideration of several key factors. The choice of quarry machinery and plant layout critically affects efficiency and profitability. ZONEDING tailors each design to specific needs. No two projects are exactly alike. ZONEDING emphasizes customization. This ensures an aggregate plant perfectly fits operational goals. Understanding these fundamental considerations assists informed decision-making. This leads to a successful and productive aggregate production operation.

This involves analyzing the raw material, desired output, and available site. ZONEDING engineers work closely with clients. They develop a solution that maximizes throughput and minimizes costs. This guarantees a high return on investment for an aggregate production facility.

The characteristics of raw material determine the plant’s design. Analysts consider factors like rock hardness, abrasiveness, moisture content, and mineralogy. Hard, abrasive rocks require more robust crushing equipment with durable wear parts. Wet, sticky materials might necessitate specialized feeders and washing equipment. Understanding these properties from the outset ensures the selection of the right mineral processing equipment. This choice prevents costly breakdowns and optimizes efficiency. ZONEDING provides expert raw material analysis. This forms the basis of customized aggregate plant designs.

Desired output capacity and product specifications drive the plant’s overall scale and complexity. For example, a plant producing 100 tons per hour differs vastly from one producing 500 tons per hour. ZONEDING also considers the number of aggregate sizes needed. Maximizing efficiency means optimizing the flow between stages. It means selecting crushers and screens that balance capacity. It also means minimizing bottlenecks. ZONEDING engineers utilize advanced simulation and design tools. This optimizes an aggregate processing plant for peak performance and profitability.

Selecting the right supplier for an aggregate processing plant represents a critical business decision. This choice determines a plant’s efficiency, reliability, and ultimately, its profitability. A partner is needed who understands the complexities of aggregate production and offers comprehensive support. For aggregate producers and construction companies, a reliable equipment supplier proves a valuable asset. ZONEDING stands as a trusted choice. It offers tailored solutions and extensive industry experience.

An ideal supplier provides more than just machinery. They offer expertise in plant design, material analysis, and after-sales support. This holistic approach ensures an aggregate plant operates at peak performance throughout its lifespan. ZONEDING distinguishes itself through its global reach, factory-direct model, and complete service support.

The aggregate production industry continues to evolve. Several key trends shape the future of aggregate processing plants in 2025 and beyond. These advancements aim to improve efficiency, reduce environmental impact, and meet the growing demand for high-quality construction materials. Staying informed about these developments helps aggregate producers maintain a competitive edge. ZONEDING incorporates these innovations into its mineral processing equipment and plant designs.

These trends focus on smarter, more flexible operations. They address challenges like escalating energy costs and increased environmental regulations. Technology plays an increasingly vital role. (120 words)

The market for aggregates remains strong due to global urbanization and infrastructure investment. However, environmental regulations and the desire for more sustainable practices drive innovation. Aggregate producers increasingly seek solutions that minimize energy consumption, reduce waste, and allow for the processing of recycled materials like construction waste recycling. This trend boosts demand for flexible and eco-friendly aggregate processing plants. This is seen as a key driver for ZONEDING’s continued development of advanced quarry machinery.

ZONEDING stands as a leading Chinese manufacturer of heavy mineral processing equipment. The company focuses on B2B solutions for mining, aggregate, and cement industries worldwide. Since its establishment in 2004, ZONEDING has built a reputation for designing and delivering robust, efficient, and customizable equipment. This applies directly to aggregate processing plant needs.

Key advantages of partnering with ZONEDING include:

An aggregate processing plant functions as a complex yet indispensable facility. It drives the supply chain for essential construction materials. Understanding its full lifecycle, from crushing and screening to washing and material handling, reveals the meticulous process behind quality aggregate production. Investing in the right quarry machinery and a well-designed aggregate plant ensures efficiency, profitability, and compliance with strict quality standards.

To maximize success, clients should choose suppliers who offer comprehensive solutions, extensive expertise, and reliable support. Modern aggregate producers must also embrace trends like automation, mobile crushing, and sustainable practices. This helps them remain competitive and meet future demands.

To build or upgrade an aggregate processing plant for optimal efficiency and output, contact ZONEDING today for expert advice and a customized equipment solution!

Explore silica sand processing flow, including crushing, washing, screening, magnetic separation, and flotation technique essential for industrial applications.

View detailsThis guide tells advantages, disadvantages, applications, capabilities, and maintenance considerations of Closed-Circuit and Open-Circuit crushing plant.

View detailsDiscover 9 most common problems on ball mill, from excessive wear to power consumption. Learn how to identify issues and implement solutions to extend lifespan.

View detailsDiscover how thickeners are essential for efficient solid-liquid separation in mining. This guide covers types, uses, and best practices.

View details