全站搜索

Search the entire website

Search the entire website

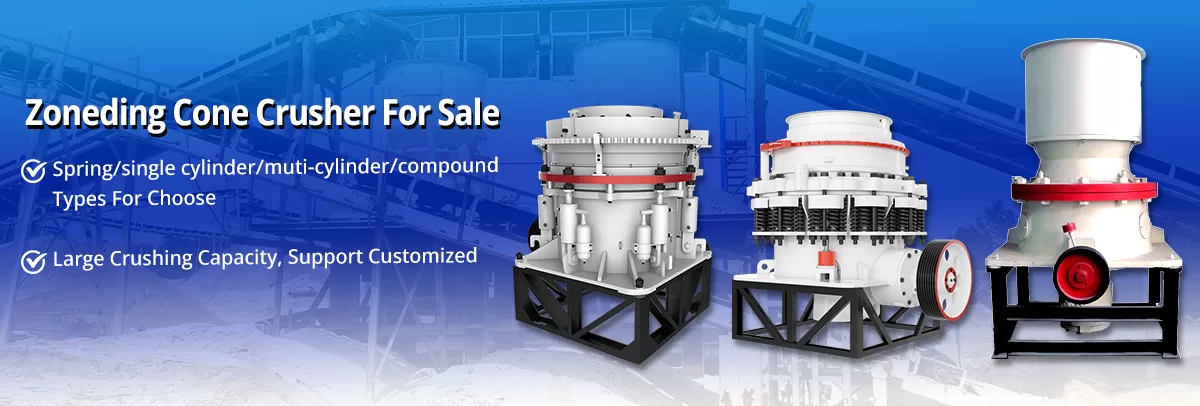

Understanding the cone crusher price is fundamental for making a sound investment. Such an investment is crucial for aggregate, mining, or recycling operations. A cone crusher is critical crushing equipment. It is known for its efficiency in secondary and tertiary crushing applications. Its cost is not a single figure. It varies widely based on numerous technical, operational, and market factors. Making an informed purchasing decision requires a clear grasp of these influencing elements. This ensures the best value for any project.

This guide uncovers 9 core factors directly impacting the cone crusher price. It explores how brand reputation, technical specifications, types of materials, and after-sales support collectively drive the final cost. This information empowers precise budgeting. It helps make strategic purchasing decisions for investments.

The model and physical size of a cone crusher are significant factors determining its price. Larger crushers are designed for higher capacities. They also process larger feed sizes. These machines naturally come with a higher price tag. This is due to increased material needs for construction. They require more powerful motors. Their engineering is also more complex. Different models are optimized for various applications. This impacts their design and cost.

For example, a small laboratory-scale cone crusher costs less. It is used for sampling. This differs significantly from a large, industrial-grade cone crusher used in high-production quarries. Capacity is measured in tons per hour (TPH). It directly correlates with size. A crusher capable of handling 500 TPH is more expensive than one designed for 100 TPH. Models like ZONEDING’s spring cone crushers or hydraulic cone crushers each have varying cost profiles. Selecting the right model ensures optimal performance and efficiency. An oversized crusher incurs unnecessary costs. An undersized one causes production bottlenecks.

Technical specifications and crushing capacity are fundamental drivers of the cone crusher price. These details go beyond just physical size. They encompass the crusher’s ability to precisely process materials to desired specifications. This includes throughput, maximum feed size, and product size range. High-performance specifications demand sophisticated engineering and robust components. This directly impacts the final cost.

Consider a cone crusher’s capacity. A machine processing 800-1000 TPH needs a powerful motor. It also needs larger crushing chambers and stronger structural components. This is compared to one rated for 150-200 TPH. Maximum feed size and adjustable crushing settings influence design complexity. Hydraulic adjustment and tramp iron release mechanisms add to performance and cost.

ZONEDING’s multi-cylinder hydraulic cone crushers offer superior power and capacity. They provide wider adjustment ranges for consistent output. These features increase the cone crusher price. However, they offer significant long-term operational advantages through efficiency and reduced downtime.

The quality of materials and internal components significantly influences the cone crusher price. High-quality materials ensure durability. They extend equipment lifespan and reduce maintenance frequency. This impacts the overall cost of ownership. Investing in superior components upfront saves substantial amounts. These savings occur over the operational life of the crusher.

High-manganese steel in mantle and concave wear parts increases abrasion resistance. This prolongs replacement intervals. Precision-machined gears ensure smooth operation. Robust bearings and reinforced mainframes provide structural integrity. The choice of hydraulic system, lubrication systems, and electrical controls all contribute to the cone crusher price.

ZONEDING prioritizes high-grade, wear-resistant materials. Precision-engineered components are used in all its crushing equipment. This commitment translates to a reliable machine with lower operational costs. It offers excellent long-term value despite a potentially higher initial cone crusher price.

Automation and advanced features are increasingly integrated into modern cone crushers. They significantly impact the cone crusher price. They also offer substantial benefits in operational efficiency, reliability, and safety. These technologies transform crushers into intelligent, responsive pieces of crushing equipment.

Features include:

These advanced features increase the initial cone crusher price. However, they deliver considerable value. This value comes from optimized production, reduced labor costs, and enhanced crushing equipment longevity. ZONEDING engineers its crushing equipment with intelligent operation. This ensures powerful, user-friendly, and highly efficient cone crushers. This maximizes return on investment.

Brand reputation and manufacturer experience play a crucial role in determining the cone crusher price. Established brands often command higher prices. This is due to their proven track record. They also invest extensively in research and development. Their reputation for reliability is strong. These companies have perfected designs over decades. They offer an assurance newer manufacturers cannot match.

Manufacturers like ZONEDING, founded in 2004, have significant industry expertise. This long history shows refined crushing equipment designs. It also demonstrates optimized production processes. The company understands customer needs deeply. This experience allows for reliable, high-performance cone crushers. These crushers meet international quality standards.

Choosing a reputable manufacturer often translates to:

ZONEDING combines extensive experience with a direct manufacturing model. This allows for competitive cone crusher prices. It eliminates intermediary markups. The team of 15 professional engineers ensures strict quality control and innovative design. This makes ZONEDING a trusted partner for crushing equipment needs.

After-sales support and warranty terms are significant factors. They often get overlooked. These influence the overall cone crusher price and long-term value. While not explicitly listed in the purchase price, they are a crucial component of the total cost of ownership. Exceptional support reduces downtime and operational headaches.

A comprehensive after-sales package includes:

A supplier offering superior after-sales support might have a slightly higher initial cone crusher price. However, the long-term benefits are substantial. Reduced downtime, lower repair costs, and optimized performance lead to a lower total cost of ownership.

ZONEDING emphasizes full-service support. This ranges from solution design to after-sales maintenance. This holistic approach ensures crushing equipment investments are secure and perform reliably.

Market demand and broader economic fluctuations considerably influence the cone crusher price. Like any major capital equipment, the cost of crushing equipment responds to supply, demand, and economic health. This means prices are not static; they can change over time.

For example, high demand periods in construction or mining mean manufacturers face increased order backlogs. This leads to longer lead times and potentially higher prices due to limited supply. Conversely, during economic downturns, manufacturers might offer competitive pricing or promotions to stimulate sales. Raw material costs, especially for steel, link to global economic cycles. Increases in these primary material costs mean higher production expenses for crushing equipment. These expenses then reflect in the final cone crusher price. Furthermore, currency exchange rates impact prices for international buyers. Import costs can fluctuate.

ZONEDING, with its global presence, strives for stable pricing despite external economic factors.

The physical location of the manufacturing plant affects the final cone crusher price. Shipping costs also significantly impact it. Due to the sheer size and weight of crushing equipment, transportation is a substantial investment. This factor is especially important for international buyers.

Shipping costs include:

ZONEDING has extensive experience with international logistics. The company has exported crushing equipment to over 120 countries. This expertise allows efficient management of the shipping process. It also provides transparent costing. These costs are external to the manufacturing process. However, they are critical to the total cone crusher price. When receiving a quote, clarify the terms (ex-works, FOB, CIF, or DDP). This helps understand the full landed cost.

The inclusion of training and installation services in the cone crusher price varies significantly. This depends on the supplier. These services are vital for any new crushing equipment. They ensure proper setup, safe operation, and optimal performance. Some basic quotes might exclude them. However, choosing a supplier that includes these services saves substantial time and resources.

Key aspects of training and installation include:

Incorporating these services may slightly increase the initial cone crusher price. However, the value added is immense. Proper installation prevents costly operational errors and delays. Thorough training empowers a team to maximize efficiency. It also minimizes downtime.

ZONEDING provides a full suite of services. These include expert scheme design, manufacturing, professional installation, commissioning, and comprehensive operator training. This full-service support ensures an investment performs optimally from day one.

Considering the many factors that shape the cone crusher price, selecting the right supplier is crucial. It is as important as the equipment itself. ZONEDING offers a distinct advantage as a partner in crushing equipment. Its commitment to delivering value goes beyond competitive pricing. It focuses on comprehensive solutions and long-term support. Clients benefit from ZONEDING’s deep industry experience since 2004. This expertise continuously refines designs and manufacturing processes. A team of 15 professional engineers rigorously ensures the quality of every cone crusher and all of ZONEDING’s crushing equipment.

ZONEDING offers a complete range of crushers. It also provides tailored solutions. As a direct manufacturer, ZONEDING delivers factory-direct sales. This cuts out middlemen. It offers a more transparent and competitive cone crusher price. Clients get superior quality and advanced features without unnecessary markups. Full-service support covers scheme design, manufacturing, professional installation, commissioning, and comprehensive operator training. ZONEDING has a global footprint, exporting to over 120 countries. This ensures clients benefit from extensive international logistics experience. Choosing ZONEDING means investing in proven efficiency, durability, and a partner dedicated to success.

Investing in a cone crusher requires a strategic understanding of its price factors. This extends far beyond the initial cost. It encompasses a comprehensive evaluation of the model and technical specifications. Material quality and automation features are also important. So are brand reputation, after-sales support, market dynamics, and shipping logistics. Critical training and installation services also play a role. Each element is pivotal in determining the total cost of ownership. It also impacts the overall return on investment in crushing equipment.

By carefully considering these 9 key factors, informed decisions can be made. These optimize project budgets. They also ensure long-term operational success. The right cone crusher meets capacity needs. It also delivers consistent performance. It reduces operational costs and minimizes downtime.

For competitive cone crusher prices and tailored crushing equipment solutions, turn to ZONEDING. It offers a full range of high-quality crushing equipment. Its expert team provides end-to-end support. This ranges from scheme design and manufacturing to installation and training. This ensures investments are robust and efficient. It also ensures they are perfectly aligned with operational goals.

Your one-stop resource for diagnosing and solving cone crusher issue. This guide tells mechanical, hydraulic, and operational problems with detailed solutions.

View detailsExplore the typical price range of jaw crushers and understand the main factors influencing their cost, such as size, capacity, features, and machine quality.

View detailsDive deep into complete Gold Ore CIP (Carbon-in-Pulp) Process Flow including crushing, grinding, leaching, adsorption, elution, electrowinning, and smelting.

View detailsUnlock economic potential of gabbro deposits. Learn what gabbro is and how the crushing plant can turn gabbro into valuable resource for construction projects.

View details