全站搜索

Search the entire website

Search the entire website

Your cone crusher is the engine of your secondary and tertiary crushing operations. When it’s running smoothly, it’s a non-stop profit center, turning oversized rock into valuable, specified products. But when it goes down, your entire production line can grind to a halt. Every minute of unexpected downtime means lost tonnage, rising costs, and missed deadlines.

This guide is your one-stop resource for understanding your machine and keeping it running. We’ll start with the basics—what a cone crusher is and the different types available. Then, we will dive into a detailed cone crusher troubleshooting manual, diagnosing the 8 most frequent problems and providing clear, step-by-step solutions to get your machine back up and running fast.

A cone crusher is a type of compression crusher used by aggregate producers, mining companies, and recycling operations to reduce the size of rock, ore, or gravel. It is typically used in the secondary, tertiary, or even quaternary stages of a crushing circuit, meaning it takes the rock that has already been broken down by a primary crusher (like a jaw crusher).

The core principle is simple: it crushes material between two conical steel surfaces. A central, moving cone called the mantle rotates with an eccentric motion inside a stationary outer bowl, which is lined with a concave or bowl liner. As the mantle wobbles, the gap between it and the bowl liner continuously opens and closes.

Material fed in from the top is squeezed and compressed in the closing gap and then falls lower into the chamber when the gap opens. This process repeats until the material is small enough to fall out of the bottom of the machine. The final product size is determined by the “Closed Side Setting” (CSS), which is the narrowest gap at the bottom of the crushing chamber.

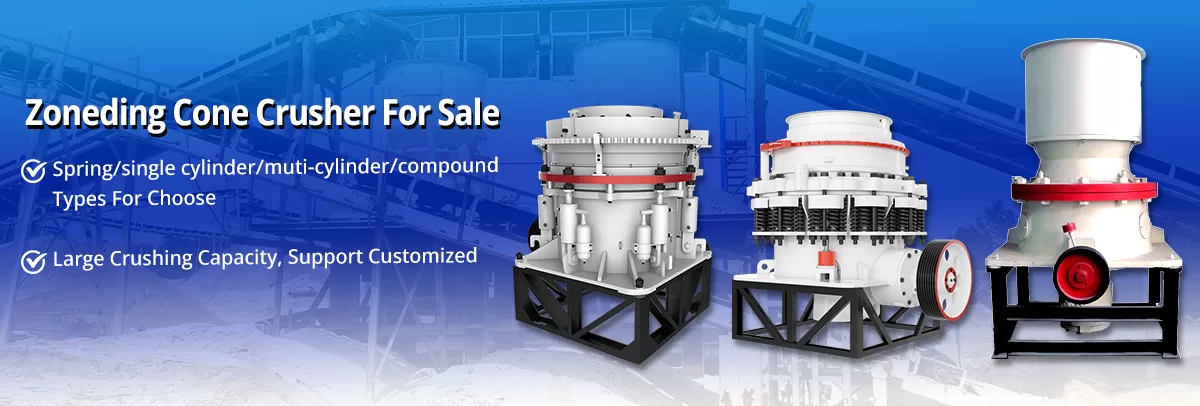

While all cone crushers operate on the same principle, their design, especially their overload protection and adjustment systems, has evolved. The main types you will encounter are Spring (Symons), Single-Cylinder Hydraulic, and Multi-Cylinder Hydraulic crushers.

The Spring Cone Crusher, often called a Symons cone crusher after its original design, is the traditional, time-tested model. Its key feature is a set of heavy-duty springs located around the outside of the crusher.

Modern crushers use hydraulic systems instead of springs, offering significant advantages in automation, safety, and ease of use.

This design uses one large hydraulic cylinder at the bottom of the crusher to both set the CSS and provide tramp release. The main shaft is supported only at its base, acting as a cantilevered beam.

This is the most advanced design, using multiple hydraulic cylinders around the base of the crusher. The main shaft is supported at both the top and bottom, creating a more rigid and stable structure.

| Crusher Type | Overload Protection | Adjustment System | Key Advantage | Best Application |

|---|---|---|---|---|

| Spring (Symons) | Mechanical Springs | Manual/Motorized Gear | Simple, Robust, Lower Initial Cost | Low-automation quarries |

| Single-Cylinder Hydraulic | Hydraulic Cylinder | Hydraulic | High Throughput, Large Feed Opening | High-tonnage secondary crushing |

| Multi-Cylinder Hydraulic | Hydraulic Cylinders | Hydraulic | Superior Product Shape, High Force, Automation | Quality-focused tertiary crushing |

Now that you understand the basics, let’s get into the practical side of keeping your machine profitable. Here are the most common cone crusher problems and how to fix them.

The mantle and bowl liner are your primary wear parts, but if you’re replacing them too frequently, an underlying issue is costing you money.

Bearing failures are among the most serious and expensive issues, often requiring a complete machine teardown.

This is a catastrophic failure that compromises the entire structure of the crusher.

Low pressure compromises the crusher’s ability to hold its setting and protect itself.

The hydraulic accumulators are your crusher’s shock absorbers. If they fail, the machine loses its most important protection.

Excessive heat breaks down hydraulic oil, reducing its effectiveness and damaging components.

The crusher is running, but the final product is long and thin (“flaky”) rather than cubical, failing to meet quality specifications.

Oversized rocks wedge in the feed opening, stopping all material flow.

The most effective way to solve cone crusher problems is to prevent them. A proactive maintenance culture saves you time, money, and stress.

| Frequency | Maintenance Task | Your Benefit |

|---|---|---|

| Daily | Check lube & hydraulic oil levels, pressures, temps. | Prevents 90% of bearing and hydraulic failures. |

| Weekly | Check drive belts tension & hydraulic cooler fins. | Ensures efficient power and prevents overheating. |

| Monthly | Take an oil sample for analysis. | Predicts bearing wear and oil contamination. |

| 6-Monthly | Check hydraulic accumulator nitrogen pre-charge. | Guarantees crusher is protected from tramp iron. |

Ready to move from reactive repairs to proactive performance? Contact the ZONEDING team today to discuss your crushing needs or to get expert advice on optimizing your current operation.

Learn how to identify gold in the ground by its color, luster, and shape. We explain why raw gold doesn't sparkle like glitter and how to spot it in dirt.

View detailsEverything you need to know about Galena (Lead Sulfide). This guide covers its identification, geological properties, and how to process it. Read More!

View detailsThis guide covers the essential stages: crushing, grinding, and various beneficiation methods like gravity separation, magnetic separation, and flotation.

View detailsExplore efficient stone crusher plant layouts. Learn how we configure feeder, jaw crusher, impact crusher, and vibrating screen for maximum aggregate output.

View details