Gold has always captivated people. It is a precious metal, highly valued across the world. Extracting gold from ore is a complex process. Oxidized gold ores present unique challenges. They differ from other ore types. Therefore, they need specialized techniques. This article aims to outline these methods. The extraction methods for these ores are very important. This article focuses on understanding how to improve gold recovery. It is also important to know about ore beneficiation, which is a process to upgrade the economic value of the gold ore.

Table of Contents

What Exactly Are Oxidized Gold Ores?

Oxidized gold ores are formed by weathering and oxidation. They often contain gold in a free state. The gold is typically not chemically bound to other minerals. This is an important distinction. This means that the extraction process is often simpler compared to sulfide ores. The primary minerals in these ores include iron oxides. Hematite and goethite are typical examples. Clay minerals are often present too. These can impact the process. They can affect the ore’s permeability. Understanding the characteristics of oxidized gold processing helps miners make more efficient decisions.

The formation of oxidized gold ores is a long process. It begins with the exposure of gold-bearing rocks to the elements. Weathering breaks down the rocks. Weathering is a combination of physical and chemical processes. Water and oxygen play key roles in this process. The gold, which may be initially locked within other minerals, becomes free. As the surrounding minerals oxidize, they transform. They form oxides and other compounds. Gold, being inert, remains. It becomes free gold. It can be further concentrated. This often happens in zones where the ore is more porous. Leaching of some minerals enhances this. This is why understanding gold metallurgy is key.

What are Features of Oxidized Gold Ores?

Oxidized gold ores have several key features. These are listed for clarity and easy understanding:

- Porosity: These ores are typically porous. The porosity comes from the leaching of some minerals.

- Gold particle size: The gold particles can vary in size. The sizes can range from very fine to relatively coarse.

- Mineral composition: Iron oxides, like hematite and goethite, are common. Clay minerals are often present.

- Presence of gangue minerals: Gangue minerals are non-valuable minerals. These can include quartz and various silicates.

These features affect which extraction methods are best. The features also impact the efficiency of gold recovery. A careful study of these features is very important. This is the first step in designing an effective plan. Understanding these features is critical to designing efficient gold ore treatment strategies.

What are Applications of Oxidized Gold Ores?

Oxidized gold ores are very valuable. The gold within these ores is highly sought after. Gold has many uses. It is used in jewelry and electronics. The economic value of these ores makes their processing important. Mining companies invest in extracting the gold. It’s a key source of revenue for these companies. The gold also drives economic activity. Processing these ores creates jobs. It stimulates growth in local communities. The efficiency of gold extraction directly impacts profits. The lower the cost of extraction, the more profit. Therefore, using the best methods is essential for mining companies. This is all part of ore beneficiation.

What are the Main Difficulties of Oxidized Gold Ores Processing?

Extracting gold from oxidized ores is not always easy. Several factors can make it challenging. Key difficulties include:

- Low Gold Grade: Some ores have low gold concentrations. This makes efficient extraction essential.

- Fine Gold: Fine gold particles can be hard to recover. These particles can float away. They can also be lost in the tailings.

- Clay Content: High clay content can reduce permeability. Reduced permeability affects the leaching process. It slows the solution flow.

- Reagent Consumption: Some ores need more reagents. More reagents can lead to higher costs. They can also impact the environment.

- Slow Kinetics: Some ores have slow reaction rates. This increases the leaching time. Extended leaching increases costs.

Mining companies need to understand these difficulties. They must choose the best extraction methods. They need to design efficient processes. This includes controlling costs and minimizing environmental impact. Effective gold processing plant optimization helps to mitigate these challenges.

Several methods can be used to extract gold. The best method depends on the ore’s characteristics. The main methods are described below. Each has its own advantages and disadvantages. This depends heavily on the gold metallurgy and the presence of refractory gold.

- Heap Leaching: It is one of the most common methods. The ore is crushed. Then it is placed on a lined pad. A cyanide solution is dripped over the ore. The cyanide dissolves the gold. The gold-bearing solution is collected. This method works well for permeable ores.

- CIP/CIL (Carbon in Pulp/Carbon in Leach): This method involves activated carbon. Activated carbon adsorbs gold from the solution. The carbon is then separated. Then, the gold is recovered from the carbon. This method is useful for ores with fine gold particles.

- Flotation: This method is used when the ore has some sulfide minerals. The ore is crushed. Chemicals are added to make the gold particles float. The gold-rich froth is then collected. Flotation oxidized gold can be combined with other methods. This improves overall recovery.

- Gravity Separation: This method uses gravity to separate gold. The heavy gold particles sink. They are separated from lighter materials. It can be used as a pre-concentration step. This helps reduce the volume of ore.

- Pre-treatment Methods (e.g., acid washing): Some ores may need pre-treatment. Acid washing can be used. It removes interfering minerals. It can improve the efficiency of the leaching process.

The best method varies. The choice depends on the ore’s composition. Other factors include the gold grade and the scale of the operation. Careful testing and analysis are vital. Careful testing and metallurgical test work gold can inform the best choices.

Heap Leaching: A Detailed Look

Here are the key aspects of heap leaching:

- Process: Ore crushed and piled on a lined pad. Cyanide solution applied to dissolve gold.

- Mechanism: Solution collects gold, forming a gold-bearing solution.

- Suitability: Cost-effective for low-grade, permeable ores.

- Key Factors: Ore particle size, even solution distribution, and leaching time affect efficiency.

Carbon in Pulp/Carbon in Leach (CIP/CIL)

Key features of the CIP/CIL method:

- Process: Ore crushed, ground, and leached with cyanide solution.

- Mechanism: Activated carbon added to adsorb dissolved gold from the slurry.

- Recovery: Gold stripped from carbon, then recovered via electrowinning and smelting.

- Suitability: Effective for fine gold particles and ores with high clay content.

Flotation

Key points about the flotation process:

- Process: Crushed ore mixed with water and chemical reagents.

- Mechanism: Reagents make gold particles hydrophobic. Air bubbles attach to gold.

- Recovery: Gold-rich froth formed at the surface is collected for further processing.

- Suitability: Effective when gold is associated with sulfide minerals or for coarse gold.

Gravity Separation

Key aspects of gravity separation:

- Process: Uses differences in density to separate gold from lighter minerals.

- Mechanism: Heavy gold particles sink and are collected using equipment like jigs or shaking tables.

- Application: Often used as a pre-concentration step to reduce ore volume.

- Suitability: Simple, cost-effective, commonly used in small-scale mining operations.

Pre-treatment Methods (e.g., Acid Washing)

Key information on pre-treatment methods like acid washing:

- Purpose: Prepare ore to improve subsequent gold leaching efficiency.

- Process (Acid Washing): Ore mixed with an acid solution to dissolve interfering minerals or organic matter.

- Effect: Cleans gold particle surfaces, enhancing contact with leaching solutions.

- Benefits: Can improve gold recovery rates and reduce cyanide consumption for specific ore types.

Several types of equipment are needed for gold extraction. The choice of equipment depends on the extraction method. Some key pieces of equipment are:

- Crushers: Crushers reduce the size of the ore. This increases the surface area for leaching. Jaw crushers and cone crushers are common.

- Grinding Mills: Grinding mills further reduce the particle size. This is particularly important for CIP/CIL processes.

- Leaching Tanks: These tanks are used for vat leaching. They hold the ore. The ore is leached with a cyanide solution.

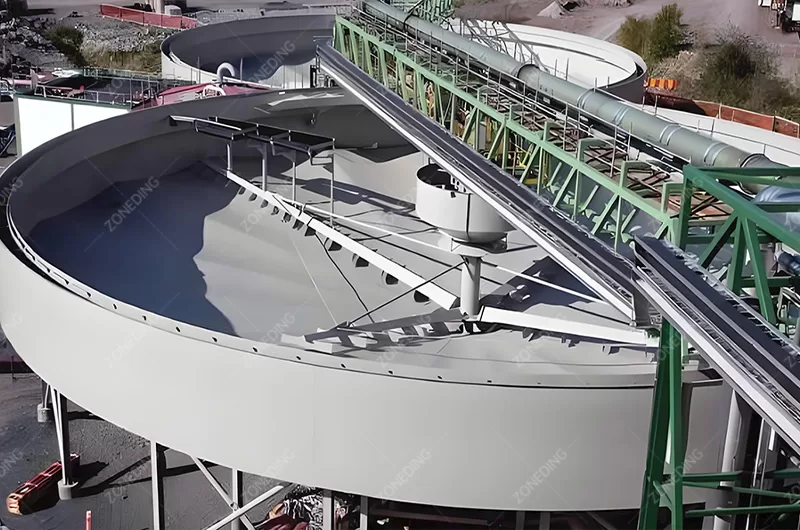

- Heap Leaching Pads: These pads are used for heap leaching. They are lined to prevent leakage.

- Carbon Adsorption Columns: These columns are used in CIP/CIL processes. They hold the activated carbon. The carbon adsorbs the gold.

- Thickeners: Thickeners separate solids from liquids. They are used in the recovery process.

- Electrowinning Cells: These cells recover gold from the pregnant solution. This is done through electrowinning.

- Smelting Furnaces: Smelting furnaces melt the gold. This creates gold bars.

The selection of equipment is essential. It must be suited for the ore type and extraction method. Proper maintenance ensures efficient and cost-effective operations.

ZONEDING provides a wide range of such equipment. Our machinery helps achieve efficient and reliable gold recovery. We focus on durable and advanced solutions. We aim to enhance gold processing plant optimization.

How to Select Right Machine for Your Oxidized Gold Ores Project?

Choosing the right equipment is critical. The success of a gold extraction project depends on this. A guide has been developed.

- Metallurgical Testing: Start with comprehensive tests. Assess the ore’s characteristics. This is the most crucial step. Conduct tests to determine the gold grade, mineralogy, and particle size distribution. Metallurgical test work gold helps understand how the ore will react. It’s essential for selecting the right processes.

- Ore Characteristics: Understand the specific ore type. Knowing the ore type guides the process choice.

- Throughput Requirements: Determine the processing capacity. The daily or annual throughput affects the equipment scale. It helps with crusher sizes, tank volumes, and more.

- Capital and Operating Costs: Evaluate both initial and ongoing costs. Balance equipment costs with operating expenses.

- Environmental Regulations: Consider environmental regulations. Choose processes and equipment that comply. The best gold extraction best practices require these aspects to be considered.

- Consult Experts: Seek the expertise of experienced professionals. ZONEDING’s team can provide assistance. They have the experience. They also have the knowledge.

This step-by-step approach guides a project’s success. Considering acid washing gold ore testing is also recommended.

What are Environmental and Safety Considerations?

The gold extraction industry has important environmental and safety aspects. These aspects must be taken into account.

- Cyanide Management: Cyanide is the main reagent used in gold leaching. It can be toxic. Safe handling and proper management are vital. This includes preventing spills. This also includes the safe disposal of cyanide-containing waste. This needs careful control, with processes that can be described as cyanidation oxidized ores and gold extraction best practices.

- Tailings Management: Tailings are the waste from the extraction process. Proper disposal is important. Tailings need to be stored in lined impoundments. This helps prevent seepage. It prevents contamination of the surrounding environment. This requires effective planning. It also needs regular monitoring. This should include methods for gold ore treatment techniques.

- Water Usage and Pollution Control: Water is used in gold extraction. Minimizing water usage is important. This is through recycling and reuse. The wastewater must be treated. This must be done to remove pollutants before discharge. Strict water quality standards should be followed.

- Worker Safety: Gold mining can be dangerous. Proper safety measures are important. These include training workers. This also includes providing safety equipment. It also includes implementing safety procedures.

These considerations help minimize environmental impact. They promote a safe work environment. This is crucial for sustainable gold extraction.

Conclusion

Extracting gold from oxidized ores is a multifaceted process. The best method depends on many factors. These factors include the ore type, the gold grade, and the scale of operations. Heap leaching, CIP/CIL, and flotation are all common methods. They each have advantages and disadvantages. Choosing the right method is important for efficiency and profitability.

Careful ore preparation, solution management, and process control are also vital. Implementing environmental best practices is essential. These guidelines minimize environmental impact. They also promote a safe work environment. For those looking to optimize their gold processing plant optimization, consulting with experts is crucial. They can assess the ore. They can recommend the most suitable methods. And They can help implement best practices. The goal is to maximize gold recovery while minimizing environmental impact.

FAQ

- Q: What is the main difference between heap leaching and vat leaching?

- A: Heap leaching works for permeable ores. Vat leaching suits ores with high clay content.

- Q: Why is cyanide used in gold extraction?

- A: Cyanide dissolves gold. It turns it into a soluble form.

- Q: What are the main environmental concerns?

- A: The main concerns are cyanide use and tailings management. These need careful control.

- Q: What is the role of activated carbon in gold recovery?

- A: Activated carbon adsorbs gold from the pregnant solution.

- Q: How do you choose the right extraction method?

- A: It depends on ore characteristics and the operation’s scale.