全站搜索

Search the entire website

Search the entire website

Selecting the most suitable sand making crusher is a paramount decision for any aggregate production venture. Whether processing robust granite, dense basalt, or common river pebbles, the choice of sand crusher directly influences operational efficiency, product quality, and overall profitability. A perfectly matched sand making crusher ensures optimal performance. It minimizes wear, reduces energy consumption, and consistently produces the desired final particle size.

This blog guides in selecting the most suitable sand making crusher based on material hardness, moisture, and final particle size. Understanding how different raw materials interact with various crushing equipment designs is key. As a leading manufacturer of mineral processing equipment, ZONEDING offers a comprehensive understanding of these complexities. This article helps navigate the options to identify the ideal sand making crusher solution for diverse material types.

Choosing the right sand making crusher begins with a thorough understanding of the raw material’s physical properties. Not all materials respond to crushing in the same way. The varying characteristics of feed materials directly impact the optimal crusher type, wear part selection, and overall sand production line design. Tailoring the crushing equipment to specific material properties ensures maximum efficiency and longevity.

Harder, more abrasive materials like granite, basalt, or quartzite demand robust, impact-resistant machines. Softer materials like limestone or sandstone may allow for different crushing technologies. For highly abrasive materials, wear parts are crucial. These materials wear down components faster.

ZONEDING’s engineers can perform material analysis. This analysis determines the best approach for the specific raw material. This ensures customers receive the most suitable sand making crusher that can withstand rigorous conditions and consistently deliver high-quality manufactured sand.

Measured on the Mohs scale, hardness dictates how much force a material can withstand before fracturing. Harder materials inherently require more energy to crush. They also cause greater wear on crusher components. A sand making crusher designed for softer materials will struggle with granite. It will also incur excessive wear and low output. Conversely, an overly robust crusher for softer materials can be inefficient. ZONEDING performs detailed material analysis. This analysis ensures the recommended sand making crusher handles the specific hardness of the feed material effectively.

This property describes a material’s tendency to cause wear on surfaces it contacts. Abrasive materials, like quartz-rich rocks, lead to rapid wear of blow bars, liners, and rotor tips. This necessitates frequent part replacement and higher maintenance costs. Selecting a sand making crusher with highly wear-resistant internal components, or a crushing mechanism that minimizes metal-on-rock contact, is crucial. ZONEDING’s VSI sand making machine often utilizes “rock-on-rock” crushing. This significantly reduces metal wear when processing abrasive materials.

High moisture content can cause fines to stick together. This creates blockages within the crusher. It also reduces screening efficiency. Sticky materials often require specialized feeders or pre-drying. They may also necessitate specific crusher designs that prevent material buildup. Ignoring moisture content can lead to frequent shutdowns and reduced throughput in the sand production line.

The maximum input size of the raw material and the required final particle size directly influence the crushing stages. A primary crusher reduces large blocks. A secondary or tertiary sand making crusher then creates the fine sand. Achieving a specific final particle size, especially for manufactured sand, often requires precise control over the crushing action. ZONEDING’s complete production line solutions integrate multiple stages for tailored size reduction.

By carefully evaluating these material characteristics, optimal crushing equipment can be selected. This ensures an efficient and cost-effective sand production line. ZONEDING’s engineering expertise ensures clients receive material-specific solutions.

For more information on the types of equipment involved, explore ZONEDING’s Mineral Processing/Beneficiation Equipment.

Granite and basalt are igneous rocks known for their high hardness and significant abrasiveness. They are widely used as aggregates in construction due to their strength and durability. However, processing these materials into manufactured sand presents specific challenges for sand making crusher equipment. High impact forces and abrasion resistance are crucial for efficient and cost-effective crushing.

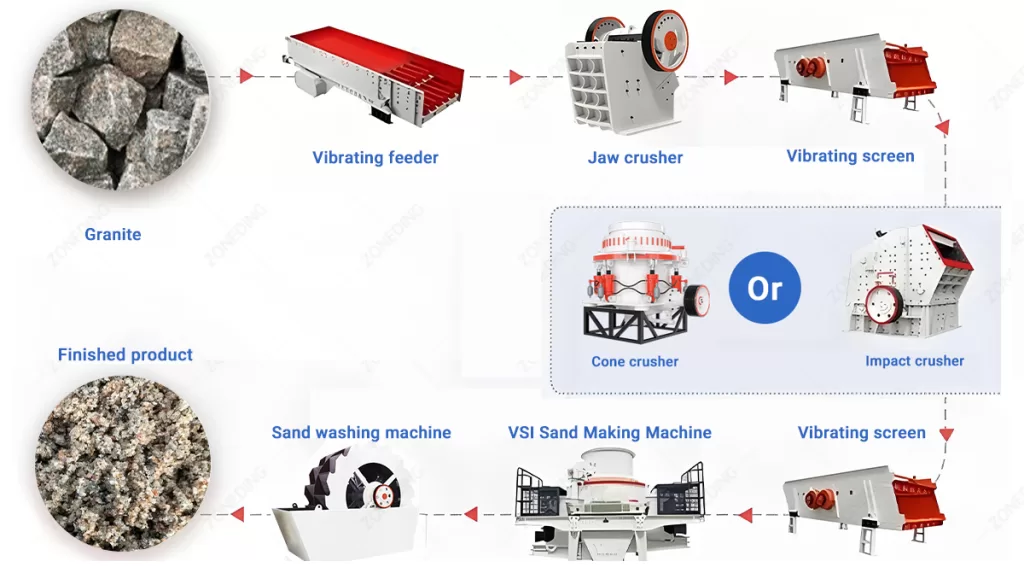

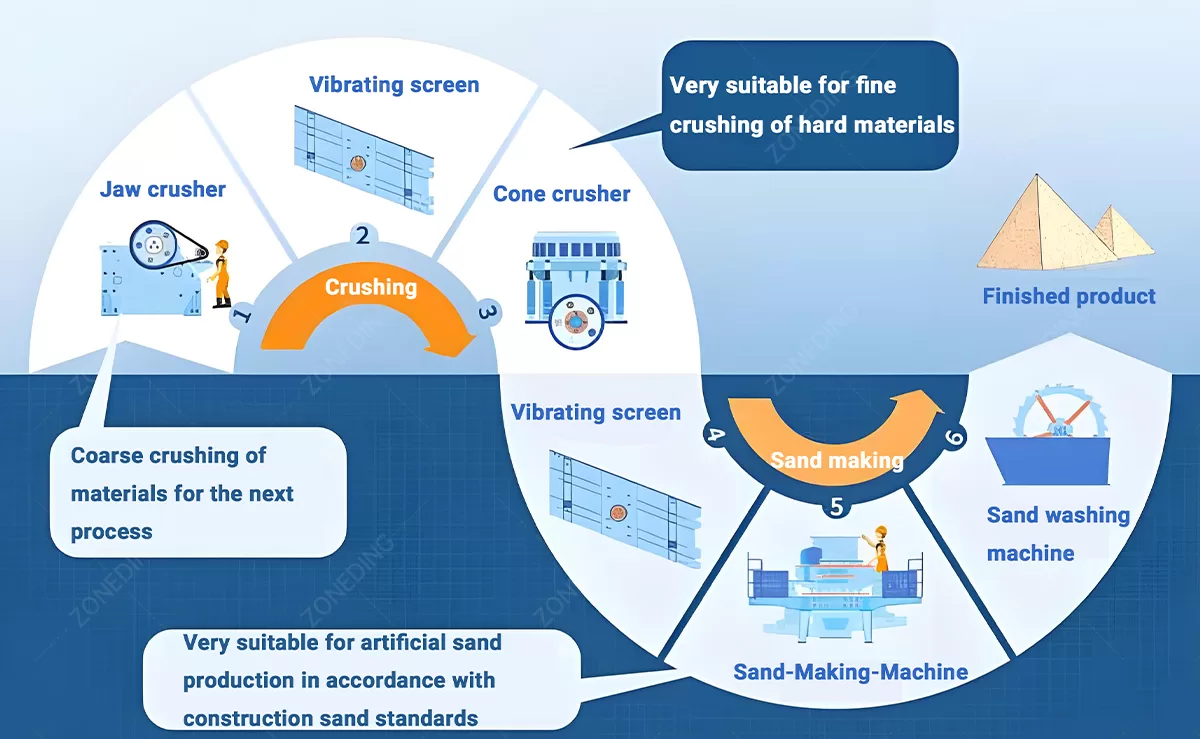

For granite and basalt crushing, the primary goal is often to reduce large blocks into smaller, cubical particles. This is important for high-quality sand. Jaw crushers serve as effective primary crushers for these materials. They handle large feed sizes and reduce them to manageable dimensions. For secondary and tertiary crushing, cone crushers are highly efficient. They provide good reduction ratios and achieve a reasonably cubical product. However, for achieving the ultimate cubical shape and fine particle size required for manufactured sand, a VSI sand making machine is indispensable. The VSI sand making machine utilizes a unique rock-on-rock crushing principle. This minimizes wear on critical parts. It also generates excellent particle shape.

ZONEDING’s VSI sand making machine series are specifically engineered with robust designs and specialized wear parts for these demanding applications. They ensure superior product quality and a longer lifespan, even with highly abrasive granite and basalt.

River pebbles and gravel are common raw materials for artificial sand production. These materials often exhibit medium to high hardness but are typically well-rounded due to natural erosion. This rounded shape can be a challenge when trying to produce cubical sand. Cubical sand is essential for good concrete and asphalt adhesion. A sand making crusher for pebbles needs to efficiently fracture and shape these rounded particles.

For river pebbles, a multi-stage approach is usually recommended. A primary jaw crusher first reduces the larger pebbles. This is followed by a cone crusher for further size reduction and initial shaping. The critical step for achieving high-quality manufactured sand from pebbles is the VSI sand making machine. Its high-speed rotor throws the pebbles against target plates or stone-lined chambers. This creates high-velocity impact crushing. This process breaks the rounded particles and reshapes them into cubical form. It also helps remove any weak or flaky particles.

ZONEDING’s VSI sand making machine are engineered to excel in this application. They produce sand with an excellent particle shape. This superior shaping minimizes the quantity of needle-like or flaky particles often found when merely crushing rounded materials. This results in manufactured sand that meets the strictest construction standards.

Limestone and sandstone are classified as medium-hard to soft materials. They are generally less abrasive than granite or basalt. These materials are widely available and commonly used for aggregate production and as raw materials for cement. Crushing these materials requires a different approach for sand making crusher selection. The focus shifts towards maximizing throughput and energy efficiency, as wear on machine components is less of a concern.

For limestone and sandstone, impact crushers (Horizontal Shaft Impact – HSI) are often an excellent choice. HSI crushers are known for their high reduction ratios and ability to produce a good cubical product from softer, less abrasive materials. They operate on a direct impact principle where rotating blow bars strike the material onto impact plates. This design makes them highly efficient for materials like limestone and sandstone. While VSI sand making machines can also process these materials, HSI crushers often offer a more cost-effective solution for sand production from medium-hard materials.

ZONEDING offers a range of impact crushers suitable for limestone and sandstone. These designs focus on energy efficiency and ease of maintenance for these types of feed. This provides clients with a reliable and economical sand production line.

A sand making crusher is rarely a standalone unit. It forms a crucial part of a larger sand production line. The efficiency and final product quality depend heavily on the integrated performance of auxiliary equipment. These components ensure a smooth material flow, proper processing, and adherence to product specifications.

ZONEDING offers complete production line solutions. These integrate all necessary auxiliary equipment with their primary, secondary, and sand making crushers. This integrated approach ensures seamless operation. It maximizes efficiency. It also guarantees optimal product quality. The ZONEDING team designs each component to work in harmony. This creates a fully optimized and automated sand production line.

ZONEDING differentiates itself through its deep understanding of various raw materials and its ability to provide tailored sand making crusher solutions. The company’s approach is rooted in “Customization” and “Full-Service Support.” It aims to optimize every aspect of the sand production line for specific client needs.

This integrated and client-focused approach allows ZONEDING to deliver sand making crusher solutions that are not just machines, but optimized systems built for long-term profitable operation.

The mineral processing equipment landscape continues to evolve. Several key trends are shaping the future of sand making crusher technology. These trends address the challenges of processing diverse raw materials more efficiently and sustainably.

These trends indicate a future where sand making crushers are not only more powerful but also smarter, more adaptable, and ultimately more efficient for handling the vast array of materials available globally. ZONEDING is at the forefront of incorporating these innovations into its mineral processing equipment designs.

Choosing the right sand making crusher is a strategic investment that hinges on a deep understanding of the raw material. Critical factors include material hardness, abrasiveness, moisture content, and the desired final particle size. Matching the crushing equipment to these properties is paramount for maximizing efficiency, minimizing operational costs, and producing high-quality manufactured sand.

It is strongly advised to conduct a thorough material analysis. Explore options for multi-stage crushing if necessary. Evaluate the manufacturer’s expertise and support. ZONEDING provides “Comprehensive Product Line and One-Stop Solution”. This ensures the selection of suitable mineral processing equipment. This approach ensures a reliable, efficient, and cost-effective sand production line tailored to any specific material.

Last Updated: July 2025

A step-by-step guide covers everything from crushing and grinding to advanced magnetic separation and dewatering, ensuring efficient magnetite processing.

View detailsLearn to produce ceramsite sand. This guide covers raw materials, crushing, pelletizing, calcining, screening, and machinery. Start manufacturing today!

View detailsAn expert comparison of 4 stone crushers: Jaw, Cone, Impact (HSI), and Hammer, including advantages,disadvantages ,cost, output shape, and suitable rock types.

View detailsWhat are key differences between Hematite and Magnetite? A comparison of magnetism, streak color, chemical formula, crystal form, &iron content. Get answer NOW.

View details