全站搜索

Search the entire website

Search the entire website

Magnetite is a crucial iron ore. It is a dense, black, and highly magnetic mineral. It contains a high percentage of iron. However, raw magnetite ore is rarely pure. It contains many impurities. These impurities include gangue minerals like quartz. They must be removed. This removal process is called beneficiation. It upgrades the iron content. Beneficiation also ensures high-grade iron concentrate recovery. This guide explains each step involved. It covers processing magnetite. It starts from mining. and It ends with producing high-quality concentrate.

The journey of magnetite from ore to valuable concentrate is complex. It requires specialized equipment. It demands precise control. High efficiency in each stage is vital. It maximizes resource utilization. It minimizes waste. This process is essential for the steel industry. This guide provides a comprehensive overview. It helps unlock the full potential of magnetite ore.

Magnetite is a key iron ore mineral. It has the chemical formula Fe₃O₄. It is naturally magnetic. This property is crucial for its processing. Magnetite is one of the most abundant iron ore minerals. It has a high iron content when pure. It typically contains about 72.4% iron. This makes it a valuable resource. It is a primary source for iron and steel production globally.

The importance of magnetite extends beyond its iron content. Its magnetic property allows for efficient separation. This means it can be upgraded to very high purity concentrates. This makes it a preferred feed for steel mills. It reduces energy consumption during steelmaking. Understanding magnetite is key to iron ore beneficiation.

Magnetite ore has distinct characteristics. These properties influence how it is processed.

The properties of magnetite dictate the iron ore beneficiation flowsheet. This impacts equipment selection and process design. ZONEDING provides suitable machinery. This machinery supports these specific requirements.

Magnetite mining is the initial step. It involves removing the ore from the earth. The choice of mining method depends on the deposit’s characteristics. This includes depth, size, and geological structure. After extraction, the ore undergoes preliminary preparation. This readies it for transport and further processing.

Efficient mining practices are critical. They ensure a steady supply of ore. They aim to maximize recovery. and They also keep operational costs down. This initial phase sets the stage for efficient magnetite processing.

Magnetite deposits are found in different geological settings.

Large ore chunks come from mining activities. They need initial size reduction. ZONEDING’s jaw crushers are ideal for this primary step. They break down large rocks. This makes them manageable for subsequent stages.

After mining, the raw ore needs size reduction.

ZONEDING’s robust crushing and screening solutions ensure efficient initial ore preparation. This sets the stage for effective iron ore beneficiation.

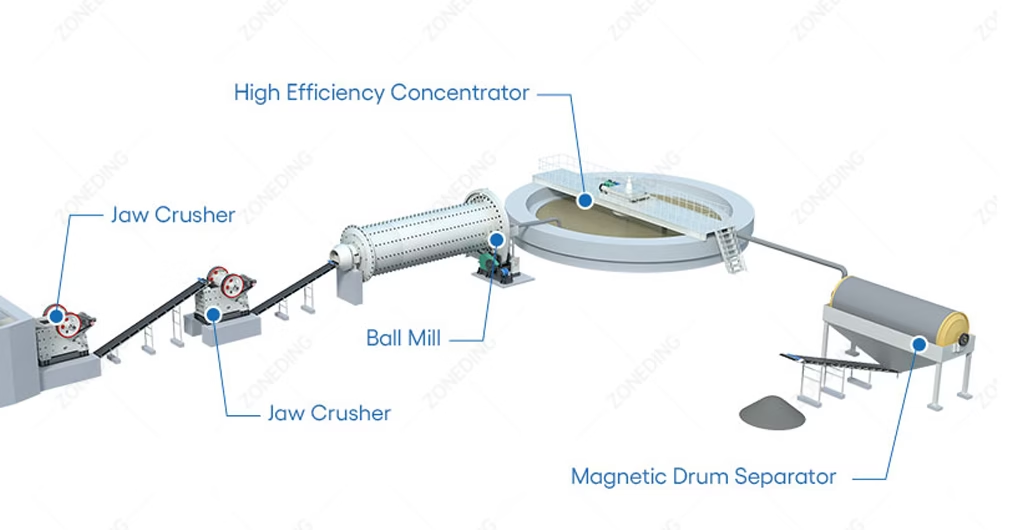

Beneficiation is the heart of magnetite processing. Its main goal is to separate magnetite from gangue minerals. This significantly increases the iron content. It produces a high-grade concentrate. The process involves several stages of size reduction. These stages ensure that magnetite particles are liberated. Then, magnetic separation methods concentrate them.

This stage is crucial for economic viability. It upgrades low-grade ore. It transforms it into a marketable product. Effective beneficiation reduces transportation costs. It lowers smelting expenses. ZONEDING provides a full range of equipment for these critical steps in iron ore beneficiation.

Magnetite is often finely disseminated in the rock. It requires extensive comminution.

Magnetic separation is the most critical step. It takes advantage of magnetite’s magnetic properties.

After magnetic separation, a large amount of waste material remains. This is known as tailings. The concentrate also contains water. Both require careful management. Proper tailings disposal is crucial for environmental compliance. Efficient dewatering prepares the concentrate for transport and further processing.

This final stage of magnetite processing ensures sustainability. It prepares the product for market. ZONEDING provides essential equipment for these vital steps in iron ore beneficiation.

Tailings consist of fine non-magnetic material. They are mixed with water.

The final iron concentrate is a slurry. It still contains a significant amount of water. This water must be removed. This reduces transportation costs. It meets the moisture specifications of steel mills.

A major mining company in Africa faced challenges. Their magnetite deposit had complex mineralogy. It had variable iron content (30-40%). The existing beneficiation plant struggled. It achieved a consistent concentrate grade. It also had high energy consumption. This company needed a solution. They had to increase magnetic separation efficiency. They also needed to reduce operational costs.

ZONEDING was engaged to optimize the magnetite processing flowsheet. The company proposed an integrated solution. It focused on multi-stage crushing, precise grinding, and advanced magnetic separation.

The result was significant. The client increased their iron concentrate grade from 62% to 68%. Overall iron recovery improved by 10%. Energy consumption per ton of concentrate decreased by 15%. ZONEDING’s equipment and process design optimized the iron ore beneficiation. It helped the client achieve their production goals. It also delivered a higher quality product for the market.

The field of magnetite processing is always evolving. New technologies and methods emerge. They aim to improve efficiency. They also seek to reduce environmental impact. These trends focus on maximizing valuable concentrate recovery. They aim to reduce operational costs. They also address sustainability concerns.

Staying updated on these trends is crucial. It ensures competitiveness. It supports long-term viability in iron ore beneficiation.

SBS technologies are gaining traction. They are used for pre-concentration.

Magnetite can be locked in very fine particles. Traditional grinding methods may not liberate them fully.

Traditional iron ore beneficiation is water-intensive. Dry magnetic separation offers an alternative.

Automation and digital control systems are transforming plants.

Magnetite processing is a complex but essential process. It transforms raw iron ore into valuable concentrate. Every step, from mining to dewatering, plays a critical role. Understanding this entire journey is vital. It is central to efficient iron ore beneficiation. Successful processing requires robust equipment. It demands precise control. It requires a commitment to sustainability.

Investing in high-quality equipment is key. It ensures maximum iron recovery. It optimizes operational efficiency. ZONEDING offers comprehensive solutions. These solutions cover all stages of magnetite processing. ZONEDING’s crushing, grinding, magnetic separation, and dewatering equipment meets industry standards. The company helps achieve high-grade concentrate production. Partner with ZONEDING. Unlock the full potential of your magnetite deposit. Contact the company today. Discuss specific project requirements.

Learn sand washing process. Understand how sand washers, dewatering screens, & other machinery work together to achieve sand cleaning and classification.

View detailsLearn 4 key gold extraction methods: dissolving it with chemicals (leaching), using density (gravity), making it float (flotation) & melting it out (smelting).

View detailsUnderstand dry grinding process: definition, workprinciple, advantages, and common applications in various industries. Get a complete overview here.

View detailsConfused between an HSI and VSI impact crusher? This guide breaks down the key differences in application, feed material, product shape (cubicity), and cost.

View details