全站搜索

Search the entire website

Search the entire website

Choosing the right crushing equipment is one of the most important decisions you make for your mining or aggregate production project. As a manufacturer of crushing equipment for over 30 years, I know that getting this step right sets the stage for your entire operation’s success. Two of the most common machines, the jaw crusher and the cone crusher, serve very different roles. This guide will walk you through the key differences between a jaw crusher vs cone crusher. It will help you understand their performance and how to choose the right one for your specific needs.

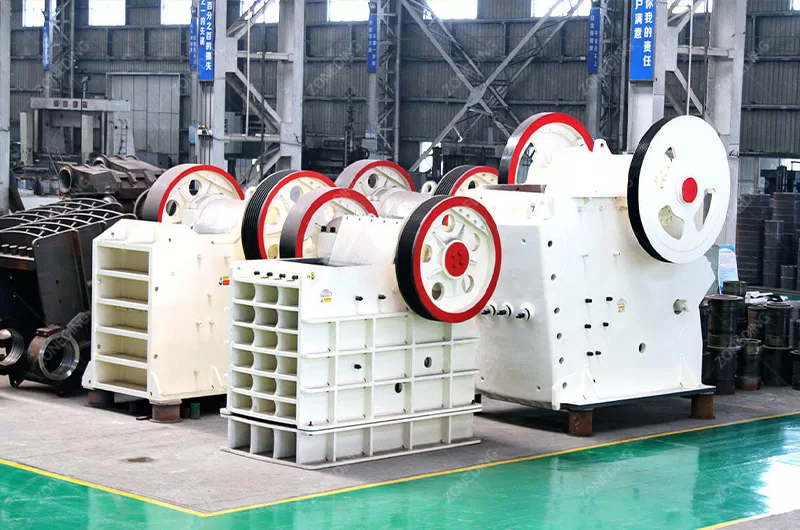

A jaw crusher performs primary crushing. It takes very large rocks and breaks them into smaller pieces. It works by compressing rock between two heavy plates. One plate stays fixed. The other plate moves back and forth. You feed the machine from the top. The moving jaw pushes against the fixed jaw. This crushes the rock in the middle. The material then falls out the bottom once it becomes small enough. Jaw crushers are simple and very strong. They form the first step in most crushing plant design layouts. At ZONEDING, we design our jaw crushers to handle the toughest materials directly from the mine.

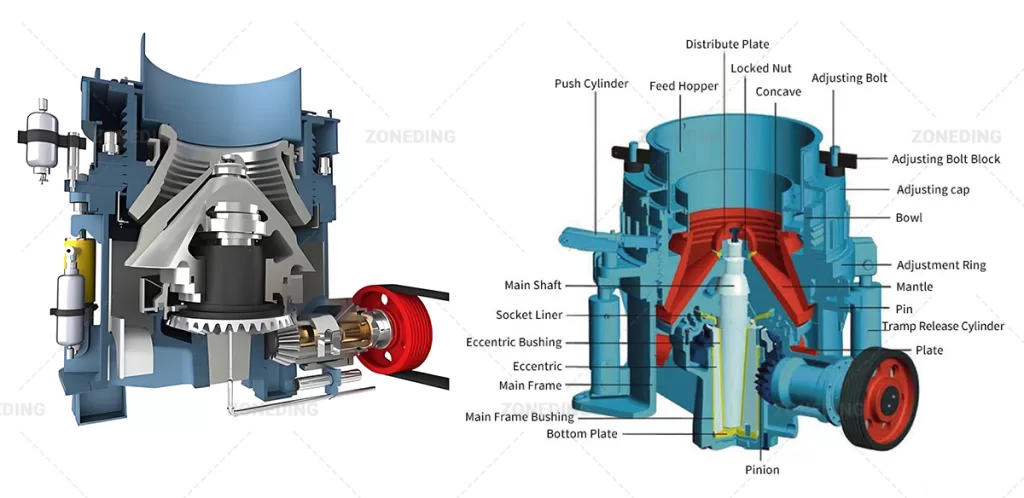

A cone crusher performs secondary or tertiary crushing. It further reduces the size of rock already processed by a primary crusher. Picture a huge, upside-down cone spinning inside a fixed outer cone. The rock gets squeezed and broken as it falls through this gap. Cone crushers work continuously. They produce a finer and more consistent product than jaw crushers. People know them for their high capacity and cubical product shape. For aggregate production, a good cone crusher is essential. Our cone crusher models at ZONEDING offer high output and efficiency.

These two types of crushing equipment differ significantly. These distinctions impact your plant layout and operating costs. Understanding how they differ helps you select the right machine for your project.

The shape and general build of jaw and cone crushers are quite distinct. This impacts how you integrate them into a plant.

The way these machines crush rock is fundamental to their application.

A jaw crusher uses compression. The swing jaw moves back and forth in an elliptical motion. It compresses the rock against the fixed jaw. The machine crushes material in cycles. It momentarily holds the rock in the chamber. It then breaks when the swing jaw moves inward. And it drops down when the jaw moves outward. This happens repeatedly until the material becomes small enough. It then passes through the discharge opening. This intermittent action is perfect for initial size reduction of very large, tough feed. It handles irregular shapes effectively. The crushing force is immense. This force allows it to break even the hardest rocks.

A cone crusher uses a gyratory crushing motion. The mantle, driven by an eccentric bushing, “wobbles” or gyrates inside the concave. This creates continuous crushing action around the full circumference of the crushing chamber. You feed material from the top. It crushes between the mantle and concave as the gap narrows. It then drops into a wider section of the chamber as the gap opens. This continuous action results in high throughput capacity. It also produces a more cubical product. The machine distributes crushing forces evenly throughout the chamber. This allows for efficient secondary and tertiary crushing stages. This principle makes it suitable for producing fine aggregates.

Throughput capacity is a critical factor. It tells you how much material your plant can process.

Jaw crushers typically have lower continuous throughput capacities compared to cone crushers of similar overall size. Their crushing action is intermittent. There is a pause between each crushing stroke. They excel at processing large input material. They prepare it for subsequent stages. For example, a large primary jaw crusher can process several hundred tons per hour. But this rate applies to initial, coarse crushing. The output is still quite large. We often measure its capacity by the rate at which it can accept and reduce large, unbroken material. This makes it ideal for feeding a secondary crushing stage. It is a crucial element in any crushing performance calculation.

| Feature | Jaw Crusher | Cone Crusher |

|---|---|---|

| Crushing Action | Intermittent, single-point compression | Continuous, multi-point compression and shearing |

| Material Flow | Pulsating, stop-and-go | Steady, continuous |

| Capacity | Typically lower for a given size, suited for primary | Higher for a given size, suited for secondary/tertiary |

Cone crushers offer high and continuous throughput. Their gyrating motion means that crushing happens constantly around the chamber. This leads to a steady flow of material. They can process thousands of tons per hour in large installations. This makes them ideal for high-volume aggregate production. The continuous action also results in a more uniform product. It also contributes to higher overall plant efficiency. Our ZONEDING cone crushers are designed for maximum material flow. They ensure your downstream processes are always well-fed. This is especially important when you need consistent production.

The reduction ratio tells you how much a crusher can reduce material size.

The type of material you feed into a crusher is important.

Jaw crushers tolerate large, irregular, and sometimes sticky feed material very well. We design them to accept “Run-of-Mine” (ROM) material directly from the blast. This includes large, angular boulders with varying sizes. They are robust enough to handle choke feeding. This is where you keep the chamber full. However, feeding excessively large pieces or pieces that are too flat can cause bridging. This interrupts the flow. Our ZONEDING primary crushers are built tough. They can manage the unpredictable nature of raw ore feeds. This is a key aspect of their crushing performance.

Cone crushers require a more uniform and consistent feed size. Material fed into a cone crusher must first be processed by a primary crusher. You should remove fines from the feed before sending it to a cone crusher. Too many fines can choke the crusher and reduce efficiency. Distribute the feed evenly around the crushing chamber. This ensures even liner wear. It also helps achieve optimal throughput capacity. Cone crushers are not suitable for sticky or wet materials. These can clog the crushing chamber. We recommend proper pre-screening for ZONEDING cone crushers. This ensures maximum efficiency and longevity.

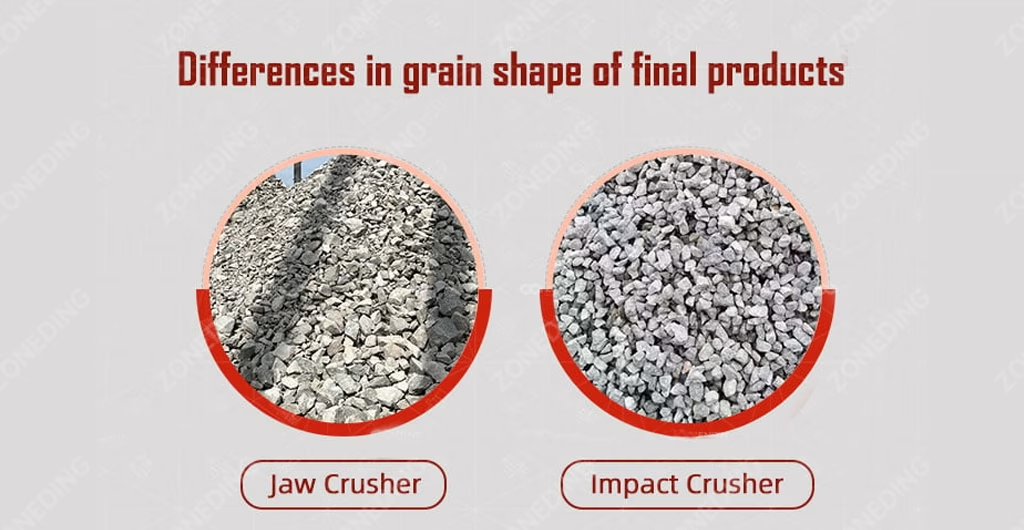

The shape of the crushed material is critical, especially for aggregate production.

The finished product from a jaw crusher tends to be angular and somewhat flaky or elongated. This results from the compression action. The rock breaks along its natural cleavage planes. While suitable for many applications, this shape is less desirable for high-quality concrete aggregate. Cubical material packs together better. It produces stronger concrete. However, for initial size reduction and filling voids, jaw-crushed material can still be very useful. The shape directly results from the primary crushing method.

Cone crushers produce a more cubical or spherical product. The gyratory action combines compression and attrition (grinding). This helps shape the material as it passes through the chamber. Cubical material is highly valued in the aggregate production industry. It creates stronger concrete and asphalt mixes. Our ZONEDING cone crusher designs optimize the crushing chamber. This ensures a superior cubical product shape. It improves the overall quality of your final aggregate. This is a critical factor when evaluating crushing performance.

Both crushers handle hard, abrasive materials effectively. However, each crusher prefers specific material types.

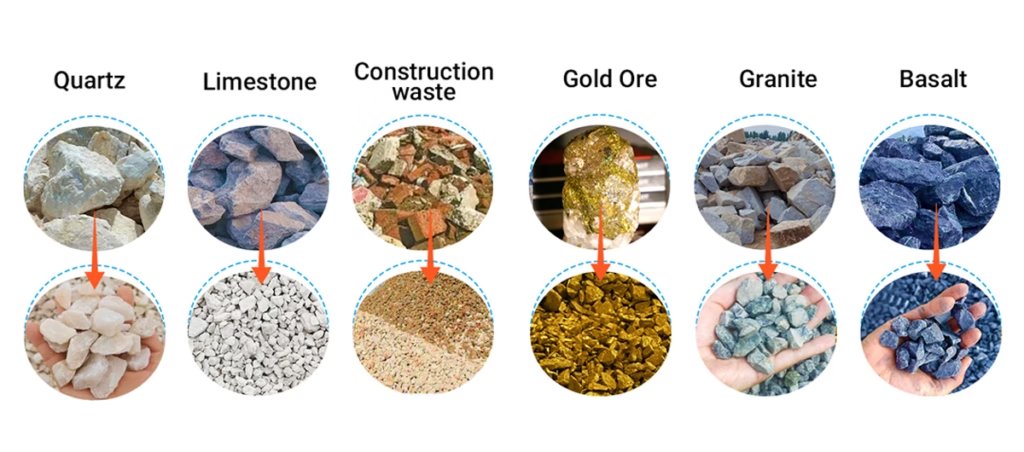

Jaw crushers are highly versatile. They can crush a wide range of materials. This includes hard and abrasive rocks like granite, basalt, and quartz. They also handle softer materials like limestone. They show less sensitivity to clay and slightly sticky materials than cone crushers. However, very sticky or wet materials can still cause clogging issues. You see them used in quarrying for aggregate. They are also common in mining operations for various ores, including iron and copper ore. ZONEDING jaw crushers withstand the rigorous conditions of crushing diverse, tough materials.

Cone crushers excel at crushing hard to medium-hard, non-abrasive to very abrasive materials. These include granite, basalt, river gravel, and various types of ore. They are particular about their feed. The material must be dry and free of excessive fines. They do not suit sticky or very wet material. This could pack the crushing chamber. Their continuous action and superior product shape are ideal for secondary and tertiary crushing of high-strength rocks. They prepare the rock for final screening or further processing. We build our ZONEDING cone crushers to handle consistent, high-intensity crushing tasks effectively. This makes them perfect for demanding aggregate production applications.

Each crusher plays a specific role in a typical crushing plant design.

The jaw crusher almost always serves as the primary crusher in a multi-stage crushing plant. It receives material directly from the mine or quarry face. Its job is to reduce these large, blasted rocks to a size that subsequent crushers can handle. You will find it at the very beginning of the processing line. It is the first machine the raw material encounters. Our ZONEDING jaw crushers are the foundational machines. They establish the initial material flow for your entire operation. Its position ensures the efficient continuation of material downsizing. It also prepares materials for downstream crushing performance by secondary units.

A cone crusher primarily works in secondary or tertiary crushing stages. It takes the output from a primary crusher (like a jaw crusher) and further reduces its size. In a secondary stage, it produces a finer aggregate. In a tertiary stage, it refines the product even further. This produces specific, high-quality aggregate sizes. These include sizes needed for concrete or asphalt. Some specialized cone crushers can even perform quaternary (fourth stage) crushing. Our ZONEDING cone crushers integrate seamlessly into these later stages. They consistently deliver desired product shape and size. This makes them vital components in advanced crushing plant design.

Energy consumption in crushing represents a significant operational cost.

Jaw crushers generally consume less power per tonne than cone crushers for the same output size. This happens because they typically handle larger material. They perform a coarser reduction. Their intermittent crushing action also contributes to this. However, the exact power consumption depends on material hardness, feed size, and desired output. While very energy efficient for primary crushing, optimizing their operation is key. We design ZONEDING jaw crushers for robust crushing performance. They also prioritize energy management. This helps you control operational cost of jaw crusher.

Cone crushers typically have higher power requirements for their given capacity compared to jaw crushers. They crush continuously. They also achieve a higher reduction ratio and produce finer material. However, when measured in terms of kWh per ton of final product with a high reduction ratio, they can be very efficient. This efficiency comes from their continuous crushing. It also comes from the inter-particle crushing. This effect helps break rock particles against each other. This improves overall crushing performance. ZONEDING cone crushers incorporate advanced drive systems. These systems aim to minimize energy consumption in crushing per ton of fine product.

Initial investment and ongoing maintenance are crucial for project economics.

A jaw crusher generally has a lower initial purchase price compared to a similarly capable cone crusher. This makes them an attractive option for projects with limited capital. Maintenance for jaw crushers is relatively simpler. This results from their straightforward design. Key maintenance involves inspecting and replacing jaw plates, cheek plates, and toggle plates. The liner wear for jaw plates can be significant with abrasive materials. But individual wear parts are often less expensive than those for cone crushers. This contributes to a generally lower operational cost of jaw crusher for basic crushing tasks.

Cone crushers typically have a higher initial capital cost. Their more complex mechanical design and advanced hydraulic systems contribute to this. Their maintenance can also be more complex. It requires specialized knowledge. However, cone crushers often show better liner wear characteristics per ton of material produced. This is due to their continuous crushing action and cubical product output. This translates into longer wear part life in many situations. While replacement parts (mantle and concave) can be more expensive, the frequency of replacement might be lower. This balances the overall crusher differences in cost effectively in the long run.

Environmental factors play a growing role in equipment selection.

Jaw crushers can produce significant noise during operation. The impact and compression of large rocks cause this. Dust generation is also common. This happens, especially with dry, friable materials. Effective dust suppression systems are essential. These include water sprays and dust collectors. Enclosing the crusher is also vital. This helps meet environmental regulations. It also protects workers. We make these measures standard in ZONEDING crushing plant design. We prioritize worker safety and environmental compliance. Our engineers always help integrate these solutions into your plant.

Cone crushers also generate noise. The continuous crushing action and material movement cause this. They produce dust, too. This is often finer dust, given their role in secondary and tertiary crushing. Like jaw crushers, they require robust dust suppression and noise reduction measures. This ensures a safe working environment. They also need to comply with local regulations. The choice between a jaw crusher vs cone crusher is not just about crushing. It also involves managing these environmental aspects. ZONEDING equips your aggregate production site responsibly.

Making the right choice is crucial. Here are the key factors to consider:

ZONEDING offers detailed consultation. We examine your specific needs. We help you design the most efficient crushing plant design. And we consider all these factors to ensure your success.

At ZONEDING, we do not just sell machines. We provide complete crushing solutions tailored to your unique project. With over 30 years of experience, we pride ourselves on building durable, high-performance crushing equipment. Our factory in China covers 8,000 square meters. It can produce over 500 units annually. This includes robust jaw crushers and advanced cone crushers. We also make screens, feeders, and other supporting equipment.

We use high-quality materials, like high wear-resistant steel. and we also use global brands for components. These include Siemens PLC control cabinets and Schneider inverters. This ensures reliability and efficiency. Our team of 15 dedicated engineers offers full-service support. This includes basic design through installation, commissioning, and after-sales service. We have helped clients in over 120 countries worldwide.

Choosing between a jaw crusher and a cone crusher is not about which machine is “better.” It is about which machine finds the right fit for its specific task. The jaw crusher is the workhorse for primary crushing. It handles the largest, toughest feed. The cone crusher is the precision instrument. It provides higher reduction ratio and superior product shape for secondary and tertiary stages. Both are essential components in different parts of a modern crushing plant design.

Understanding these crusher differences in their work principles, capacities, and product outputs is key to maximizing your crushing performance. Do not hesitate to leverage expert advice for your specific project.

Learn 4 key gold extraction methods: dissolving it with chemicals (leaching), using density (gravity), making it float (flotation) & melting it out (smelting).

View detailsLooking for answers? We list 7 essential facts about limestone. 1. It's sedimentary. 2. Made of calcite. 3. Used in concrete. Click to read the full list.

View detailsThis article details extraction methods, pre-treatment strategies, and best practices to process refractory oxidized gold ore and improve gold yield.

View detailsLearn how to identify gold in the ground by its color, luster, and shape. We explain why raw gold doesn't sparkle like glitter and how to spot it in dirt.

View details