All You Need to Know About Silver Ore: A Complete Guide

Silver has captivated humanity for centuries. It is not just for jewelry or coins. Silver plays a crucial role in modern technology, from electronics to solar panels. As a leading manufacturer of mining equipment, ZONEDING understands that successful silver mining starts with deeply understanding the ore itself. This guide will provide a comprehensive look at silver ore. We will cover everything from its formation and types to silver processing methods and market viability.

Table of Contents

What is Silver Ore?

Silver ore is rock or mineral that contains enough silver to be mined profitably. Silver rarely occurs as pure, native metal. It is typically found mixed with other elements. These are often sulfur, lead, copper, or zinc. The process of extracting silver from this ore is complex. It involves several stages, from crushing and grinding to chemical separation.

What Does the Silver Ore Look Like?

Silver ore is not always shiny and metallic. Its appearance varies greatly depending on the specific mineral.

- Native Silver: This is rare, but when found, it appears as bright, metallic silver nuggets or wires. It tarnishes to a dull gray or black over time.

- Argentite (Silver Sulfide): This is a common silver mineral. It is dark gray to black. It has a metallic to submetallic luster. And It might look like dull lead.

- Pyrargyrite (“Dark Red Silver Ore”): This mineral is deep red to grayish-black. It has a metallic luster. It can be quite striking.

- Stephanite (“Brittle Silver Ore”): This is iron-black. It has a metallic luster. It can be brittle.

- Galena (Lead Sulfide): Silver is often a by-product of lead mining. Galena is a shiny, bluish-gray mineral with a metallic luster. If your ore is primarily galena, silver will be a secondary target.

- Chalcopyrite (Copper Iron Sulfide): Silver is also a by-product of copper mining. Chalcopyrite is a brassy yellow with a metallic luster.

The most important thing for you to know is that silver ore often does not look like the shiny silver you know. It is often within other minerals.

Silver ore forms through various geological processes. It usually happens when dissolved silver is deposited in specific environments.

- Hydrothermal Processes: This is the most common way. Hot, mineral-rich water flows through cracks in the earth’s crust. As the water cools or reacts with other rocks, silver-bearing minerals precipitate out. They fill veins and fractures. These veins often contain other metals too, like lead, zinc, and copper.

- Volcanogenic Massive Sulfide (VMS) Deposits: These deposits form on the seafloor near volcanic activity. Hot, metal-rich fluids vent into the ocean. They create massive sulfide deposits rich in copper, zinc, lead, gold, and silver.

- Sedimentary Exhalative (SEDEX) Deposits: Similar to VMS deposits, but they form in sedimentary basins. Metal-rich brines are expelled onto the seafloor or just below it. This creates large, stratiform (layered) deposits of base metals and silver.

- Epithermal Deposits: These form relatively close to the Earth’s surface. They are associated with volcanic activity. They create shallow, bonanza-grade silver veins.

- Porphyry Deposits: These are very large, low-grade deposits. They are with intrusive igneous rocks. They are primary sources for copper, but they often contain significant amounts of silver as a by-product.

What is the Composition and Properties of Silver Ore?

The exact composition and properties of silver ore depend on the mineral where we find silver.

- Composition of silver ore:

- Silver Content: The amount of silver in the ore can range from a few parts per million (ppm) in base metal ores to thousands of ppm in high-grade silver veins.

- Associated Metals: Silver is usually with other base metals. These include lead (in galena), zinc (in sphalerite), copper (in chalcopyrite), and gold. It can also be with antimony, arsenic, and sulfur.

- Properties (of common silver minerals):

- Luster: Metallic to submetallic.

- Hardness: Varies, but generally soft (2-3 on Mohs scale for native silver, 2-2.5 for argentite).

- Specific Gravity: Relatively high due to the presence of heavy metals.

- Malleability: Native silver is highly malleable (can be hammered into thin sheets).

- Electrical Conductivity: Silver is the best electrical conductor. This property is important in its applications.

- Tarnishing: Most silver minerals and native silver will tarnish (oxidize) to a dark gray or black when exposed to air.

What are Types of Silver Ore?

Silver ore is broadly classified by the primary mineral where the silver is concentrated.

- Native Silver: Pure silver metal. Rare but highly prized.

- Sulfide Ores: These are the most common. Silver is chemically bonded with sulfur.

- Argentite (Acanthite): Ag₂S, a major source of silver.

- Pyrargyrite & Proustite: Silver antimony sulfides and silver arsenic sulfides respectively. Known as “ruby silvers” for their red color.

- Stephanite, Polybasite, etc.: Other complex silver sulfides or sulfosalts.

- Halide Ores: Silver combined with halogens like chlorine.

- Chlorargyrite (Horn Silver): AgCl, forms in the oxidized zones of silver deposits. It resembles wax or horn.

- Telluride Ores: Silver combined with tellurium. These are less common but can be important in some gold-silver deposits.

- Associated Ores: Silver found as a by-product in other metal ores.

- Galena (PbS): Lead ore that commonly contains significant silver. Often called “argentiferous galena.”

- Sphalerite (ZnS): Zinc ore that can also host silver.

- Chalcopyrite (CuFeS₂): Copper ore that frequently contains silver.

Where Can We Find the Silver Ore Deposits?

Silver deposits are in all over the world, often in historically rich mining districts.

- North America: Mexico is the world’s largest silver producer. It has extensive epithermal vein deposits. The United States (Nevada, Idaho, Alaska) and Canada (Yukon, British Columbia) also have significant deposits.

- South America: Peru, Chile, and Bolivia are major silver producers. These countries have a long history of silver mining, often from hydrothermal veins and SEDEX deposits.

- Asia: China is a significant producer, with various deposit types. Russia also has notable silver resources.

- Australia: Australia produces silver mainly as a by-product of lead-zinc mining.

- Europe: Poland has large silver resources associated with copper deposits.

Many of the world’s largest silver mines are base metal mines. They extract silver as a valuable co-product.

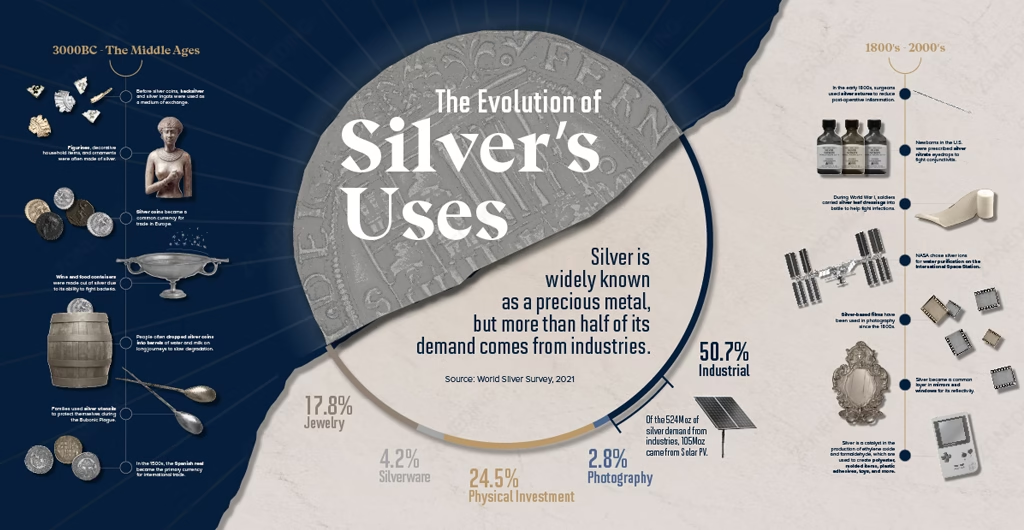

What are Applications of Silver Ore?

Silver ore, once refined, finds its way into countless applications thanks to its unique properties.

- Industrial Uses (50% of Demand):

- Electronics: Silver is critical for electrical contacts, conductors, and switches due to its high electrical conductivity. It is in phones, computers, and medical devices.

- Solar Panels: It applies in crystalline silicon photovoltaic (PV) cells to conduct electricity.

- Automotive: Found in switches, contacts, and battery connections in cars, especially electric vehicles.

- Brazing Alloys and Solders: Used in joining metals due to its strength and ability to create strong bonds.

- Photography: Historically a major use, but less prominent now with digital cameras.

- Jewelry and Decorative Items (20% of Demand): Its luster and malleability make it popular for jewelry, silverware, and decorative objects.

- Investment (20% of Demand): Silver is seen as a safe-haven asset. It is held in bullion, coins, and ETFs (Exchange-Traded Funds).

- Coinage: Used in circulating and commemorative coins worldwide.

- Medical Applications: Due to its antimicrobial properties, it is used in wound dressings, medical coatings, and some surgical instruments.

How to Mine and Process the Silver Ore?

Silver extraction involves several stages. These steps reduce the ore size and separate the silver-bearing minerals.

Mining:

- Drilling and Blasting: Hard rock silver deposits require drilling holes and placing explosives. This breaks the rock into manageable pieces.

- Loading and Haulage: Broken ore is loaded by excavators or loaders into haul trucks. It is then transported to the processing plant.

- Underground Mining: Many high-grade silver veins are accessed through shafts and tunnels. This allows miners to follow the narrow ore bodies.

- Open Pit Mining: For larger, lower-grade deposits, open-pit mining is used. Silver can be a co-product in these large-scale operations.

Crushing and Grinding:

- Primary Crushing: Large ROM (Run-of-Mine) ore is fed into robust jaw crushers. These reduce the rock to a few inches in size.

- Secondary and Tertiary Crushing: The ore then goes through cone crushers. This further reduces the size to millimeters.

- Grinding: The crushed ore is fed into ball mills. Here, steel balls grind the ore into a fine powder (a slurry). This liberates the silver-bearing minerals from the waste rock. This is crucial for ore beneficiation.

Beneficiation (Separation):

- Flotation: This is the most common method for silver sulfide ores. Air bubbles are introduced into the ore slurry with chemical reagents. These reagents make the silver minerals stick to the bubbles. The bubbles float to the surface, forming a concentrate. This is then skimmed off. ZONEDING can help with flotation plant design.

- Cyanidation: For some silver ores, especially those containing native silver or silver halides, cyanide solutions are used. The silver dissolves into the solution. It is then precipitated out later. This method requires careful environmental management.

- Gravity Separation: For coarser, denser silver minerals, gravity methods (like spirals or jigs) can be used. These separate minerals based on their density.

- Leaching: A chemical process where the desired metal is dissolved from the ore. It removes silver from the ore materials.

- Smelting & Refining: The final silver concentrates are sent to smelters. Here, high heat separates the silver from other metals. Further refining steps produce pure silver bullion.

What Essential Equipment is Needed for Crushing and Grinding Silver Ore?

ZONEDING specializes in providing the core mining equipment for efficient silver processing.

- Crushing Equipment:

- Jaw Crushers: For primary reduction. Handles large, hard material.

- Cone Crushers: For secondary and tertiary crushing. Produces a finer, more uniform feed for grinding.

- Impact Crushers: Used in some applications for specific material characteristics.

- Grinding Equipment:

- Ball Mills: Essential for grinding the crushed ore into a fine slurry. This is where the silver minerals are liberated from the waste rock.

- Rod Mills: Sometimes used for coarser grinding stages, providing a more uniform product than ball mills.

- Screening Equipment:

- Vibrating Screens: Used after crushing to separate ore particles by size and ensure efficient feed to the next stage.

- Conveying Equipment:

- Belt Conveyors: To efficiently transport ore throughout the plant, connecting different stages of crushing, grinding, and processing.

How Do Investment Factors and Market Trends Influence Silver Ore Project Viability?

Investing in silver ore mining is complex. It is affected by many factors beyond geology.

- Global Silver Market Price: The price of silver deeply influences viability. Higher prices make lower-grade deposits profitable. Sustained low prices can shut down mines. You need to keep an eye on the global silver market.

- Operational Costs: Fuel, labor, power, reagents, and wear parts are major expenses. Efficient mining equipment from ZONEDING helps reduce these costs.

- Geopolitical Stability: Silver mining often occurs in regions prone to political instability. This can affect operations and investment.

- Environmental Regulations: Strict environmental rules for waste disposal, water use, and re-forestation add to costs.

- By-Product Credits: Most silver comes as a by-product. The prices of lead, zinc, and copper greatly affect the overall economics of a silver-producing mine.

- Technological Advancements: New silver metallurgy methods or exploration techniques can change project viability.

- Demand Trends: Growing demand from solar panels and electronics supports long-term silver prices. This makes projects more appealing.

- Investment Capital: Mining projects require huge upfront capital. Access to financing depends on investor confidence and market outlook.

How Can You Ensure Sustainable Practices in Silver Ore Extraction and Processing?

Sustainable mining practices are critical for both the environment and long-term project viability.

- Reduce Waste:

- Efficient Processing: Optimize ore beneficiation to maximize silver recovery. This reduces waste material that goes to tailings.

- Tailings Management: Design modern, stable tailings dams. Explore options for converting tailings into useful products, like construction materials.

- Minimize Environmental Impact:

- Water Management: Implement closed-loop water systems. Minimize water consumption. Treat and recycle process water.

- Energy Efficiency: Use energy-efficient mining equipment. Optimize crushing and grinding circuits to reduce power use.

- Land Reclamation: Plan for progressive reclamation. Restore mined areas to their natural state or for other beneficial uses.

- Biodiversity Protection: Protect local ecosystems and wildlife during and after operations.

- Social Responsibility:

- Community Engagement: Work closely with local communities. Provide jobs and local economic development.

- Safety: Ensure the highest safety standards for all workers.

- Fair Labor Practices: Uphold ethical labor practices and human rights.

- Technological Innovation:

- Advanced Metallurgy: Continuously research and implement new silver metallurgy methods that are more efficient and less impactful.

- Automation: Use automation to improve safety and efficiency.

- Remote Monitoring: Monitor environmental parameters and equipment performance remotely.

What Critical Data Do You Need Before Investing in a Silver Ore Project?

Before investing, you need comprehensive data:

- Geological and Resource Data: Confirmed mineral reserves and resources through drilling.

- Metallurgical Test Work: Detailed studies on silver recovery rates, optimal processing methods, and concentrate quality.

- Economic Feasibility Study: Detailed financial modeling, sensitivity analysis to silver prices, and operational cost projections.

- Environmental and Social Impact Assessments: Full understanding of regulatory requirements and community relations.

- Market Analysis: Long-term outlook for silver and co-product metal prices.

FAQ

- How Can You Maximize Silver Recovery from Complex Ores?

- Maximizing silver recovery from complex ores involves detailed mineralogical studies. You must identify all silver-bearing minerals. Then you can design a multi-stage beneficiation circuit. This might combine flotation, gravity separation, and sometimes leaching. Our flotation plant design expertise at ZONEDING can help optimize these circuits.

- What are the Environmental Concerns Specific to Silver Mining?

- Key environmental concerns include:

- Tailings disposal: Improperly managed tailings can leach heavy metals.

- Water contamination: Acid mine drainage and the use of chemicals like cyanide in some processes.

- Land disturbance: Habitat destruction from mining operations.

Mitigation involves careful planning, advanced waste management, and stringent regulatory compliance.

- What is the Role of By-Product Silver in the Global Market?

- The majority of the world’s silver comes as a by-product from copper, lead-zinc, and gold mines. This means its supply is less sensitive to standalone silver prices. The economic viability of these mines primarily depends on the main metal price. This makes the global silver market more complex. It adds stability to silver supply volumes even when silver prices fluctuate.

- How Does Ore Grade Influence Processing Choices and Equipment Selection?

- Higher ore grades generally allow for simpler processing. Lower-grade ores, particularly those with finely disseminated silver, require more intensive crushing, finer grinding, and more complex beneficiation circuits. This directly affects the type and scale of mining equipment you need, and your overall silver processing costs.

Conclusion and Final Advice

Silver ore is a vital resource. Its extraction and processing are complex. They demand careful planning and the right technology. Understanding the geology, composition, and processing methods is key to a successful silver mining venture. ZONEDING advocates for a holistic approach. This involves thorough ore characterization, smart equipment selection, and a strong commitment to sustainable mining practices.

Do not underestimate the importance of robust, reliable mining equipment. Every stage, from crushing to beneficiation, needs the right tools. Investing wisely in your plant design and machinery ensures efficiency. It helps maximize your silver extraction and maintains profitability.