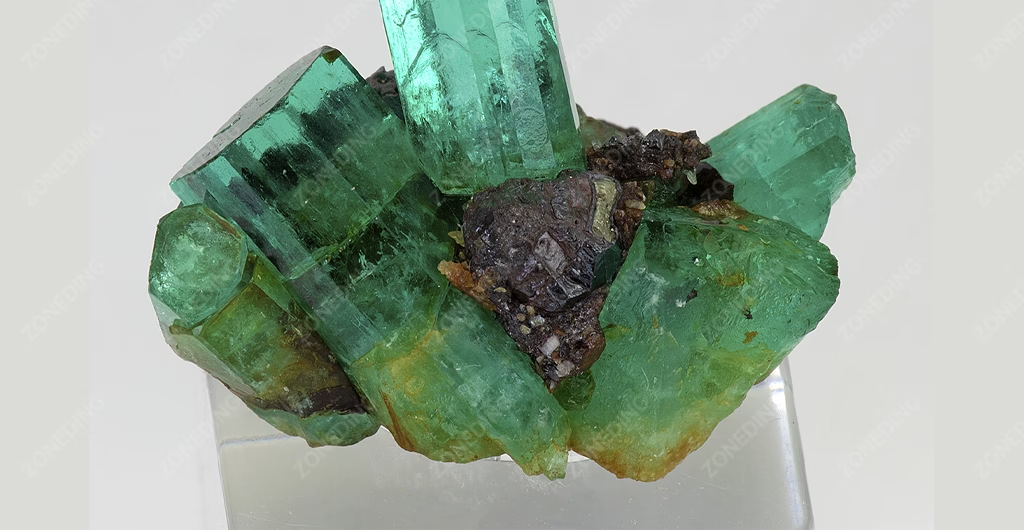

Beryl is one of those minerals. Most people know it from its famous family members, like the brilliant green Emerald and the sea-blue Aquamarine. These are beautiful gemstones. But for us, Beryl is much more than just a pretty stone. It is also the main source of a critical industrial metal: beryllium. This dual identity makes Beryl fascinating. It is a star in both the jewelry store and the aerospace factory. In this guide, we will share our hands-on knowledge of what is Beryl, its properties, and how it gets from a rough stone in a mine to a valuable final product.

Table of Contents

What is Beryl?

So, what is Beryl exactly? It is a mineral that belongs to a group called cyclosilicates. It forms beautiful, often large, six-sided crystals deep within the earth’s crust. Its true value, however, comes from its perfect and often colorful crystal formations.

Brief Introduction of Beryl

A Beryl mineral is fundamentally a beryllium aluminum cyclosilicate. That is a technical way of saying it is from beryllium, aluminum, silicon, and oxygen arranged in a specific crystal structure. A perfectly pure Beryl crystal is actually colorless. All of the amazing colors we see in gemstones like Emerald and Aquamarine come from tiny amounts of other elements inside the crystal as it grew millions of years ago.

What Does the Beryl Look Like?

In its raw, natural form, Beryl typically looks like a six-sided column or prism. The crystal shape is very distinct. These crystals can be very small, or they can be massive, sometimes weighing several hundred pounds. Their color can vary a lot depending on the impurities. They can be milky white, pale green, yellow, pink, or light blue stones embedded in other rocks like granite. The most valuable pieces are those that are transparent with a deep, rich color.

What are the Structure of Beryl?

The structure of Beryl is what gives it its classic six-sided shape. At a molecular level, its silicon and oxygen atoms link together to form rings. This strong, stable, repeating pattern is what we call a hexagonal crystal system. This internal structure is also responsible for many of Beryl’s key properties, like its hardness and the way it breaks.

Chemical composition of Beryl?

The chemical formula for Beryl is Be₃Al₂(SiO₃)₆. Let’s break that down into its main ingredients:

- Beryllium (Be): This is the key element that makes Beryl valuable for industrial applications.

- Aluminum (Al): A common element in the earth’s crust.

- Silicon (Si) and Oxygen (O): Together, they form silicate rings, the mineral’s backbone.

The color of a Beryl gemstone comes from trace elements. A tiny bit of chromium or vanadium makes Beryl green, creating Emerald. A small amount of iron makes it blue or greenish-blue, creating Aquamarine. Manganese is what gives Morganite its beautiful pink color.

Physical and optical properties of Beryl?

When we evaluate a mineral for processing or for gem quality, we look at several key Beryl properties. These tell us how it will behave in our machines and how it will look as a polished stone.

- Hardness: Beryl scores a 7.5 to 8 on the Mohs scale of hardness. This is very hard. It means it is durable and resistant to scratching, which is excellent for jewelry.

- Specific Gravity: It has a specific gravity of 2.63 to 2.92. This density helps us separate it from other, lighter minerals during processing.

- Luster: Beryl has a vitreous, or glass-like luster.

- Refractive Index: This measures how light bends as it passes through the stone. For Beryl, it is between 1.56 and 1.60, which gives it a nice brilliance.

- Cleavage: It has indistinct cleavage, meaning it does not break cleanly along a flat plane. It is more likely to fracture like glass.

Types and Varieties of Beryl?

The Beryl family is full of famous members. The different types of Beryl gems:

- Emerald: The most famous Beryl. It is green due to chromium and/or vanadium. High-quality emeralds are among the most valuable gemstones in the world.

- Aquamarine: The second most famous variety. Its color ranges from a very light blue to a deep sea-blue, caused by iron.

- Morganite: A pink to orange-pink variety, colored by manganese.

- Heliodor: A golden-yellow or greenish-yellow Beryl. Its color also comes from iron.

- Goshenite: This is the pure, colorless form of Beryl.

- Red Beryl (Bixbite): The rarest variety of Beryl. This deep red gem is in only a few locations in Utah and is extremely valuable.

What are the Main Applications of Beryl?

The Beryl uses includes two very different worlds: the world of high fashion and the world of high technology.

Industrial Uses

The main industrial use of Beryl is as the primary ore for the metal Beryllium. Beryllium is a remarkable material. It is as strong as steel but as light as aluminum. It also has a very high melting point and is an excellent conductor of heat. Because of these unique properties, the industrial uses of Beryllium are critical in several advanced industries:

- Aerospace: Used in high-speed aircraft, missiles, and satellites.

- Electronics: Used for electrical connectors and components in phones and computers.

- Nuclear Energy: Used in nuclear reactors as a neutron moderator.

- Medical: Used in X-ray machine windows.

Jewelry

This is the application most people know. For thousands of years, the colorful, transparent varieties of Beryl have been cut and polished into gemstones. Emerald and Aquamarine are two of the most popular colored gemstones in the world. Their hardness makes them perfect for all types of jewelry, including rings, necklaces, and earrings, as they can withstand daily wear.

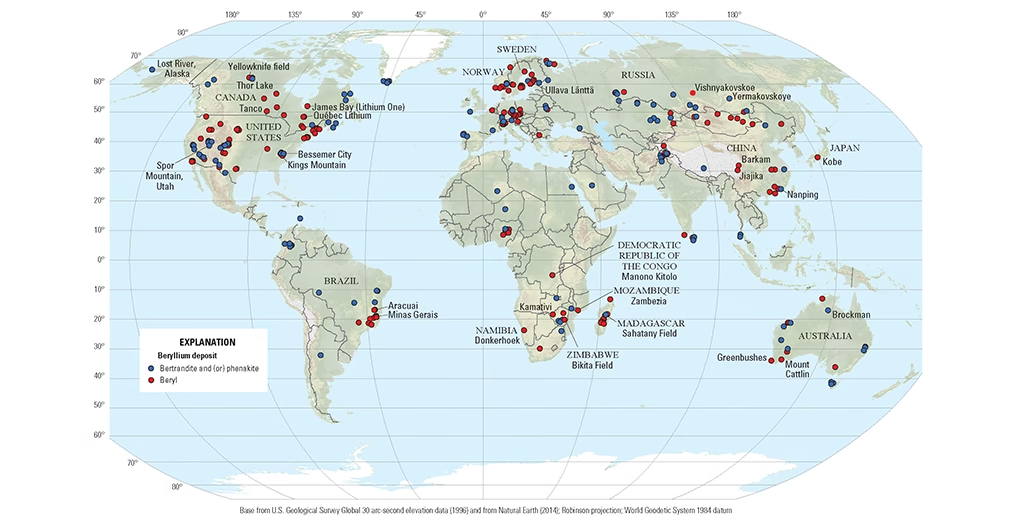

Where Can We Find the Beryl Deposits?

Beryl is in igneous and metamorphic rocks, specifically in granite pegmatites. Significant commercial deposits are in several countries around the world.

- Colombia: Famous for producing the world’s finest and most valuable emeralds.

- Brazil: A major source for a wide variety of Beryl, especially Aquamarine and Heliodor.

- Zambia: Another key producer of high-quality emeralds.

- United States: Deposits are in states like Utah (Red Beryl), North Carolina, and Idaho.

- Other locations: Russia, Afghanistan, Pakistan, and parts of Africa also have important Beryl deposits.

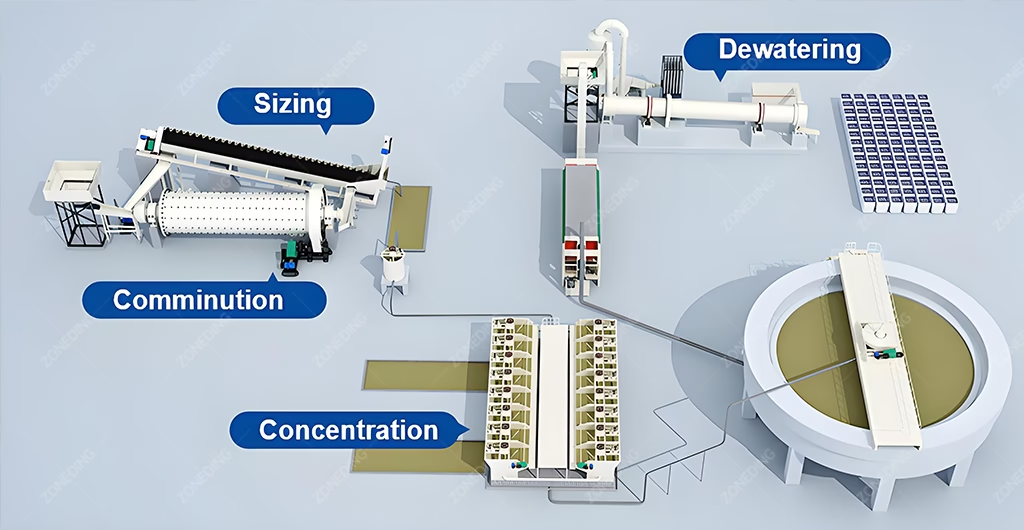

How is Beryl Processed from Raw Ore?

Getting the small Beryl crystals out of tons of hard rock is a complex job. This is where our expertise at ZONEDING comes in. The process of Beryl processing from raw stone involves several key stages to liberate the Beryl and concentrate it.

- Mining and Crushing: First, the Beryl-bearing rock (pegmatite) is mined from the earth. This rock is then transported to the processing plant. The large rocks are fed into a jaw crusher. This machine acts like a powerful mechanical jaw, breaking the giant rocks down into smaller, more manageable pieces, about the size of a fist.

- Grinding: The crushed rock is then moved to a ball mill. A ball mill is a large rotating drum filled with steel balls. As the drum turns, the steel balls tumble and grind the rock into a fine powder, like sand or flour. The goal is to make the particles small enough to free the individual Beryl crystals from the host rock.

- Separation (Froth Flotation): This is the clever part. The fine powder is mixed with water and special chemicals in a flotation machine. Air is then bubbled through the mixture. The chemicals make the Beryl particles water-repellent, so they stick to the air bubbles and float to the top, forming a froth. The other worthless minerals (gangue) get wet and sink to the bottom. This froth is skimmed off, giving us a concentrate rich in Beryl.

- Drying: The Beryl concentrate is then dewatered and dried. The result is a fine powder with a high percentage of Beryl, ready to be sent for beryllium extraction or gem sorting.

Which Equipment Do We Need to Process Beryl?

To build a complete Beryl processing plant, you need a lineup of tough, reliable machinery. Each piece performs a specific job in the process we just described.

A typical plant would include:

- Jaw Crusher: For the primary crushing of large rocks from the mine.

- Cone Crusher: For secondary crushing, to make the particles even smaller before grinding.

- Vibrating Screen: Used to sort the crushed material by size, ensuring only the right-sized particles go to the ball mill.

- Ball Mill: For grinding the crushed rock into a fine powder.

- Flotation Machine: This is the core of the separation process, where the Beryl is separated from waste rock.

- Thickener and Dryer: To remove water from the final Beryl concentrate.

- Conveyors: To move the material between the different machines.

How to Choose the Right Supplier for Your Beryl Processing Plant?

Choosing a partner to build your processing plant is a huge decision. You need more than just a machine seller; you need an engineering partner.

- Look for Experience: Has the supplier built plants for similar minerals before? Ask for case studies and references. With over three decades in the business, we at ZONEDING have a deep library of successful mineral processing projects.

- One-Stop Solution: It is much easier to work with a supplier who can provide the complete line of equipment. This ensures all the machines work together perfectly. ZONEDING designs and manufactures the entire processing line, from the crusher to the dryer.

- Customization: Your ore is unique. A good supplier will test your ore and customize the plant design and equipment for your specific needs to get the best recovery rate.

- After-Sales Support: What happens after the sale? Ensure the supplier provides support for installation, commissioning, training your staff, and supplying spare parts. Our service team supports clients around the world.

What is the Price of a Beryl Processing Plant?

This is a common question, and the answer is that the cost of a complete beryl processing plant can range widely, from around $150,000 for a small-scale pilot operation to over $2,000,000 for a large, high-capacity industrial plant. A processing plant is a custom project, not an off-the-shelf product.

The final price depends on these key factors:

- Processing Capacity: How many tons of ore do you need to process per hour? This is the biggest cost driver, as it determines the size and power of every machine in the line.

- Ore Characteristics: What is the hardness of your rock? What is the concentration of Beryl? A low-grade ore might require a more complex process to achieve good recovery.

- Scope of Supply: Do you need just the core equipment, or a full turnkey solution that includes steel structures, piping, electrical controls, and installation support?

- Level of Automation: A plant with a central SIEMENS PLC control system will have a higher initial cost than one with manual controls, but it can reduce long-term labor costs.

As a factory-direct manufacturer, ZONEDING works with you to design a plant that fits your budget. The best way to get a real number is to contact us with the details of your project.

FAQ

- What Factors Determine a Beryl Gemstone’s Value?

- The value is determined by the “Four Cs”: Color (the most important factor; deep, pure colors are best), Clarity (fewer internal flaws or inclusions), Cut (how well the stone is faceted to maximize brilliance), and Carat weight (the size of the stone).

- How Can You Identify Raw Beryl in the Field?

- Look for its classic six-sided hexagonal crystal shape. Check its hardness; it should be able to scratch glass and quartz easily. Beryl is also often found in granite pegmatites, associated with minerals like quartz, feldspar, and mica.

- How Should You Care For and Clean Beryl Jewelry?

- Beryl is hard, but it can be brittle. Avoid hard knocks. To clean it, simply use warm soapy water and a soft brush. Avoid harsh chemicals and ultrasonic cleaners, especially for Emerald, which is often treated with oils to fill fractures.

- Which Type of Beryl is the Right Choice for You?

- This is a personal choice. If you love classic green and have a higher budget, choose Emerald. If you love blue, Aquamarine offers great value and durability. For a unique pink, Morganite is a wonderful option. For a bright, sunny gem, consider Heliodor.

Conclusion

Beryl is a truly exceptional mineral, valuable in both its raw and refined forms. From the industrial might of beryllium to the timeless beauty of an emerald ring, it all begins with processing the stone efficiently. Understanding the properties of Beryl is key to unlocking its full potential.

At ZONEDING, we are passionate about providing the robust and reliable equipment needed for this process. We offer a one-stop solution, from initial ore testing and plant design to manufacturing, installation, and long-term support. If you are looking to build a Beryl processing plant, our team of experienced engineers is ready to help you design a solution that maximizes your efficiency and profitability.

Contact us today to discuss your project and get a customized solution.