全站搜索

Search the entire website

Search the entire website

Asphalt concrete is a vital construction material. It forms durable roads, pavements, and parking lots. Its production requires precise steps. Raw material selection is crucial. The mixing process demands accuracy. This guide details each stage. It covers making asphalt concrete. It is a comprehensive overview. Understanding asphalt production is key.

This material connects cities and towns. It facilitates daily travel. High-quality asphalt concrete ensures long-lasting infrastructure. Poor production leads to early road failure. This guide explains selection of materials. It details preparation and final mixing. It also highlights quality control. This information supports your project needs.

Asphalt concrete is a composite material. It is used for surfacing roads. It is a key element in pavement construction. This material combines several components. It uses mineral aggregate. It also contains an asphalt binder. This binder acts as glue. The mix is heated for production. This creates hot mix asphalt (HMA). Asphalt concrete provides a smooth, durable surface. It withstands heavy traffic loads. It resists weather conditions.

The term “asphalt” often refers to the binder. However, “asphalt concrete” describes the final pavement material. This material offers flexibility. It also provides water resistance. These properties make it ideal for roads. Correct asphalt production is essential. It ensures the longevity of infrastructure.

Asphalt concrete relies on three main components. Each component plays a specific role. Their proper proportion creates a strong, lasting material. Variations in these components alter the asphalt’s performance.

Making high-quality asphalt concrete begins with the right materials. Each component has strict specifications. Their proper selection impacts the final product. Understanding material properties is vital. This ensures successful asphalt production. High-quality raw materials contribute to a durable road surface. They prevent premature pavement failure.

Material quality control starts at the source. It continues through preparation. This comprehensive approach guarantees a superior final product. Your asphalt needs depend on the project. Project load and climate affect material choice.

Aggregates form the primary structural component. They account for over 90% of a typical asphalt mix. These small, solid particles create stability. They withstand traffic loads. Aggregates include crushed stone, gravel, and sand. Their quality significantly affects asphalt concrete performance.

Proper aggregate characteristics are essential. They include hardness, durability, and cleanliness. Angular faces provide better interlocking. This increases mix strength. Flat or elongated particles reduce stability. This should be avoided. The aggregate gradation is also critical. It refers to the distribution of particle sizes. A well-graded aggregate creates a dense mix. It has minimal voids. This reduces water penetration.

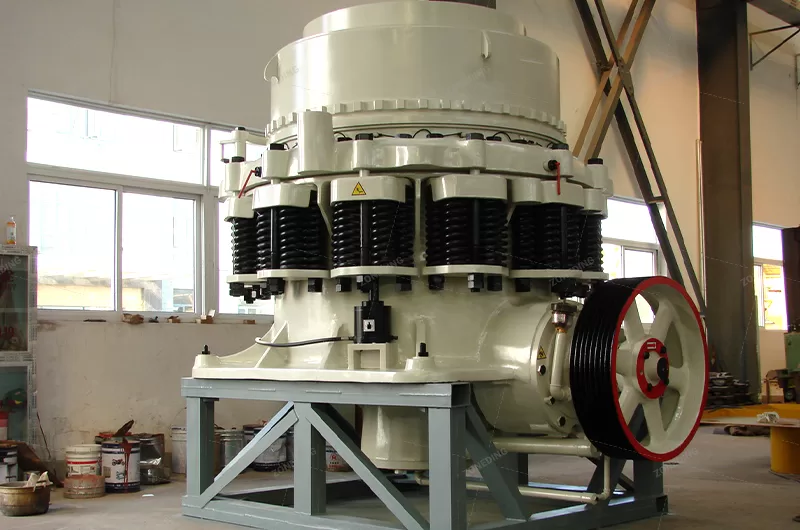

ZONEDING provides robust jaw crushers for primary crushing. Cone crushers offer secondary reduction. Vibrating screens classify them precisely. These ensure you get the right aggregate for asphalt mixing.

The asphalt binder is a type of bitumen. It acts as the cementing agent. It holds the aggregates together. This dark, petroleum-based material provides cohesion. It adds flexibility and waterproofing. The binder’s quality is paramount. It dictates the overall performance of the asphalt concrete.

Binder properties affect the mix. They include viscosity and aging resistance. Viscosity is the fluid’s resistance to flow. It changes with temperature. It is critical for successful mixing. Modified binders often contain polymers. These polymers enhance binder performance. They improve elasticity. They increase fatigue resistance. Selecting the correct binder type suits specific climatic conditions. It impacts traffic loads. This is crucial for pavement design.

Mineral filler comprises very fine particles. Its size is usually less than 0.075 mm. Common fillers include limestone dust, fly ash, or Portland cement. These fine materials fill small voids. They exist between the larger aggregate particles. This creates a denser, more cohesive mix.

Minerals fillers enhance the asphalt binder’s properties. They increase its stiffness. They improve its workability. And They reduce the amount of binder needed. This can lower costs. It can improve performance. Mineral fillers prevent aggregate segregation. They reduce moisture susceptibility. Their inclusion results in a more stable and durable asphalt concrete.

Material preparation is a critical phase. It directly impacts the quality of asphalt concrete. Proper preparation ensures consistent mix properties. It also guarantees optimal performance. Incorrect preparation leads to pavement failures. This includes cracking or rutting. Each component requires specific treatment steps. These steps ensure readiness for asphalt mixing. ZONEDING offers robust equipment for these preparation stages.

Efficient preparation processes save time. They also reduce operational costs. Investing in quality preparation equipment pays off. It results in superior final products.

Aggregates arrive at the plant in various sizes. They need processing for the correct gradation. This ensures a uniform asphalt mix. ZONEDING’s jaw crushers handle primary crushing. They reduce large rocks to manageable sizes. Following this, cone crushers perform secondary and tertiary crushing. They create smaller, cubical aggregate particles. This shape offers better interlocking within the mix.

After crushing, vibrating screens classify aggregates. They separate particles into specific size fractions. This precise sizing is crucial. It ensures controlled aggregate gradation. Consistent gradation leads to a stable asphalt concrete. It reduces voids. It minimizes water penetration. This step forms the foundation for quality asphalt production.

Aggregates often contain moisture. Moisture must be removed before mixing. It prevents foaming of the asphalt binder. Foaming reduces coating effectiveness. It compromises mix quality. Aggregates also need heating. This ensures the binder remains fluid. It allows for proper coating. The target temperature varies. It depends on binder type. It also depends on environmental conditions.

Rotary dryers heat the aggregates efficiently. These machines rotate rapidly. They expose aggregates to hot air. This drives off moisture. It raises aggregate temperature. ZONEDING’s rotary dryers offer consistent performance. They provide uniform heating. This prepares aggregates perfectly for asphalt mixing. This step is vital for strong asphalt concrete.

Asphalt binder is a viscous material. Its viscosity must be reduced for mixing. Heating achieves this reduction. The binder becomes more fluid. This allows it to coat aggregate particles evenly. Coating quality directly impacts mix strength. It dictates durability. Proper binder temperature prevents premature hardening. It ensures full aggregate coverage.

Binder heating occurs in specialized tanks. These tanks maintain precise temperatures. Excessive heating can damage the binder. It causes oxidative hardening. This reduces its flexibility. Insufficient heating results in poor coating. It leads to weak asphalt concrete. Therefore, temperature control is paramount. It applies during this critical preparation stage.

An asphalt plant is a complex facility. It combines prepared materials. It produces hot mix asphalt. The process involves several precise steps. These steps ensure material homogeneity. They guarantee the correct temperature. This entire operation is called asphalt mixing. It requires advanced machinery and control systems. The efficiency of your asphalt plant impacts production cost. It affects the final quality.

Modern asphalt plants operate continuously or in batches. Both methods prioritize precision. They aim for consistent output. ZONEDING provides key components for diverse asphalt plant configurations.

Precise material proportioning is essential. It guarantees the correct asphalt concrete mix design. Aggregates of different sizes are stored separately. They are then weighed accurately. Load cells measure their exact quantities. The asphalt binder is also weighed or measured volumetrically. Mineral fillers are added in small, precise amounts. Computerized control systems manage this batching process. They ensure adherence to the specified mix formula. Any deviation affects the mix properties.

Accurate batching leads to consistent quality. It reduces material waste. It optimizes performance. This stage is fundamental. It impacts the structural integrity of the final asphalt concrete pavement.

Once batched, materials enter a mixer. A pugmill mixer is common in batch plants. It has rotating blades. These blades vigorously mix the heated aggregates. They distribute the hot asphalt binder evenly. The mineral filler is added at this stage. It blends throughout the mix. Mixing time is crucial. It needs optimization. Insufficient mixing leads to poor coating. Over-mixing can degrade the binder. It can damage aggregates.

The goal is to achieve total aggregate coating. Each particle gets covered with a uniform binder film. This ensures optimal adhesion. It provides maximum strength. This process culminates in hot mix asphalt. It is ready for transport and paving. The quality of asphalt mixing determines pavement performance.

Asphalt plants operate using two main production types. Each has advantages for asphalt production.

ZONEDING provides essential equipment for both plant types. Their rotary dryers are key components for drum mix plants. Their crushing and screening solutions support material preparation for all asphalt production.

Quality control is paramount. It ensures the asphalt concrete meets specifications. It also guarantees optimal performance. Strict measures are applied throughout production. They cover raw materials to the final mix. Poor quality control leads to early pavement failure. It results in costly repairs. Consistent asphalt production relies on these checks. Each step ensures a durable output.

These measures prevent defects. They promote uniformity. They uphold industry standards. Your project’s success depends on rigorous quality control.

ZONEDING provides essential equipment. It optimizes various stages of asphalt production. Your facility benefits from reliable machinery. These machines enhance efficiency. They improve material quality. ZONEDING specializes in mineral processing equipment. This expertise directly supports top-tier asphalt concrete manufacturing. Our solutions create cost-effective operations.

Making high-quality asphalt concrete involves many crucial steps. It starts with careful material selection. Precise preparation is essential. The mixing process demands accuracy. Strict quality control ensures a durable final product. Each stage impacts the pavement’s performance. Understanding these steps helps produce superior asphalt. Sustainable asphalt production focuses on efficiency. It promotes recycling.

Investing in reliable equipment is vital. It optimizes every part of the process. ZONEDING provides robust solutions. These solutions support aggregate production for asphalt concrete. Our crushing, screening, and drying equipment enhances efficiency. It ensures material quality. Partner with ZONEDING. Achieve consistent, high-quality asphalt production. Contact us today. Discuss your project needs.

Improve sand plant's efficiency! This blog explains how hydrocyclones and separators work, and when to choose each for optimal sand processing and recovery.

View detailsUnderstand dry grinding process: definition, workprinciple, advantages, and common applications in various industries. Get a complete overview here.

View detailsEverything you need to know about beryl. Learn the properties, discover how it's processed from raw stone to finished gem, and explore all its uses.

View detailsLearn the list of the top 10 most precious metals. Understand their critical uses, market value, and the scientific reasons behind their exceptional scarcity.

View details