全站搜索

Search the entire website

Search the entire website

If your crushed stone or gravel is full of clay, silt, and other debris, it is a big problem for your construction projects. Dirty aggregate leads to weak concrete and poor asphalt bonding, which can cause structures to fail. The solution is coarse material washing. This guide will explain why washing is so important. I will walk you through the different types of machines and help you choose the right one. This will help you produce high-quality, valuable aggregate for any project.

Coarse material is simply large-sized aggregate. When we talk about coarse materials, we mean gravel, crushed stone, and other rock fragments. These are generally larger than 4.75mm, or about 3/16 of an inch. Think of the stones you see in ready-mix concrete or the gravel used for road bases. This material is the backbone of many construction projects. Its quality is extremely important for strength and stability.

We separate it from “fine material,” which is sand. The size and cleanliness of your coarse material directly impact the strength and durability of your final product. This is why you cannot afford to have it contaminated with unwanted substances like clay or silt. The entire purpose of an aggregate washing plant is to make sure your coarse material is perfectly clean before you use it.

Washing coarse material removes harmful contaminants that weaken your final product. Things like clay, silt, dust, and organic matter act as a barrier. They prevent the aggregate from bonding strongly with cement or asphalt. Using dirty aggregate is like trying to glue two dusty surfaces together. The glue sticks to the dust, not the surface itself. This creates a very weak connection.

The results of using unwashed material are serious and costly. You get weaker concrete that can crack under pressure or fail over time. You get asphalt that unravels easily, creating potholes and unsafe roads. For any project that requires strength and longevity, coarse material washing is not just an option; it is a necessary step. It is how you guarantee quality and safety. Clean aggregate is a core part of all modern, reliable construction.

Clean coarse material is needed in almost every type of construction. Any time you need to create a strong, reliable final product, the quality of your aggregate is the first thing to consider. Washing is a key step in producing these high-grade materials. The demand for clean aggregate is constantly growing as building standards become stricter.

Some of the most common applications include:

A good aggregate washing plant can remove a wide range of unwanted materials. The main job of the washer is to break down and wash away the sticky, fine particles that cling to the surface of your valuable stone. Even a small amount of these contaminants can have a big negative effect on your final product’s quality.

The most common materials we design our machines to remove are:

There are several types of machines, each designed for different levels of contamination. The three most common types are Screw Washers, Log Washers, and Blade Washers. Choosing the right one depends entirely on how dirty your material is and what kind of contamination you are dealing with.

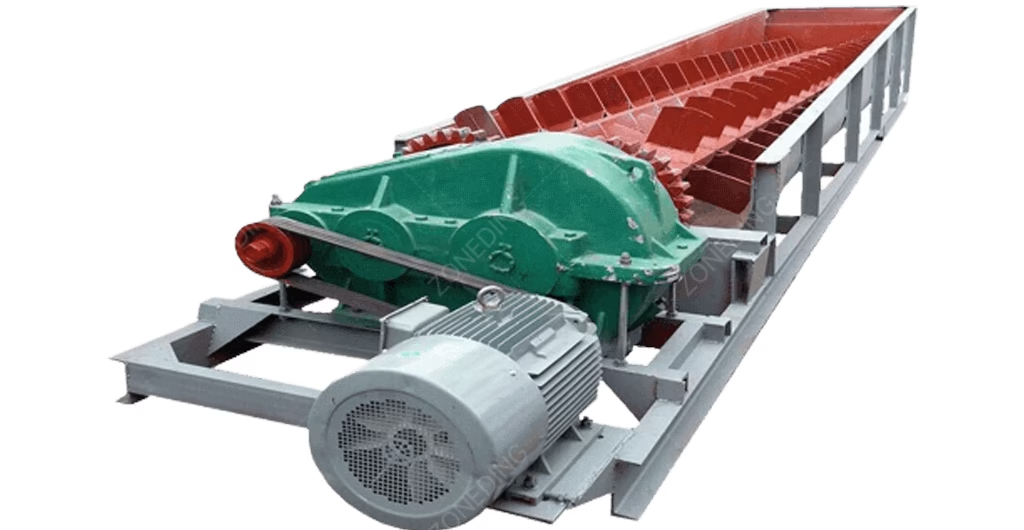

A Coarse Material Screw Washer uses a large, rotating screw inside an inclined tub. You feed dirty material into the lower end of the tub with water. As the screw turns, it tumbles the material against itself, which scrubs the surfaces clean. The dirty water and fine contaminants overflow from a weir at the back. Meanwhile, the clean aggregate is carried up the screw and discharged at the top, dewatered and ready to use.

A Log Washer is a heavy-duty scrubbing machine built for the toughest jobs. It features two massive shafts, or “logs,” with very durable paddles. These shafts rotate in opposite directions inside a tub. This creates an intense, grinding action that breaks down even the toughest, stickiest clays. The severe scrubbing action is what separates a log washer from a screw washer. It is designed for maximum force and attrition.

A Blade Washer, sometimes called a Blade Mill, is another type of aggressive scrubbing machine. It looks similar to a log washer but often uses a different paddle design. The paddles, or blades, are designed to create both a scrubbing and a cutting action. This is particularly useful when the feed material contains not just clay but also other debris like roots or soft, friable materials that need to be broken up.

These washers are designed for a range of sizes and production rates. It is critical to match the machine’s specifications to your material and your operational needs. Feeding oversized rock into a washer can cause serious damage, while choosing a machine that is too small for your capacity will create a bottleneck in your plant.

You must match the machine to the type and amount of contamination. A common and expensive mistake is buying a screw washer for a job that really needs a log washer. This leads to a poor-quality final product and wasted money. Making the right choice from the start is the most important step.

Here is a simple way to decide:

The price of a coarse material washer can range from $20,000 to over $150,000. The cost is influenced by several key factors. Understanding them helps you see what you are paying for and why a cheaper machine may not be the best value in the long run.

Good maintenance is key to keeping your washer running for years. These machines work in a tough, wet, and abrasive environment. Neglecting maintenance will lead to costly breakdowns. Daily and weekly checks are essential for a reliable operation.

Here is a basic maintenance schedule you can follow:

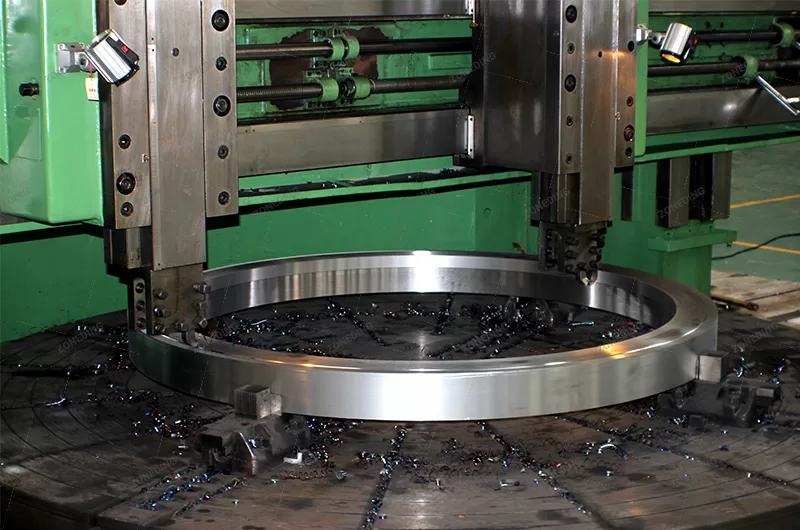

At ZONEDING, we build our washing equipment to be tough and reliable. We know that downtime costs you money, so our primary focus is on durability and performance. We have over 30 years of experience providing complete production lines, from crushing and washing to screening and Minerals Processing Plant. We understand the entire process.

Our washers are designed with features that matter to you:

You see quartz every day, but you probably do not recognize it. It is in the glass of your phone screen and the windows of your house. It is even in the countertop in your kitchen. Raw quartz stone from the ground is not ready for these jobs. It ...

View detailsAre you struggling with inefficient mineral separation, leaving valuable materials behind? Are you experiencing low recovery rates and high operating costs? This comprehensive guide will give all the details about shaking tables. Shaking...

View detailsChoosing the right rock crusher is the single most important decision for your quarry, mining, or recycling operation. It's the engine of your business. The right choice maximizes your output and profit, while the wrong one leads to constant head...

View detailsAre you looking for a more flexible and cost-effective way to process rock, ore, or construction waste? A mobile crusher could be the perfect solution. Instead of hauling materials to a fixed machine, a mobile crushing plant brings the processing...

View details