You see quartz every day, but you probably do not recognize it. It is in the glass of your phone screen and the windows of your house. It is even in the countertop in your kitchen. Raw quartz stone from the ground is not ready for these jobs. It must be cleaned and refined. This is done through quartz processing. This guide will explain how we take a rough, impure rock and turn it into an extremely valuable industrial material. I will show you the step-by-step process. We will look at the necessary equipment and what it takes to build your own quartz processing plant.

Table of Contents

What is Quartz?

Quartz is one of the most common minerals on Earth. Its chemical name is silicon dioxide, or SiO2. You know it as the crystal-like rock you might find on a hike. The most important thing to know about quartz is that it is very hard. On the Mohs scale of hardness, it is a 7 out of 10. That is harder than most steel. This hardness makes it very durable. But it also means you need very tough equipment to process it. Its purity and hardness are why it is so useful in many industries.

It comes in many forms. You can find it as large white veins in other rocks, as a solid rock called quartzite, or as the main component of sand. No matter its form, its basic properties are the same.

Why We Need to Process Quartz?

Raw quartz from a mine is full of impurities and is the wrong size. You cannot just take a rock from the ground and use it to make a computer chip. The raw stone might have clay, iron, feldspar, and other minerals mixed in with it. These impurities can ruin the final product. For example, a tiny bit of iron will turn glass green instead of clear.

The main goals of quartz processing are simple:

- Purification: We need to remove all the other minerals and contaminants. We want to get the SiO2 content as high as possible, sometimes over 99.9%.

- Size Reduction: We need to crush and grind the quartz into a specific size. Different industries require different particle sizes, from coarse sand to a fine powder.

Processing adds huge value. A raw rock might be worth a few dollars per ton. After processing into high-purity quartz sand, it can be worth hundreds or even thousands of dollars per ton.

What are Applications of Quartz?

Processed quartz is a critical ingredient for modern technology and construction. Because it is pure, strong, and has special electrical properties, it is used in many high-tech fields. The demand for high-quality quartz is always growing.

Here are some of the biggest applications:

- Glassmaking: This is a huge market. High-quality quartz sand is the main ingredient for all types of glass, from windows to bottles to fiber optic cables.

- Electronics: This is the highest value market. Ultra-high-purity quartz is used to grow silicon crystals for computer chips and solar panels.

- Engineered Stone: You have seen this used for kitchen countertops. Crushed quartz is mixed with resin to create a very durable and beautiful surface.

- Construction: Quartz sand is used in high-strength concrete, mortar, and as a filler.

- Ceramics and Refractories: It is used in making tiles, glazes, and the fire-resistant bricks used in furnaces.

- Metallurgy: It is used as a flux to remove impurities during metal smelting.

How to Get High-Purity Quartz?

Getting high-purity quartz requires a multi-stage process. You cannot just use one machine. You need a complete system where each machine does a specific job. The exact process depends on your raw ore and the purity you need to achieve. A simple plant for construction sand will be different from a complex plant for electronics-grade quartz.

Here is a typical flow for a silica sand washing plant:

- Crushing: First, we break the big rocks into smaller, manageable pieces. This usually happens in two stages. A Jaw Crusher does the primary crushing. Then a Cone Crusher makes the pieces even smaller.

- Grinding: Next, we grind the crushed stone into sand-sized particles. We use a Ball Mill or a Rod Mill for this. The machine tumbles the rock with steel balls or rods to grind it down.

- Scrubbing and Washing: Now we wash the sand to remove clay and other surface impurities. An Attrition Scrubber is like a powerful washing machine. It violently agitates a thick slurry of sand and water, causing the grains to scrub against each other and clean their surfaces.

- Magnetic Separation: To get really white sand, you must remove iron particles. We pass the sand through a high-intensity magnetic separator. The magnetic field pulls out any iron-containing minerals.

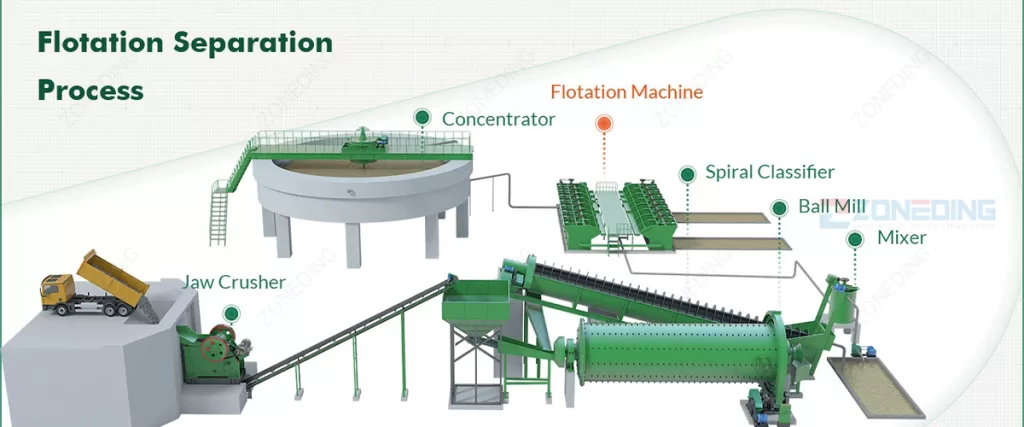

- Flotation: This step removes other mineral contaminants like feldspar. We add special reagents to a water slurry. These reagents attach to the impurities and make them float to the surface as a froth, which we can skim off.

- Acid Leaching (Optional): For the highest purity levels (above 99.9%), the sand is washed with acid in special tanks. This dissolves the last tiny bits of impurities.

Which Equipment Do We Need for Quartz Processing?

You need a series of robust machines that can handle hard, abrasive rock. At ZONEDING, we provide the full range of equipment needed to build a complete quartz processing plant. Each machine is designed to work as part of an integrated system.

Here is the essential equipment list:

- Crushers: You will need a primary Jaw Crusher for the big rocks and a secondary Cone Crusher for finer crushing.

- Grinding Mills: A Ball Mill is the standard choice for grinding quartz into sand. It is a reliable and efficient machine.

- Vibrating Screen: This machine sorts the material by size. It ensures that only correctly sized particles move to the next stage.

- Washing Equipment: An Attrition Scrubber or a Log Washer is crucial for removing clay and slime.

- Separators: This includes Magnetic Separators and Flotation Machines to purify the sand.

- Supporting Equipment: You will also need Belt Conveyors to move material between machines and a Thickener to recycle water.

Is it Profitable for Quartz Processing?

Yes, quartz processing can be very profitable. The business model is simple: you take a low-cost raw material and add significant value to it through processing. The global demand for high-quality quartz sand and powders is strong and growing, driven by the electronics, solar, and construction industries.

Your profitability depends on several factors:

- Cost of Raw Material: The cheaper you can get your raw stone, the better. Owning your own quarry is a big advantage.

- Level of Purity: The higher the purity you can achieve, the more you can charge. Electronics-grade quartz sells for a huge premium.

- Production Costs: This includes electricity, water, labor, and equipment maintenance. An efficient plant design, like the ones we provide at ZONEDING, helps keep these costs low.

- Market Price: The price for quartz products varies by region and quality. Researching your local market is a critical first step.

What is the Cost of A Quartz Processing Plant?

A quartz processing plant can cost from $100,000 to over $2 million. This is a very wide range because the final cost depends completely on your project’s specific needs. A small plant making construction sand is much cheaper than a large plant producing high-purity quartz for electronics.

Here are the main factors that determine the quartz processing plant cost:

- Capacity: How many tons per hour do you want to process? A 100-ton-per-hour plant will cost much more than a 10-ton-per-hour plant.

- Final Purity Required: If you need to include flotation and acid leaching stages, the cost will increase significantly.

- Equipment Quality: Investing in heavy-duty, reliable equipment from an experienced manufacturer like ZONEDING may cost more upfront but will save you money on maintenance and downtime later.

- Automation Level: A fully automated plant with a central control system will have a higher initial cost but lower labor costs over time.

The best way to get an accurate number is to talk to an expert. We can provide a detailed quotation based on a chemical analysis of your raw ore and your production goals.

Why ZONEDING’s Equipment is Reliable for Quartz Processing?

Our equipment is built specifically to handle the challenges of processing quartz. Quartz is very hard and abrasive, which will quickly destroy low-quality machinery. We have over 30 years of experience building machines that can withstand these tough conditions day after day.

Here is why customers trust ZONEDING for their quartz processing needs:

- Wear Resistance: We use high-manganese steel for the wear parts in our Quartz Crusher, and high-chromium steel liners in our Quartz Grinding Mill. These materials are extremely tough and last much longer, reducing your maintenance costs.

- Complete Solutions: We are not just a machine seller. We are a solution provider. We design, manufacture, and help you install the entire plant. This ensures every machine works perfectly with the others.

- Customized Design: No two quartz deposits are the same. We start by analyzing your ore sample. Then, our engineers design a process flow and equipment list that is optimized for your specific raw material to get you the best results.

- Proven Experience: We have successfully built hundreds of processing plants around the world. We know the common problems and how to solve them, ensuring your project is a success from the start.

FAQ

- What is the Typical Maintenance Schedule for Quartz Crushers and Mills?

- Regular maintenance is key to long life. For a jaw crusher, you should check the wear on the jaw plates daily and check bearing lubrication weekly. For a ball mill, you should inspect the liner bolts weekly and monitor the grease seals and gear lubrication daily. We provide a detailed maintenance manual with every machine.

- Which Raw Materials are Suitable for Quartz Processing?

- The best raw materials are those with a high initial quartz content. This includes vein quartz, which is almost pure SiO2, quartzite rock, and high-purity sandstone. Starting with a cleaner raw material means you will need a simpler, less expensive processing plant.

- How do you choose the best quartz products when you buy?

- As an end-user, look for three things. First, check the chemical analysis for high SiO2 content and low levels of impurities like iron (Fe2O3) and aluminum (Al2O3). Second, ensure the particle size distribution matches your needs. Third, for applications like glass or engineered stone, the whiteness and consistency of the color are very important.