全站搜索

Search the entire website

Search the entire website

Are you watching your profits wash away with your wastewater? In many sand washing plants, a significant amount of fine sand (75 microns / 200 mesh and smaller) escapes with the overflow water. This isn’t just waste; it’s lost product and lost revenue. A hydrocyclone separator is a simple, powerful machine designed to solve this exact problem. It recovers valuable fine sand, improves your final product quality, and significantly boosts your sand plant efficiency. At ZONEDING, we help our clients turn this common waste stream into a consistent profit center.

Losing fine sand is a bigger problem than you might think. First, it’s a direct financial loss. You are throwing away a saleable product. Second, it ruins your sand’s grading. High-quality concrete requires a specific mix of coarse and fine particles for maximum strength and workability. Without enough fines, your sand fails to meet specifications and sells for a lower price. Third, it creates an environmental problem. Your settling ponds fill up with sediment quickly, requiring expensive and frequent cleanouts. Fine sand recovery solves all three issues at once.

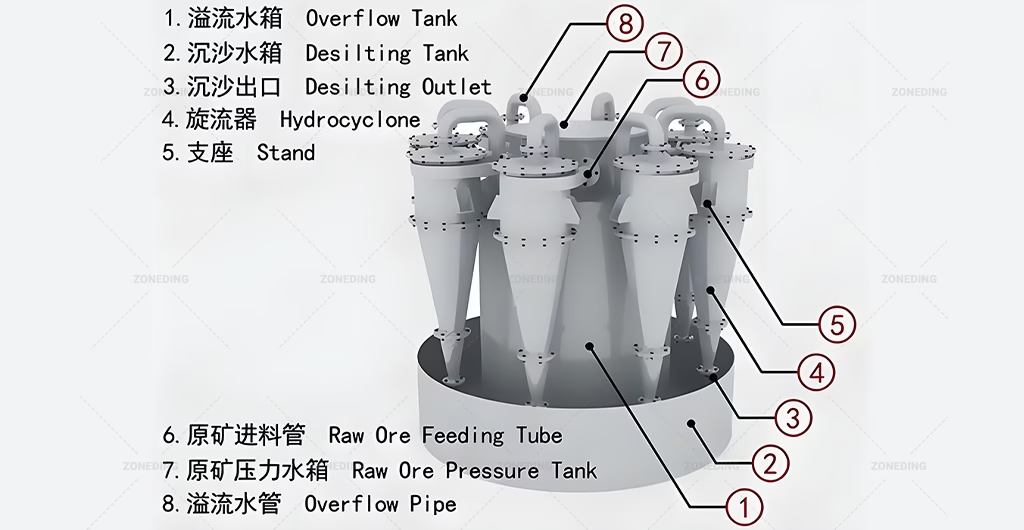

A hydrocyclone separator is a machine that uses centrifugal force to separate particles in a liquid slurry. The most surprising thing about it is that it has no moving parts. It’s essentially a cone-shaped chamber. A slurry of water and sand is pumped into it at high pressure, and the physics of the spinning fluid does all the work. It separates the heavier, coarser sand particles from the lighter, ultra-fine particles and water. It is a core component of any modern sand washing plant.

The sand cyclone separator working principle is simple but very effective. Here is the process step by step:

The cost for a single hydrocyclone unit can range from $200 to over $20,000. However, the cyclone itself is just one part of a complete system. A full fine sand recovery module, including the cyclone, a slurry pump, a motor, a collection tank (sump), and the interconnecting pipes, will have a different price point. A complete system integrated with a dewatering screen represents the most effective solution and will be a larger investment. The hydrocyclone for sand washing price depends entirely on the scale and completeness of the system you need.

Several key factors determine the final price of a hydrocyclone system. It is important to look beyond just the sticker price.

Choosing the right hydrocyclone is about matching the machine to your specific material and goals. Here are the steps you should follow:

At ZONEDING, we design our hydrocyclone systems for maximum efficiency and minimum downtime.

When selecting a supplier, you should look for a partner, not just a vendor.

Since 1990, ZONEDING has been a direct manufacturer of high-performance aggregate processing equipment. We have delivered complete solutions to over 120 countries. And we don’t just sell machines; we design and build integrated systems.

By manufacturing directly, we control the quality of every component, from the polyurethane formula in our liners to the grade of steel in our frames. This factory-direct model allows us to provide superior technology and expert support at a more competitive price. Our engineers are ready to help you design a fine sand recovery system that is perfectly tailored to your needs.

A hydrocyclone separator is not a cost; it’s an investment with a rapid return. It stops the loss of valuable product, improves the quality and value of your final sand, and reduces your environmental and maintenance burdens. The key is to view it as a complete system—pump, cyclone, and dewatering screen—working together. By choosing a supplier who understands this system-based approach, you can transform your plant’s profitability.

Your next step is to quantify your losses. Take a sample of your overflow water and see exactly what you are throwing away. Then, contact an expert to discuss how a properly designed recovery system can turn that waste back into profit.

Are you struggling with inefficient mineral separation, leaving valuable materials behind? Are you experiencing low recovery rates and high operating costs? This comprehensive guide will give all the details about shaking tables. Shaking...

View detailsChoosing the right rock crusher is a major decision for your quarry or mining operation. The wrong choice can lead to wasted money, inefficient production, and lower profits. Jaw crushers and impact crushers are two of the most common types of cr...

View detailsGypsum is a foundational material in the modern construction industry. You can find it everywhere, from the walls of your home to the plaster in art studios. As a manufacturer of mineral processing equipment at ZONEDING, we have helped clients wo...

View detailsIn your mining or aggregate operation, managing water is not just an operational task—it is a core driver of your profitability. Excess water in your product inflates shipping costs, reduces material quality, and creates significant safety risks....

View details